Introduction: Mass Balancing and Reconciliation for Metal Accounting

Mass balance and reconciliation are important concepts in metal accounting, which is the process of calculating and tracking the flow of metals in a mineral processing plant.

The goal of metal accounting is to ensure that the amount of metal entering the plant is equal to the amount of metal leaving the plant, while accounting for losses due to process inefficiencies, impurities, and other factors. Mass balance involves measuring the amount of metal entering the plant, the amount of metal leaving the plant, and the amount of metal stored within the plant at any given time.

This requires careful measurement and monitoring of the various streams of material flowing through the plant, including the feed, concentrate, tailings, and intermediate streams. Reconciliation involves comparing the actual metal production in the plant with the expected metal production based on the mass balance calculations. Any discrepancies between the expected and actual production are investigated and analyzed in order to identify the causes of the discrepancies and take corrective action.

The mass balance and reconciliation process is critical for accurate metal accounting, as it ensures that all metal in the plant is accounted for and that any losses or inefficiencies are identified and addressed. This helps to improve the overall efficiency and profitability of the plant, as well as ensuring compliance with regulatory requirements.

What is a mass balance for Metal Accounting?

Mass balance is a fundamental concept in metal accounting that involves tracking the flow of metal through a mineral processing plant. The goal of mass balance is to ensure that the amount of metal entering the plant is equal to the amount of metal leaving the plant, while accounting for any losses due to process inefficiencies, impurities, or other factors.

To achieve a mass balance for metal accounting, the various streams of material flowing through the plant are carefully monitored and measured. This includes the feed, concentrate, tailings, and intermediate streams.

The amount of metal in each stream is measured, and the flow rates of each stream are tracked.

The mass balance equation for metal accounting can be

expressed as:

Input = Output + Losses

where "Input" represents the total amount of metal entering the plant, "Output" represents the total amount of metal leaving the plant, and "Losses" represents any metal that is lost or unaccounted for due to process inefficiencies, impurities, or other factors.

By calculating and analyzing the mass balance for a mineral processing plant, it is possible to identify areas of inefficiency or loss and take corrective action to improve the overall efficiency and profitability of the plant. This helps to ensure that all metal in the plant is accounted for and that regulatory requirements are met.

What is material Balance for metal Accounting?

Material balance is a fundamental concept in metal accounting that involves tracking the flow of all materials, including both metal and non-metal components, through a mineral processing plant.

The goal of material balance is to ensure that the amount of all materials entering the plant is equal to the amount of all materials leaving the plant, while accounting for any losses due to process inefficiencies, impurities, or other factors.

To achieve a material balance for metal accounting, the various streams of material flowing through the plant are carefully monitored and measured. This includes the feed, concentrate, tailings, and intermediate streams. The amount of all materials in each stream is measured, and the flow rates of each stream are tracked. The material balance equation for metal accounting can be expressed as:

Input = Output + Accumulation + Generation - Consumption

where "Input" represents the total amount of all materials entering the plant, "Output" represents the total amount of all materials leaving the plant, "Accumulation" represents any build-up of materials within the plant, "Generation" represents any new materials generated within the plant, and "Consumption" represents any materials consumed within the plant.

By calculating and analyzing the material balance for a mineral processing plant, it is possible to identify areas of inefficiency or loss and take corrective action to improve the overall efficiency and profitability of the plant. This helps to ensure that all materials in the plant are accounted for and that regulatory requirements are met.

What is reconciliation for Metal Accounting?

Reconciliation is an important process in metal accounting that involves comparing the actual metal production in a mineral processing plant with the expected metal production based on the mass balance calculations.

Any discrepancies between the expected and actual production are investigated and analyzed in order to identify the causes of the discrepancies and take corrective action.

Reconciliation involves comparing the mass balance data with the actual metal production data obtained from assay results, plant instrumentation, and other sources. This allows for a comparison of the theoretical metal production with the actual metal production, and any discrepancies can be identified.

There are two types of reconciliation in metal accounting: quantitative and qualitative.

Quantitative reconciliation involves comparing the actual metal production to the expected metal production in terms of quantity, while qualitative reconciliation involves comparing the actual metal production to the expected metal production in terms of quality, such as the grade of the metal produced.

Reconciliation is an important part of metal accounting because it allows for the identification of any inefficiencies, losses, or errors in the mineral processing plant, which can be corrected to improve the overall efficiency and profitability of the plant. It also ensures that all metal in the plant is accounted for, which is important for regulatory compliance and accurate reporting of production figures.

What is the objective of a Reconciliation System for Metal Accounting?

The primary objective of a reconciliation system for metal accounting is to ensure that there is consistency and accuracy in the accounting of metal production and losses throughout the entire mining and processing operation.

The reconciliation process involves comparing the metal produced, as measured by sampling and analysis, to the metal expected based on the inputs and outputs of the process.

The objective of this comparison is to identify and quantify any differences or discrepancies, which can then be investigated and explained. The reconciliation system aims to provide a clear and accurate view of the material flow and the performance of the metal accounting system.

By identifying discrepancies and investigating the root causes, the reconciliation system can help to identify areas of inefficiency or waste in the process, as well as opportunities for optimization and improvement. Ultimately, the objective of a reconciliation system is to provide stakeholders with the information they need to make informed decisions about the mining and processing operation, including resource planning, production forecasting, and financial reporting.

By ensuring the accuracy and consistency of metal accounting, the reconciliation system can help to minimize risk and maximize profitability for the mining company.

What is Mine Call Factor MCF and how does it relate to Metal Accounting?

Mine Call Factor (MCF) is a commonly used term in the mining industry and refers to the discrepancy between the metal content of the ore mined and the metal content of the final product.

In other words, it is a comparison between the metal content estimated in the mine plan versus the actual metal content recovered in the process plant. MCF is an important metric in metal accounting because it provides an indication of the accuracy and completeness of the metal accounting system. Ideally, the MCF should be as close to 1 as possible, indicating that there is no significant loss of metal between the mine and the final product.

A high MCF can be an indication of inaccuracies in the sampling and assaying process, inadequate controls over the material flow, or errors in the metal accounting calculations.

Conversely, a low MCF can suggest that there are unreported losses of metal in the process, such as through inefficiencies in the recovery process or unaccounted for material losses.

By monitoring and analyzing the MCF, mining companies can identify areas of improvement in their metal accounting system and take corrective actions to reduce the losses of metal and improve the accuracy of their reporting. MCF can also be used to identify potential areas of improvement in the mining and processing operations, leading to more efficient use of resources and increased profitability.

What is the industry trends when it comes to MCF measurement and its reliability?

The mining industry is constantly striving to improve the accuracy and reliability of the MCF measurement, as it is a critical metric in metal accounting and has a direct impact on the financial performance of the operation.

One trend in recent years has been the increased use of automated sampling and analysis technologies, such as online elemental analyzers and cross-belt analyzers, to improve the accuracy and timeliness of the metal content measurements.

These technologies can provide real-time data on the metal content of the ore as it is being mined, allowing for better control over the material flow and reducing the risk of unreported losses of metal. Another trend is the increased focus on quality control and quality assurance (QC/QA) procedures throughout the metal accounting process.

This includes regular checks on the accuracy and precision of the sampling and analysis methods, as well as the use of independent check assays and duplicate samples to verify the results.

Additionally, there is a trend towards the integration of advanced data analytics and machine learning algorithms to improve the reliability and efficiency of the metal accounting system.

These tools can help identify patterns and anomalies in the data, allowing for early detection of potential issues and proactive measures to prevent metal losses.

Overall, the trend is towards a more rigorous and integrated approach to metal accounting, with a focus on continuous improvement and data-driven decision making to minimize the MCF and maximize the value of the operation.

How to carry out a simple Mass Balance around a given Process?

Carrying out a simple mass balance around a given process involves the following steps:

Define the system: Identify the boundaries of the process and define the inputs and outputs.

List the inputs: Make a list of all the materials that enter the system, including raw materials, water, energy, and chemicals.

Measure the inputs: Measure the mass or volume of each input and record the values. List the outputs: Make a list of all the materials that leave the system, including products, waste materials, emissions, and other outputs.

Measure the outputs: Measure the mass or volume of each output and record the values.

Check for any losses: Check for any unaccounted materials that may have been lost in the process. These losses could be due to leaks, spills, or other factors.

Calculate the mass balance: Calculate the mass balance by subtracting the total mass of inputs from the total mass of outputs. The result should be zero if all inputs and outputs are accounted for.

Analyze the results: Analyze the mass balance to identify any discrepancies or areas of concern. Investigate any losses or discrepancies and take steps to correct them.

Repeat the process: Repeat the mass balance calculation periodically to ensure that the process is operating efficiently and effectively.

Overall, carrying out a simple mass balance around a process involves identifying inputs and outputs, measuring their mass or volume, and calculating the mass balance. This information can be used to optimize the process and ensure that it is operating efficiently and sustainably.

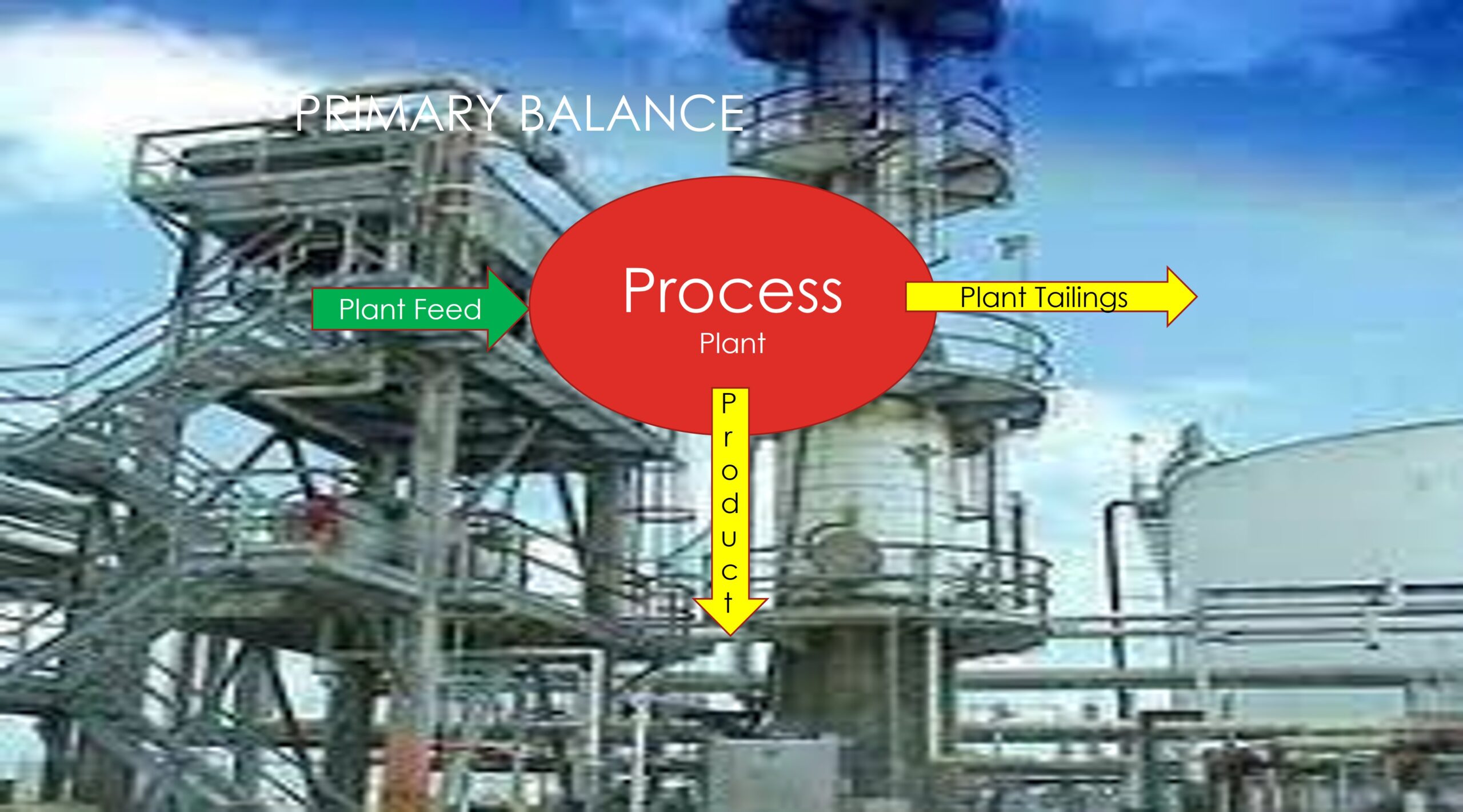

Primary Mass Balance: Simple Process

The diagram below depicts a Primary Mass balance system.

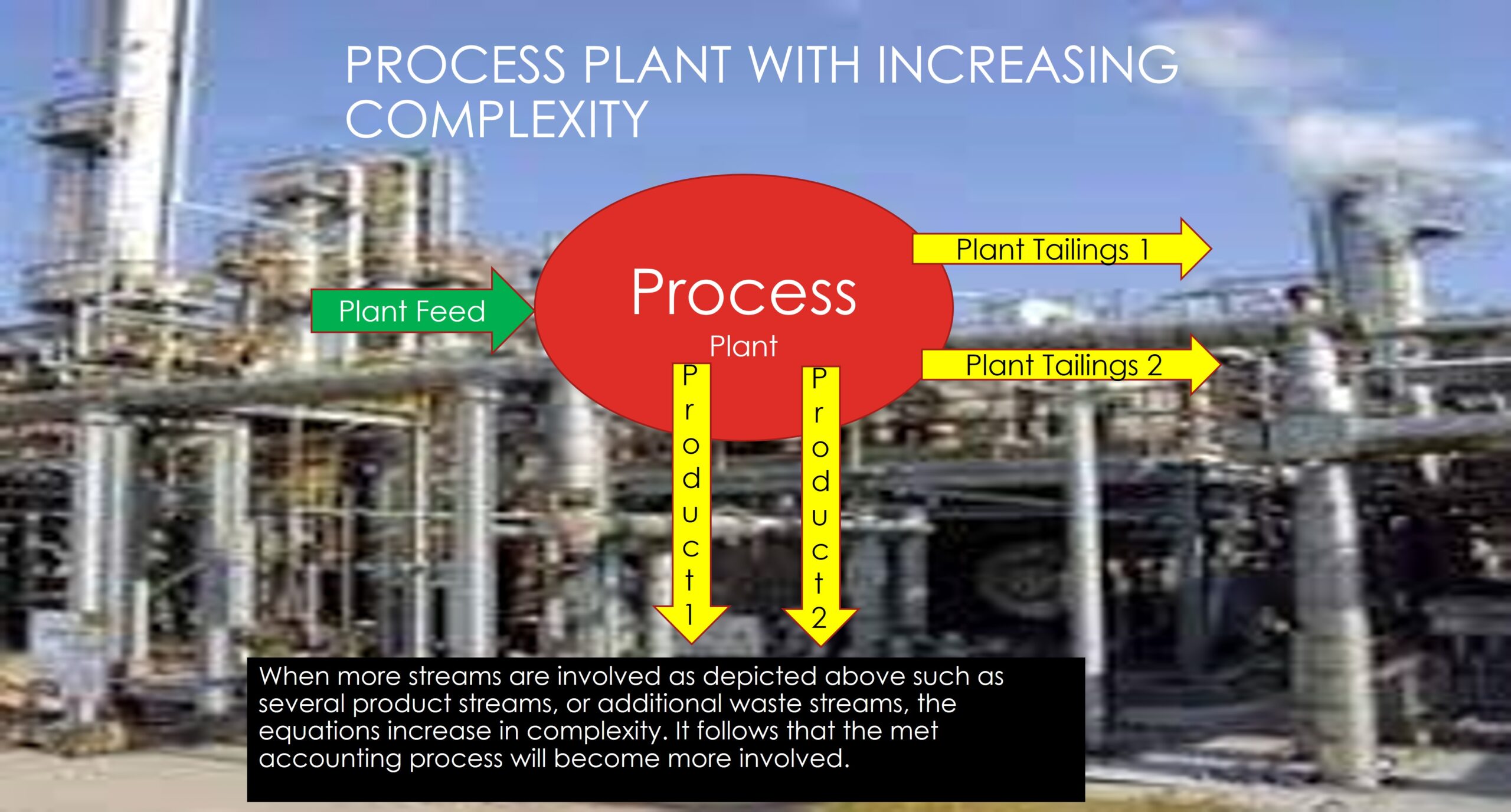

More complex process

Diagram below depicts a process with multiple streams

What are the tools required to carry out a simple Mass Balalnce?

To carry out a simple mass balance around a given circuit, the following measurements and measuring devices may be required:

Weighing scales: Weighing scales are used to measure the mass of solid materials, such as ore, concentrates, or tailings.

Flow meters: Flow meters are used to measure the flow rate of liquids, such as water, chemicals, or reagents. They may be installed at various points in the circuit to measure the flow of different materials.

Level sensors: Level sensors are used to measure the volume of liquids or solids in tanks, vessels, or silos. They can be used to track the inventory of materials in the circuit.

Sampling equipment: Sampling equipment, such as sampling pumps or samplers, are used to collect representative samples of materials at various points in the circuit. These samples can be used to measure the composition or quality of the materials.

Analytical instruments: Analytical instruments, such as assay equipment or spectrometers, are used to measure the metal content or purity of materials. These measurements can be used to calculate the amount of metal produced in the circuit.

Environmental monitoring equipment: Environmental monitoring equipment, such as emissions meters or air quality monitors, may be used to measure the emissions or environmental impact of the circuit.

Overall, the measurement and measuring devices required to carry out a mass balance will depend on the specific circuit being analyzed and the materials being processed. It is important to select appropriate measuring devices and ensure that they are calibrated and maintained properly to ensure accurate measurements.

How to calculate the amount of material on a stockpile when the Inputs and outputs are known?

To calculate the amount of material on a stockpile when the amount of material entering and leaving the stockpile is known, you can use the following formula:

Material on stockpile = Material in - Material out

where:

Material in: The total amount of material that has been fed onto the stockpile, either by truck, conveyor, or other means.

Material out: The total amount of material that has been removed from the stockpile, either for processing, transport, or other purposes.

It is important to note that the amount of material on the stockpile will vary over time, as material is added or removed.

Therefore, it is necessary to track the amount of material entering and leaving the stockpile on a regular basis, in order to calculate the material balance and ensure that the stockpile does not become too full or too empty.

To ensure accuracy in the calculation, it is important to use consistent units of measurement for the inputs and outputs.

For example, if the material in and material out are measured in tonnes, then the material on the stockpile should also be expressed in tonnes.

Overall, calculating the amount of material on a stockpile involves tracking the amount of material that enters and leaves the stockpile, and using the material balance equation to calculate the amount of material on the stockpile at any given time.

What is a multi-dimensional mass balancing system for Metal Accounting?

Multi-dimensional mass balance is a concept in metal accounting that involves tracking the flow of multiple components, including both metal and non-metal components, through a mineral processing plant in multiple dimensions.

The goal of multi-dimensional mass balance is to provide a more detailed understanding of the movement of materials through the plant, including variations in the quality and quantity of materials over time and across different stages of the process.

Multi-dimensional mass balance involves the use of advanced software and modeling techniques to integrate data from a range of sources, including assay results, plant instrumentation, and other sources, to create a detailed picture of the flow of materials through the plant.

This can include tracking the flow of individual elements or minerals, as well as variations in the grade, particle size, and other properties of the materials. By analyzing multi-dimensional mass balance data, it is possible to identify areas of inefficiency or loss in the mineral processing plant and take corrective action to improve the overall efficiency and profitability of the plant. It can also help to identify opportunities for optimization and process improvement, and to provide more accurate and detailed reporting of production figures for regulatory compliance.

Overall, multi-dimensional mass balance is an important tool in metal accounting that can provide a more detailed and comprehensive understanding of the movement of materials through a mineral processing plant, allowing for more effective and efficient management of the plant's operations.

How can a multi-dimensional mass balance sytem be applied to metal Accounting process?

A multi-dimensional mass balancing system can be applied in metallurgical accounting for diamond processing to track and reconcile the material flow and ensure accurate accounting of the diamond production.

In this case, the system can be used to balance the inputs and outputs of the diamond processing plant by tracking the flow of material through various stages of processing.

The system can be used to track the weight of each size class of the diamond product and its associated value, which can be used for accounting purposes. The system can also be used to monitor the efficiency of the processing plant by comparing the actual output of diamonds to the expected output based on the input material.

This information can be used to identify any inefficiencies in the processing plant and make improvements to optimize production. Additionally, the system can be used to track the grade of the diamond product at each stage of processing and reconcile the grade with the expected grade based on the input material.

This information can be used to optimize the processing plant to achieve the desired grade and improve the overall efficiency of the process.

Overall, a multi-dimensional mass balancing system can provide a comprehensive view of the material flow in diamond processing, enabling accurate accounting and optimization of the processing plant.

What is a multi-mineral mass balancing system for metal accounting?

Multi-mineral mass balance is a concept in metal accounting that involves tracking the flow of multiple minerals through a mineral processing plant.

The goal of multi-mineral mass balance is to provide a more comprehensive understanding of the mineralogy of the materials being processed, including variations in the quantity and quality of different minerals over time and across different stages of the process.

In a multi-mineral mass balance, the flow of each mineral is tracked separately, in addition to the tracking of metal and non-metal components.

This requires the use of advanced software and modeling techniques to integrate data from a range of sources, including assay results, plant instrumentation, and other sources.

By analyzing multi-mineral mass balance data, it is possible to identify areas of inefficiency or loss in the mineral processing plant that are specific to certain minerals or mineral combinations.

This can help to optimize the processing of each mineral, leading to improved overall efficiency and profitability of the plant. Multi-mineral mass balance can also provide valuable information for mine planning and resource estimation, as it allows for a more detailed understanding of the mineralogy of the materials being processed.

This information can be used to improve the accuracy of geological models and resource estimates, leading to more effective mining and processing strategies.

Overall, multi-mineral mass balance is an important tool in metal accounting that can provide a more detailed and comprehensive understanding of the mineralogy and processing of materials in a mineral processing plant.

What is the porpose of a multi-mineral mass balancing systen and how can it be used to improve Metallurgical Performance?

The purpose of a multi-mineral mass balancing system in metal accounting is to provide a more comprehensive understanding of the mineralogy and processing of materials in a mineral processing plant.

By tracking the flow of multiple minerals through the plant, in addition to metal and non-metal components, a multi-mineral mass balancing system can provide a more accurate and detailed picture of the materials being processed.

The multi-mineral mass balancing system can be used to improve the accounting system in several ways:

Better understanding of material flow: The multi-mineral mass balancing system can help to identify the flow of each mineral through the plant, which can help to optimize the processing of each mineral and improve overall efficiency.

Improved grade control: By tracking the flow of each mineral separately, the multi-mineral mass balancing system can help to identify variations in the grade of each mineral and allow for better grade control.

More accurate resource estimation: The multi-mineral mass balancing system can provide valuable information for resource estimation and mine planning, as it allows for a more accurate estimation of the quantity and quality of each mineral being processed.

Better reporting: The use of a multi-mineral mass balancing system can improve the accuracy and detail of production reporting, which is important for regulatory compliance and for tracking production performance over time.

Overall, the use of a multi-mineral mass balancing system in metal accounting can provide a more comprehensive understanding of the processing of materials in a mineral processing plant, leading to improved efficiency, better grade control, more accurate resource estimation, and better reporting.

How can a multi mineral mass balancing system be used to better understand the material flow?

A multi-mineral mass balancing system can be used to better understand the material flow in a mineral processing plant in several ways:

Identify variations in mineral flow: By tracking the flow of each mineral separately, a multi-mineral mass balancing system can help identify variations in the flow of each mineral through the plant. This can help to identify areas of inefficiency or loss in the mineral processing plant that are specific to certain minerals or mineral combinations.

Optimize processing: By understanding the flow of each mineral, the plant can optimize the processing of each mineral to improve overall efficiency. For example, if a particular mineral is being lost in the tailings, the plant can adjust the processing conditions to reduce the loss of that mineral.

Improve grade control: By tracking the flow of each mineral separately, a multi-mineral mass balancing system can help to identify variations in the grade of each mineral. This information can be used to adjust the processing conditions to improve grade control.

Monitor plant performance: A multi-mineral mass balancing system can be used to monitor the performance of the plant over time, tracking changes in the flow of each mineral and identifying areas for improvement.

Overall, a multi-mineral mass balancing system can provide a more detailed and comprehensive understanding of the material flow in a mineral processing plant, allowing for more effective management of the plant's operations and optimization of the processing conditions to improve efficiency and profitability.

How can a multi-mineral mass balancing system be used to improve grade control?

A multimineral mass balancing system can be used to improve grade control in a mineral processing plant in several ways:

Identify variations in mineral grades: By tracking the flow of each mineral separately, the multimineral mass balancing system can help identify variations in the grade of each mineral. This information can be used to adjust the processing conditions to improve grade control.

Monitor grade performance: The multimineral mass balancing system can be used to monitor the grade performance of the plant over time, tracking changes in the grade of each mineral and identifying areas for improvement.

Optimize processing: By understanding the flow of each mineral, the plant can optimize the processing of each mineral to improve overall grade control. For example, if a particular mineral has a high variability in grade, the plant can adjust the processing conditions to reduce the variability.

Ensure compliance: A multimineral mass balancing system can be used to ensure compliance with grade specifications and regulatory requirements, by tracking the grade of each mineral through the plant and ensuring that the final product meets the required grade.

Overall, a multimineral mass balancing system can provide a more accurate and detailed understanding of the grade of each mineral being processed, allowing for better grade control and more effective management of the plant's operations.

How can a multi-mineral mass balancing system be used for improved resource estimation?

A multi-mineral mass balancing system can be used to improve resource estimation in a mineral processing plant in several ways:

Accurate quantification of minerals: By tracking the flow of each mineral separately, a multi-mineral mass balancing system can provide a more accurate quantification of each mineral being processed. This information can be used to estimate the quantity and quality of each mineral in the ore body.

Identification of mineral associations: The multi-mineral mass balancing system can be used to identify mineral associations in the ore body, which can help to predict the distribution of each mineral in the deposit. This information can be used to estimate the overall mineral content of the deposit and to optimize the mining and processing operations.

Optimization of processing: By understanding the flow of each mineral, the plant can optimize the processing of each mineral to improve overall efficiency and recovery. This can help to improve the accuracy of the resource estimation by ensuring that all minerals are being processed as efficiently as possible.

Improved geological modeling: The information provided by the multi-mineral mass balancing system can be used to create more accurate geological models of the ore body, which can be used to optimize the mining and processing operations.

Overall, a multi-mineral mass balancing system can provide a more accurate and comprehensive understanding of the mineralogy and processing of materials in a mineral processing plant. This information can be used to improve the accuracy of resource estimation, optimize the mining and processing operations, and improve the overall efficiency and profitability of the plant.

How can a multi-mineral mass balancing system be used to improve reporting?

A multimineral mass balancing system can be used to improve reporting in a mineral processing plant in several ways:

Accurate and comprehensive reporting: A multimineral mass balancing system can provide accurate and comprehensive reporting on the flow of each mineral through the plant. This information can be used to create detailed reports that accurately reflect the mineral processing operations.

Timely reporting: By automating the data collection and analysis process, a multimineral mass balancing system can provide timely reporting on the flow of each mineral through the plant. This can help to identify problems or issues early, before they become more serious.

Compliance reporting: The multimineral mass balancing system can be used to ensure compliance with regulatory requirements and reporting obligations, by tracking the flow of each mineral through the plant and providing accurate and detailed reports.

Improved decision-making: By providing accurate and comprehensive reporting on the flow of each mineral through the plant, the multimineral mass balancing system can help improve decision-making in the mineral processing plant. This information can be used to identify areas for improvement, optimize the processing conditions, and improve the overall efficiency and profitability of the plant.

Overall, a multimineral mass balancing system can help to improve reporting in a mineral processing plant by providing accurate, timely, and comprehensive information on the flow of each mineral through the plant. This information can be used to improve decision-making, ensure compliance, and optimize the processing operations.

What is the purpose of tracking trace mineral content in Metal Accounting?

The purpose of tracking the trace mineral content in metal accounting is to accurately account for the presence of valuable minerals that occur in small quantities, such as precious metals or rare earth elements.

Trace minerals can be difficult to detect and quantify, but they can have a significant impact on the overall value of a mineral deposit. Accurately accounting for trace minerals is important for several reasons:

Economic value: Trace minerals can have a high economic value, even in small quantities. Accurately tracking their content can help mining companies to optimize their operations and extract the maximum value from the deposit.

Metallurgical performance: The presence of trace minerals can affect the metallurgical performance of the ore, including recovery rates and concentrate quality. By tracking trace minerals, mining companies can optimize their processing operations to improve recovery and concentrate quality.

Environmental considerations: Some trace minerals, such as arsenic or mercury, can have negative environmental impacts if not properly managed. Accurately tracking the content of these minerals can help mining companies to manage their environmental impacts.

Therefore, tracking the trace mineral content in metal accounting is important for accurately accounting for the presence of valuable minerals, optimizing processing operations, and managing environmental impacts.

How can the tracking of trace mineral content improve metal reconciliation?

The tracking of trace mineral content can improve metal reconciliation in several ways:

Accurate metal accounting: By tracking the trace mineral content of the material flow, mining companies can accurately account for the presence of valuable minerals that occur in small quantities. This information can be used to improve the accuracy of metal accounting, which is important for metal reconciliation.

Improved grade control: The presence of trace minerals can affect the grade of the ore. By tracking the trace mineral content, mining companies can improve their grade control, which is important for accurate metal reconciliation.

Improved metallurgical performance: The presence of trace minerals can also affect the metallurgical performance of the ore. By tracking the trace mineral content, mining companies can optimize their processing operations to improve recovery rates and concentrate quality, which can help to improve metal reconciliation.

Identification of mineral losses: Trace minerals can be lost during processing, particularly if they occur in small quantities. By tracking the trace mineral content, mining companies can identify areas where losses are occurring and take steps to reduce them, which can help to improve metal reconciliation.

Overall, the tracking of trace mineral content can improve metal reconciliation by providing more accurate and comprehensive information on the mineral deposit. This information can be used to improve grade control, optimize processing operations, identify mineral losses, and ultimately improve the accuracy of metal reconciliation.

What is the economic benefit of implementing a multi-mineral mass balancing system?

Using a multimineral mass balancing system for metal accounting in mining operations can provide several economic benefits, including:

Increased recovery of multiple minerals: By accurately tracking the flow of multiple minerals through the process, a multimineral mass balancing system can help identify areas where valuable minerals are being lost. This information can be used to optimize the process and increase the recovery of multiple minerals, which can have a significant economic impact.

Improved resource estimation: A multimineral mass balancing system can help provide a more accurate picture of the mineral deposit, which can be used to improve resource estimation. This information can help mining companies make better decisions about future exploration and development activities, ultimately leading to more profitable mining operations.

Reduced operating costs: A multimineral mass balancing system can help identify inefficiencies in the process, such as excessive use of reagents or energy. By addressing these inefficiencies, mining companies can reduce their operating costs and improve their profitability.

Better process control: The information provided by a multimineral mass balancing system can be used to monitor and control the process, improving the efficiency and effectiveness of the process.

Improved compliance: Accurate metal accounting is essential for compliance with regulatory requirements. By using a multimineral mass balancing system, mining companies can improve their compliance and avoid costly fines and penalties.

Overall, using a multimineral mass balancing system can help mining companies optimize their processes, increase their recovery of multiple minerals, improve their compliance, and make better investment decisions. These economic benefits can have a significant impact on the profitability and sustainability of mining operations.

What are the problems associated with proper mass balance for metal Accounting?

There are several problems associated with mass balancing for metal accounting, including:

Inaccurate measurements: The accuracy of mass balancing depends on the accuracy of the measurements taken at various points in the process. Errors in measurements can lead to inaccuracies in the mass balance calculations.

Variations in material properties: The properties of the materials being processed, such as density and particle size distribution, can vary significantly over time. These variations can make it difficult to accurately track the material flow through the process.

Sampling errors: Sampling errors can occur if the samples taken from different points in the process do not accurately represent the material being processed. This can lead to inaccuracies in the mass balance calculations.

Process changes: Changes in the process, such as changes in the feed grade or changes in the operating conditions, can affect the accuracy of the mass balance calculations.

Limited information: Mass balancing relies on the available information about the process, such as the mass flow rates and the chemical compositions. If there is limited information available, it can be difficult to accurately balance the material flow.

Human error: Finally, human error can also contribute to inaccuracies in mass balancing. For example, errors in data entry or calculation mistakes can lead to errors in the mass balance calculations.

Overall, mass balancing is an important tool for metal accounting, but it is not without its challenges. To minimize these problems, it is important to ensure accurate measurements, minimize variations in material properties, use representative samples, and carefully monitor and document any process changes.

What are the problems associated with reconciliation for Metal Accounting?

There are several problems associated with metal reconciliation for metal accounting systems, including: I

naccurate measurements: Similar to mass balancing, the accuracy of metal reconciliation depends on the accuracy of the measurements taken at various points in the process. Errors in measurements can lead to inaccuracies in the metal reconciliation calculations.

Incomplete data: Metal reconciliation requires complete and accurate data on the material flow and the chemical composition of the material. Incomplete or missing data can make it difficult to accurately reconcile the metal balance.

Sampling errors: Sampling errors can occur if the samples taken from different points in the process do not accurately represent the material being processed. This can lead to inaccuracies in the metal reconciliation calculations.

Process changes: Changes in the process, such as changes in the feed grade or changes in the operating conditions, can affect the accuracy of the metal reconciliation calculations.

Assay errors: Assay errors can occur if the assays used to determine the metal content of the material are inaccurate. This can lead to errors in the metal reconciliation calculations.

The timing of measurements: The timing of measurements can also affect the accuracy of the metal reconciliation calculations. If the measurements are not taken at the same time, there can be discrepancies in the metal balance.

Human error: Finally, human error can also contribute to inaccuracies in metal reconciliation. For example, errors in data entry or calculation mistakes can lead to errors in the metal reconciliation calculations.

Overall, metal reconciliation is an important tool for metal accounting, but it is not without its challenges. To minimize these problems, it is important to ensure accurate measurements, use representative samples, carefully monitor and document any process changes, and take steps to minimize assay errors and human error.

What is the economic impact of a poorly managed and developed metal Accounting System?

A poorly managed or developed metal accounting system can have significant economic impacts on a mining operation. Some of the potential consequences are:

Loss of revenue: If the metal accounting system is not accurately measuring the amount of metal being produced, it can result in a loss of revenue due to underreporting.

Over-reporting of losses: Inaccuracies in the metal accounting system can result in over-reporting of metal losses, leading to unnecessary costs and reduced profitability.

Increased costs: A poorly developed or managed metal accounting system can lead to higher costs due to the need for additional sampling and testing, increased labor costs, and potential penalties for non-compliance.

Regulatory fines and penalties: If the metal accounting system is not compliant with regulations, it can result in fines and penalties from regulatory agencies, which can be costly and negatively impact the reputation of the mining operation.

Inaccurate resource estimates: Inaccuracies in metal accounting can lead to inaccurate resource estimates, which can impact mine planning and scheduling, potentially resulting in over-extraction or under-extraction of resources.

Reduced investor confidence: A poorly managed metal accounting system can negatively impact investor confidence in the mining operation, potentially leading to reduced investment and lower valuation.

Overall, a poorly managed or developed metal accounting system can result in significant economic consequences, impacting the profitability, compliance, and reputation of the mining operation.

What is Best practice when it comes to Mass balance and Reconciliation for Metal Accounting?

Best practices for mass balancing and reconciliation in metal accounting include:

Accurate and representative sampling: Sampling is a critical component of mass balancing and reconciliation. It is essential to ensure that the samples collected are representative of the material being processed to ensure accurate accounting.

Rigorous testing and analysis: Rigorous testing and analysis of samples are necessary to accurately measure metal content and detect trace minerals. The use of modern analytical techniques such as XRF, ICP-MS, and automated mineralogy can improve accuracy and reduce the potential for errors.

Robust data management: A robust data management system is necessary to ensure the accuracy and integrity of data used in mass balancing and reconciliation. This includes using standardized data formats, ensuring data quality, and regularly backing up data.

Continuous improvement: Regularly reviewing and improving the mass balancing and reconciliation process is essential to identify and correct errors and ensure ongoing accuracy.

Compliance with regulatory requirements: Compliance with regulatory requirements is critical to avoid fines and penalties and maintain the reputation of the mining operation.

Staff training and awareness: Staff involved in the mass balancing and reconciliation process should be properly trained and aware of best practices to ensure accurate and consistent results.

Implementing these best practices can improve the accuracy and reliability of mass balancing and reconciliation in metal accounting, resulting in improved profitability, compliance, and reputation for the mining operation.

Rigorous testing and analysis - what is involved?

Rigorous testing and analysis in metal accounting typically involves several steps, including:

Sample preparation: Samples are collected from various points in the production process and prepared for analysis. The preparation can involve crushing, milling, and homogenization to ensure that the sample is representative.

Chemical analysis: The prepared samples are subjected to chemical analysis to determine the metal content. Several techniques can be used, including X-ray fluorescence (XRF), inductively coupled plasma mass spectrometry (ICP-MS), atomic absorption spectrometry (AAS), and fire assay.

Mineralogical analysis: Mineralogical analysis involves identifying the mineralogy of the samples. This can be done using optical microscopy, scanning electron microscopy (SEM), and automated mineralogy techniques.

Quality control and assurance: Quality control and assurance measures are necessary to ensure the accuracy and reliability of the analytical data. This involves using certified reference materials (CRMs) and duplicates to check the accuracy of the analysis.

Data processing and interpretation: The analytical data is processed and interpreted to calculate the mass balance and reconcile metal accounting. This involves identifying any discrepancies and investigating the causes.

Reporting: The results of the testing and analysis are reported to stakeholders, including management, regulators, and investors.

Rigorous testing and analysis are essential for accurate and reliable metal accounting. The use of modern analytical techniques can improve the accuracy and reduce the potential for errors. Quality control and assurance measures are necessary to ensure the accuracy and reliability of the data, and proper data processing and interpretation can improve the effectiveness of metal accounting.

Robust Data management - what is involved?

Robust data management is essential for effective metal accounting. It involves several steps, including:

Data collection: Collecting data from various sources within the production process, including laboratory analysis, equipment measurements, and operational data.

Data validation: Validating the accuracy and completeness of the data. This involves checking for errors, inconsistencies, and missing data.

Data integration: Integrating the collected data into a central database to create a complete picture of the production process. This involves developing a standardized data format and ensuring that all data is captured consistently.

Data storage: Storing the data in a secure and organized manner, with appropriate backups and disaster recovery procedures.

Data analysis: Analyzing the data to identify trends, patterns, and anomalies. This can be done using statistical methods and data visualization tools.

Reporting: Presenting the data and analysis to stakeholders, including management, regulators, and investors.

Robust data management is essential to ensure that the data used for metal accounting is accurate, complete, and reliable. It enables the identification of trends and patterns in the production process, which can be used to improve performance and optimize operations. Proper data management can also facilitate compliance with regulatory requirements and support decision-making processes.

Data Validation - What is involved?

Data validation is the process of verifying the accuracy, completeness, and consistency of data collected or received from various sources. It involves checking the data to ensure that it is reliable and conforms to predefined standards and rules.

The aim of data validation is to identify and correct errors, omissions, and inconsistencies in the data.

Data validation involves several steps, including:

Data completeness check: This involves checking whether all required data has been collected and whether any data is missing.

Data consistency check: This involves verifying whether the data is internally consistent and conforms to predefined rules or standards.

Data accuracy check: This involves verifying the accuracy of the data by comparing it against independent sources or measurements.

Data timeliness check: This involves verifying whether the data is collected and reported in a timely manner.

Data integrity check: This involves verifying whether the data has been tampered with or altered in any way.

Data duplication check: This involves checking for duplicate records or data that has been entered more than once.

Data format check: This involves verifying whether the data is in the correct format and meets the required specifications.

Data validation is an essential step in data management, as it helps to ensure the accuracy and reliability of the data used for metal accounting. It helps to identify and correct errors and inconsistencies in the data, which can lead to incorrect reporting and decision-making.

Data Intergration - what is involved?

Data integration is the process of combining data from different sources and formats to create a unified and consistent view of the data. It involves bringing together data from various systems, databases, and files to provide a more comprehensive understanding of the data. Data integration involves several steps, including:

Data mapping: This involves identifying the structure and format of the data from different sources and mapping it to a common format.

Data transformation: This involves converting the data from its original format to a common format that can be used for analysis and reporting.

Data cleansing: This involves identifying and correcting errors and inconsistencies in the data, such as misspellings, duplicates, and missing values.

Data consolidation: This involves combining data from different sources into a single location, such as a data warehouse or data mart.

Data validation: This involves checking the accuracy and completeness of the integrated data to ensure that it is reliable and consistent.

Data aggregation: This involves summarizing the data to provide a higher-level view of the information.

Data integration is an essential step in data management, as it helps to ensure that the data used for metal accounting is complete, accurate, and consistent. It allows different departments and systems within an organization to share data and collaborate more effectively, which can improve decision-making and business performance.

Data analysis - What is involved?

Data analysis involves the process of examining, cleaning, transforming, and modeling data to extract insights and draw conclusions from the data. In the context of metal accounting, data analysis is used to identify trends, patterns, and anomalies in the material flow, as well as to calculate the metal content and reconciliation. The process of data analysis typically involves several steps, including:

Data preparation: This involves cleaning and transforming the data to ensure that it is consistent and accurate.

Data exploration: This involves examining the data to identify patterns and trends, using tools such as charts, graphs, and statistical models. Data modeling: This involves creating statistical models and algorithms to analyze the data and make predictions or forecasts.

Data visualization: This involves creating visual representations of the data, such as charts and graphs, to help communicate insights and findings.

Data interpretation: This involves drawing conclusions from the data and making recommendations based on the findings.

The goal of data analysis in metal accounting is to improve the accuracy and reliability of the metal accounting system by identifying and correcting errors, optimizing material flow, and improving resource estimation. By analyzing the data, metal accounting professionals can gain a better understanding of the material flow and identify opportunities for improvement, which can ultimately lead to increased productivity and profitability.

Data reporting - What is involved?

Data reporting is the process of presenting the results of data analysis in a clear and concise manner, typically in the form of reports, dashboards, or other visualizations. In the context of metal accounting, data reporting is an important component of the overall metal accounting system, as it enables stakeholders to track the performance of the system and make informed decisions based on the insights provided by the data. The process of data reporting typically involves several steps, including:

Identifying the audience: The first step in data reporting is to identify the intended audience for the report, as this will determine the level of detail and the format of the report.

Selecting the appropriate visualizations: The next step is to select the appropriate visualizations to present the data, such as tables, charts, or graphs.

Creating the report: This involves putting together the report, including the visualizations and any accompanying text or explanations.

Reviewing and validating the report: The report should be reviewed and validated by relevant stakeholders to ensure that it accurately reflects the data and provides useful insights.

Sharing and distributing the report: Finally, the report should be shared and distributed to the relevant stakeholders in a timely manner.

The goal of data reporting in metal accounting is to provide stakeholders with a clear and accurate view of the material flow and the performance of the metal accounting system. By providing actionable insights and recommendations, data reporting can help stakeholders make informed decisions and optimize the performance of the system.

What is the difference between pulp and slurry?

Measuring of pulp density

Calculation of % solids

Dilution ratio

Practical Mass balancing with examples

Current advances and challenges

Mass balance equations

Why Mass balance

Reconciliation

Recovery percentage and grade

Mass recovery vs mass yield

Concentration ratio

Solid split

Enrichment ratio

Purpose of material balance

Material balance in steady state or continuous system

The two product formula

Calculations involved

How to perform a material balance?

Law of conversation of mass

Reactive and non reactive systems

Accumulation

Continuous process

Five steps in material balance

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.info/cs/register?ref=S5H7X3LP

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

ai therapy chatbot https://www.ai-therapist22.com .

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

самые точные прогнозы на спорт самые точные прогнозы на спорт .

ставки прогнозы на спорт stavki-na-sport-prognozy2.ru .

трансформаторы масляные http://www.maslyanie-transformatory-kupit2.ru .

трансформаторы силовые масляные купить maslyanie-transformatory-kupit.ru .

узи аппараты цена http://kupit-uzi-apparat15.ru .

сотовый телефон айфон https://kupit-ajfon-cs1.ru .

сантехника gessi http://www.gessi-santehnika-1.ru/ .

Thank you, your article surprised me, there is such an excellent point of view. Thank you for sharing, I learned a lot.

кашпо для цветов напольное http://www.kashpo-napolnoe-spb.ru/ – кашпо для цветов напольное .

sportbets sportbets14.ru .

Your article helped me a lot, is there any more related content? Thanks!

электрокарниз купить в москве https://elektrokarnizy50.ru/ .

новости дня http://www.novorjev.ru/ .

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Hi

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your article helped me a lot, is there any more related content? Thanks!

“You get some of me but not tomorrow as they want me in as soon as I can make it happen. This is the one time when they say jump and I ask how high due the financial gains the company could benefit from and it being important enough for the client to appear in person.”

“Well I get an extra night of you at least! I wonder what we could do with that? Meantime, what about food? I am starving and delicious as it was a second breakfast is not quite enough to replenish me!”

“Well get something on and we’ll sort that out first.”

We drove into town and decided that a daytime visit to Charlie’s was going to be the answer. I parked in the bar lot and Elise dashed in to change into something more appropriate, jeans and a t-shirt along with her biker jacket but keeping her Converses on.

Walking down to the restaurant was different from the middle of the night visits as the streets were bustling and all of the shops and outlets were open.

Reaching Charlie’s we entered the front door and sat in a booth near the window. A beautiful young American Chinese girl came,smiled and said hello to Elise and gave us menus and asked if we wanted drinks in the meantime.

“No thanks Lin just a pot of Jasmine tea for us please.” Lin went back to the kitchen area. “No booze for me today as I will have to work in the bar so it is just tea for me.”

Not in a drinking mood either, I agreed with her.”

https://imageevent.com/kactety1982

https://talnax1967.diary.ru/

https://imageevent.com/knopka1211985

https://okwave.jp/profile/u3138402.html

https://rastaman1968.bandcamp.com/album/jamie-chapter-2-a-squirt-adventure

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

“You get some of me but not tomorrow as they want me in as soon as I can make it happen. This is the one time when they say jump and I ask how high due the financial gains the company could benefit from and it being important enough for the client to appear in person.”

“Well I get an extra night of you at least! I wonder what we could do with that? Meantime, what about food? I am starving and delicious as it was a second breakfast is not quite enough to replenish me!”

“Well get something on and we’ll sort that out first.”

We drove into town and decided that a daytime visit to Charlie’s was going to be the answer. I parked in the bar lot and Elise dashed in to change into something more appropriate, jeans and a t-shirt along with her biker jacket but keeping her Converses on.

Walking down to the restaurant was different from the middle of the night visits as the streets were bustling and all of the shops and outlets were open.

Reaching Charlie’s we entered the front door and sat in a booth near the window. A beautiful young American Chinese girl came,smiled and said hello to Elise and gave us menus and asked if we wanted drinks in the meantime.

“No thanks Lin just a pot of Jasmine tea for us please.” Lin went back to the kitchen area. “No booze for me today as I will have to work in the bar so it is just tea for me.”

Not in a drinking mood either, I agreed with her.”

https://rentry.org/zyc23pqo

https://okwave.jp/profile/u3136816.html

https://permacultureglobal.org/users/61679-nicole-yingling

https://tubeteencam.com/user/utiyds1976/profile

http://www.babelcube.com/user/cory-rodriguez

“You get some of me but not tomorrow as they want me in as soon as I can make it happen. This is the one time when they say jump and I ask how high due the financial gains the company could benefit from and it being important enough for the client to appear in person.”

“Well I get an extra night of you at least! I wonder what we could do with that? Meantime, what about food? I am starving and delicious as it was a second breakfast is not quite enough to replenish me!”

“Well get something on and we’ll sort that out first.”

We drove into town and decided that a daytime visit to Charlie’s was going to be the answer. I parked in the bar lot and Elise dashed in to change into something more appropriate, jeans and a t-shirt along with her biker jacket but keeping her Converses on.

Walking down to the restaurant was different from the middle of the night visits as the streets were bustling and all of the shops and outlets were open.

Reaching Charlie’s we entered the front door and sat in a booth near the window. A beautiful young American Chinese girl came,smiled and said hello to Elise and gave us menus and asked if we wanted drinks in the meantime.

“No thanks Lin just a pot of Jasmine tea for us please.” Lin went back to the kitchen area. “No booze for me today as I will have to work in the bar so it is just tea for me.”

Not in a drinking mood either, I agreed with her.”

https://www.haikudeck.com/presentations/rHRmmNQlca

https://imageevent.com/vorkg1990

https://cannabis.net/user/158613

https://www.dnnsoftware.com/activity-feed/my-profile/userid/3204249

https://imageevent.com/sapnotajs1971

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.com/ar-BH/register?ref=V2H9AFPY

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

“You get some of me but not tomorrow as they want me in as soon as I can make it happen. This is the one time when they say jump and I ask how high due the financial gains the company could benefit from and it being important enough for the client to appear in person.”

“Well I get an extra night of you at least! I wonder what we could do with that? Meantime, what about food? I am starving and delicious as it was a second breakfast is not quite enough to replenish me!”

“Well get something on and we’ll sort that out first.”

We drove into town and decided that a daytime visit to Charlie’s was going to be the answer. I parked in the bar lot and Elise dashed in to change into something more appropriate, jeans and a t-shirt along with her biker jacket but keeping her Converses on.

Walking down to the restaurant was different from the middle of the night visits as the streets were bustling and all of the shops and outlets were open.

Reaching Charlie’s we entered the front door and sat in a booth near the window. A beautiful young American Chinese girl came,smiled and said hello to Elise and gave us menus and asked if we wanted drinks in the meantime.

“No thanks Lin just a pot of Jasmine tea for us please.” Lin went back to the kitchen area. “No booze for me today as I will have to work in the bar so it is just tea for me.”

Not in a drinking mood either, I agreed with her.”

http://www.babelcube.com/user/travis-chilton

https://rentry.org/cyboa7wq

https://fairmage1984.diary.ru/

https://magstihij19781972.bandcamp.com/album/training-programme-leads-to-unbelieveable-sex-part-2

https://rentry.org/fooviqb6

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

“You get some of me but not tomorrow as they want me in as soon as I can make it happen. This is the one time when they say jump and I ask how high due the financial gains the company could benefit from and it being important enough for the client to appear in person.”

“Well I get an extra night of you at least! I wonder what we could do with that? Meantime, what about food? I am starving and delicious as it was a second breakfast is not quite enough to replenish me!”

“Well get something on and we’ll sort that out first.”

We drove into town and decided that a daytime visit to Charlie’s was going to be the answer. I parked in the bar lot and Elise dashed in to change into something more appropriate, jeans and a t-shirt along with her biker jacket but keeping her Converses on.

Walking down to the restaurant was different from the middle of the night visits as the streets were bustling and all of the shops and outlets were open.

Reaching Charlie’s we entered the front door and sat in a booth near the window. A beautiful young American Chinese girl came,smiled and said hello to Elise and gave us menus and asked if we wanted drinks in the meantime.

“No thanks Lin just a pot of Jasmine tea for us please.” Lin went back to the kitchen area. “No booze for me today as I will have to work in the bar so it is just tea for me.”

Not in a drinking mood either, I agreed with her.”

https://imageevent.com/scrappy1962

https://rentry.org/wfr367rk

https://rustamix1966.diary.ru/

https://www.haikudeck.com/presentations/O0hb1rFB2Y

https://okwave.jp/profile/u3120098.html

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Yeah bookmaking this wasn’t a speculative conclusion outstanding post! .

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

It appears that you know a lot about this topic. I expect to learn more from your upcoming updates. Of course, you are very much welcomed to my website YK3 about Thai-Massage.

Thank you for the feedback. Much appreciated.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://accounts.binance.com/cs/register?ref=S5H7X3LP

Thank you for your feedback. Much appreciated

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Any suggestions. You are welcome. Thanks for your feedback.

I like more so how to attend this training !!

Thank you for you interest. Follow out chat on Whatsapp and join our whatsapp chat group https://chat.whatsapp.com/K9bEVozOM3jFiXmd6tsxk0