Stockpile Management for Blended ore feed - Introduction

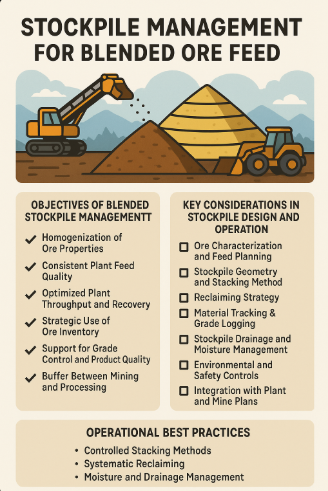

--- ## **Stockpile Management for Blended Ore Feed**

Efficient stockpile management plays a critical role in ensuring consistent feed quality to mineral processing plants. Variability in ore characteristics such as grade, hardness, moisture content, and mineralogy can significantly impact plant performance. Blended stockpiles serve as a buffer between mining and processing, helping to homogenize these variations. The goal is to deliver a steady, predictable ore feed that supports optimal plant operation, product quality, and throughput.

### **Objectives of Blended Stockpile Management**

* **Homogenization**: Reduce short-term variability in ore properties.

* **Process Optimization**: Enable stable operating conditions for crushers, mills, flotation, or DMS circuits.

* **Grade Control**: Meet specific product specifications, especially for multi-element ores.

* **Inventory Flexibility**: Store and reclaim ore as per operational schedules or plant availability.

* **Selective Feeding**: Enable strategic dispatch of ores based on plant needs (e.g., high-grade, low-moisture, or soft ore).

### **Key Considerations in Stockpile Design and Operation**

* **Ore Characterization**: Detailed knowledge of ore types and their metallurgical behavior is vital for blending. This includes assays, hardness indices (like Bond Work Index), and density.

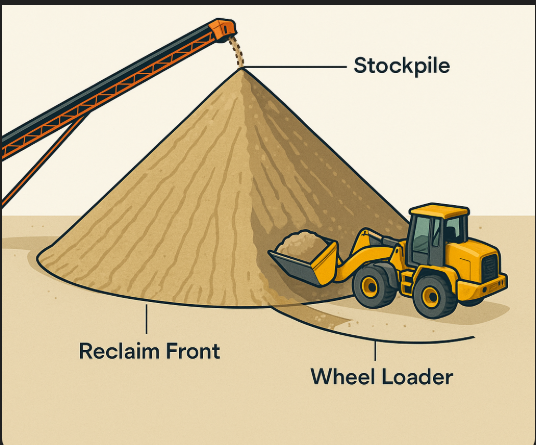

* **Stockpile Geometry**: The shape and reclaim method influence blending efficiency. Chevron and cone-shell stacking methods are common. Live reclaim designs (e.g., by dozer or apron feeders) promote better homogenization.

* **Layering and Tracking**: Accurate logging of the source, tonnage, and properties of each layer placed into the stockpile helps track variability and enables intelligent reclaiming.

* **Blending Algorithms and Control Systems**: Advanced software tools or manual systems guide operators on how to blend different ore parcels to match target specs, often using real-time data or pre-modeled scenarios.

* **Reclaiming Strategies**: Reclaiming from multiple points or cross-cutting layers minimizes stratification. Automated reclaimers or dozer-assisted reclaiming can provide better control of blend quality.

* **Moisture Management**: Preventing excessive wetting or drying in stockpiles ensures reliable downstream handling, especially for sticky ores or when feeding into SAG mills or DMS units.

### **Operational Best Practices**

* **Grade Batching Before Stockpiling**: Pre-classify ores into grade or hardness bins before stacking.

* **Regular Stockpile Sampling**: Implement a routine sampling schedule to monitor in-situ grade and moisture.

* **Short-Term vs Long-Term Stockpiles**: Use short-term surge piles for immediate plant needs and longer-term stockpiles for seasonal or strategic blending.

* **Data Integration**: Link geological models, mine plans, and plant SCADA systems to optimize real-time decisions about ore feed.

--- ## **Benefits of Well-Managed Blended Stockpiles**

* Reduces fluctuations in processing recovery and throughput.

* Lowers reagent consumption and energy use by stabilizing plant input.

* Prevents unplanned downtime from ore incompatibility (e.g., hardness swings).

* Enhances forecasting accuracy and metallurgical accounting.

* Supports economic orebody exploitation by enabling lower-grade blending.

Objective Of Blended Stockpile

Trending

Sensor Based Ore sorting – A Game Changer in Mineral Processing

Here’s a focused breakdown of the **Objectives of Blended Stockpile Management** in mineral processing:--- ## **Objectives of Blended Stockpile Management**

1. **Homogenization of Ore Properties** Blending stockpiles aim to smooth out the natural variability in ore characteristics such as grade, hardness, mineralogy, and moisture content. This homogenization helps reduce processing fluctuations and stabilizes downstream operations like crushing, milling, flotation, or dense media separation (DMS).

2. **Consistent Plant Feed Quality** A key goal is to maintain a steady feed composition that meets the processing plant’s specifications. This includes managing grade targets, hardness levels, and contamination thresholds to avoid abrupt changes that could disrupt plant performance.

3. **Optimized Plant Throughput and Recovery** When feed variability is reduced, plants can operate closer to design capacity, avoid overload or underload conditions, and improve metallurgical recovery. Consistent ore behavior reduces the risk of processing inefficiencies and increases overall productivity.

4. **Strategic Use of Ore Inventory** Stockpiles enable operators to store, schedule, and dispatch ore based on current plant needs, mine output, or market demands. This strategic flexibility allows for the blending of high-grade and low-grade ores to meet sales specifications, reduce dilution, or defer marginal material.

5. **Support for Grade Control and Product Quality** In multi-element deposits or polymetallic operations, blended stockpiles help meet strict product specifications (e.g., Cu%, Fe%, SiO₂ content). Proper blending avoids penalties for off-spec shipments and supports customer contract compliance.

6. **Buffer Between Mining and Processing** Stockpiles provide operational decoupling between the mine and the plant. This allows the plant to keep running even when mining activities are delayed or adjusted, ensuring continuous feed and avoiding costly downtimes.

Homogenization of ore properties

--- ## **Homogenization of Ore Properties**

### **Purpose** Homogenization aims to reduce short-term and batch-to-batch variability in the physical and chemical characteristics of ore fed to a mineral processing plant. By blending different ore parcels, the stockpile acts as a buffer that smooths out fluctuations caused by natural geological variation or operational factors in the mine.

--- ### **Key Ore Properties Needing Homogenization**

1. **Grade (e.g., Cu%, Fe%, Au g/t)** Ore from different zones may have variable metal content. Blending ensures the average grade aligns with plant targets and avoids sharp fluctuations that can destabilize recovery efficiency or violate product specs.

2. **Hardness (e.g., Bond Work Index, UCS)** Differences in ore hardness impact crushing and milling energy requirements. Homogenizing hardness helps maintain stable power draw, grinding efficiency, and throughput.

3. **Moisture Content** Wet ore can lead to handling issues (e.g., chute blockages, screening problems). By mixing dry and wet ore, operations can avoid moisture spikes that disrupt processing.

4. **Mineralogy and Liberation Behavior** Variability in mineral associations or particle liberation characteristics affects flotation and gravity separation performance. Blending minimizes this variability to support consistent recovery rates.

5. **Density and Specific Gravity** Particularly important in DMS and gravity circuits, homogenizing ore with similar specific gravities ensures the separation cut point remains optimal.

--- ### **Mechanisms of Homogenization**

* **Chevron, Cone Shell, or Windrow Stockpiling**: These stacking methods disperse ore layers in a pattern that promotes mixing during reclaiming.

* **Dozer or Reclaimer-Assisted Reclaiming**: Controlled reclaiming across multiple layers and zones further blends the material.

* **Blending Algorithms and Dispatch Control**: Real-time ore tracking and software-assisted blending decisions guide operators in creating balanced feed mixtures.

--- ### **Benefits of Homogenization**

* **Stable plant operation** (less load fluctuation and downtime)

* **Improved metallurgical performance** (better recovery and grade)

* **Reduced reagent and energy consumption** (more predictable processing behavior)

* **Enhanced product quality compliance** (avoids penalties from spec violations)

Consistent Plant Feed Quality

--- ## **Consistent Plant Feed Quality**

### **Purpose** Consistent plant feed quality ensures the processing plant receives material with stable and predictable characteristics—primarily in terms of grade, particle size distribution, hardness, moisture, and mineralogy. This stability allows for optimized operation, higher throughput, and predictable recovery and product quality.

--- ### **Key Aspects of Consistency**

1. **Stable Feed Grade**

* Sudden variations in metal content (e.g., Cu%, Au g/t, Fe%) can disrupt flotation, leaching, or DMS performance.

* A well-blended feed ensures the plant operates within its designed recovery curve and avoids high-recovery losses due to dilution or spikes.

2. **Uniform Hardness and Competency**

* Abrupt changes in ore hardness can lead to crusher or mill overload, inefficient grinding, and reduced throughput.

* Consistent feed hardness allows for better control of comminution parameters such as mill speed, media load, and power draw.

3. **Controlled Moisture Levels**

* Excessively wet or dry feed can impact screening, crushing, and conveyor systems.

* Balanced moisture levels ensure reliable material handling and prevent blockages or material hang-ups.

4. **Predictable Mineralogical Composition**

* Variations in mineral assemblages (e.g., sulfides vs. oxides) influence reagent consumption, flotation behavior, and downstream separation strategies.

* Blended feeds minimize process disruptions due to mineralogical shifts.

5. **Consistent Particle Size Distribution (PSD)**

* If stockpile reclaim is not controlled, large boulders or fines can dominate in waves, impacting screening, grinding, or DMS classification.

* Blending maintains an even PSD, aiding classification and separation efficiency.

--- ### **Operational Advantages**

* **Enhanced Process Stability** Reduces the need for frequent control adjustments and alarm-based interventions.

* **Improved Recovery and Throughput** The plant can operate near optimal conditions, minimizing losses and increasing tonnage.

* **Reduced Operating Costs** Less variability leads to more stable reagent and energy usage, reducing waste and improving efficiency.

* **Better Predictive Maintenance and Planning** Consistent feed results in fewer mechanical shocks and better performance forecasting.

--- ### **Summary** Maintaining consistent plant feed quality through effective stockpile blending is a foundational practice for process reliability, economic efficiency, and product quality. It directly impacts every major KPI—from throughput and recovery to unit costs and equipment wear.

Optimized Plant throughput and Recovery

--- ## **Optimized Plant Throughput and Recovery**

### **Purpose** Blended stockpiles are designed to deliver a steady, well-characterized feed to mineral processing circuits. This directly supports the ability to **maximize throughput**—the volume of ore processed over time—while simultaneously **optimizing metallurgical recovery**, i.e., the percentage of valuable minerals extracted. These two outcomes are essential for maximizing the economic efficiency of any mineral operation.

--- ### **How Blending Supports Throughput**

1. **Reduced Variability in Ore Competency and Hardness**

* Blending ensures a predictable energy demand in crushers and mills, allowing equipment to be operated close to capacity without risk.

2. **Minimized Operational Disturbances**

* A stable feed prevents surges, blockages, or unplanned adjustments in crushing, screening, milling, or separation units.

* This results in fewer stoppages and more effective use of installed capacity.

3. **Streamlined Process Control**

* When input variability is minimized, process control systems (e.g., PLC, SCADA, APC) can perform more effectively, further pushing throughput limits with less risk.

--- ### **How Blending Enhances Recovery**

1. **Better Match to Circuit Design Parameters**

* Most recovery circuits (e.g., flotation, leaching, DMS) are optimized for specific feed grades, densities, or mineralogical profiles.

* Blending helps keep these properties within the sweet spot, maximizing separation efficiency.

2. **Improved Liberation and Particle Size Control**

* Uniform ore leads to predictable grind size and mineral liberation patterns.

* This enables reagents, residence times, and flowrates to be tuned for maximum extraction efficiency.

3. **Minimized Losses Due to “Off-Spec” Feed**

* Sharp shifts in feed grade or mineralogy can lead to misclassification, overgrinding, or incomplete separation.

* Blending cushions such shifts, helping prevent valuable mineral loss in tailings.

--- ### **Benefits of Optimized Throughput and Recovery**

* **Increased Daily Tonnage** without compromising quality.

* **Higher Payable Metal Output** due to improved recovery.

* **Lower Unit Costs** through economies of scale and reduced energy/reagent per ton.

* **Reduced Wear and Tear** due to fewer upsets and mechanical stress.

--- ### **Summary**

Blended stockpiles are a strategic tool for optimizing both plant throughput and recovery. By reducing variability in ore properties, they create a controlled processing environment that enables plants to run harder, longer, and more efficiently—ultimately extracting more value from every tonne of ore.

Strategic Use of Ore Inventory

--- ## **Strategic Use of Ore Inventory**

### **Purpose** Strategically managing ore inventory through blended stockpiles enables mines and processing plants to optimize resource utilization, align feed characteristics with plant capabilities, and respond flexibly to operational, market, or logistical constraints. This approach turns stockpiles from passive storage into an active tool for production and value optimization.

--- ### **Key Strategic Functions of Ore Inventory**

1. **Flexible Ore Dispatching**

* Blending stockpiles allow operators to choose specific ore types or combinations based on real-time plant needs (e.g., soft ore to boost mill throughput or high-grade ore to meet production targets).

* Enables adaptive planning based on equipment availability, energy prices, or reagent supply.

2. **Grade Optimization and Value Uplift**

* Lower-grade ores can be blended with higher-grade material to achieve target product grades without violating recovery or specification constraints.

* This extends the life of the mine by economically processing marginal or low-grade zones that would otherwise be uneconomic.

3. **Smoothing Supply Chain Gaps**

* Stockpiles act as buffers between the mine and the plant, enabling continuous operation even when mining is interrupted (e.g., due to weather, equipment failure, or labor disruptions).

* Supports decoupling of mine scheduling and processing requirements.

4. **Selective Feeding for Metallurgical Objectives**

* Enables plant teams to optimize for different outcomes (e.g., maximize recovery, minimize impurities, meet smelter specs).

* For example, when downstream circuits are constrained by flotation cell capacity or DMS stability, a different blend can be selected to relieve that bottleneck.

5. **Market-Responsive Operations**

* In volatile commodity markets, blending strategies can be adjusted to prioritize ore parcels that align with profitable contract specs or higher metal payability.

* Supports grade banking—accumulating high-grade stock during low-price periods for future processing during more favorable conditions.

--- ### **Benefits of Strategic Inventory Management**

* **Improved Financial Flexibility** through tactical grade scheduling.

* **Reduced Operational Downtime** by maintaining consistent feed despite upstream disruptions.

* **Extended Orebody Life** through better utilization of low-grade or complex ores.

* **Enhanced Compliance with Product Specifications** for export or sale.

* **Better Coordination Between Mine, Plant, and Marketing Teams** using shared inventory intelligence.

--- ### **Summary**

Blended stockpiles enable mining operations to transform static ore piles into dynamic tools for strategic decision-making. Whether the goal is to stabilize production, improve recovery, defer low-value ore, or respond to market shifts, strategic use of ore inventory empowers plant operators and planners to extract greater value with greater control.

Support for Grade control and Product quality

--- ## **Support for Grade Control and Product Quality**

### **Purpose** Blended stockpiles are essential for achieving tight control over feed grade and ensuring final product quality meets customer or smelter specifications. They serve as a key link between the geological variability of the orebody and the processing plant’s ability to deliver a consistent, saleable product. Effective blending mitigates the impact of natural fluctuations in ore grade and chemistry, enhancing both internal control and market compliance.

--- ### **Grade Control Functions**

1. **Maintaining Target Feed Grade**

* Blending allows the average feed grade (e.g., Cu%, Fe%, Au g/t) to be aligned with plant recovery curves and economic models.

* Prevents sudden grade spikes or dips that could cause overloading, dilution, or recovery losses.

2. **Selective Grade Scheduling**

* Stockpiles enable operations to control when and how different grades are fed into the plant (e.g., high-grade campaigns to meet quarterly targets or compensate for previous underperformance).

3. **Dilution Management**

* By blending high- and low-grade materials, dilution can be minimized to remain within processing limits, maximizing recovered value.

--- ### **Product Quality Assurance**

1. **Control of Penalty Elements and Impurities**

* Blending helps dilute or manage deleterious elements (e.g., As, Sb, S, MgO, SiO₂, Al₂O₃) that could lead to downstream smelter penalties or product rejection.

* This is particularly important for iron ore, base metals, and battery minerals.

2. **Meeting Multi-Element Specifications**

* In polymetallic deposits (e.g., Cu-Pb-Zn, Li-Ta, Fe-Ti-V), achieving the right balance of element ratios in the product is critical.

* Blended stockpiles allow for fine-tuning these ratios through feed control.

3. **Compliance with Contractual Tolerances**

* Export or toll-treatment contracts often specify tight tolerances for product quality (e.g., moisture content, size distribution, LOI).

* Controlled feed from well-managed stockpiles improves the plant’s ability to meet these contractual standards consistently.

--- ### **Benefits of Supporting Grade and Product Quality**

* **Avoidance of Smelter or Customer Penalties**

* **Improved Process Efficiency and Recovery**

* **Higher Realized Metal Price and Payability**

* **Better Forecasting for Production and Sales**

* **Enhanced Reputation for Quality and Consistency**

--- ### **Summary**

Blended stockpile management is an essential tool for grade control and product quality assurance in mineral processing. By actively managing what goes into and comes out of the stockpile, operations can tightly regulate feed composition, minimize variability, and deliver a final product that aligns with commercial and metallurgical targets.

Buffer between Mining and Processing

--- ## **Buffer Between Mining and Processing**

### **Purpose** Blended stockpiles serve as a physical and operational **buffer** between mining activities and the mineral processing plant. Since mining and processing are often subject to different constraints (e.g., equipment, scheduling, weather, maintenance), stockpiles help **decouple these operations**, ensuring that plant throughput remains stable even when mining output varies.

--- ### **Why This Buffer Is Critical**

1. **Absorbs Variability in Mine Production**

* Mining rates fluctuate due to blasting delays, equipment breakdowns, or labor shortages.

* Stockpiles allow the plant to continue operating at full capacity even when mining is disrupted.

2. **Supports Continuous Plant Operation**

* Processing plants are most efficient when they operate continuously and near design capacity.

* Stockpiles ensure there's always material available for feed, reducing the risk of costly downtime.

3. **Facilitates Maintenance and Mine Scheduling**

* Allows mine planners to schedule equipment maintenance or focus on pre-stripping without stopping the plant.

* Buffering helps shift ore from periods of high mine productivity to times when mining is limited.

4. **Enables Flexible Feed Blending**

* When various ore types are mined from different zones at different times, stockpiling allows them to be stored and blended later to meet feed specifications.

--- ### **Operational Advantages**

* **Greater Planning Flexibility** Plant feed schedules can be optimized independently of mine schedules, enhancing both operational and financial performance.

* **Stabilized Feed Supply** Reduces stop-start behavior at the plant, improving equipment utilization and process control.

* **Improved Logistics Coordination** Stockpiles ease the coordination of haulage, loading, and equipment deployment between mining and plant operations.

* **Enables Just-in-Time Delivery** With proper stockpile management, materials can be reclaimed and fed into the plant exactly when needed—minimizing rehandling or double-hauling.

--- ### **Summary**

By acting as a buffer between mining and processing, blended stockpiles add essential **operational resilience** to mineral operations. They absorb disruptions, enable smoother plant operation, and provide the flexibility needed to optimize both upstream and downstream performance.

Key consideration in Stockpile design and operation

--- ## **Key Considerations in Stockpile Design and Operation**

### **1. Ore Characterization and Feed Planning** Before any stockpile is constructed or operated, it’s critical to understand the properties of the ore being handled.

This includes:

* **Grade distribution** (e.g., Cu%, Fe%, Au g/t)

* **Hardness and abrasion index**

* **Moisture content and stickiness**

* **Mineralogy and density**

* **Contaminants or deleterious elements** This data is the foundation for effective blending strategies and stockpile layout planning.

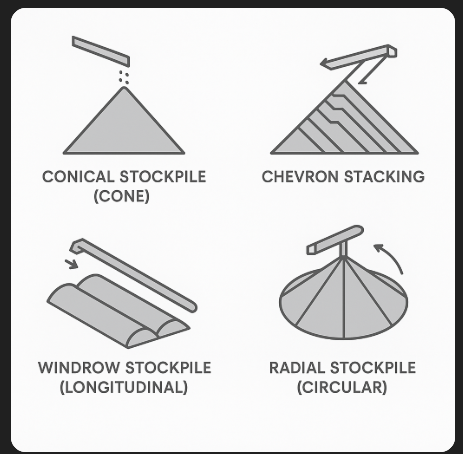

--- ### **2. Stockpile Geometry and Stacking Method** The physical shape and stacking method directly influence the stockpile’s blending effectiveness and reclaim efficiency:

* **Chevron Stacking**: Promotes cross-layer mixing during reclaim.

* **Cone Shell Stacking**: Easy to implement but can lead to stratification if not reclaimed properly.

* **Windrow or Radial Stacking**: Allows better layer control but may need advanced dozer or stacker coordination.

* **Horizontal Layering**: Helps preserve consistent chemical or physical characteristics layer-by-layer. The choice of method depends on site layout, material behavior, and equipment availability.

--- ### **3. Reclaiming Strategy** Reclaiming governs how well the blended material is actually delivered to the plant:

* **Dozer Push Reclaim**: Manual but flexible, can follow blending logic.

* **Multiple Reclaim Points**: Allows simultaneous draw from different stockpile zones for better blending.

* **Automated Reclaimers** (e.g., bucket wheels, apron feeders): Ideal for large-scale, consistent reclaiming but need precise control systems.

* **Live Reclaim Zones**: Areas designed to allow free-flowing material movement under gravity or controlled discharge. Reclaim should ideally draw from multiple layers or time periods to break up stratification.

--- ### **4. Material Tracking and Grade Logging** Accurate tracking of the source, properties, and placement of each ore load within the stockpile is essential:

* Use **GPS, RFID, or barcode systems** on haul trucks.

* Maintain a **real-time stockpile model** to predict in-situ grade and chemistry.

* Integrate with **blending software** to match target feed specifications. This enables informed decision-making during reclaim and dispatch.

--- ### **5. Stockpile Drainage and Moisture Management** Water accumulation affects ore flow, handling, and downstream processing:

* Design proper **surface drainage** and **internal moisture control**.

* Use **underdrain systems** or geofabric liners for wet climates.

* Position critical stockpiles on compacted, sloped surfaces or concrete pads. Proper drainage preserves ore flowability and prevents material hang-ups.

--- ### **6. Environmental and Safety Controls** Design must incorporate:

* **Dust suppression systems** (e.g., sprays, enclosures)

* **Slope stability** and safe dozer operation angles

* **Fire risk management** in sulfide-rich stockpiles

* **Access control** for safe equipment movement This ensures compliance with health, safety, and environmental regulations.

--- ### **7. Integration with Plant and Mine Plans** Stockpile operations should be aligned with both:

* **Mine scheduling** (e.g., timing of ore availability)

* **Plant feed requirements** (e.g., grade, hardness, throughput targets) This requires good communication between geology, mine planning, plant operations, and logistics teams.

--- ### **Summary**

Effective stockpile design and operation hinge on blending science, engineering layout, and logistical precision. When these elements are properly managed, stockpiles become powerful tools for feed optimization, process stability, and economic gain.

Ore Characterization and feed Planning

--- ## **Ore Characterization and Feed Planning**

### **Overview** Ore characterization and feed planning are foundational steps in designing and managing blended stockpiles. Understanding the physical and chemical properties of the ore enables effective blending strategies that optimize plant performance and product quality.

--- ### **Key Elements of Ore Characterization**

* **Grade Distribution** Analyze metal content (e.g., copper, gold, iron) variability within the orebody to predict blending needs.

* **Hardness and Comminution Properties** Determine crushing and grinding energy requirements through tests like Bond Work Index or drop-weight tests.

* **Moisture Content** Measure water content, which affects material handling and downstream processing.

* **Mineralogy and Liberation** Assess mineral types, associations, and liberation characteristics critical for flotation or separation.

* **Density and Specific Gravity** Important for separation methods like Dense Media Separation (DMS) or gravity concentration.

* **Contaminants and Deleterious Elements** Identify impurities that may affect processing or product quality (e.g., arsenic, sulfur).

--- ### **Feed Planning**

* **Ore Categorization and Binning** Group ore into categories based on key properties (grade, hardness, moisture) to enable controlled stacking and blending.

* **Blending Targets** Set specific goals for feed grade, hardness range, moisture levels, and impurity limits to guide stockpile management.

* **Scheduling and Logistics** Coordinate mine production schedules with blending and stockpile stacking to maintain a consistent feed supply.

* **Integration with Plant Requirements** Align feed planning with plant capacity, recovery optimization, and downstream processing constraints.

--- ### **Benefits**

* Enables predictable plant operation with reduced feed variability.

* Supports metallurgical recovery and product quality targets.

* Improves operational efficiency and cost control.

Stock Pile Geometry and Stacking

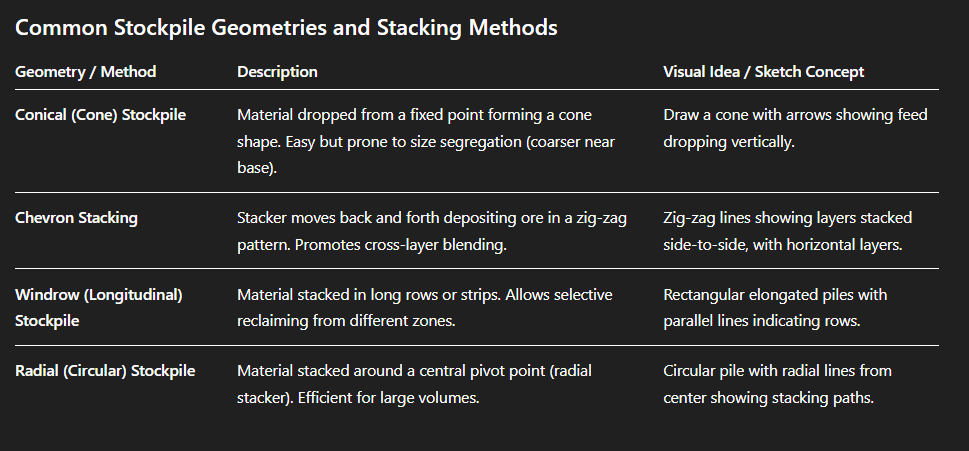

--- ## **Stockpile Geometry and Stacking Method** ### **Overview** The geometry and stacking method of a stockpile are key factors that influence blending effectiveness, material flow, reclaim efficiency, and operational safety. Choosing the right stacking technique and designing the stockpile shape carefully helps ensure a uniform, consistent feed to the processing plant.

--- ### **Common Stockpile Geometries**

* **Conical (Cone) Stockpile** Formed by dropping material from a fixed point, resulting in a cone-shaped pile.

*Pros:* Simple to build.

*Cons:* Can cause material segregation with fines and coarse particles separating by size and density.

* **Chevron Stockpile** Created by stacking material in layers while moving the stacker back and forth in a chevron (zig-zag) pattern.

*Pros:* Promotes cross-layer mixing and homogenization, reducing stratification.

*Cons:* Requires careful stacking control and equipment coordination.

* **Windrow (Longitudinal) Stockpile** Material is stacked in long rows or strips.

*Pros:* Easier to reclaim selectively from different zones.

*Cons:* May require more space and planning to maintain blend quality.

* **Radial or Circular Stockpile** Stacked around a central point by a radial stacker.

*Pros:* Efficient use of space, good for continuous reclaim systems.

*Cons:* Risk of layering segregation if reclaim is not managed carefully.

--- ### **Stacking Methods**

* **Layered Stacking** Ore is stacked in defined horizontal layers representing different ore types or grades.

*Benefit:* Easier to track and control blending.

* **Blending by Mixing** Stacking ore from different sources simultaneously to mix materials actively during stacking.

*Benefit:* Immediate homogenization, but harder to track ore origin.

* **Automated Stacking Control** Use of GPS and stacker control software to place material precisely and manage blending zones.

--- ### **Design Considerations**

* **Stack Height and Slope Angles** Should comply with geotechnical stability limits and material flow requirements. Typical angles of repose range from 30° to 45° depending on ore type.

* **Space and Layout Constraints** Stockpile location and shape must optimize available land and integrate with haul roads, reclaim points, and plant feed conveyors.

* **Access for Equipment** Sufficient space for stackers, dozers, reclaimers, and safety zones.

* **Segregation Prevention** Use stacking methods and geometry that minimize size or grade segregation, preserving blend quality.

--- ### **Summary**

Choosing the right stockpile geometry and stacking method is crucial for achieving effective ore blending, preventing segregation, and ensuring smooth reclaiming. Proper design enhances feed consistency, plant stability, and overall operational efficiency.

Common Stock Pile Geometries and Stacking methods

-- ### **Common Stockpile Geometries and Stacking Methods**

--- ### **Stacking Methods**

* **Layered Stacking**: Horizontal layers stacked one after the other, each layer represents a batch or ore type.

*Visual*: Layers stacked like a cake with clear separations.

* **Mixed Blending Stacking**: Different ores stacked simultaneously to mix material during stacking.

*Visual*: Overlapping colors or patterns showing mixed layers.

* **Automated Stacking**: Controlled placement via GPS/software to manage blending zones precisely.

*Visual*: Schematic of stacker with GPS markers controlling material placement.

Reclaiming Strategy

--- ## **Reclaiming Strategy**

### **Overview** Reclaiming strategy refers to the method by which material is withdrawn from stockpiles to ensure a consistent, blended, and uninterrupted feed to the processing plant. An effective reclaiming strategy minimizes feed variability, avoids dead zones, and supports operational flexibility.

--- ### **Key Reclaiming Methods**

#### **1. Dozer Push & Front-End Loader**

* **Method**: Material is pushed or scooped from the pile to a reclaim feeder.

* **Use Case**: Small to medium stockpiles or emergency reclaim.

* **Pros**: Flexible, easy to control manually.

* **Cons**: Labor-intensive, risk of variable feed quality if not managed carefully.

#### **2. Tunnel Reclaim with Feeders**

* **Method**: Stockpile is built over reclaim tunnels with apron feeders or vibrating feeders.

* **Use Case**: Large, permanent stockpiles.

* **Pros**: Controlled, continuous reclaim; good for automation.

* **Cons**: High capital cost, potential for bridging and flow stoppage.

#### **3. Bridge or Portal Reclaimer**

* **Method**: Reclaimer moves across the pile, scraping material onto a conveyor.

* **Use Case**: High-throughput, well-blended reclaiming.

* **Pros**: Consistent blending, automated control.

* **Cons**: High cost, complex maintenance.

#### **4. Mobile Reclaimers or Bucket-Wheel Reclaimers**

* **Method**: Rotating wheel removes ore from stockpile face.

* **Use Case**: Port terminals, large continuous operations.

* **Pros**: High capacity, consistent reclaiming.

* **Cons**: Expensive, requires engineered stockpile layout.

--- ### **Best Practices for Reclaiming**

* **Multiple Draw Points**: Use several reclaim feeders across the stockpile width to draw evenly and reduce segregation.

* **Blending Zones**: Design reclaiming to pull material from different layers and zones simultaneously.

* **Live vs. Dead Storage**: Ensure adequate “live” reclaim volume to prevent starvation during flow interruptions.

* **Flow Patterns**: Design piles to promote funnel flow or mass flow, depending on material characteristics and blending needs.

* **Automation**: Integrate reclaim operations with real-time feed monitoring for grade control and throughput stability.

--- ### **Benefits of Effective Reclaiming**

* Maintains feed consistency to the plant

* Reduces risk of process upset or downtime

* Supports blending strategies set during stacking

* Improves recovery and product quality

Material Tracking and Grade Logging

--- ## **Material Tracking & Grade Logging**

### **Overview** Material tracking and grade logging are essential to maintaining visibility and control over ore movement from pit to plant. These systems ensure that blending targets are met, ore quality is predictable, and stockpile usage aligns with metallurgical and production goals.

--- ### **Core Components of a Material Tracking System**

#### **1. Source Identification**

* Each truckload or conveyor batch is tagged with source information (pit, bench, blast block).

* Integration with mine planning software ensures geospatial accuracy.

#### **2. Grade & Property Logging**

* Grade (e.g., %Cu, g/t Au) and other characteristics (hardness, moisture, contaminants) are logged by batch or shift.

* Sources: blast-hole sampling, field assays, online analyzers (e.g., PGNAA, XRF), lab results.

#### **3. Material Movement Recording**

* Use of RFID tags, GPS, weighbridges, and dispatch systems to track haul truck movements and dumping points.

* Conveyor-based tracking through belt scales and real-time flow sensors.

#### **4. Stockpile Modeling**

* 3D stockpile models updated continuously with volume, material type, and grade distribution.

* Tracks inflows and outflows over time for each stockpile zone.

* Supports virtual blending simulation and reclaim planning.

#### **5. Integration with Plant Systems**

* Stockpile feed data links to plant control systems for real-time feed quality monitoring.

* Enables dynamic adjustment of processing parameters (e.g., reagent dosage, grind size) based on feed grade.

--- ### **Technologies Commonly Used**

* **GPS & RFID** for haul truck tracking

* **SCADA systems** for real-time conveyor and stockpile monitoring

* **Mine-to-Mill software platforms** (e.g., MineSense, SmartStockpile)

* **Online grade analyzers** for rapid property updates

* **Digital twins** for visualizing stockpile conditions and predictions

--- ### **Benefits**

* Improves feed predictability and plant stability

* Reduces misrouting and ore/waste confusion

* Enables proactive blending and feed optimization

* Enhances metallurgical accounting accuracy

Stockpile Drainage and Moisture Management

--- ## **Stockpile Drainage and Moisture Management**

### **Overview** Effective drainage and moisture control are essential for maintaining ore flowability, minimizing handling issues, and ensuring consistent processing performance. Poorly managed moisture can lead to compaction, blockage, excessive fines generation, and variable plant feed characteristics.

--- ### **Challenges of Excess Moisture in Stockpiles**

* **Flow Blockages**: Wet material tends to cake, bridge, or form stagnant zones, especially during reclaim.

* **Segregation & Slumping**: Water promotes size segregation and uneven settling in the pile.

* **Handling Issues**: Sticky ore may clog conveyors, feeders, and crushers.

* **Processing Instability**: High moisture affects grinding efficiency, flotation kinetics, and density-based separation.

* **Contamination Risk**: Surface runoff may cause environmental contamination or dilute nearby stockpiles.

--- ### **Drainage and Moisture Control Strategies**

#### **1. Stockpile Base and Pad Design**

* **Free-Draining Layer**: Install crushed rock or coarse material as a base layer to allow water to percolate.

* **Drainage Pipes and Trenches**: Channel water away from the pile using sub-surface drains or sloped concrete pads.

* **Lining Systems**: Use impermeable liners or geotextiles to control seepage and avoid ground contamination.

#### **2. Stockpile Geometry and Height**

* **Sloped Surfaces**: Promote runoff with engineered slope angles (typically 3–5%) to avoid water pooling.

* **Avoid Over-Stacking**: Excess height increases compaction and moisture retention in the lower zones.

#### **3. Covering and Surface Management**

* **Capping Layers**: Apply dry, coarse material as a surface layer to shed water.

* **Rain Covers or Tarpaulins**: Temporary or permanent covers help reduce rainwater ingress.

* **Windrows & Ridges**: Form shallow channels on the stockpile surface to direct rainwater away from critical zones.

#### **4. Moisture Monitoring**

* **Probes & Sensors**: Install moisture sensors in key areas for real-time moisture content tracking.

* **Sampling Programs**: Regularly sample material from different stockpile zones to assess vertical and horizontal moisture profiles.

#### **5. Operational Practices**

* **Stack During Dry Periods**: Schedule stacking and reclaim during favorable weather conditions when possible.

* **Water Diversion Systems**: Build berms or trenches to divert stormwater from upstream sources away from the stockpile area.

--- ### **Benefits of Moisture Management**

* Ensures consistent reclaim and feed flow

* Enhances ore handling efficiency

* Improves plant stability and throughput

* Reduces environmental and safety risks

Environmental and safety Controls

--- ## **Environmental and Safety Controls in Stockpile Management**

### **Overview** Stockpiles, when improperly managed, can pose significant environmental and safety risks. A robust control strategy is essential to prevent dust emissions, water contamination, spontaneous combustion, slope instability, and operational hazards. These controls ensure regulatory compliance, reduce environmental impact, and protect worker and community health.

--- ### **Key Environmental Controls**

#### **1. Dust Suppression**

* **Sources**: Wind erosion, dozing, truck tipping, and reclaiming.

* **Controls**:

* **Water Sprays / Cannons**: Regular wetting of stockpile surfaces.

* **Dust Binders / Suppressants**: Chemical coatings that form crusts over dusty materials.

* **Vegetative Cover**: Inactive piles can be seeded with grass to stabilize fine particles.

* **Wind Fencing**: Barriers reduce wind velocity across pile surfaces.

#### **2. Water Runoff and Contamination Prevention**

* **Risks**: Acid mine drainage, heavy metal leaching, siltation.

* **Controls**:

* **Perimeter Drains and Collection Ponds**: Capture and treat runoff.

* **Lined Pads and Berms**: Prevent seepage into groundwater.

* **Sedimentation Traps**: Remove suspended solids before water discharge.

#### **3. Noise and Visual Impact Reduction**

* **Controls**:

* **Acoustic Barriers**: Reduce noise from mobile equipment.

* **Landscaping**: Use earthen bunds and vegetation to screen stockpiles from communities or public roads.

--- ### **Key Safety Controls**

#### **1. Slope Stability**

* **Hazards**: Stockpile collapse, engulfment of equipment/operators.

* **Controls**:

* **Safe Stack Angles**: Maintain design slope (typically ≤37° for dry ore).

* **Slope Monitoring**: Use visual inspections or ground radar/LiDAR for high piles.

* **Controlled Access Zones**: Demarcate areas with high wall or overhang risk.

#### **2. Traffic and Equipment Safety**

* **Controls**:

* **Clearly Defined Traffic Routes**: Signage and separation between light/heavy vehicles.

* **Dozer Safety Protocols**: Tethered dozers or radar alert systems on large piles.

* **Reclaim Tunnel Safety**: Install guards, access interlocks, and emergency egress options.

#### **3. Fire and Spontaneous Combustion Prevention**

* **Relevant for**: Coal or sulfide-rich ores.

* **Controls**:

* **Temperature Monitoring**: Detect hot spots early.

* **Compaction Control**: Avoid over-compacting which traps heat.

* **Layer Management**: Limit buildup of fine, reactive materials.

--- ### **Benefits of Effective Controls**

* Protects workers and surrounding communities

* Preserves water and air quality

* Avoids costly environmental liabilities

* Enhances operational sustainability and public trust

Integration with Plant and Mine Plans

--- ## **Integration with Plant and Mine Plans**

### **Overview** Stockpiles serve as the physical and operational interface between the **mine** (ore production) and the **processing plant** (ore utilization). To optimize their function, stockpile management must be tightly integrated with both **short-term and long-term mine planning** and **plant scheduling**. This alignment ensures production continuity, feed quality, and recovery efficiency.

--- ### **Key Integration Objectives**

#### **1. Align Ore Delivery with Plant Demand**

* Match mining output (tonnage and grade) to plant requirements using stockpiles to:

* Absorb short-term mismatches (e.g., during maintenance or shutdowns).

* Enable blending strategies to meet metallurgical targets.

* Stockpiles act as **buffers**, decoupling mine variability from processing constraints.

#### **2. Enable Feed Flexibility Based on Market/Product Requirements**

* Feed planning adjusts based on:

* Target product specs (e.g., concentrate grade, moisture).

* Market conditions (e.g., prioritizing high-grade ore during price spikes).

* Stockpiles allow selective reclaim to meet changing product goals.

#### **3. Support Strategic Mining Sequences**

* Early stripping or development ore can be stockpiled and later reclaimed when economically favorable.

* Managing low-grade and marginal ore in dedicated stockpiles helps extend resource value.

* Prioritize high-recovery blends for high-value recovery phases.

#### **4. Optimize Metallurgical Performance**

* Feed planning uses stockpile data to:

* Blend for consistent grindability, flotation response, or leach kinetics.

* Avoid problem ores (e.g., high talc, arsenic, or clays) during critical plant campaigns.

* Adjust reagent strategies or circuit configurations.

--- ### **Tools and Practices for Integration**

* **Unified Mine-Plant Planning Tools**: Use platforms like Deswik, MinePlan, or GEOVIA to integrate mining and processing models.

* **Stockpile Forecasting Dashboards**: Visualize material balances and grade trends across multiple stockpiles.

* **Scenario Simulations**: Test different mining and reclaim sequences to predict impacts on plant performance and product quality.

* **Digital Twin Models**: Link live plant data with stockpile models to support adaptive planning.

--- ### **Benefits of Integrated Planning**

* Reduces downtime due to feed interruptions

* Improves recovery and product consistency

* Enables agile response to ore variability and market dynamics

* Ensures better resource utilization and longer mine life

Operational Best Practices

--- ## **Operational Best Practices for Stockpile Management**

### **1. Controlled Stacking Methods**

* **Consistent Layering**: Use systematic stacking (e.g., Chevron, Cone Shell, Windrow) to avoid material segregation.

* **Height Control**: Limit stockpile height to prevent compaction and maintain reclaim flowability.

* **Material Tracking**: Mark each layer or lift with source and quality data for traceability and blending planning.

--- ### **2. Systematic Reclaiming**

* **Reclaim in Horizontal Layers**: Promotes uniformity in feed properties.

* **Use Blending Reclaim Patterns**: Reclaim across multiple zones or stockpiles to achieve feed consistency.

* **Avoid Spot Picking**: Prevent selective reclaim that can create variability in feed grade or texture.

--- ### **3. Moisture and Drainage Management**

* **Regular Moisture Monitoring**: Sample and test to manage process impacts (e.g., flotation or grinding efficiency).

* **Surface Management**: Maintain slope and surface capping to promote drainage and prevent pooling.

* **Wet Material Handling**: Keep wet stockpiles isolated and schedule reclaim during dry periods when possible.

--- ### **4. Equipment Utilization and Safety**

* **Dozer Safety**: Use tethered or radar-monitored dozers on large or steep piles.

* **Reclaim Tunnel Protocols**: Routine inspections and safe access controls for reclaim feeders and tunnels.

* **Mobile Equipment Zoning**: Clearly mark haulage and tipping areas with safe traffic flow paths.

--- ### **5. Real-Time Monitoring and Control**

* **Stockpile Management Systems**: Use SCADA or MES systems for live tracking of pile volumes, grades, and moisture.

* **Integrated Mine-Plant Dashboards**: Align mining, blending, and processing plans dynamically.

* **Sensors and Drones**: Use LiDAR, UAVs, or ground radar to monitor stockpile geometry and volume accurately.

--- ### **6. Maintenance and Housekeeping**

* **Dust Control Measures**: Regular watering, use of dust suppressants, and vegetation cover where applicable.

* **Erosion and Runoff Control**: Maintain berms, drains, and sediment traps to protect environment and working surfaces.

* **Routine Inspections**: Track compaction, drainage performance, slope stability, and reclaim reliability.

--- ### **7. Training and Communication**

* **Operator Training**: Teach stack/reclaim techniques, safety procedures, and blending principles.

* **Cross-Department Coordination**: Ensure mine, plant, and maintenance teams communicate material changes and constraints.

* **Documentation**: Keep logs of daily operations, issues, and adjustments made.

--- ### **Benefits of Adhering to Best Practices**

* Enhances feed consistency and plant performance

* Reduces material losses and rehandling costs

* Improves safety and environmental compliance

* Strengthens coordination across production teams

Cobtrolled Stacking Method

--- ## **Controlled Stacking Methods**

### **Purpose** Controlled stacking ensures that ore is placed in a way that **minimizes segregation**, **preserves blend quality**, and **maintains flowability** during reclaim. The chosen stacking method directly impacts feed consistency to the plant, ease of reclaim, and material handling efficiency.

--- ### **Common Stacking Methods**

#### **1. Chevron Stacking (Back-and-Forth)**

* **Method**: Material is deposited in continuous layers using a moving stacker that reverses direction.

* **Advantages**:

* Good for blending different ore types or grades.

* Minimizes particle size segregation along the length of the pile.

* **Considerations**:

* Segregation still possible across the width.

* Requires stacker with precise travel control.

#### **2. Windrow Stacking**

* **Method**: Material is laid in parallel rows side-by-side across the pile surface.

* **Advantages**:

* Reduces fine/coarse segregation.

* Simple for dozer or conveyor placement.

* **Best For**: Short-term stockpiles where segregation control is key.

#### **3. Cone Shell (Conical) Stacking**

* **Method**: Material is dropped in a single point, forming a cone. Repetition forms a “shell” of overlapping cones.

* **Advantages**:

* Easy to implement with fixed stackers.

* Suited for single-source, homogenous ore.

* **Drawbacks**: * Promotes radial segregation (fines in center, coarse outside).

* Poor blend uniformity if not reclaimed properly.

#### **4. Stratified Layering**

* **Method**: Stack in layers based on specific ore properties (grade, moisture, type).

* **Advantages**:

* Enables planned reclaim of desired blends.

* Supports feed strategy for varying plant needs.

* **Use Case**: Multi-source ore with different metallurgical characteristics.

#### **5. Dozer Stacking / Bulldozed Heaps**

* **Method**: Material is pushed into place using a dozer.

* **Advantages**:

* Low-cost method for small or temporary piles.

* **Challenges**: * Risk of compaction and uneven layering.

* Increased safety risk on steep slopes.

--- ### **Stacking Best Practices**

* **Limit Drop Heights**: Reduces fines loss and segregation.

* **Control Pile Height**: Prevents compaction and improves drainage.

* **Use Compaction Selectively**: Avoid over-compacting unless required for stability.

* **Track Source Material**: Document layers or lifts for blending and quality control.

--- ### **Integration with Reclaim Strategy**

* Stack with **future reclaiming in mind**—ideally from multiple access points and with reclaim geometry aligned to stacking layers.

* For blending, align stacking and reclaim directions orthogonally (e.g., stack east-west, reclaim north-south).

--- ### **Benefits of Controlled Stacking**

* Improved feed homogeneity to the plant

* Reduced rehandling and blending corrections

* Enhanced reclaim efficiency

* Lower risk of process variability due to segregation

Systematic Reclaiming

--- ## **Systematic Reclaiming**

### **Overview** Systematic reclaiming refers to the deliberate, planned extraction of ore from stockpiles in a manner that maintains **blend uniformity**, **feed consistency**, and **operational efficiency**. Effective reclaiming prevents process upsets, reduces variability in feed grade, and ensures optimal use of the ore inventory.

--- ### **Reclaiming Strategies**

#### **1. Horizontal Layer Reclaiming**

* **Method**: Ore is reclaimed layer by layer from the bottom or side.

* **Benefits**:

* Promotes consistent feed by mixing ore within a layer.

* Especially effective when ore was stacked with controlled layering.

* **Tools**: Dozers, front-end loaders, or reclaimers from reclaim tunnels.

--- #### **2. Multiple Face Reclaiming**

* **Method**: Material is extracted from different stockpiles or zones simultaneously.

* **Benefits**:

* Enhances blending by combining different ore types or grades in real time.

* Allows flexibility to match changing plant feed requirements.

* **Control**: Often guided by live grade tracking and plant feedback loops.

--- #### **3. Longitudinal Reclaiming**

* **Method**: Reclaiming proceeds in the same direction as stacking (e.g., front to back).

* **Challenge**:

* Can result in grade swings due to segregation during stacking.

* **Solution**:

* Only used when stacking is done using methods that preserve uniformity.

--- #### **4. Cross-Pile Reclaiming**

* **Method**: Reclaiming occurs across the width of a stockpile (perpendicular to stacking direction).

* **Benefits**:

* Maximizes blending effect, especially when stacking was layered longitudinally.

* **Ideal for**: Chevron or windrow stacked piles.

--- ### **Best Practices in Reclaiming**

* **Avoid Spot Picking**: Reclaiming only from visible high-grade spots can create sharp feed fluctuations and bias reconciliation.

* **Follow Reclaim Maps**: Use planned reclaim patterns based on stockpile build history and grade models.

* **Use Automation Where Possible**: Automated stacker-reclaimers can ensure consistent reclaim rates and patterns.

* **Match Reclaim Rate to Plant Demand**: Prevents overloading or starving the plant and maintains steady-state operation.

* **Adjust in Response to Plant Feedback**: Continuously tune reclaiming based on flotation, leach, or grinding performance.

--- ### **Integration Tools**

* **Grade Control Models**: 3D models showing material type, grade, and location.

* **Live Monitoring Systems**: Real-time sensors and belt analyzers provide feedback on reclaimed ore quality.

* **Mine-Plant Coordination Platforms**: Align reclaim plans with mining output and plant schedule.

--- ### **Benefits of Systematic Reclaiming**

* Reduces feed variability and process disruptions

* Improves metallurgical recovery and product quality

* Enables proactive blending to mitigate orebody variability

* Enhances reconciliation and tracking accuracy

Moisture and drainage Management

--- ## **Moisture and Drainage Management in Stockpiles**

### **Why It Matters** Excessive or uneven moisture in stockpiles can:

* Impair ore flowability and cause hang-ups in hoppers or feeders

* Affect downstream processing (e.g., flotation, screening, leaching)

* Increase haulage costs due to added water weight

* Promote bacterial growth or geotechnical instability

* Complicate blending and grade control due to variable dry tonnage

--- ### **Key Components of Effective Moisture Management**

#### **1. Stockpile Base Preparation**

* **Graded Base with Drainage Slopes**: Ensure the stockpile sits on a compacted surface that slopes toward drainage points to prevent pooling.

* **Subsurface Drainage Systems**: Install perforated pipes, gravel layers, or geotextiles to facilitate underdrainage.

* **Lined Pads (for sensitive ores)**: Use HDPE or clay liners when water contamination or leachate is a concern.

--- #### **2. Surface Water Control**

* **Top Shaping and Capping**: Shape stockpiles into domes or slopes that promote runoff. Avoid flat tops where water accumulates.

* **Surface Sealing**: Light compaction or use of crusting agents to reduce infiltration during rainfall.

* **Diversion Channels**: Build berms or channels around stockpiles to redirect rainwater runoff away from active reclaim areas.

--- #### **3. Moisture Monitoring**

* **Regular Sampling and Analysis**:

* Use moisture probes or lab drying methods to test ore from different pile zones (top, middle, base).

* Track temporal variations—especially after rainfall or during seasonal changes.

* **Moisture Sensors on Reclaim Belts**: Inline sensors can monitor live feed moisture to help adjust plant controls.

--- #### **4. Pile Design Considerations**

* **Height and Volume Management**:

* Limit height to reduce compaction and prevent water from being trapped in lower layers.

* **Segregation Control**:

* Avoid creating low-permeability layers (e.g., excessive fines) that trap moisture.

--- #### **5. Operational Tactics**

* **Wet/Dry Stockpiling Strategy**: Separate high-moisture material from dry feed when possible to allow drainage or air-drying.

* **Dry Period Reclaiming**: Prioritize reclaiming wet zones during dry weather to reduce process impact.

* **Temporary Covers or Tarps**: For critical piles or during wet seasons, use temporary covers to limit water ingress.

--- ### **Consequences of Poor Moisture Management**

* Plant feed variability due to wet slugs or dry surges * Screen blinding, chute blockages, and sticky ore buildup

* Increased maintenance on conveyors and feeders

* Process inefficiencies or unexpected dilution in metallurgical accounting

--- ### **Benefits of Moisture and Drainage Management**

* Consistent tonnage and quality delivered to the plant

* Better process performance, especially for flotation and grinding circuits

* Reduced rehandling and material loss

* Safer and more stable stockpiles

Equipment Utilization and Safety

--- ## **Equipment Utilization and Safety in Stockpile Management**

### **1. Key Equipment in Stockpile Operations** Stockpile management relies on a combination of fixed and mobile equipment:

#### **Mobile Equipment**

* **Dozers** – for stacking, leveling, and reclaiming.

* **Front-End Loaders** – for reclaim, loading, and short-distance hauling.

* **Excavators** – used in shaping, drainage maintenance, or emergency reclaim.

* **Haul Trucks** – deliver ore to stockpiles from the mine or primary crusher.

#### **Fixed Equipment**

* **Stacker Conveyors** – automated or semi-automated placement of material in controlled patterns.

* **Reclaim Feeders** – extract ore from tunnels or pads at a controlled rate.

* **Stacker-Reclaimer Machines** – dual-function machines that automate both stacking and reclaiming, common in large operations.

--- ### **2. Safety Risks and Controls**

#### **A. Stockpile Stability**

* **Risk**: Slumping or collapse of over-steepened slopes.

* **Control**: Maintain safe slope angles (typically ≤37° for unconsolidated material). Enforce exclusion zones near pile faces.

#### **B. Equipment Sinkage**

* **Risk**: Mobile equipment can sink into soft or waterlogged pile bases.

* **Control**: Inspect foundations regularly. Restrict access during/after rain. Use designated safe travel paths.

#### **C. Visibility and Communication**

* **Risk**: Blind spots lead to collisions or near-misses between mobile units.

* **Control**: Use spotters, cameras, and GPS tracking systems. Enforce radio communication protocols.

#### **D. Reclaim Tunnel Hazards**

* **Risk**: Material hang-ups, flooding, confined space risks.

* **Control**: Routine inspection, moisture monitoring, proper ventilation, and lockout/tagout procedures.

#### **E. Dust and Airborne Particulates**

* **Risk**: Health hazard and visibility impairment.

* **Control**: Use water sprays, dust suppression chemicals, and PPE.

--- ### **3. Best Practices for Equipment Utilization**

* **Match Equipment to Task**: Use dozers for shaping, not for prolonged reclaiming. Use loaders with high breakout force for dense or sticky material.

* **Plan Traffic Flow**: Design one-way traffic systems with dedicated entry/exit points to minimize interaction risk.

* **Train Operators**: Ensure operators understand stockpile hazards and follow standardized operating procedures (SOPs).

* **Routine Maintenance**: Keep all equipment in peak condition to avoid breakdowns, especially in high-moisture or abrasive environments.

* **Automate Where Possible**: Remote or automated stacking and reclaiming reduces operator exposure to hazardous zones.

--- ### **4. Safety Enhancements**

* **Guardrails and Berms**: Prevent mobile equipment from falling off pile edges.

* **Emergency Response Plans**: Define procedures for engulfment, vehicle rollovers, and tunnel blockages.

* **Safety Signage**: Clearly mark exclusion zones, active equipment paths, and emergency routes.

* **Real-Time Monitoring**: Use cameras, sensors, and fleet management systems to monitor equipment location, health, and operator performance.

--- ### **Benefits of Optimized Utilization and Safety**

* Improved material handling efficiency and throughput

* Reduced equipment wear and operational cost

* Lower incident rates and insurance liabilities

* Higher compliance with health and safety standards

* Increased equipment uptime and operator productivity

Real Time Monitoring and control

--- ## **Real-Time Monitoring and Control in Stockpile Management**

### **1. Purpose and Benefits** Implementing real-time monitoring systems in stockpile operations enables:

* **Immediate detection** of material quality changes (grade, moisture, size)

* **Better coordination** between mining, stockpiling, and processing

* **Faster response** to anomalies such as feed surges, moisture spikes, or safety hazards

* **Data-driven optimization** of reclaiming, stacking, and blending ---

### **2. Key Monitoring Parameters**

#### **A. Ore Quality Monitoring**

* **On-Belt Analyzers**: Use XRF, PGNAA, or LIBS to measure real-time grade (Fe, Ni, Cu, etc.) and elemental composition.

* **Moisture Sensors**: Measure surface and total moisture on conveyor belts or reclaim points.

* **Particle Size Monitoring**: Laser or camera-based systems track fines content or oversize trends.

#### **B. Stockpile Conditions**

* **Thermal Sensors**: Detect self-heating in sulphidic ores or prevent smoldering.

* **Weight and Volume Sensors**: Load cells or radar systems track stockpile mass and shape.

* **Reclaim Rates**: Monitored via belt scales, dozer tracking, or feeder speeds.

#### **C. Equipment Status**

* **Telematics Systems**: Monitor dozer or loader location, utilization, and condition.

* **Conveyor and Feeder Health**: Vibration, current, and motor load sensors detect early faults.

--- ### **3. Control Systems Integration**

#### **Centralized SCADA or DCS Platforms**

* Integrates inputs from analyzers, weighers, and mobile fleet for centralized decision-making.

* Automates alarms, interlocks, and control loops (e.g., reclaim feeder speed adjustment).

#### **Advanced Process Control (APC)**

* Uses live data to dynamically adjust blending, reclaiming sequence, and plant feed targets.

* Can incorporate machine learning for predictive adjustments based on historical trends.

#### **Mobile and Cloud-Based Dashboards**

* Supervisors and planners access live stockpile data remotely.

* Integration with mine planning and plant optimization platforms.

--- ### **4. Use Cases and Examples**

* **Ore Grade Stabilization**: Adjust reclaim blend based on live PGNAA data to meet mill feed specs.

* **Moisture Control**: Delay reclaiming high-moisture zones after rainfall, guided by inline sensors.

* **Equipment Optimization**: Auto-schedule dozer or loader cycles based on fill levels and reclaim rate.

--- ### **5. Implementation Considerations**

* **Sensor Placement**: Strategic installation is critical—e.g., belt tail for grade, feeder chute for moisture.

* **Calibration and Validation**: Regular checks ensure accuracy of grade and moisture data.

* **Network Reliability**: Stable communication between field devices and control rooms is essential.

* **Training and SOPs**: Operators must understand how to respond to system alerts and use live data effectively.

--- ### **Benefits of Real-Time Monitoring & Control**

* Tighter process control and consistent mill feed

* Reduced manual sampling and operator intervention

* Early detection of safety or operational risks

* Improved ore reconciliation and reporting accuracy

* Enhanced agility in adapting to mining variability

Maintenance and House Keeping

--- ## **Maintenance and Housekeeping in Stockpile Management**

### **1. Why It Matters** Routine maintenance and good housekeeping are critical to:

* Ensuring safe access and operations * Preventing unplanned downtime due to equipment failure

* Avoiding environmental violations (dust, runoff, contamination)

* Preserving ore quality and reclaim efficiency

* Enhancing productivity through reduced cleanup and smoother operations

--- ### **2. Maintenance Priorities**

#### **A. Fixed Infrastructure**

* **Conveyors and Feeders**:

* Inspect belts, pulleys, scrapers, and gearboxes.

* Monitor motor load and vibration for early fault detection.

* Keep tension and alignment within limits.

* **Stackers and Reclaimers**:

* Grease tracks, joints, and hydraulics.

* Monitor wheel and rail wear.

* Check for sensor calibration and functional interlocks.

* **Tunnel Systems**:

* Check ventilation, lighting, drainage pumps, and emergency egress paths.

* Inspect structural supports and detect signs of cave-ins or moisture damage.

#### **B. Mobile Equipment**

* **Dozers, Loaders, Excavators**:

* Schedule pre-use inspections and regular servicing (brakes, hydraulics, lights).

* Track tire/wheel wear and undercarriage health.

* Monitor fuel and lubricant systems to prevent contamination or fire risk.

#### **C. Drainage and Environmental Systems**

* Clear blocked drainage channels and pump pits.

* Inspect liners, berms, and bunds for leaks or erosion.

* Maintain stormwater control systems—especially ahead of rainy seasons.

--- ### **3. Housekeeping Best Practices**

#### **A. Daily Cleaning and Organization**

* Remove spillage at transfer points, feeders, and base of conveyors.

* Clear access walkways, ladders, and operator stations.

* Ensure tools, hoses, and PPE are stored in designated places.

#### **B. Dust Control**

* Sweep dry material accumulations manually or with mobile vacuums.

* Apply water or surfactants to high-dust zones.

* Maintain fogging systems or dust extraction fans.

#### **C. Lighting and Visibility**

* Replace or clean lights regularly in tunnels and night-shift areas.

* Trim vegetation or obstructions around roadways and work areas.

--- ### **4. Safety and Inspection Protocols**

* **Inspection Checklists**: Use shift-based, weekly, and monthly inspection sheets for critical equipment and structures.

* **Tag and Lockout Procedures**: Ensure maintenance activities are done under full energy isolation.

* **Training**: All personnel should know how to identify and report hazards—especially around reclaim feeders and stockpile edges.

* **Housekeeping Logs**: Document daily cleaning and hazard mitigation actions.

--- ### **5. Benefits of Strong Maintenance & Housekeeping**

* Reduces incidents of tripping, engulfment, or equipment fires

* Prevents equipment failures and process disruptions

* Supports consistent material flow and feed quality

* Enhances environmental compliance and community perception

* Promotes pride, morale, and professionalism among staff

Training and Communication

--- ## **Training and Communication in Stockpile Management**

### **1. Purpose and Importance** Effective training and communication are critical to:

* Ensuring safe equipment operation and material handling

* Minimizing human error in reclaiming, stacking, and blending activities

* Enhancing situational awareness and hazard recognition

* Coordinating between mining, processing, and maintenance teams

* Promoting continuous improvement and compliance

--- ### **2. Training Components**

#### **A. Safety Training**

* **Hazard Recognition**: Slope instability, engulfment risks, tunnel safety, equipment blind spots.

* **Emergency Response**: Procedures for vehicle rollovers, fire, material collapse, or tunnel blockages.

* **PPE Usage**: Site-specific PPE requirements (e.g., respiratory protection in dusty zones).

* **Permit to Work & Lockout/Tagout**: When performing maintenance in high-risk areas.

#### **B. Equipment Operation**

* **Pre-start Inspections**: Dozers, loaders, stackers, reclaimers.

* **Safe Work Practices**: Approaching pile faces, reversing protocols, using spotters.

* **Reclaiming and Stacking Protocols**: Understanding patterns, limits, and avoidance of segregation.

#### **C. Systems and Controls**

* **SCADA or DCS Interfaces**: How to interpret real-time data and respond to alarms.

* **Sensor Awareness**: Understanding moisture meters, grade scanners, and flow controls.

* **Data Logging and Reporting**: How to document tonnage, grades, and anomalies.

--- ### **3. Communication Best Practices**

#### **A. Shift Handover and Coordination**

* **Daily Briefings**: Recap of previous shifts, current challenges, equipment status.

* **Handover Logs**: Written notes on safety issues, process changes, or delays.

#### **B. Radio and Signage Protocols**

* **Clear Language**: Standard call signs, confirmation protocols, channel usage.

* **Visual Communication**: Use of hand signals, lights, and flags for spotters.

#### **C. Cross-Department Alignment**

* **Mine–Plant–Stockpile Interface**:

* Shared production targets.

* Daily coordination on ore blending plans.

* **Maintenance–Operations Interface**:

* Downtime scheduling.

* Advance warning of inspections or service.

--- ### **4. Tools and Methods**

* **Induction Programs**: For all new hires and contractors.

* **Simulation and Virtual Training**: For loader/dozer operators or SCADA users.

* **Toolbox Talks**: Weekly focused discussions on specific hazards or performance topics.

* **SOPs and Visual Aids**: Laminated cards or posters at operator stations.

--- ### **5. Benefits of Strong Training and Communication**

* Fewer safety incidents and equipment damages

* Greater consistency in ore feed quality

* Improved equipment utilization and reduced downtime

* Stronger morale and engagement across crews

* Easier integration of automation and monitoring tools

Benefits of well Managed Blended Stockpile

---

##

### **1. Stable and Predictable Plant Feed**

* **Consistent grade, moisture, and size distribution** improve plant stability and throughput.

* Reduces **surges, fluctuations, and upset conditions** that can lead to inefficiencies or downtime.

* Supports **accurate reagent dosing, grinding performance, and recovery control**.

--- ### **2. Optimized Metal Recovery and Revenue**

* Prevents high- and low-grade spikes that can result in **sub-optimal recovery** or **metal losses**.

* Enhances **grade control at the mill**, leading to better performance against sales specs or smelter penalties.

* Supports **strategic use of ore types** (e.g., blending hard/soft ores, oxidized/sulfidic ores) to optimize recovery.

--- ### **3. Increased Operational Flexibility**

* Acts as a **buffer between mining and processing**, decoupling short-term production rates.

* Allows the plant to **continue operating during mining disruptions**, weather events, or breakdowns.

* Enables **stock rotation**, reclaim sequencing, and prioritization based on market conditions or plant needs.

--- ### **4. Improved Resource Utilization**

* Reduces **waste through better blending** of marginal or borderline ore types.

* Allows for **economic processing of variable ore bodies**, increasing total resource recovery.

* Reduces the need for costly rehandling or bypass stockpiles by maintaining a **centralized blending plan**.

--- ### **5. Enhanced Compliance and Reporting**

* Supports **more accurate metallurgical accounting**, grade reconciliation, and resource modeling.

* Minimizes environmental and regulatory risks through **controlled drainage and dust management**.

* Improves **traceability of ore sources**, which is increasingly important for ESG and responsible sourcing.

--- ### **6. Safety and Equipment Longevity**

* Reduces hazards associated with unplanned rehandling, poor pile geometry, or unstable reclaim conditions.

* Minimizes mechanical wear and damage by reducing material variability and handling stress.

* Facilitates safe dozer and loader access with maintained surfaces and clear reclaim zones.

Stable and Predictive Plant Feed

---

##

### **1. Process Stability**

* Consistent ore properties (grade, hardness, moisture, and particle size) reduce variability in the comminution and flotation circuits.

* Stabilized feed allows for steady **mill power draw**, **cyclone performance**, and **flotation response**.

### **2. Improved Control Loop Performance**

* Control systems (e.g., PID loops on flotation level, pH, or SAG mill load) operate more effectively with consistent input conditions.

* Fewer manual interventions are required, reducing operator fatigue and risk of human error.

### **3. Enhanced Reagent Efficiency**

* Predictable feed chemistry allows for optimized and **stable reagent dosing**, improving recovery and reducing reagent overuse or underuse.

* Fewer chemistry fluctuations lead to **better selectivity** and cleaner concentrates.

### **4. Downtime Reduction**

* Reduces unplanned shutdowns caused by feed surges, blockages, or density fluctuations.

* Extends equipment life by minimizing the mechanical stress from handling highly variable material.

### **5. Consistency in Product Quality**

* Helps ensure that the concentrate grade and tailings grade meet production targets and contractual requirements.

* Supports long-term metallurgical accounting accuracy and planning.

--- ### **Summary Statement**

A stable and predictable feed is the backbone of efficient plant performance. Well-blended stockpiles act as a feed stabilizer, protecting the plant from upstream variability and enabling consistent, high-quality throughput.

Optimized Metal Recovery and Revenue

---

##

### **1. Improved Metallurgical Recovery**

* **Blending ore with variable mineralogy** (e.g., refractory, oxidized, or complex ores) ensures more uniform metallurgical response.

* Avoids sharp feed fluctuations that can reduce flotation efficiency or overburden leaching and gravity circuits.

* Prevents low-recovery events caused by improper pH, residence time, or mineral locking.

### **2. Strategic Grade Management**

* Enables **controlled delivery of feed grades** to maximize recoverable metal rather than just chasing high feed grades.

* Avoids dilution or processing of waste/marginal material that would lower recovery or increase reagent and energy costs.

### **3. Avoids Recovery Penalties**

* Mitigates the risk of **grade spikes or impurities** (e.g., arsenic, sulfur, or carbon) that may lead to:

* **Smelter penalties** * **Off-spec product rejection**

* **Delayed payment or deductions**

### **4. Consistent Product Quality**

* Better feed control leads to tighter specification compliance for concentrate grade, moisture, and impurity levels.

* Facilitates **more reliable delivery against contracts**, improving commercial reputation and customer satisfaction.

### **5. Revenue Maximization**

* Ensures **higher saleable metal output** per ton mined through stable processing conditions.

* Allows prioritization of **high-value ore** during favorable market conditions without disrupting plant operation.

* **Reduces the need for reprocessing or stockpile retreatment**, which can tie up capital and reduce cash flow.

---

###

Increased Operational Flexibility

---

##

### **1. Decouples Mining and Processing**

* Stockpiles act as a **buffer between the mine and the plant**, allowing mining and processing to operate on **independent schedules**.

* Processing can continue uninterrupted during:

* **Mine equipment breakdowns**

* **Weather delays**

* **Blasting or haulage disruptions**

### **2. Enables Selective Reclaiming**

* Operators can **target specific zones** within a stockpile based on:

* Grade * Mineralogy

* Moisture or hardness

* Facilitates **real-time feed adjustments** in response to plant performance or market conditions.

### **3. Supports Blending for Special Requirements**

* Flexibility to blend ores to meet:

* Specific **grade targets**

* **Density and hardness constraints** for SAG/ball mills

* **Impurity level thresholds** (e.g., arsenic, sulfur, organics)

* Useful for managing **orebody transitions**, such as shifts from oxidized to fresh material.

### **4. Adapts to Market and Plant Needs**

* Can **defer lower-value material** or build strategic stockpiles for:

* Periods of higher metal prices

* Scheduled maintenance shutdowns

* Contract delivery timing

### **5. Reduces Plant Downtime**

* By maintaining sufficient stockpile inventory, the plant avoids:

* Starvation events

* Start-stop inefficiencies

* Rushed, unsafe restarts after unplanned stops

---

###

Improved Resource Utilization

---

##

### **1. Maximizes Use of Lower-Grade or Marginal Ore**

* Blending allows inclusion of **low-grade or borderline material** without compromising plant feed quality.