Real Time Process Control : How to achieve stability - Introduction

Trending

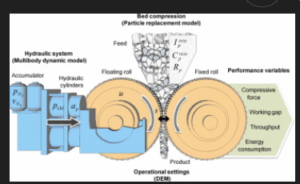

High Pressure Grinding Roll Crushers – HPGR: Trends and Best Practice

**Real-Time Process Control:How to Achieve Stability**

Achieving stability in **real-time process control** is fundamental to maintaining efficient, safe, and high-quality operations in industrial environments such as mineral processing, chemical manufacturing, or power generation.

Stability means the system remains within acceptable operational bounds, responds predictably to disturbances, and avoids oscillations or runaway conditions.

Here’s how to achieve it:

--- ### 1. **Understand the Process Dynamics** Before designing a control system, it is essential to understand how the process behaves over time—its delays, gains, nonlinearities, and interactions between variables. Techniques like **step response testing**, **system identification**, and **process modeling (first-principles or empirical)** are used to develop a process control model. This model guides the controller design.

--- ### 2. **Choose the Right Control Strategy** Common control strategies include:

* **PID (Proportional-Integral-Derivative) Control:** Most widely used for continuous control loops. Proper tuning of the three parameters is essential for stability.

* **Advanced Process Control (APC):** Techniques like **Model Predictive Control (MPC)** can manage multivariable systems with constraints and delays.

* **Feedforward Control:** Anticipates disturbances before they affect the process, complementing feedback loops.

* **Cascade Control:** Stabilizes fast inner loops before slower outer loops take action—useful for temperature or pressure control systems.

--- ### 3. **Implement Robust Sensor & Actuator Infrastructure** Reliable **real-time data acquisition** is critical. Sensors must be accurate, fast-responding, and resistant to noise. Actuators (valves, motors, etc.) must be responsive and well-maintained to execute control actions precisely.

**Signal filtering** (e.g., low-pass filters, moving averages) is also used to prevent control loop destabilization due to sensor noise.

--- ### 4. **Tune Control Loops for Stability** Loop tuning balances speed of response with stability. Poorly tuned loops can cause oscillations or instability.

Key tuning approaches include:

* **Ziegler-Nichols Method**

* **Cohen-Coon Tuning**

* **Trial-and-Error (with monitoring)**

* **Auto-tuning algorithms** in modern DCS/PLC systems Proper tuning requires analyzing **gain margins**, **phase margins**, and **closed-loop response**.

--- ### 5. **Integrate Real-Time Monitoring and Alarming** Use **real-time dashboards**, **SCADA systems**, and **digital twins** to continuously monitor process variables, controller outputs, and disturbances. Set up alarms for deviation thresholds and failed sensors. **Trend analysis** helps preempt instability before it becomes critical.

--- ### 6. **Design for Disturbance Rejection and Setpoint Tracking** Your control system should quickly reject disturbances (e.g., feed rate changes, raw material variability) and return to steady-state. **Dead-time compensation**, **gain scheduling**, and **adaptive control** are valuable in variable or nonlinear processes.

--- ### 7. **Ensure Operator Competence and Intervention Protocols** Operators must understand the control system and its behavior. In unstable conditions, rapid, informed human intervention can prevent plant trips. **Operator training simulators** and **control room dashboards** help maintain awareness and readiness.

--- ### 8. **Continuously Improve with Data Analytics and AI** Modern AI/ML tools can detect early instability patterns, optimize control parameters, or even suggest controller redesign. Real-time **performance metrics** like IAE (Integral of Absolute Error) or control loop oscillation indices help guide improvements.

--- ### Final Thoughts Achieving stability in real-time process control requires a blend of **control theory, instrumentation, data systems, operator expertise, and automation intelligence**.

The process must be dynamic but predictable, responsive but dampened, and continuously monitored for improvement.

Understanding The Process Dynamics

Trending

How can I use AI to enhance Metallurgical Performance of Mineral Processing Plants

### **Understand the Process Dynamics** Achieving real-time process control stability starts with a deep understanding of **process dynamics**—how inputs, outputs, and disturbances interact over time within your system. Without this foundational knowledge, even the most advanced control strategies will struggle to deliver consistent and reliable performance.--- #### 🔁 **What Are Process Dynamics?** Process dynamics describe how a process responds to changes in input conditions.

This includes:

* **Response time (lag/delay):

** How long it takes for the system to begin reacting after an input change.

* **Time constant:** How quickly the system reaches a new steady state.

* **Dead time (transport delay):

** Time between when a change is made and when the first effect is observed.

* **Gain:** The ratio of output change to input change.

* **Non-linearity:** Many industrial processes do not respond in a linear fashion, especially over wide operating ranges.

* **Coupling:** In multivariable systems, changing one input can affect multiple outputs.

--- #### 🧪 **Techniques to Analyze Process Dynamics**

1. **Step Testing:** Introduce a known change (e.g., increase in feed rate) and measure the output’s response over time.

2. **Pulse Testing:** Apply a short, temporary change and observe the transient behavior.

3. **System Identification Tools:** Use software (MATLAB, Aspen DMC, etc.) to fit mathematical models (transfer functions or state-space models) to real process data.

4. **Historical Data Analysis:** Leverage trend logs and process historian data to study real-world responses to changes, disturbances, or failures.

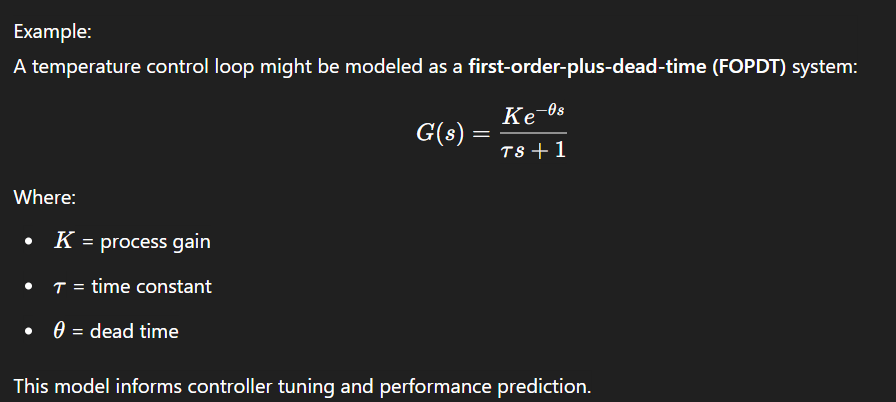

--- #### 📉 **Modeling the Process** The goal is to develop a **dynamic model** that represents your system’s behavior.

Two common approaches are:

* **First-Principles Modeling:** Based on physical laws (e.g., mass balance, energy balance). Useful for complex or safety-critical processes.

* **Empirical (Data-Driven) Modeling:** Uses historical or experimental data to fit a mathematical model without detailed physics. Faster and often more flexible.

Example:

A temperature control loop might be modeled as a **first-order-plus-dead-time (FOPDT)** system:

--- #### ✅ **Why It Matters**

Understanding process dynamics allows engineers to:

* Select the most effective **control structure**

* **Tune controllers** appropriately (e.g., PID gains)

* Anticipate and manage **process instabilities**

* Simulate scenarios and perform **“what-if” analyses**

* Build a robust foundation for **model-based control** and **digital twins**

Choose the right control Strategy

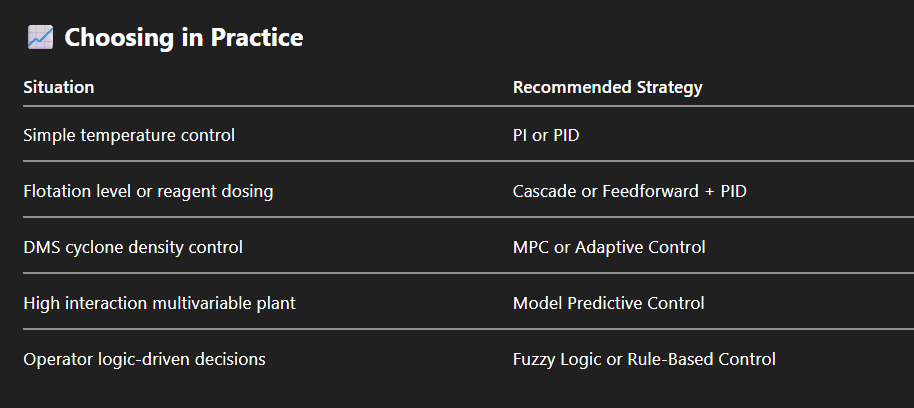

Once the process dynamics are well understood, the next step toward real-time control stability is choosing a **control strategy** tailored to your process's behavior, complexity, and performance requirements.

The right strategy balances responsiveness, robustness, and practicality—ensuring that the control system can maintain stability in the face of disturbances and varying operating conditions.

--- ### 🧭 **Control Strategy Selection Framework**

The choice of control strategy depends on:

* **Process characteristics:**

Is it linear or nonlinear? Single-input-single-output (SISO) or multivariable (MIMO)? Are there significant delays?

* **Stability requirements:**

How sensitive is the process to instability or oscillation?

* **Precision needs:** Are tight tolerances critical (e.g., metallurgy, blending)?

* **Disturbance profiles:** How frequent and severe are disturbances?

* **Infrastructure:**

What sensors, actuators, and control hardware/software are available?

--- ### ⚙️ **Common Control Strategies**

#### 1. **PID Control (Proportional–Integral–Derivative)**

* **Best for:** Simple, well-understood SISO loops (temperature, pressure, level, flow).

* **Advantages:**

* Easy to implement and tune

* Good balance between performance and simplicity

* **Limitations:**

* Struggles with long delays, non-linear systems, or strong interactions between variables > Example: Maintaining flotation cell level using PI control for smooth froth interface.

--- #### 2. **Cascade Control**

* **Best for:** Processes with nested dynamics (e.g., heating where flow affects temperature).

* **Structure:** An inner fast loop controls a secondary variable, while the outer loop controls the primary variable.

* **Benefits:**

* Faster response to internal disturbances

* More stable control under variable loads > Example: Inner loop controls steam flow; outer loop maintains reboiler temperature.

--- #### 3. **Feedforward Control**

* **Best for:** Managing predictable disturbances (e.g., changes in feed composition).

* **How it works:** Anticipates and compensates for disturbances before they affect the process.

* **Used with:** Feedback control for full coverage

> Example: Adjusting lime addition rate in a neutralization tank based on incoming acidic flow rate.

--- #### 4. **Ratio Control**

* **Best for:** Keeping a fixed proportion between two variables (e.g., fuel-to-air ratio).

* **Application:** Common in blending, combustion, and chemical dosing.

--- #### 5. **Model Predictive Control (MPC)**

* **Best for:** Multivariable systems with constraints and interactions.

* **How it works:** Uses a dynamic process model to predict future behavior and optimize control actions.

* **Strengths:**

* Handles time delays, process constraints, and variable interactions

* Improves efficiency and quality in complex operations

* **Limitations:**

* Requires a good process model and more computational power > Example: Controlling a dense media separation (DMS) circuit with varying feed density and pressure constraints.

--- #### 6. **Adaptive Control**

* **Best for:** Nonlinear or time-varying processes.

* **Features:** Adjusts controller parameters in real time based on process behavior.

* **Used in:** Batch processes, startup phases, or where process gains drift over time

--- #### 7. **Rule-Based and Fuzzy Logic Control**

* **Best for:** Systems where human operator logic needs to be automated.

* **Uses:** Linguistic rules (e.g., “If pressure is high and flow is low, then reduce valve opening”).

* **Effective in:** Semi-structured processes where exact modeling is difficult

> Example: Fuzzy control of thickener underflow pump based on bed level and torque feedback.

--- ### 📈 **Choosing in Practice**

-- ### 🔍 Final Tip Often, a **hybrid approach** works best—combining PID for fast loops, feedforward for disturbance anticipation, and MPC for complex optimization.

Implement Robust Sensor and Actuator Infrastructure

To achieve stability in **real-time process control**, having a **robust, accurate, and responsive sensor and actuator infrastructure** is just as important as the control algorithm itself.

Even the best-tuned controllers will fail if the signals they rely on are delayed, noisy, or unreliable. Ensuring high data quality and fast response from field instruments underpins the entire control loop.

--- ### 🧭 **Why It Matters**

* **Sensors** provide the real-time data that controllers use to make decisions.

* **Actuators** implement those decisions in the physical process.

* Faulty or slow sensors and sluggish actuators introduce **instability**, **oscillations**, and **inefficient operation**.

* Sensor or actuator failure can lead to **process upsets**, **equipment damage**, or **safety incidents**.

--- ### 📡 **Best Practices for Sensor Infrastructure**

#### ✅ **Choose Appropriate Sensor Types**

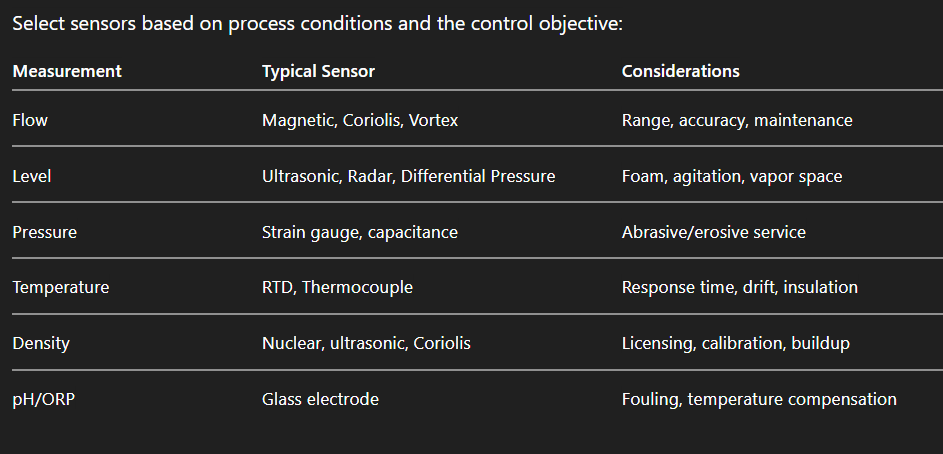

Select sensors based on process conditions and the control objective:

--- #### 🛠 **Ensure Proper Installation and Calibration**

* Position sensors in representative locations (avoid dead zones, turbulent zones).

* Calibrate regularly using traceable standards.

* Apply compensation for **temperature, pressure**, or **drift over time**.

--- #### 🧹 **Manage Noise and Filtering**

* Use **hardware filters**, **digital signal filters** (e.g., low-pass), or **moving averages** to smooth out random noise without suppressing valid signals.

* Balance between filtering and response time to avoid control lag.

--- #### 🔄 **Redundancy and Diagnostics**

* Use **dual sensors** on critical variables for validation and voting logic.

* Enable **self-diagnostics** to detect sensor failure, disconnection, or drift.

* Monitor for **flatlines**, **spikes**, or **saturation**, and trigger alarms or fallback logic.

--- ### 🔧 **Best Practices for Actuator Infrastructure**

#### ✅ **Use Reliable and Responsive Final Control Elements**

* **Control valves:** Must have good resolution and fast response. Pneumatic or electric actuators should match process speed.

* **Variable frequency drives (VFDs):** Provide smooth and fast speed control for motors.

* **Dampers & gates:** In material handling, ensure quick and full closure/opening.

* **Pumps:** Select based on flow/pressure range and ability to modulate.

--- #### 🔍 **Maintain Actuator Health**

* Regularly inspect for **stiction**, **leaks**, **positioner faults**, or **air supply issues**.

* Implement **actuator testing routines** (e.g., partial stroke testing for valves).

* Monitor actuator feedback signals (e.g., position vs. command) for anomalies.

--- #### 🧠 **Use Smart Instrumentation**

Modern transmitters and actuators offer:

* **HART, Foundation Fieldbus, or WirelessHART protocols** for diagnostics and configuration

* **Built-in signal filtering**, **self-calibration**, and **status indicators**

* **Integration with control system** for asset health monitoring

--- ### 🔗 **System Integration Tips**

* Use **high-speed data acquisition** and **low-latency networks** (e.g., Ethernet/IP, Profinet).

* Ensure **proper scaling and engineering units** are set in control systems (DCS/PLC).

* Avoid signal conversion errors between analog and digital stages.

--- ### 📌 Example in Mineral Processing In a Dense Media Separation (DMS) plant:

* Poor cyclone underflow density control is often caused by **faulty or slow density sensors** or **sticky valves**.

* Upgrading to **fast-response Coriolis meters** and **smart control valves** with real-time feedback can drastically improve stability and cutpoint control.

--- ### 🧭 Final Thought A robust sensor and actuator infrastructure isn't just about buying high-end instruments—it's about **reliability, maintainability, responsiveness, and integration**.

When the control system can trust its inputs and outputs, stability follows naturally.

Time Control Loops for stability

Poorly tuned loops can cause erratic behavior, process upsets, and excessive wear on equipment. Proper tuning is essential for achieving **stable, efficient, and robust real-time process control**.

--- ### 🎯 **Objectives of Control Loop Tuning**

* **Stability:** Prevent oscillations or runaway conditions.

* **Responsiveness:** Reach setpoint quickly with minimal delay.

* **Minimal overshoot:** Avoid exceeding the target value.

* **Robustness:** Handle disturbances and parameter changes gracefully.

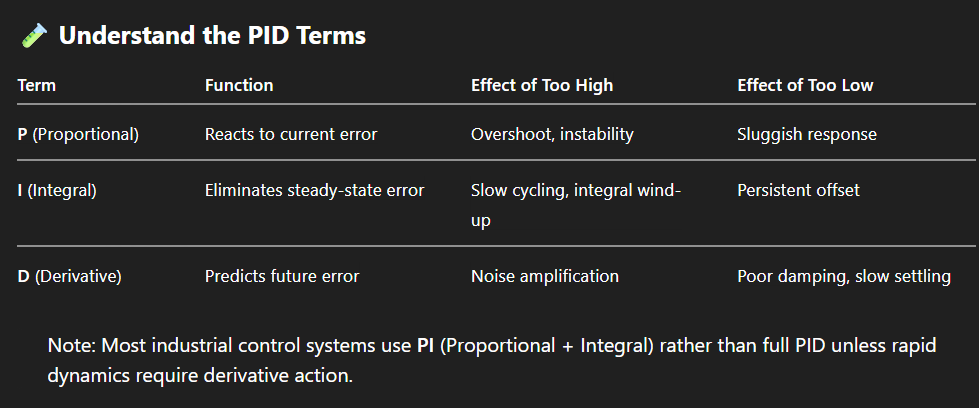

--- ### 🧪 **Understand the PID Terms**

--- ### 🛠️ **Loop Tuning Methods**

#### 1. **Manual (Trial-and-Error) Tuning**

* Start with only proportional gain.

* Add integral to eliminate offset.

* Add derivative (if needed) for fast-response systems.

> Best used by experienced engineers or when system dynamics are well understood.

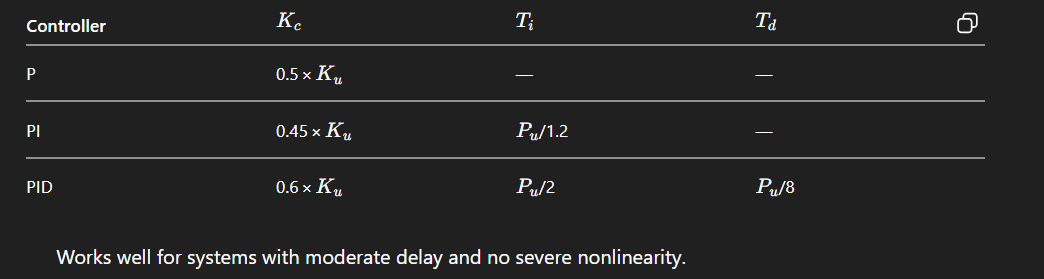

--- #### 2. **Ziegler–Nichols Method**

* Increase P gain until the system reaches the **ultimate gain** ($K_u$) and begins to oscillate.

* Record the **oscillation period** ($P_u$).

* Apply formulas for $P$, $I$, and $D$ settings.

--- #### 3. **Cohen–Coon Tuning**

* Based on step response fitting a **first-order-plus-dead-time** (FOPDT) model.

* Useful for processes with significant **dead time**.

--- #### 4. **Software-Based Auto-Tuning**

* Most modern DCS/PLC systems include auto-tuners.

* They apply a test signal and calculate optimal PID parameters.

* Ideal for systems with variable dynamics or many loops.

> Example: ABB, Siemens PCS 7, Emerson DeltaV, and Yokogawa CENTUM all offer auto-tuning features. -

-- #### 5. **Model-Based Tuning (e.g., Internal Model Control)** * Uses a mathematical model of the process.

* Ensures **predictive tuning** and better performance across operating ranges.

--- ### 🧭 **Tips for Tuning in Real-Time Systems**

* **Isolate the loop:** Ensure no other controller or operator is influencing the variable.

* **Start conservatively:** Avoid aggressive gains that might cause overshoot or oscillation.

* **Use bump tests** if step testing is too disruptive.

* **Monitor response:** Track rise time, settling time, overshoot, and steady-state error.

* **Apply anti-reset windup logic:** Prevent integrator saturation during large disturbances or valve limits.

* **Retune after changes:** If process conditions (e.g., feed variability or throughput) change, re-tuning may be necessary.

--- ### 🧪 Example: Flotation Cell Level Control

* **Without tuning:** PID loop oscillates due to long froth response time and flow delays.

* **With tuning:** Adjusted integral time and added damping via proportional gain.

* **Result:** Smooth control with stable froth depth and improved recovery.

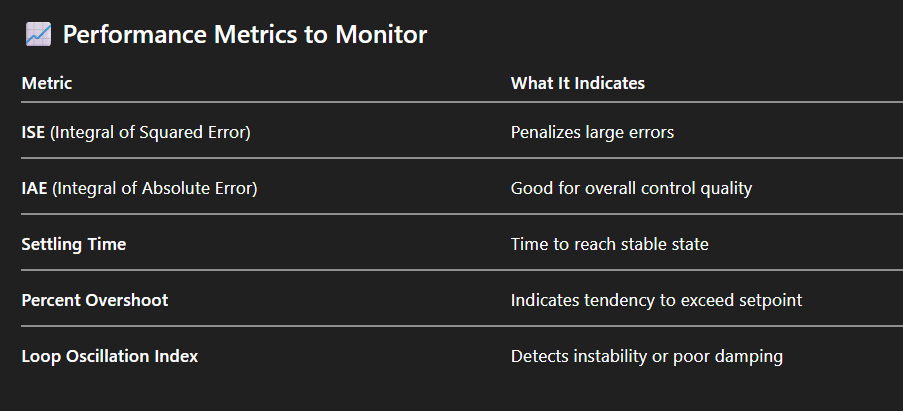

--- ### 📈 Performance Metrics to Monitor

--- ### ✅ Final Thoughts

Tuning is both a science and an art. Combine empirical methods with process knowledge, model-based tools, and modern software to achieve **stable, high-performance control**.

In mission-critical loops—like cyclone pressure control, leach tank pH, or thickener underflow—tuned control loops can be the difference between steady operation and repeated shutdowns.

Integrate Real-Time Monitoring and Alarming

A stable control system is only as effective as its **visibility and responsiveness** to abnormal conditions. Integrating **real-time monitoring and alarming** ensures that operators, engineers, and control systems are continuously aware of the process state and can act promptly to prevent instability, equipment damage, or safety incidents.

Effective monitoring and alarm systems create a feedback layer around your control strategy—**detecting deviations, diagnosing issues early**, and enabling fast corrective actions.

--- ### 🎯 **Objectives of Monitoring and Alarming**

* **Detect process deviations or disturbances early** * **Prevent excursions and trips**

* **Provide actionable insight to operators**

* **Improve situational awareness**

* **Support root cause analysis and long-term optimization**

--- ### 🖥️ **Real-Time Monitoring Components**

#### 1. **Live Dashboards and HMIs**

* Display **key process variables** (e.g., flow, pressure, temperature, pH, density) in real time.

* Show **trends** over different time horizons (minutes to days).

* Include **SP-PV (Setpoint–Process Variable)** tracking, controller outputs, and valve positions.

* Use **color-coding and symbols** to highlight abnormal conditions or loops in manual mode.

> Example: A DMS plant dashboard shows cyclone pressure, medium density, underflow density, and pump speed in synchronized graphs. -

-- #### 2. **Control Loop Performance Monitoring**

* Track loop responsiveness, oscillations, or actuator saturation.

* Use KPIs like:

* **IAE (Integral of Absolute Error)**

* **Valve Travel Index** (excessive movement = poor tuning or noise)

* **Controller Mode Duration** (e.g., % of time in auto vs. manual)

--- #### 3. **Soft Sensors & Digital Twins**

.* Use inferred measurements from models or correlations (e.g., estimate feed grade based on density and mass flow).

* Digital twins compare live data against expected behavior to highlight anomalies.

--- ### 🚨 **Effective Alarming Strategy**

#### 1. **Set Smart, Meaningful Alarm Limits**

* Avoid flooding operators with nuisance alarms.

* Use **process limits**, not just arbitrary high/low values.

* Implement **rate-of-change** alarms for fast disturbances.

> Example: “Underflow density dropping faster than 0.2 g/cm³ per minute” can detect pump failure or water intrusion before hitting hard limits.

--- #### 2. **Use Alarm Prioritization**

* **Critical (High Priority):** Equipment protection, safety trips, environmental breaches

* **Important (Medium Priority):** Process performance, deviation from control

* **Informational (Low Priority):** Status changes, operator reminders

--- #### 3. **Enable Alarm Suppression and Filtering**

* Suppress alarms during planned transitions (e.g., startup, washout).

* Avoid repeated alarms from noisy signals by using **deadbands**, **delay timers**, or **dynamic alarming** based on process state.

--- #### 4. **Enable Alarm Notifications**

* Deliver alerts via **control room panels**, **email**, **SMS**, or **mobile apps**.

* Use **escalation logic** if alarms go unacknowledged beyond a threshold.

--- ### 📈 **Post-Alarming Analysis**

* **Alarm logs** and **event chronologies** provide root cause context for excursions.

* Analyze **alarm frequency and duration** to tune alarm system effectiveness.

* Conduct **“Bad Actor” analysis** to remove or retune noisy/uninformative alarms.

--- ### 🔄 **Example Application: Flotation Circuit Monitoring**

* **Real-Time:** Dashboard displays pH, reagent dosing, froth height, air flow.

* **Alarms:** High froth depth triggers warning; rapid pH drop alarms chemical loss or pump failure.

* **Action:** Operator receives SMS and dashboard highlight; trend view helps identify root cause (reagent blockage).

--- ### 🧠 Integration with AI & Predictive Tools

* Combine alarms with **machine learning anomaly detection** for early warnings.

* Let AI suggest probable causes based on historical patterns and past alarms.

--- ### ✅ Final Thoughts Integrating real-time monitoring and alarming is **not just about visibility—it’s about proactive control**.

A well-designed system helps operators and engineers prevent minor disturbances from becoming major disruptions. Focus on clarity, responsiveness, and context-awareness to maintain process stability and safety.

Design for Disturbance Rejection and Set point Tracking

To maintain stable and high-performing real-time process control, your system must be able to **reject disturbances** quickly and **track setpoint changes** accurately.

These two objectives lie at the heart of control system design. A well-designed controller not only keeps the process stable under normal conditions but also **responds intelligently to unplanned changes** in operating conditions or control targets.

--- ### 🎯 **Key Concepts**

* **Disturbance Rejection:** The controller’s ability to return the process variable to setpoint after an external disturbance (e.g., feed variability, ambient changes, equipment wear).

* **Setpoint Tracking:** The system’s ability to smoothly and accurately follow changes in desired process conditions.

A robust system balances both:

it **reacts quickly to disturbances** without excessive overshoot and **follows new setpoints** without inducing oscillations.

--- ### 🧪 **Techniques to Enhance Disturbance Rejection**

#### 1. **Feedforward Control**

* Measures a known disturbance and compensates before it affects the process.

* Works in parallel with feedback control.

* Requires an accurate model of how the disturbance affects the process.

> Example:

In a neutralization tank, adjust alkali addition rate based on measured acid flow rate before the pH drifts.

--- #### 2. **Cascade Control**

* An outer loop sets the setpoint for a faster inner loop.

* Inner loop quickly handles disturbances before they propagate to the primary process variable.

> Example:

Outer loop controls DMS cyclone density; inner loop maintains pump speed to stabilize medium flow rate.

--- #### 3. **Derivative (D) Action in PID**

* Anticipates future trends by analyzing the rate of change.

* Helps suppress overshoot and respond faster to disturbances.

* Use carefully: it amplifies noise and is best suited for fast loops with good signal quality.

--- #### 4. **Adaptive Control**

* Automatically retunes the controller when the process dynamics change.

* Effective for systems with varying feed characteristics, load shifts, or aging equipment.

--- #### 5. **Disturbance Observers / State Estimators**

* Advanced method that estimates unmeasured disturbances and corrects in real time.

* Requires accurate process modeling.

--- ### 🧮 **Techniques to Improve Setpoint Tracking**

#### 1. **Setpoint Filtering / Ramping**

* Smooths out abrupt setpoint changes to prevent shock loading or overshoot.

* Common in temperature, level, or pressure control systems.

> Example: Instead of jumping from 150 °C to 200 °C instantly, ramp over 5 minutes.

--- #### 2. **Two-Degree-of-Freedom (2DOF) PID**

* Separates tuning for disturbance rejection and setpoint tracking.

* Provides faster tracking without compromising disturbance handling.

--- #### 3. **Model Predictive Control (MPC)**

* Predicts future process behavior and optimizes control actions over a time horizon.

* Handles multivariable interactions and constraints while maintaining precise setpoint tracking.

> Example: An MPC controller in a flotation circuit adjusts reagent flows and froth air rate to match grade setpoints while maintaining cell stability.

--- #### 4. **Anti-Reset Windup**

* Prevents integrator saturation when actuators hit physical limits.

* Allows quick recovery when the actuator re-enters controllable range.

> Especially important in level or pH loops where long disturbances can drive valves to 0% or 100%.

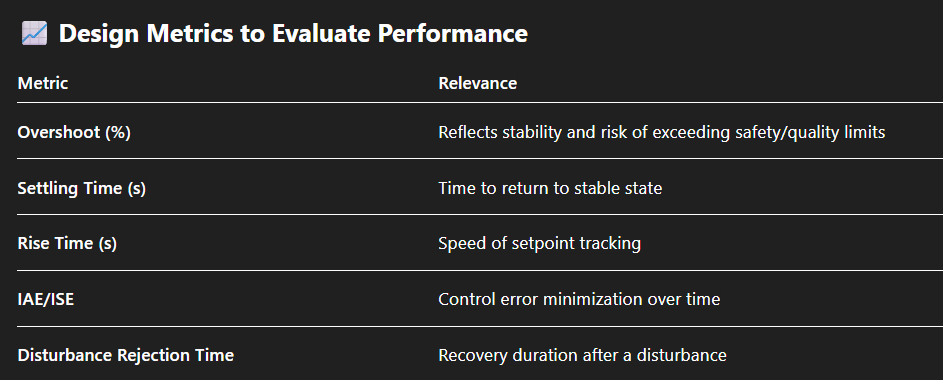

--- ### 📈 **Design Metrics to Evaluate Performance**

--- ### ⚒️ **Practical Design Tips**

* **Include disturbance paths in your process model** during controller design.

* **Simulate setpoint changes** and disturbances before deploying new control logic.

* For safety-critical systems, **design for worst-case disturbances**, not just typical conditions.

* Ensure actuators have **sufficient speed and authority** to implement corrections effectively.

--- ### 🧠 Example: Thickener Underflow Control

* **Disturbance:** Sudden change in feed solids percentage.

* **Strategy:** Cascade control (torque → rake speed) and feedforward (adjust flocculant based on inlet flow).

* **Setpoint Tracking:** Slowly ramp underflow density target to avoid rake overload or bed upset.

--- ### ✅ Final Thought Balancing **agility (setpoint tracking)** with **robustness (disturbance rejection)** is critical to real-time process control design. Use a layered approach—basic PID for local loops, cascade or feedforward where needed, and MPC or adaptive control for complex or dynamic systems.

Ensure Operator Competence and Intervention Protocols.

Ensuring **operator competence and clear intervention protocols** is a cornerstone of control system stability and safe plant operation.

--- ### 🎯 **Why It Matters**

* Operators are the **first responders** to process upsets and alarms.

* Human error is a leading cause of **instability, downtime**, and **safety incidents**.

* Skilled operators make **informed decisions** that enhance control performance and reduce reliance on emergency shutdowns.

* Well-defined protocols prevent **confusion**, **panic actions**, and **conflicting decisions** during abnormal conditions.

--- ### 🧠 **Build Operator Competence**

#### 1. **Structured Training Programs**

* Include theoretical understanding of:

* Control principles (e.g., what a PID loop does)

* Process behavior and dynamics

* Instrumentation basics

* Provide hands-on training on:

* DCS/SCADA/HMI operation * Manual control and loop tuning basics

* Alarm acknowledgement and diagnostics

> Example: Train DMS operators on how medium density responds to feed variability and what pump control options they have.

--- #### 2. **Simulation-Based Training**

* Use **process simulators** or **digital twins** to replicate:

* Normal operations

* Disturbances (e.g., feed surges, valve failures)

* Emergency scenarios

* Helps develop **muscle memory** for interventions, without plant risk.

> Example: Simulate thickener bed level rising due to flocculant pump failure, and assess operator reaction.

--- #### 3. **Knowledge Retention & Assessment**

* Regular refresher courses

* Certification for control-critical positions * On-the-job assessments and troubleshooting drills

--- ### ⚠️ **Define Intervention Protocols**

#### 1. **Clear Operator Actions per Scenario**

* What to do in case of:

* Sensor failure

* Unstable control loop

* Alarm escalation (e.g., high density, low flow)

* Manual override requirement

* Use decision trees, SOPs, and laminated cheat-sheets in the control room.

> Example: “If cyclone pressure drops below 1.2 bar and pump speed is at max: check for blockages or suction loss.”

--- #### 2. **Manual Mode Protocols**

* When switching from AUTO to MANUAL mode:

* Record the reason and expected duration.

* Specify hand-control setpoints or targets.

* Monitor deviation from expected trend.

* Procedures for **restoring AUTO mode** once stabilized.

--- #### 3. **Alarm Escalation and Communication**

* Who gets notified for different alarm tiers?

* What is the **response time target**?

* Use digital logs for operator comments and event tracking.

--- #### 4. **Emergency Shutdown and Recovery Steps**

* Predefined response plans for:

* Power failure

* Pump trip

* Reagent loss

* Include steps for controlled recovery and reinitialization of loops.

--- ### 📈 **Operator Support Tools**

* **Real-time dashboards** with annotations, setpoint limits, and guidance text

* **Automated hints or SOP triggers** tied to alarm conditions

* **Live chat/helpdesk access** to engineers or supervisors

* **Checklists for pre-shift handovers** and post-event reviews

--- ### ✅ Final Thought Control stability is not just an automation challenge—it’s a **human–machine collaboration**. When operators are competent, confident, and equipped with clear protocols, they become powerful allies in maintaining process reliability and responding to change.

Training, tools, and teamwork make the difference between reactive firefighting and proactive control.

Continuous Improvement with Data Analytics and AI

Real-time process control doesn’t end with loop tuning and automation.

To maintain **long-term stability and performance**, leading operations now embrace **data analytics** and **AI-driven optimization**.

These tools uncover inefficiencies, detect early signs of instability, and provide actionable insights that traditional monitoring can miss.

The goal is a **learning control system**—one that evolves and improves based on continuous feedback and real-world data.

--- ### 🎯 **Why Continuous Improvement Matters**

* **Processes drift over time** due to wear, fouling, feed variability, and external conditions.

* Even well-tuned loops can become unstable or inefficient without recalibration.

* Data-driven insights help **predict issues**, **optimize performance**, and **reduce manual intervention**.

* AI can identify complex patterns and nonlinear behaviors that are difficult for traditional control to handle.

--- ### 📊 **Leverage Data Analytics for Control Improvement**

#### 1. **Historical Trend Analysis**

* Review months of process data to:

* Identify recurring disturbances or instability

* Pinpoint control loops with frequent manual overrides

* Correlate process deviations with equipment conditions or raw material properties

> Example: Analyze historical underflow density vs cyclone pressure to tune PID parameters better.

--- #### 2. **Loop Performance Auditing**

* Use control system KPIs:

* **IAE / ISE / Mean Absolute Error**

* **Valve Travel Index (VTI)** * **% Time in Manual vs Auto**

* Highlight “bad actors” among control loops for retuning or hardware inspection.

--- #### 3. **Statistical Process Control (SPC)**

* Apply SPC charts (e.g., X-bar, R charts) to detect trends or deviations before alarms trigger.

* Use **control limits** based on actual process capability rather than arbitrary thresholds.

--- ### 🤖 **Use AI and Machine Learning to Enhance Control**

#### 1. **Anomaly Detection**

* AI models trained on “normal” behavior flag subtle process deviations or sensor drift.

* Detect faults early—before alarms or operators intervene.

> Example: AI detects abnormal vibration trend in a cyclone feed pump 24 hours before failure.

--- #### 2. **Predictive Modeling**

* Train ML models (Random Forests, Neural Networks, Gradient Boosted Trees) to:

* Predict product quality (e.g., recovery, grade)

* Forecast process variable trends

* Estimate future maintenance needs

--- #### 3. **Reinforcement Learning for Control Optimization**

* AI agents experiment (in simulation or controlled environments) to find **optimal control actions**.

* Can outperform human tuning in complex, dynamic systems.

> Example: A reinforcement learning agent optimizes air flow and reagent addition in a flotation plant to maximize recovery while minimizing reagent use.

--- #### 4. **AI-Assisted Operator Guidance**

* Real-time suggestions: “Increase thickener rake speed based on bed density trend.”

* Decision support: “Low medium density likely due to increased dilution water—verify valve position.”

--- #### 5. **Digital Twins and Simulation**

* Mirror real-time operations with a calibrated simulation model. * Run “what-if” scenarios, test control logic changes, or train operators.

--- ### 🔗 **Key Enablers for AI & Analytics**

* **Clean, structured data** from historians and control systems

* **Reliable time synchronization** across instruments

* **Process knowledge** to validate AI model outputs

* **Cross-functional teams** (operators + engineers + data scientists)

--- ### ✅ Final Thought By continuously analyzing data and applying AI, process control systems can move from **reactive** to **predictive**—and ultimately to **autonomous optimization**.

It’s not about replacing operators or engineers, but **augmenting their capabilities** to keep systems stable, efficient, and ready for the future.

Case Study: Using Data Analytics and AI

--- ## **Case Study:

AI-Driven Stability and Optimization in a DMS Plant**

### **Background** A large-scale **Dense Media Separation (DMS)** plant in Southern Africa processes over 5,000 tons per hour of ore, using magnetite as the dense medium. The plant experienced frequent instability in cyclone performance, causing variability in product grade, underflow density, and increased wear on pumps and cyclones.

Key challenges:

* Frequent **manual intervention** on cyclone feed pumps and medium density control

* **Oscillating PID loops** on underflow control due to poorly tuned valves and sensor noise

* Reactive operation, with **delayed responses to disturbances** in ore feed characteristics

--- ### **Solution:

AI + Data Analytics Approach**

#### **1. Data Infrastructure and Integration**

* Integrated **real-time sensor data** (flow, density, pressure) from PLCs into a central historian.

* Developed a **data pipeline** to clean, standardize, and visualize process KPIs.

* Deployed an **AI monitoring dashboard** with live health status of control loops and equipment behavior.

#### **2. Loop Performance Audit**

* Used historical data to identify:

* Underperforming PID loops (e.g., cyclone pressure and medium density)

* Excessive valve cycling and noise-induced control fluctuations

* Dead time mismatches and process nonlinearity

.* Generated **IAE and control variability indices** for each loop.

#### **3. ML-Based Anomaly Detection**

* Implemented a **machine learning model (Isolation Forest

+ LSTM)** to detect early signs of:

* Magnetite dilution

* Cyclone overload or roping

* Pump cavitation conditions

* Models triggered **early warnings**—hours before conventional alarms.

#### **4. AI-Supported Optimization**

* Developed a **Reinforcement Learning (RL) agent** in simulation to optimize:

* Medium density setpoint adjustment in response to ore variability

* Cyclone feed pump speed modulation to minimize instability

* Once validated, the recommendations were **integrated into the plant HMI**, allowing operators to accept or reject AI suggestions.

#### **5. Operator Training and Intervention Protocols**

* Introduced a simulator with real operational scenarios based on historical data.

* Refined intervention procedures (e.g., actions during rapid density drop or magnetite spillage).

* Rolled out short refresher courses with dashboards explaining loop behavior and AI insights.

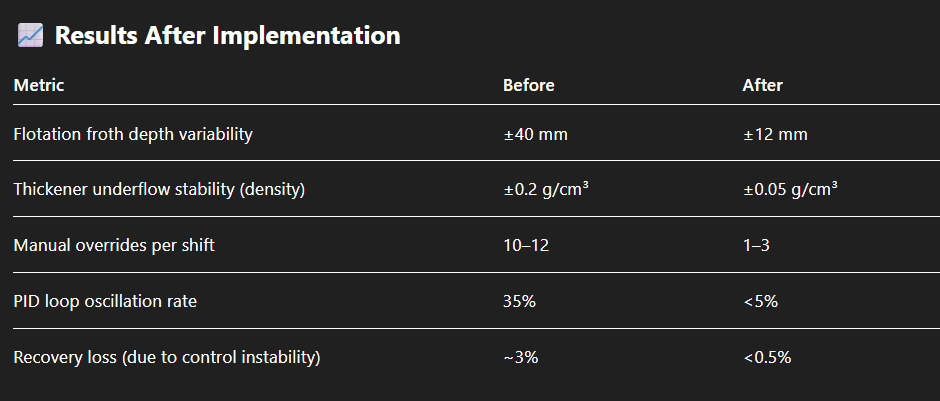

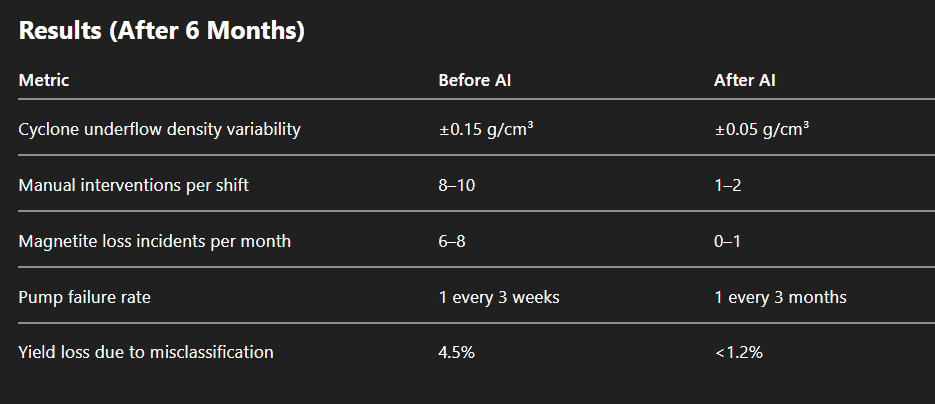

--- ### **Results (After 6 Months)**

Case Study: Real Time Process Control

--- ## ✅ **Case Study:

Real-Time Process Control – How to Achieve Stability in a Mineral Processing Plant**

### 📍 **Background** A large mineral processing plant in West Africa operating a **copper-gold circuit** was facing increasing instability in its **grinding, flotation, and tailings thickener** operations.

Despite having modern instrumentation and PLC-based automation, the plant suffered from:

* Frequent **process oscillations**

* **Manual mode overrides** on critical loops

* Delayed **operator response** to disturbances

* Inefficient handling of **feed variability** This led to **product losses**, **energy waste**, and **increased maintenance** on pumps, valves, and cyclones.

--- ### 🎯 **Objective** To design and implement a **real-time process control strategy** that ensures:

* **Loop stability**

* **Fast disturbance rejection**

* **Smooth setpoint tracking**

* Improved **operator awareness and intervention capability**

--- ### 🔍 **Approach: A Structured Stability Framework**

The project team followed a **seven-step control strategy improvement process**:

--- ### 1. **Understand the Process Dynamics**

* Conducted **step tests** on flotation level, regrind mill feed rate, and thickener underflow density.

* Built **first-order-plus-dead-time (FOPDT)** models using system identification software.

* Found that several loops were suffering from **long dead times** and **nonlinear gain responses**.

--- ### 2. **Choose the Right Control Strategies**

* Replaced standard PID control with:

* **Cascade control** for flotation cell level (froth depth → tail valve)

* **Feedforward + PI** for thickener underflow density

* **Adaptive PI** for grinding mill feed rate

* Introduced **anti-windup** logic for loops subject to actuator saturation.

--- ### 3. **Implement Robust Sensors and Actuators**

* Upgraded:

* Level sensors to **non-contact radar**

* Density meters to **Coriolis meters with fast update rates**

* Control valves with **position feedback and diagnostics**

* Integrated **valve stiction detection** alerts into the HMI.

--- ### 4. **Tune Control Loops for Stability**

* Used **auto-tuning tools** to generate optimized PI settings.

* Applied **Ziegler–Nichols tuning** as a benchmark for comparison.

* Monitored:

* Settling time

* Overshoot

* Integral of Absolute Error (IAE)

* Tuning improvements reduced valve oscillation and controller cycling by 80%.

--- ### 5. **Integrate Real-Time Monitoring and Alarming**

* Built **custom dashboards** for each critical unit operation.

* Enabled:

* Live trending of SP, PV, and control output

* Alarm filtering and prioritization

* Intelligent alerts for pump trips, density deviation, or froth instability

* Added **email + SMS escalation** for unacknowledged alarms.

--- ### 6. **Design for Disturbance Rejection and Setpoint Tracking**

* Applied:

* **Setpoint ramps** to prevent process shock during changeovers

* **Feedforward correction** for density changes due to variable ore hardness

* **Dead time compensators** for high-lag loops (e.g., thickener bed level)

* Result: Faster return to setpoint after a disturbance without overshoot.

--- ### 7. **Ensure Operator Competence and Intervention Protocols**

* Rolled out **simulation-based training** for manual override and recovery scenarios.

* Implemented **intervention SOPs** tied to HMI alarms:

* Clear logic trees for froth depth control

* Decision guides for thickener overload handling

* Added on-screen prompts and reasoning behind AI recommendations.

--- ### 📈 **Results After Implementation**