Water recycling in Mineral Processing Plants: Where are the opportunities?

Trending

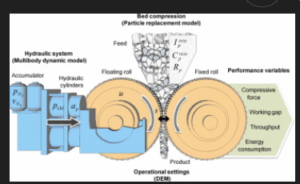

High Pressure Grinding Roll Crushers – HPGR: Trends and Best Practice

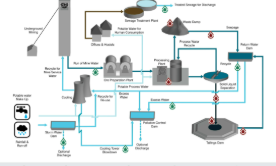

**Water Recycling in Mineral Processing Plants**Water is a critical resource in mineral processing, but its use comes with significant operational, environmental, and economic implications. As freshwater availability becomes increasingly constrained globally, water recycling in mineral processing plants has become not only a best practice but often a necessity.

### 1. **Why Recycle Water?**

Recycling water reduces the need for freshwater intake, lowers operating costs, and minimizes environmental impacts. Most mineral processing operations—such as grinding, flotation, and tailings transport—require substantial volumes of water. In regions where water is scarce or where regulations on discharge are strict, recycling helps ensure long-term sustainability and compliance.

### 2. **Sources of Recyclable Water in Plants**

Water in mineral processing circuits can be recovered from:

* **Tailings thickeners** and **settling ponds**:

These allow for clarification and recovery of process water.

* **Filter presses** and **vacuum filters**:

Used for dewatering concentrates and tailings, they release significant volumes of relatively clean water.

* **Flotation circuits**:

Excess water from flotation overflows can be collected and reused after treatment.

### 3. **Water Treatment Techniques for Recycling**

Recycled water often contains residual reagents, fine particles, or dissolved salts, which can impact plant performance if not properly managed.

Common treatment techniques include:

* **Sedimentation and thickening**:

Settling of solids before reuse.

* **Filtration**: Using sand, pressure filters, or membranes to remove suspended solids.

* **Chemical treatment**:

pH adjustment, flocculants, or lime addition to remove harmful ions or contaminants.

* **Reverse osmosis** or **ion exchange**:

For high-purity requirements or when dealing with problematic solutes.

### 4. **Benefits of Effective Water Recycling**

* **Reduced operating costs**:

Less water procurement and wastewater treatment.

* **Improved plant efficiency**:

Stable water quality supports consistent metallurgy.

* **Environmental compliance**:

Reduced discharge volumes and better community relations.

* **Resilience**:

Helps operations continue during drought or water restrictions.

### 5. **Challenges and Considerations**

* **Water quality degradation**:

Accumulation of dissolved solids or organics can affect flotation, reagent performance, and scaling in pipelines.

* **Tailings management**:

High-density or dry tailings methods reduce water loss and improve water recovery.

* **System integration**:

Recycling loops must be designed into the plant to ensure water availability at the right location and quality.

--- ### #Tags \

#WaterRecycling #MineralProcessing #SustainableMining #TailingsManagement #WaterConservation #ProcessOptimization #CircularWaterUse #MiningSustainability #WaterTreatment #ThickenerEfficiency

Why Recycle water in Mineral Processing Plants

Trending

How can I use AI to enhance Metallurgical Performance of Mineral Processing Plants

### Why Recycle Water in Mineral Processing Plants?Water recycling in mineral processing is essential due to the high volumes of water required for ore beneficiation and the growing scarcity and cost of fresh water. Here's a breakdown of the key reasons:

--- #### 1. **Water Scarcity and Environmental Regulations** Many mining operations are located in arid or semi-arid regions where water is limited. Additionally, environmental regulations are increasingly strict about water withdrawal and discharge. Recycling minimizes the need for fresh water intake and helps companies comply with environmental standards, such as zero-liquid discharge (ZLD) policies or effluent quality limits.

--- #### 2. **Cost Reduction** Fresh water sourcing, pumping, and treatment come with significant costs. By recycling process water, plants can reduce expenses related to:

* Water supply infrastructure

* Energy consumption (e.g., for pumping and treatment)

* Chemical reagents needed to treat fresh or discharge water

--- #### 3. **Improved Operational Continuity** Access to water can be a limiting factor for production, especially during droughts, seasonal fluctuations, or community water use conflicts. Recycling allows plants to buffer against water shortages and maintain steady operations.

--- #### 4. **Reduced Environmental Footprint** Discharging untreated or partially treated process water can damage ecosystems and expose companies to legal and reputational risks. Recycling water minimizes effluent volumes, reduces tailings dam load, and helps achieve more sustainable mining practices.

--- #### 5. **Supports Process Stability and Efficiency** Recycling can stabilize water chemistry over time. This consistency helps maintain optimal reagent performance, pH levels, and flotation conditions, which leads to more efficient mineral separation and better product recovery.

--- In short, recycling water is not just an environmental initiative—it’s an operational strategy that ensures economic efficiency, regulatory compliance, and long-term viability of mineral processing plants.

Water Scarcity and Environmental Regulations in Mineral Processing Plants

Water scarcity and tightening environmental regulations are two of the most critical drivers behind the push for water recycling in mineral processing operations. These factors are reshaping how mines source, use, and discharge water.

--- #### 1. **Water Scarcity** Mining often takes place in remote regions where freshwater is limited or shared with communities, agriculture, and ecosystems.

In areas like parts of Africa, Australia, Chile, and Central Asia, mining companies face mounting pressure to reduce their freshwater consumption.

Climate change is further intensifying the issue through more frequent droughts, lower rainfall, and reduced river flows.

Without adequate water supply, mineral processing operations—especially those relying on wet techniques like flotation, gravity separation, or dense media separation—can grind to a halt.

Recycling water allows operations to maintain continuity, reduce dependence on external sources, and become more resilient to climate variability.

--- #### 2. **Tightening Environmental Regulations** Governments and environmental agencies are increasingly enforcing stricter water management policies to protect surface and groundwater resources.

Regulations may limit:

* The volume of water that can be extracted from natural sources.

.* The quality and quantity of wastewater that can be discharged.

* The footprint and stability of tailings storage facilities. To comply, plants must invest in closed-loop water systems, tailings thickening, or even advanced treatment like membrane filtration or reverse osmosis. In some jurisdictions, zero-liquid discharge (ZLD) is becoming a requirement.

--- #### 3. **Social License to Operate**

Local communities and environmental groups are paying closer attention to how mines impact water availability and quality. Operations that demonstrate responsible water use—including high recycling rates—are more likely to secure community trust and long-term permits.

--- In summary, water scarcity and environmental regulations are no longer peripheral concerns—they are central to risk management and operational strategy in modern mineral processing.

Proactive water recycling not only ensures legal compliance but also protects long-term profitability and reputation.

Cost Reduction Through Water Recycling

Water recycling in mineral processing plants can lead to substantial cost savings across multiple areas of operation.

By reducing reliance on fresh water and minimizing wastewater treatment needs, plants can lower both capital and operating expenditures.

Here's how:

--- #### 1. **Lower Fresh Water Procurement Costs**

Sourcing fresh water can be expensive, especially in water-scarce regions where water may need to be transported from distant sources or purchased from municipalities. Recycling internal process water reduces the volume of fresh water required, decreasing the cost per tonne of ore processed.

--- #### 2. **Reduced Energy Consumption**

Water transport and treatment require significant energy—whether for pumping, heating, cooling, or pressure-based filtration.

Reusing water from within the process loop (e.g., from thickener overflows or filter press filtrate) lowers the need for extensive pumping or re-treatment, resulting in reduced power usage and lower energy bills.

--- #### 3. **Decreased Chemical Reagent Use**

Fresh water often requires chemical adjustment (pH correction, flocculation, or scale prevention) before it can be used in processing circuits.

Recycled water, which has already been conditioned by previous process steps, may need fewer chemical additives. This leads to direct savings on reagents like lime, flocculants, and anti-scalants.

--- #### 4. **Minimized Wastewater Treatment and Disposal Costs**

Treating and disposing of tailings and effluent water can be one of the most expensive components of mineral processing. Recycling reduces the volume of water that must be treated before discharge or stored in tailings ponds.

This translates to:

* Smaller tailings impoundments

* Reduced demand for treatment infrastructure

* Lower sludge management costs

--- #### 5. **Extended Equipment Life and Maintenance Savings**

Water impurities, such as abrasive particles or corrosive ions, can accelerate wear in pumps, pipes, and valves.

Controlled recycling systems that include filtration or clarification help maintain better water quality, which in turn reduces maintenance frequency and extends equipment life.

--- In conclusion, water recycling is a powerful cost optimization tool. It supports long-term operational sustainability by improving resource efficiency, cutting down on energy and reagent use, and minimizing infrastructure and maintenance costs—without compromising process performance.

Improved operational Continuity Through water recycling

Water recycling enhances **operational continuity**, ensuring that mineral processing plants can function reliably, even under challenging external conditions. In many regions, access to water is unpredictable due to climate, seasonal changes, or competing demands. +

Recycling internal process water helps decouple plant operations from these external risks.

--- #### 1. **Resilience to Water Supply Disruptions**

In water-scarce areas or during drought conditions, external water sources (rivers, lakes, municipal supplies) may become unreliable or restricted.

A plant that recycles a high percentage of its process water can continue operating independently of these fluctuations. This resilience is particularly valuable in arid mining regions such as northern Chile, southern Africa, and parts of Australia.

--- #### 2. **Steady Production Rates**

Water shortages or inconsistent supply can lead to reduced throughput or even temporary shutdowns, especially for water-intensive processes like flotation, gravity separation, and dense media separation (DMS).

Recycling ensures that critical operations receive a stable water supply, maintaining consistent production volumes and recovery rates.

--- #### 3. **Buffering Against Regulatory Delays**

Water use licenses, discharge permits, and environmental impact approvals can delay new projects or expansions.

Recycling water within the plant reduces dependence on external permits and helps fast-track approvals by demonstrating reduced environmental impact.

--- #### 4. **Emergency and Contingency Planning**

Recycled water systems act as a buffer during emergencies—such as pump failures, pipeline breakdowns, or contamination incidents—by keeping a stock of usable water within the circuit.

This internal redundancy enables plants to maintain minimum process flows and avoid costly unplanned downtime.

--- #### 5. **Enabling Remote or Off-Grid Operations**

Mines in remote locations often face logistical challenges in securing consistent water supplies. High-efficiency recycling systems allow these operations to minimize water transport and storage requirements, making them more viable and cost-effective over the long term.

--- In essence, water recycling supports **operational reliability and flexibility**, reduces the risk of production stoppages, and strengthens the plant’s ability to manage environmental, regulatory, and logistical uncertainties.

Reduced Environmental Footprint Through water recycling

Water recycling in mineral processing plants plays a pivotal role in minimizing the environmental impact of mining operations.

By decreasing fresh water intake and limiting wastewater discharge, recycling contributes directly to sustainability goals and improves a plant’s overall environmental performance.

--- #### 1. **Lower Freshwater Withdrawal from Natural Sources** Reducing dependency on rivers, lakes, and groundwater helps protect local ecosystems.

Excessive water withdrawal can lower water tables, degrade wetlands, and disrupt aquatic habitats.

--- #### 2. **Minimized Effluent Discharge and Pollution**

Process water often contains fine particles, residual reagents, dissolved metals, and other contaminants.

Discharging this water—even after basic treatment—can lead to soil, surface water, or groundwater pollution.

Recycling internal water flows drastically reduces the volume of wastewater released, thereby minimizing the risk of:

* Acid mine drainage (AMD)

* Cyanide or heavy metal contamination

* Suspended solids and turbidity in downstream water bodies

--- #### 3. **Smaller and Safer Tailings Facilities**

Water is a major component of tailings. Reducing water in the tailings stream through thickening and recycling enables:

* Smaller tailings dams

* Lower risk of dam failure

* Improved stability and safety of tailings impoundments Dry or paste tailings systems—enabled by efficient water recovery—further enhance safety and environmental stewardship.

--- #### 4. **Improved Public and Regulatory Perception**

Demonstrating a strong commitment to water stewardship improves relationships with regulators, local communities, and NGOs.

Companies that proactively reduce their environmental footprint through water recycling are more likely to earn a social license to operate, face fewer legal disputes, and enjoy a better reputation. --- In summary, water recycling is a key strategy for reducing the environmental footprint of mineral processing.

It protects ecosystems, minimizes pollution, supports safer tailings management, and helps mining operations meet increasingly stringent environmental standards.

Recycling allows a plant to operate within strict environmental water-use limits and reduces the ecological stress on surrounding water bodies.

Supports Process Stabilty and efficiency through Water recycling

**consistent water quality and availability** are essential for maintaining stable and efficient operations.

Recycling water helps to regulate and standardize the chemical and physical properties of process water, which has a direct impact on recovery rates, reagent performance, and equipment reliability.

--- #### 1. **Consistent Water Chemistry**

When fresh water is continuously introduced into the process, its varying composition (e.g., pH, hardness, salinity, organic content) can affect flotation, leaching, or gravity separation.

Recycled water, on the other hand, tends to have a **more stable chemical profile**, which:

* Improves reagent performance (e.g., collectors, frothers, flocculants)

* Enhances pH control and reduces variability in reaction kinetics

* Reduces the need for constant chemical adjustment

--- #### 2. **Improved Flotation Performance**

In flotation circuits, variations in water quality can change bubble formation, froth stability, and mineral selectivity.

Recycled water that has already interacted with reagents and ore surfaces can help maintain **predictable flotation conditions**, leading to:

* More stable froth layers

* Consistent recovery rates

* Better concentrate grade control

--- #### 3. **Reduced Scaling and Corrosion Risks** Properly treated recycled water contains fewer dissolved solids and corrosive ions than some sources of untreated raw water.

This reduces the risk of:

* Scaling in pipelines and heat exchangers

* Corrosion in tanks, pumps, and circuit components

* Premature equipment wear and failures

--- #### 4. **Enhanced Thickening and Dewatering**

Stable water chemistry helps improve settling behavior in thickeners and performance in filter presses. Flocculants and coagulants work more predictably in water with consistent characteristics, which means:

* Better solid-liquid separation

* Improved water recovery from tailings

* Drier tailings and smaller tailings storage needs

--- #### 5. **Lower Variability in Metallurgical Accounting** Water quality variability can introduce fluctuations in recovery and concentrate quality, complicating metallurgical balances and forecasting. Recycling promotes **process repeatability**, which supports better data interpretation, KPI tracking, and metallurgical accounting.

--- In summary, water recycling supports **process stability, efficiency, and predictability**—key factors for optimizing plant performance. Stable process water translates into tighter operational control, higher throughput, and more consistent product quality.

Sources of Recyclable water

Mineral processing plants generate several internal water streams that can be recovered and reused within the operation. Identifying and efficiently managing these **sources of recyclable water** is central to building a sustainable and cost-effective water management strategy.

--- #### 1. **Tailings Thickeners**

Tailings thickeners are one of the **primary sources of recyclable water** in most plants.

They separate solids from process slurry, producing a clear overflow that can be reused.

This water typically contains:

* Minor residual reagents

* Fine suspended solids

* Dissolved ions With minimal treatment (e.g., clarification or filtration), thickener overflow can be fed back into grinding, flotation, or milling circuits.

--- #### 2. **Settling Ponds and Dams**

Many operations use **settling ponds** as passive systems to allow suspended solids to settle before water is discharged or reused. While they take up more space and settle solids slowly, they are cost-effective and low-maintenance.

Recovered water from these ponds is often reused for:

* Dust suppression

* Tailings transport

* General plant cleaning

--- #### 3. **Filter Press and Vacuum Filter Filtrate**

In dewatering operations (for concentrates or tailings), **filter presses and vacuum disc filters** produce a filtrate stream that is usually low in suspended solids.

This water is highly reusable and often directed back to:

* Concentrate thickening

* Reagent mixing

* General process water tanks

--- #### 4. **Flotation Cell Overflows and Wash Water** Flotation circuits generate excess water from froth overflows, spray water systems, and cell drainage.

This water contains:

* Reagent residues

* Fine gangue particles

* Dissolved organics While this water may require clarification or treatment to manage reagent buildup, it can be reused in:

* Conditioning tanks

* Reagent dilution

* Secondary flotation stages

--- #### 5. **Screening and Washing Effluents** Water from ore washing, desliming screens, and dewatering screens can be collected, settled, and reused.

This stream may contain clay-rich fines, which can be handled using:

* Hydrocyclones

* Clarifiers

* Lamella settlers Recovered water is often directed back to washing or classification circuits.

--- #### 6. **Mine Dewatering Systems** Although not internal to processing, **mine dewatering** produces large volumes of water from underground workings or open pits.

If this water meets quality standards—or is treated—it can supplement recycled plant water for use in:

* Grinding mills

* Utility water systems

* Tailings dilution

--- In summary, mineral processing plants have **multiple points of water recovery**, and integrating these into a closed-loop system can significantly reduce fresh water intake, lower costs, and improve environmental compliance.

Effective recycling requires thoughtful design, balancing quality requirements with available treatment solutions.

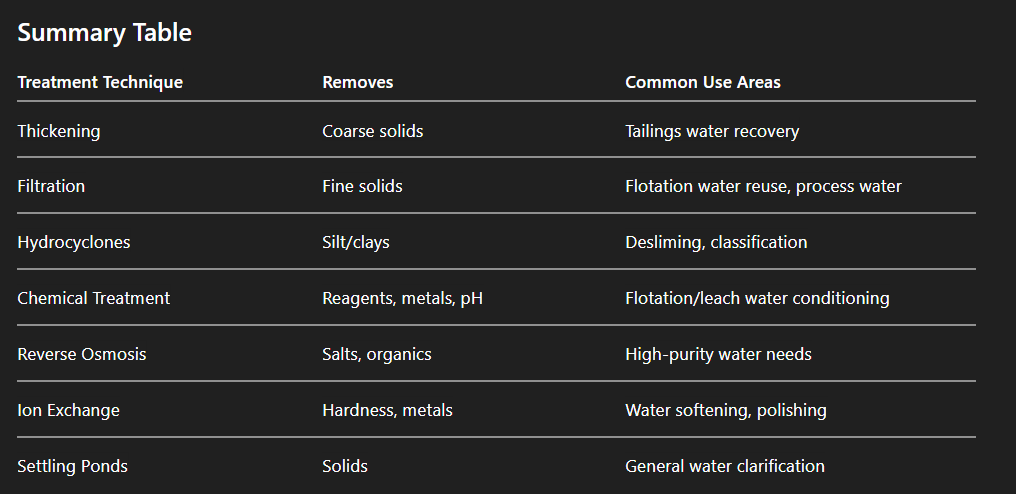

Water Treatment Techniques

To ensure that recycled water can be safely and effectively reused in mineral processing circuits, it must often undergo treatment to remove suspended solids, dissolved salts, and residual reagents.

The selection of treatment methods depends on the source and quality of the water, the process requirements, and the plant’s environmental obligations.

--- #### 1. **Sedimentation and Thickening**

This is the **first and most common step** in water recovery. Thickeners and clarifiers allow suspended solids to settle, producing: * A dense underflow (for tailings disposal)

* A clear overflow (for reuse) **Flocculants** are often added to accelerate settling and improve clarity. This method is ideal for:

* Tailings water recovery

* Settling pond overflow

* Pre-treatment for filtration

--- #### 2. **Filtration** Filtration removes fine suspended solids and, in some cases, bacteria or colloids. Techniques include:

* **Sand or multimedia filters** (coarse filtration)

* **Cartridge or bag filters** (moderate filtration)

* **Membrane filtration** (ultra-fine filtration)

**Use case**: Final polishing of thickener overflow before flotation reuse or equipment cooling systems.

--- #### 3. **Cyclones and Hydrocyclones** Hydrocyclones are used for **particle classification and water cleaning**.

They separate fine solids from water through centrifugal force and are widely used after:

* Screening

* Washing operations

* Desliming circuits They require no chemicals and are ideal for high-throughput, low-maintenance separation.

--- #### 4. **Chemical Treatment** Recycled water may contain residual reagents, dissolved metals, or other chemical contaminants.

Common chemical treatments include:

* **pH adjustment** (e.g., lime or acid addition)

* **Coagulation and flocculation** (to remove colloids)

* **Oxidation** (to remove organics or neutralize cyanide)

* **Precipitation** (to remove heavy metals)

**Use case**: Treatment of flotation water or leach circuit returns to control ion buildup.

--- #### 5. **Reverse Osmosis (RO) and Membrane Filtration** These advanced techniques use semi-permeable membranes to remove **dissolved salts, heavy metals, sulfates, and organics** from water.

They are energy-intensive but offer high purity water.

**Use case**: When water must meet high-quality standards (e.g., boiler feed water, reagent make-up water, or discharge compliance).

--- #### 6. **Ion Exchange** Ion exchange systems swap undesirable ions (e.g., calcium, magnesium, heavy metals) with benign ones (e.g., sodium or hydrogen).

These systems are useful for:

* Softening hard water

* Removing specific contaminants (e.g., arsenic, uranium)

* Polishing RO permeate

--- #### 7. **Biological Treatment (for Specific Applications)** Though rare in most mineral processing, **constructed wetlands** or **bioreactors** may be used to degrade organics or oxidize dissolved metals in water from bioleaching or heap leaching.

--- #### 8. **Settling Ponds and Natural Evaporation** Low-tech but still relevant, **settling ponds** provide passive treatment and are often combined with evaporation to reduce water volume.

These systems can help pre-treat water before mechanical processes are applied.

--- ### Summary Table

--- By selecting the appropriate mix of water treatment methods, plants can optimize water quality for reuse, reduce reagent costs, prevent scaling and corrosion, and meet environmental discharge limits—all while supporting efficient and sustainable operations.

Benefits of effective Water recycling

Implementing a well-designed water recycling strategy in mineral processing offers a wide range of **economic, operational, environmental, and social benefits**.

These advantages not only enhance plant efficiency and reduce costs but also align operations with modern sustainability standards.

--- #### 1. **Reduced Freshwater Consumption** By reusing internal process water, plants significantly lower their reliance on external freshwater sources.

This is especially critical in:

* **Water-scarce regions**

* **Remote mining operations** * **Areas with strict water abstraction regulations** Less freshwater intake also reduces the costs and environmental impact of water extraction, pumping, and storage.

--- #### 2. **Lower Operating Costs** Recycling water translates to substantial cost savings through:

* Reduced need for water sourcing and transportation

* Lower energy consumption for pumping and heating

* Decreased use of treatment chemicals for fresh water

* Less need for wastewater treatment and disposal infrastructure These savings can directly improve the plant’s bottom line.

--- #### 3. **Stable Process Performance** Recycled water provides a more **consistent chemical and physical profile**, which helps stabilize:

* Reagent interactions

* Flotation kinetics

* Thickener and filtration performance This leads to better recovery rates, product quality, and throughput consistency.

--- #### 4. **Improved Tailings Management** Water recycling reduces the water content in tailings, enabling:

* **Denser tailings deposition**

* Smaller or safer tailings storage facilities

* Lower risk of dam failure and seepage This also supports the shift toward **dry stacking** and **paste backfilling** practices.

--- #### 5. **Regulatory Compliance and Risk Reduction** Effective recycling helps meet legal and environmental obligations, such as:

* Effluent discharge limits

* Zero-liquid discharge (ZLD) policies

* Environmental impact assessments It also lowers the risk of **non-compliance penalties**, license delays, or shutdowns due to water-related infractions.

--- #### 6. **Enhanced Environmental Stewardship** By minimizing water intake and discharge, water recycling reduces the plant’s environmental footprint, helping to:

* Protect nearby ecosystems and aquatic life

* Reduce groundwater depletion

* Lower pollution of local water bodies This enhances a company's sustainability credentials and supports long-term resource conservation.

--- #### 7. **Stronger Social License to Operate** Communities are increasingly concerned about water use in mining. Recycling demonstrates a commitment to responsible resource management, fostering:

* Greater public trust

* Improved community relations

* Easier access to permits and project approvals

--- In summary, **effective water recycling** delivers a **strategic advantage** in mineral processing—boosting plant resilience, reducing costs, improving environmental outcomes, and securing stakeholder support. It is not just an operational necessity, but a cornerstone of sustainable mining practice.

Challenges and consideration in Water recycling

Understanding these challenges ensures that recycling systems are designed and operated effectively without compromising plant performance.

--- #### 1. **Water Quality Degradation Over Time** As water is reused repeatedly, **dissolved solids, fine particles, and residual reagents** accumulate.

This can lead to:

* Increased salinity or hardness

* Organic and inorganic contamination

* Reagent carryover that interferes with flotation, leaching, or thickening **Mitigation**:

Monitor water chemistry regularly, and implement selective treatment steps (e.g., partial bleed-off, filtration, chemical polishing).

--- #### 2. **Build-Up of Reagents and Contaminants** Flotation and leaching reagents—such as xanthates, cyanide, or frothers—can persist in recycled water, leading to:

* Poor separation efficiency

* Froth instability

* Unintended interactions with new reagent additions **Mitigation**:

Use advanced treatment (e.g., activated carbon, oxidation, or pH control) to neutralize or remove residual chemicals.

--- #### 3. **Scaling, Corrosion, and Biofouling** Recycled water may be saturated with ions such as calcium, sulfate, or silica, causing: * **Scaling** in pipelines, pumps, and heat exchangers

* **Corrosion** in metal equipment

* **Biofouling** in warm or stagnant zones **Mitigation**: Apply water conditioning (e.g., softening, anti-scalants) and regular maintenance protocols.

--- #### 4. **Tailings Rheology and Deposition Issues** Water content affects the flow properties (rheology) of tailings. Dense or paste tailings with limited water may:

* Be more difficult to pump

* Cause pipeline blockages

* Settle too quickly or unevenly in tailings dams **Mitigation**: Design tailings transport systems with adjustable flow control and conduct rheological studies during plant design.

--- #### 5. **High Capital and Operating Costs for Treatment** Installing advanced treatment systems (e.g., reverse osmosis, ion exchange, ultrafiltration) can be expensive.

Ongoing operational costs include:

* Energy for pumping and filtration

* Replacement of membranes or filters

* Skilled personnel to manage treatment systems **Mitigation**: Conduct cost-benefit analysis to match treatment complexity to water reuse requirements.

--- #### 6. **Integration with Existing Circuits** Retrofitting water recycling systems into existing plants may require:

* Additional tanks, pumps, or pipelines

* Reconfiguration of water distribution systems

* Process control system updates **Mitigation**:

Engage process engineers early in the design phase to plan integration with minimal disruption.

--- #### 7. **Regulatory and Permitting Constraints**

Even when recycling water, plants must meet strict discharge and reuse standards.

Some jurisdictions require:

* Water reuse permits

* Monitoring and reporting of recycled water quality

* Emergency contingency plans

**Mitigation**:

Stay updated on local regulations and engage regulators during planning to ensure compliance.

--- #### 8. **Water Balance Complexity** Maintaining a stable water balance in a recycling system is more complex than in once-through systems.

Operators must carefully control:

* Evaporation and losses

* Water inventory in thickeners, filters, and tailings

* Seasonal variations in water inflows and outflows

**Mitigation**:

Use water balance models and monitoring systems to predict and manage variations.

--- ### Final Thought Water recycling in mineral processing is **technically achievable and economically justifiable**, but it requires **thoughtful design, real-time monitoring, and ongoing water quality management**.

The key to success lies in balancing the benefits with the risks, ensuring that recycled water supports—not hinders—efficient and sustainable processing.

Case Studies: Water recycling in Mineral Processing Plants

Water Recycling in Mineral Processing Plants Real-world examples demonstrate how water recycling has been successfully implemented in mineral processing plants across various commodities and geographies.

These **case studies** highlight different strategies, technologies, and outcomes—offering valuable lessons for other operations looking to improve water management.

--- #### **1. Los Pelambres Copper Mine – Chile** **Operator:** Antofagasta Minerals

**Challenge:**

Operating in one of the driest regions in the world with limited freshwater resources.

**Solution:**

* Implemented a **closed-loop water circuit** using high-capacity thickeners and high-efficiency tailings dewatering.

* Installed **seawater desalination** and long-distance pipelines to supplement freshwater when needed.

* Used **paste thickening** to recover water from tailings before deposition.

**Result:**

* Over **80% of process water is recycled**.

* Reduced freshwater abstraction significantly while maintaining production levels.

--- #### **2. Khumani Iron Ore Mine – South Africa**

**Operator:

** Assmang **Challenge:**

Limited surface water availability and high water demand for crushing, screening, and dense media separation (DMS).

**Solution:**

* Designed a **comprehensive water recycling system** with high-rate thickeners.

* Reused water from **DMS, tailings thickeners, and return dams** in the primary processing circuit.

* Continuous monitoring of water quality to prevent process interference.

**Result:**

* Achieved over **90% water recovery**, reducing dependency on local water sources.

* Lowered operating costs and improved water balance reliability.

--- #### **3. Fekola Gold Mine – Mali**

**Operator:** B2Gold **Challenge:**

Operating in a remote desert location with highly limited water access.

**Solution:**

* Introduced a **zero-liquid discharge system** with advanced water recycling technologies.

* Recycled process water from tailings and plant discharge using filtration and clarification units.

* Strictly controlled reagent dosing and water losses via evaporation and seepage.

**Result:**

* Maintained **continuous production without drawing from local freshwater sources**.

* Met strict environmental standards and improved community relations.

--- #### **4. Northparkes Copper-Gold Mine – Australia**

**Operator:** CMOC **Challenge:**

Regulatory pressure to reduce environmental footprint and secure long-term water sustainability.

**Solution:** * Installed **ultra-fine filtration** and water recovery systems from concentrate and tailings circuits.

* Implemented an integrated **water balance model** to monitor and optimize usage.

**Result:**

* Reduced total water consumption by **up to 60%** over 10 years.

* Enabled consistent metallurgical performance despite changing ore characteristics.

--- #### **5. Konkola Copper Mines – Zambia**

**Operator:** Vedanta Resources **Challenge:**

Managing large volumes of water from underground mining and reducing environmental discharge.

**Solution:**

* Treated and reused **mine dewatering water** in mineral processing operations.

* Combined thickener overflow and mine inflows to reduce fresh water intake.

* Used sedimentation and pH correction before reuse.

**Result:**

* Increased total water reuse across the mine and mill complex.

* Lower environmental discharge and reduced pumping costs.

--- ### Key Lessons from the Case Studies

* **Tailings water recovery** is often the largest contributor to successful recycling.

* **Water treatment must be tailored** to ore type and process chemistry.

* **Integrated water management plans**, including modeling and real-time monitoring, are essential.

* **Community engagement and regulatory alignment** strengthen the social license to operate.

Case Study: Chile

**Los Pelambres Copper Mine – Chile**

**Operator:** Antofagasta Minerals

**Location:** Coquimbo Region, Chile

**Commodity:** Copper **Processing Method:**

Crushing, grinding, flotation, tailings thickening **Climate:**

Semi-arid to arid – severe water scarcity

--- #### **Background** The Los Pelambres mine is one of the largest copper operations in Chile, located in a mountainous, water-stressed region.

As a result, water availability is a critical operational constraint. From early on, the mine prioritized **sustainable water management** and has become a benchmark for large-scale water recycling in mineral processing.

--- #### **Challenges**

* **Chronic water scarcity** in the Coquimbo Region

* Increasing **regulatory pressure** on freshwater abstraction

* Rising **community concerns** about shared water resources

* Large volumes of water required for grinding and flotation

* High cost of water transport over long distances

--- #### **Water Recycling Strategy**

##### 1. **Closed-Loop Circuit**

* The mine operates a **semi-closed-loop water system**, where water from tailings thickeners and reclaim ponds is collected, treated, and reused in the process plant.

* This significantly reduces dependency on fresh water from rivers or aquifers.

##### 2. **Tailings Thickening and Water Recovery**

* Los Pelambres installed **high-capacity tailings thickeners** to increase water recovery before tailings disposal.

* Thickener overflow water is reused in grinding, flotation, and concentrate transport circuits.

##### 3. **Seawater Integration**

* To further reduce freshwater dependence, the mine added a **desalination plant** and a 140 km pipeline to deliver seawater from the Pacific Ocean.

* This water supplements recycled water during peak demand or drought conditions.

##### 4. **Water Treatment and Quality Management**

* Clarifiers and filtration systems treat recycled water to remove fine particles and residual reagents.

* The water chemistry is managed carefully to prevent flotation performance issues and equipment scaling.

##### 5. **Water Balance and Monitoring**

* Real-time **water balance models** are used to track inflows, outflows, losses (e.g., evaporation), and quality across the site.

* Data-driven controls ensure recycling rates are optimized and losses are minimized.

--- #### **Results and Impact**

* **Over 80% of process water is recycled**, reducing freshwater use per tonne of ore processed.

* Reduced the need to extract water from the Choapa River basin.

* **Improved community relations** by demonstrating responsible water stewardship.

* Compliance with **Chilean environmental regulations** and long-term operating permits.

* Helped Los Pelambres meet sustainability goals while maintaining full production capacity.

--- #### **Key Takeaways**

* **Tailings thickening** is a powerful tool for water recovery at scale.

* **Hybrid water strategies** (recycling + seawater use) build operational resilience.

* A well-designed **monitoring and control system** is essential for water balance management.

* Sustainable water practices enhance both **license to operate** and cost efficiency.

Case Study: South Africa

**Khumani Iron Ore Mine – South Africa**

**Operator:** Assmang (a joint venture between African Rainbow Minerals and Assore Ltd.)

**Location:** Northern Cape Province, South Africa

**Commodity:** Iron Ore

**Processing Method:**

Crushing, screening, Dense Media Separation (DMS), jigging **Climate:**

Arid to semi-arid – limited surface water availability

--- #### **Background** The Khumani Iron Ore Mine is a large open-pit operation located in the dry Northern Cape region. Water availability is one of the most significant operational constraints in this desert-like environment.

From the design phase, the mine adopted a **closed-loop water recycling strategy** to minimize freshwater intake and support sustainable operations.

--- #### **Challenges**

* **Extreme water scarcity** with minimal natural surface water

* High water consumption in **DMS and jigging circuits**

* Strict **environmental permitting** requirements for water abstraction

* Large processing capacity (13+ Mtpa), demanding a robust and reliable water supply

* High potential for water loss through evaporation and tailings seepage

--- #### **Water Recycling Strategy**

##### 1. **Tailings Thickening**

* Installed **high-rate tailings thickeners** to maximize water recovery from the tailings stream.

* The thickener overflow is returned to the plant and reused in:

* DMS circuit

* Jigging and screening operations

* Dust suppression and general plant use

##### 2. **Return Water Dams**

* Constructed a **series of lined return water dams** to capture thickener overflow and stormwater runoff.

* These dams act as buffer storage, ensuring continuous water supply even during short interruptions in tailings flow.

##### 3. **Slimes Management**

* Fine slimes from washing and screening are treated in **settling ponds** and **clarifiers**, allowing for further recovery of clarified water.

##### 4. **Process Water Monitoring**

* Real-time monitoring systems track flow rates, tank levels, and water quality parameters such as turbidity and pH.

* This allows **fine control over water reuse** and identifies potential issues like contamination or process variability.

##### 5. **Water-Efficient Equipment**

* Use of **efficient dewatering screens, filters, and cyclones** minimizes water loss in the process stream.

* Pumps and pipelines are optimized to reduce leakage and friction losses.

--- #### **Results and Impact**

* Achieved **water recycling rates of over 90%**, drastically reducing the need for external water sources.

* **Minimized environmental footprint**, with limited discharge and high recovery from tailings.

* Allowed the mine to operate at full throughput in a water-stressed region without expanding water abstraction rights.

* Reduced operational risk by maintaining internal water security during drought periods.

--- #### **Key Takeaways**

* **DMS and jig plants** are water-intensive but can be highly efficient when combined with thickening and settling systems.

* **Integrated water recovery from multiple circuits** (DMS, jigs, screening) boosts overall efficiency.

* **Lined and engineered return dams** are crucial in arid climates to prevent losses and contamination.

* Water recycling improves not only sustainability but also **cost control, permitting success, and operational resilience**.

Case Study: Mali

**Fekola Gold Mine – Mali**

**Operator:** B2Gold Corp.

**Location:** Southwestern Mali, near the border with Senegal

**Commodity:

** Gold

**Processing Method:**

Crushing, grinding, carbon-in-leach (CIL), thickening, tailings disposal

**Climate:**

Arid–Sahelian — **extremely limited water availability**

--- #### **Background** Fekola is a flagship open-pit gold mine operated by B2Gold in a region with **very low rainfall, limited surface water**, and **high evaporation rates**.

Because of the remote desert location, **securing a reliable and sustainable water supply** was critical from both a cost and environmental standpoint.

The mine has been recognized for implementing one of the most **water-efficient gold processing systems** in West Africa.

--- ### **Challenges**

* Scarce freshwater availability in the project area

* High evaporation losses due to extreme temperatures

* No reliable surface water bodies and limited groundwater recharge

* Regulatory pressure to minimize environmental discharge

* Need to support year-round operations in a low-rainfall environment

--- ### **Water Recycling Strategy**

#### 1. **Zero-Liquid Discharge (ZLD) Approach** Fekola was designed to operate with **no off-site water discharge**.

All water used in the process is either:

* Recycled

* Retained in the system (e.g., within tailings)

* Lost through evaporation (managed as part of the water balance) This closed-loop system aligns with strict environmental controls and sustainability goals.

--- #### 2. **Tailings Water Recovery**

* **High-rate tailings thickeners** recover the bulk of process water before tailings are deposited.

* Thickener overflow water is routed back into:

* Grinding and milling circuits

* CIL processing and wash stages

* The **clarity and chemical consistency** of this water support stable metallurgical performance.

--- #### 3. **Stormwater and Mine Dewatering Reuse**

* Any water from **mine pit dewatering**, rainfall catchment, or runoff is collected, stored, treated (if needed), and reused in the plant.

* This supplements recycled water during dry periods and helps **maintain water inventory stability**.

--- #### 4. **Minimization of Water Losses**

* All tailings are deposited into a **lined tailings storage facility (TSF)** to prevent seepage.

* Use of **covered pipelines and tanks** to reduce evaporation.

* Optimized **CIL and wash circuits** to reduce overall water demand per tonne of ore.

--- #### 5. **Process Water Monitoring and Modeling**

* Continuous monitoring of **pH, TDS, reagent carryover**, and flow balances across the plant.

* Integrated water balance models help predict seasonal changes and plan for contingencies.

--- ### **Results and Impact**

* **Water recycling rate exceeds 85–90%**, among the highest for gold operations in Africa.

* Enabled consistent gold production with **minimal environmental impact**.

* Demonstrated feasibility of gold mining in **hyper-arid regions** using sustainable design.

* Supported **regulatory compliance**, reduced permitting risk, and improved investor perception.

* Built stronger relationships with local communities through responsible water stewardship.

--- ### **Key Takeaways**

* **Zero-liquid discharge** systems are viable even in large-scale gold mining when designed around water recovery.

* **Thickener-based recovery and sealed TSFs** are essential in arid environments.

* **Integrated water reuse with stormwater and pit dewatering** maximizes resilience.

* Effective water recycling **reduces operational costs and secures the social license to operate** in water-sensitive areas.

Case Study: Australia

**Northparkes Copper-Gold Mine – Australia**

**Operator:** CMOC (China Molybdenum Co., Ltd)

**Location:** Central West New South Wales, Australia

**Commodity:** Copper and Gold

**Processing Method:**

Underground mining, crushing, grinding, flotation, thickening, tailings disposal

**Climate:**

Semi-arid – moderate to low rainfall, periodic droughts

--- ### **Background** Northparkes is a globally recognized underground block-cave mine with a strong focus on innovation, automation, and sustainable practices.

Located in a water-stressed region of Australia, the mine has prioritized **advanced water recycling and conservation measures** as part of its long-term environmental management strategy.

--- ### **Challenges**

* **Variable and declining rainfall**, with frequent drought periods * Increasing **regulatory scrutiny** on water abstraction and discharge

* **Community pressure** to share water responsibly with agriculture and towns

* Maintaining stable water chemistry in high-performance flotation circuits

* High volumes of water required for flotation, thickening, and tailings handling

--- ### **Water Recycling Strategy**

#### 1. **Integrated Water Balance Modeling** Northparkes developed a **comprehensive, real-time water balance model** that accounts for:

* Recycled process water

* Rainfall capture and evaporation

* Tailings water return

* Groundwater inflows This model supports proactive water management and contingency planning.

--- #### 2. **Flotation and Thickener Water Reuse**

* Flotation tailings are thickened using **high-rate thickeners**, and the overflow is recycled to the flotation plant.

* Recycled water is carefully managed to ensure **froth stability** and **consistent reagent performance**, especially given potential buildup of residual collectors or frothers.

--- #### 3. **Ultra-Fine Filtration and Clarification**

* Installed **ultra-fine filtration systems** and lamella clarifiers to improve water clarity before reuse.

* Helps control the accumulation of ultra-fines and colloids, which could otherwise reduce flotation performance or cause scaling.

--- #### 4. **Stormwater and Site Drainage Capture**

* Rainfall and surface runoff from plant areas are collected in **lined stormwater ponds**, treated as needed, and reused in:

* Grinding

* Reagent preparation

* Dust suppression This helps buffer against seasonal water shortages and reduces fresh water drawdown.

--- #### 5. **Monitoring and Adaptive Control**

* Water quality parameters (e.g., turbidity, TDS, pH, residual reagent levels) are **monitored in real time**.

* Adjustments are made to reagent dosing and flotation parameters to maintain metallurgical performance even as recycled water quality varies.

--- ### **Results and Impact**

* **Reduced total freshwater intake by over 60%** over a 10-year period.

* Achieved consistently high copper and gold recovery while relying on recycled water.

* Improved tailings facility water recovery and reduced discharge to the environment.

* Strengthened community relations and regulatory standing through transparent water stewardship.

--- ### **Key Takeaways**

* **Real-time water balance and monitoring** is critical to managing water quality in flotation-based circuits.

* **Ultrafine filtration and clarification** can extend the usability of recycled water and protect process efficiency.

* **Stormwater reuse and rainfall capture** are valuable sources of supplementary water in drought-prone areas.

* Long-term investment in **water recycling infrastructure** pays off in regulatory, operational, and social performance.

Case Study: Zambia

**Konkola Copper Mines (KCM) – Zambia**

**Operator:** Vedanta Resources (under government-appointed provisional management as of recent years)

**Location:** Copperbelt Province, Zambia

**Commodity:** Copper

**Processing Method:** Underground mining, crushing, milling, flotation, tailings management

**Climate:** Tropical wet and dry – heavy seasonal rains and high groundwater inflows

--- ### **Background** Konkola Copper Mines (KCM), particularly the **Konkola Deep Mining Project (KDMP)**, operates one of the wettest underground mines in the world.

The mine faces the unique challenge of managing **extremely high volumes of mine inflow water**, with more than **300,000 m³/day** being pumped from underground workings. Rather than treating all of this water as waste, KCM has turned it into a valuable resource by **integrating it into the mineral processing water circuit**.

--- ### **Challenges**

* **Excessive groundwater inflow** requiring continuous pumping

* High costs associated with water treatment and disposal

* Need to reduce dependence on surface water sources (e.g., Kafue River)

* Variable water quality (iron, manganese, suspended solids) from mine inflows

* Regulatory obligations to reduce effluent discharge and environmental contamination

--- ### **Water Recycling Strategy**

#### 1. **Mine Dewatering Water Reuse**

* Water pumped from underground is collected in **large surface storage reservoirs**.

* After **basic clarification and pH adjustment**, this water is reused in:

* Milling and flotation circuits

* Reagent preparation

* Dust suppression systems This significantly offsets the need for external water supply.

--- #### 2. **Tailings Water Recovery**

* Water from tailings thickeners is recovered and reused in the plant.

* A series of **return water dams and pumps** allow continuous circulation back to the processing plant.

#### 3. **Onsite Water Treatment**

* Simple **sedimentation tanks and clarifiers** remove suspended solids from mine water.

* **pH adjustment** (typically with lime) is used to reduce corrosiveness and manage metal solubility.

* In some areas, more advanced systems (e.g., oxidation and neutralization) are used to treat water with elevated iron and manganese.

--- #### 4. **Stormwater and Plant Runoff Capture**

* Surface drainage from plant areas and tailings facilities is collected in **lined holding ponds**.

* After sedimentation, the water is redirected to the process circuit. -

-- #### 5. **Water Monitoring and Control**

* The mine uses a **water accounting and flow control system** to manage inflow, usage, and discharge volumes.

* Regular testing of TSS, TDS, pH, and metal concentrations ensures compliance with environmental discharge standards.

--- ### **Results and Impact**

* **Significantly reduced reliance on surface water**, saving millions of cubic meters per year.

* Improved management of mine water reduced environmental discharge loads.

* Lowered treatment and pumping costs by reusing water instead of treating it for disposal.

* Enhanced the mine’s ability to **operate sustainably in a water-stressed region**, despite extreme inflows.

--- ### **Key Takeaways**

* **Mine dewatering water**—often seen as a burden—can be a major asset if properly treated and reused.

* Integrating **mine inflow water into the plant’s water circuit** improves sustainability and cost efficiency.

* **Basic treatment systems** (clarification and pH adjustment) are often sufficient for reuse in non-sensitive circuits.

* **Strong water accounting and balance models** are critical for managing large inflow volumes without process disruptions.