Introduction

Key geotechnical factors in tailings dam design include:

### 1. **Foundation Conditions**

- **Soil Properties**: Understanding the strength, compressibility, and permeability of the foundation material is crucial. Weak or highly compressible soils can lead to settlement or failure.

- **Bedrock Conditions**: Bedrock beneath the dam must be stable and impermeable. If fractured or weak, it could cause seepage issues or reduce overall dam stability.

### 2. **Tailings Characteristics**

- **Material Type**: The physical properties of the tailings (particle size, density, moisture content) affect their behavior when compacted and the overall stability of the dam.

- **Shear Strength**: The strength of both the tailings and the foundation soils must be sufficient to resist shear failure.

- **Consolidation**: Tailings material consolidates over time, which impacts the stability and long-term settlement behavior of the dam.

- **Permeability**: Low permeability is often desirable to reduce seepage, but it can lead to pore pressure buildup if not managed.

### 3. **Pore Water Pressure**

- **Drainage Design**: High pore water pressure reduces shear strength and can cause slope instability or liquefaction. Proper drainage systems, including internal drains and filter layers, should be designed to dissipate pore pressure effectively.

- **Phreatic Surface Control**: Controlling the phreatic surface (the level at which the soil is saturated) is essential to prevent failure due to increased pore water pressures.

### 4. **Slope Stability**

- **Static Stability**: Analyze slope stability under static (normal) loading conditions. This includes factors like the dam slope angle, loading from tailings and water, and external conditions.

- **Seismic Stability**: Tailings dams must also be designed for seismic loading, particularly in earthquake-prone regions. Earthquakes can cause liquefaction, slope failure, or overtopping.

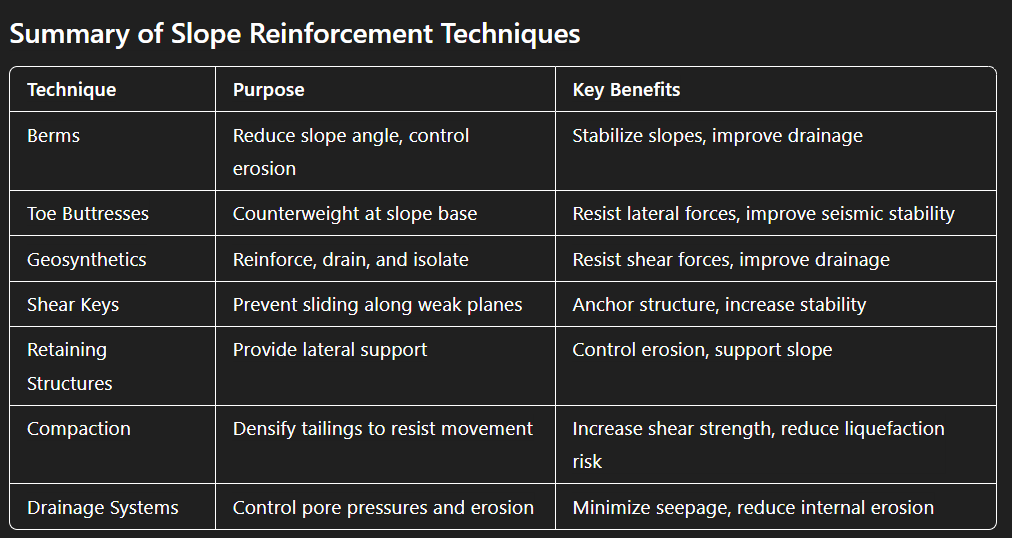

- **Slope Reinforcement**: Geotechnical measures like berms, toe buttresses, or reinforcing the tailings with geosynthetic materials can improve slope stability.

### 5. **Seepage Control**

- **Permeability of the Dam**: A well-constructed core or liner system can minimize water seepage through the dam, preventing erosion or internal failures.

- **Cutoff Walls or Curtains**: Installing cutoffs beneath the dam can prevent seepage through weak zones or porous foundation layers.

- **Tailings Pond Management**: Maintaining low water levels in the tailings pond reduces the hydraulic gradient and lowers the risk of seepage-related problems.

### 6. **Liquefaction Potential**

- **Loose, Saturated Tailings**: If tailings become saturated, they may be prone to liquefaction under seismic or rapid loading conditions. Evaluating the liquefaction potential through laboratory testing and numerical simulations is essential.

- **Compaction and Densification**: Ensuring proper compaction and consolidation of tailings reduces the risk of liquefaction.

### 7. **Climate and Hydrological Conditions**

- **Rainfall and Flooding**: Heavy rainfall can raise water levels in the tailings pond, increasing pore pressures and threatening dam stability. Drainage systems must be designed to handle extreme weather events.

- **Freeze-Thaw Cycles**: In cold regions, freeze-thaw cycles can impact soil strength and stability. Frozen tailings or water can create pore pressure issues when thawed.

### 8. **Embankment Construction Method**

- **Upstream, Downstream, or Centerline**: Each method of tailings dam construction has different geotechnical implications. The upstream method can be less stable, while downstream or centerline methods offer better stability but are more expensive.

- **Material Selection**: The choice of construction materials (rockfill, earthfill, or a combination) affects the dam's strength, permeability, and resistance to erosion.

### 9. **Geotechnical Instrumentation and Monitoring**

- **Real-Time Monitoring**: Installing piezometers, inclinometers, and other instruments can help monitor pore pressures, slope movements, and water levels. This data is critical for assessing dam performance and early detection of potential failure.

- **Regular Inspections**: Frequent visual inspections, coupled with geotechnical monitoring, can help identify early signs of instability, seepage, or erosion.

### 10. **External Loads and Erosion**

- **Wind and Wave Erosion**: In regions with significant wind or water activity, surface erosion of the dam face may be a concern. Proper armoring or vegetation can mitigate these effects.

- **Loading from Tailings and Water**: The dam must be designed to withstand both the immediate and long-term loading from the weight of the deposited tailings and any ponded water.

### 11. **Design for Closure**

- **Post-Closure Stability**: Geotechnical design should also account for long-term stability once the dam is decommissioned. This includes considering slope angles, water management, and erosion control to ensure long-term safety. These geotechnical factors are critical in designing safe and effective tailings dams. Integrating detailed site-specific investigations, lab testing, and numerical modeling is essential for developing a robust dam design.

Foundation Conditions in Tailings Dam Design

#### 1. **Soil Properties**

- **Strength**: The strength of the foundation soil determines its ability to support the weight of the dam and the tailings without excessive settlement or failure. A weak foundation soil can lead to bearing capacity failure or excessive deformation, which compromises the stability of the dam.

- **Undrained Shear Strength (Su)**: Critical for understanding short-term behavior under loading. Tailings dams are often built in stages, and understanding undrained strength is important during construction.

- **Drained Shear Strength**: Relevant for long-term stability, especially once consolidation and pore water pressures have dissipated.

- **Compressibility**: Highly compressible soils can settle significantly under the weight of the dam and tailings. This can lead to:

- **Settlement**: Excessive settlement can cause uneven loading and lead to slope instability or structural damage.

- **Differential Settlement**: Varying compressibility across the foundation can cause uneven settlement, which may induce stresses in the dam structure and cause cracking or deformation.

- **Permeability**: Foundation soils with high permeability may allow excessive seepage, leading to:

- **Piping and Erosion**: If seepage is uncontrolled, it can cause erosion of soil particles, leading to piping (internal erosion) and dam failure.

- **Seepage-Induced Instability**: Excessive water flow through the foundation can raise pore water pressures, reducing soil strength and causing slope failure.

- **Soil Improvement Techniques**: In cases where foundation soils are weak or compressible, soil improvement methods such as compaction, grouting, or installing vertical drains may be necessary to enhance the soil's load-bearing capacity and drainage characteristics.

#### 2. **Bedrock Conditions**

- **Stability**: The bedrock beneath the tailings dam must be stable and capable of bearing the load without significant movement.

Key considerations include:

- **Fracturing**: Fractures or faults in the bedrock can create pathways for water to seep through, undermining the dam's stability and potentially causing leakage into surrounding areas.

- **Weathering**: Weathered bedrock may be less competent and more prone to failure compared to fresh, unweathered bedrock. It's important to assess the depth and extent of weathering to determine the suitability of the bedrock as a foundation.

- **Impermeability**: An impermeable bedrock layer is crucial for controlling seepage. If the bedrock is permeable or contains fractures, it can lead to uncontrolled seepage beneath the dam, which could:

- **Compromise Stability**: Uncontrolled seepage can raise pore pressures and weaken both the foundation and the embankment materials, increasing the risk of failure.

- **Pollute Groundwater**: Seepage through permeable bedrock can contaminate local aquifers, making environmental containment a concern.

- **Grouting or Cutoff Walls**: If the bedrock is fractured or permeable, grouting techniques or the construction of cutoff walls may be necessary to seal the bedrock and prevent seepage. Proper assessment and mitigation of foundation conditions, through geotechnical investigations and soil improvement techniques, are critical to ensure the long-term stability and safety of a tailings dam.

Material Type in Tailings Dam Design

The **physical properties of the tailings** play a critical role in the overall behavior and stability of the tailings dam.

Key characteristics to consider include particle size, density, and moisture content, as these influence how the material behaves when compacted, its stability over time, and its interaction with water.

Here’s how each factor affects the dam's performance:

#### 1. **Particle Size**

- **Coarse vs. Fine Tailings**: Tailings are typically composed of varying proportions of coarse and fine particles.

- **Coarse Tailings (Sand-sized)**: Coarser materials are often more stable and less prone to liquefaction. They drain better, reducing the risk of pore pressure buildup. However, they may require careful placement and compaction to minimize settlement.

- **Fine Tailings (Silt- and Clay-sized)**: Finer particles retain more water, which can lead to higher pore water pressures and lower shear strength. Fine-grained tailings are more susceptible to liquefaction under seismic or dynamic loading conditions. They also consolidate more slowly, which can lead to long-term settlement and reduced dam stability.

- **Grading and Uniformity**: Well-graded materials (those with a wide range of particle sizes) typically have better compaction properties and can provide better structural stability. Uniformly graded tailings (mostly of one particle size) may require special handling to avoid excessive voids or poor drainage characteristics.

#### 2. **Density**

- **Dry Density**: The dry density of tailings reflects how much solid material is present per unit volume without water. Higher dry density generally improves the stability of the dam by increasing the material's shear strength and reducing the likelihood of liquefaction.

- **Compaction**: Tailings with higher dry density are more compacted, which makes them stronger and less likely to experience large settlements. Proper compaction during construction is critical to achieving optimal dry density and ensuring long-term stability.

- **Bulk Density**: The bulk density accounts for both the solid material and the water in the tailings. High bulk density could imply the tailings are saturated, which could lead to higher pore pressures and lower stability, particularly if drainage is inadequate.

- **Critical State Density**: Understanding the critical state density helps in predicting how tailings will behave under stress. If tailings are too loose, they can contract under loading, leading to potential liquefaction. If they are dense, they tend to dilate, increasing stability.

#### 3. **Moisture Content**

- **Water Content**: Tailings with high moisture content may be more prone to pore pressure buildup, especially in fine-grained materials. High moisture content reduces the shear strength of the tailings, making them more susceptible to deformation or failure.

- **Saturation and Pore Pressure**: Saturated tailings, especially those containing a significant proportion of fine particles, can develop excess pore water pressures when loaded, which reduces their stability. Managing the water content of tailings is critical to maintaining dam integrity.

- **Dewatering**: Proper dewatering of tailings can enhance stability by reducing the moisture content and allowing for better compaction. Dewatering can be achieved through methods like thickening, filtration, or the use of tailings paste technologies.

- **Moisture Variability**: Variability in moisture content within the tailings can create differential settlements or uneven compaction, leading to localized weak zones within the dam structure. Proper control of moisture during deposition and compaction is essential to avoid these issues.

#### 4. **Compaction Behavior**

- **Compaction Requirements**: The tailings must be compacted to achieve a density that ensures stability and minimizes settlement. Coarse tailings usually require less effort to compact but may require careful water management to prevent erosion. Fine tailings need more controlled compaction to prevent excess pore water pressures from developing.

- **Optimum Moisture Content**: There is a specific moisture content (optimum moisture content) at which tailings achieve maximum compaction. If the moisture content is too high or too low, compaction efforts may be ineffective, leading to loose or unstable layers.

- **Layered Deposition**: Tailings dams are often built in layers, with each layer compacted before the next is deposited. This reduces the potential for voids, enhances drainage, and improves the overall stability of the dam.

#### 5. **Behavior Over Time**

- **Consolidation**: Fine-grained tailings typically consolidate over time as water drains out and the material becomes more compacted. This process can take years or even decades, depending on the tailings material and the drainage conditions. As the tailings consolidate, settlement occurs, which can affect the long-term performance and stability of the dam.

- **Primary and Secondary Consolidation**: Primary consolidation occurs as excess pore pressures dissipate, while secondary consolidation (creep) continues at a slower rate. Designers need to account for both phases in predicting long-term settlement.

- **Cohesion and Shear Strength**: Over time, the tailings may gain cohesion and shear strength as they consolidate and dry out. However, this is dependent on the particle size distribution and the initial moisture content of the material.

#### 6. **Influence on Seepage and Drainage**

- **Permeability and Drainage**: The permeability of the tailings is influenced by particle size and density. Coarse tailings tend to have higher permeability, promoting drainage and reducing pore pressure buildup. Fine-grained tailings, on the other hand, may require engineered drainage systems to handle seepage and pore pressure management.

- **Filter Design**: The gradation of the tailings impacts the design of the internal drainage filters or transition zones. Filters must be designed to prevent migration of fine particles while still allowing water to drain effectively.

#### 7. **Material Segregation**

- **Deposition Methods**: How the tailings are deposited can lead to segregation of materials, with coarse particles settling closer to the deposition point and finer particles traveling further. This segregation can result in areas of varying stability within the dam, and designers need to manage the deposition process to ensure uniformity.

- **Homogenization**: Blending or homogenizing tailings before deposition can improve the uniformity of the material, reducing segregation and improving compaction and stability. Understanding and managing the physical properties of the tailings is essential for ensuring the long-term stability and safety of the tailings dam. Proper characterization, handling, and compaction of the tailings material, combined with effective drainage and monitoring systems, are key to maintaining dam integrity.

Shear Strength in Tailings Dam Design

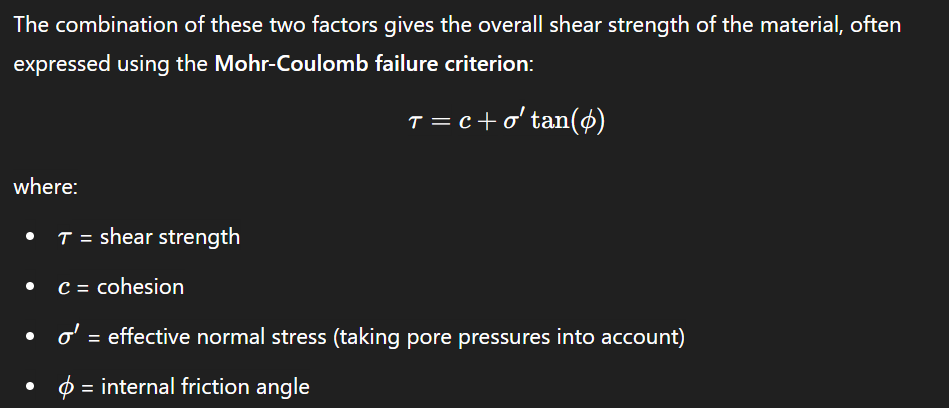

The **shear strength** of both the tailings and the foundation soils is a crucial factor in ensuring the stability of a tailings dam. Adequate shear strength is necessary to resist shear failure, which could lead to slope instability, sliding, or catastrophic dam collapse. Shear strength is a measure of a material’s ability to resist deformation and failure under applied stresses, and it is governed by several factors, including the type of material, its density, moisture content, and the external forces acting on the dam.

#### Components of Shear Strength Shear strength can be divided into two primary components:

1. **Cohesion (c)**: The natural "stickiness" or bonding of particles within the soil or tailings material.

2. **Internal Friction Angle (ϕ)**: The resistance due to friction between individual particles, which is often higher in coarse materials like sands and gravels.

### Factors Affecting Shear Strength

#### 1. **Tailings Shear Strength**

- **Cohesive vs. Non-Cohesive Tailings**:

- **Cohesive Tailings (Clay or Silt)**: These have higher cohesion but may have a lower internal friction angle. Fine-grained materials like silts and clays typically rely more on their cohesive properties for strength but are more sensitive to moisture content and pore water pressure.

- **Non-Cohesive Tailings (Sand)**: Coarse materials like sands primarily depend on internal friction for shear strength. They generally have high friction angles, making them more resistant to shear failure, but less cohesive, so proper compaction and placement are necessary to prevent loose packing that could lead to instability.

- **Effective Stress Conditions**: The shear strength of tailings is influenced by the effective normal stress (total stress minus pore pressure). Tailings in a saturated condition may exhibit reduced effective stress, thus lowering their shear strength.

- **Densification and Compaction**: Densely compacted tailings exhibit higher shear strength because the particles are more tightly packed, which increases both cohesion and internal friction. Loose or poorly compacted tailings are more prone to shear failure, especially under dynamic loads like earthquakes.

#### 2. **Foundation Shear Strength**

- **Bearing Capacity of Foundation Soils**: The foundation soils must have sufficient shear strength to support the weight of the dam and tailings without undergoing shear failure. Weak foundation soils may lead to excessive settlement, slope failure, or sliding of the entire structure.

- **Undrained Shear Strength**: For clays and other cohesive soils, the **undrained shear strength** is an important measure, particularly during rapid loading or the early stages of dam construction when pore water pressures have not dissipated.

- **Drained Shear Strength**: For long-term stability, the **drained shear strength** (which accounts for drainage and pore pressure dissipation over time) is typically considered. Sandy or gravely foundations usually exhibit good drained shear strength.

- **Shear Strength of Bedrock**: In cases where the dam is constructed on or near bedrock, the shear strength of the bedrock must be evaluated. Fractured or weathered bedrock may have lower shear strength than solid, intact rock, which could lead to sliding or instability along fracture planes.

- **Pore Pressure in Foundation Soils**: High pore water pressure in foundation soils can reduce the effective stress and, consequently, the shear strength. Drainage measures, such as installation of drains or relief wells, are often necessary to manage pore pressures in the foundation.

#### 3. **Pore Water Pressure and Effective Stress**

- **Saturation and Seepage**: Saturated tailings are more prone to shear failure due to elevated pore water pressures. The increase in pore pressure reduces the effective stress, which in turn reduces the material’s shear strength. Managing water content and ensuring proper drainage are essential to maintaining stability.

- **Liquefaction Potential**: Fine-grained, saturated tailings or loose sand tailings are susceptible to liquefaction, particularly during dynamic events like earthquakes. Liquefaction leads to a sudden loss of shear strength as the tailings behave like a liquid, which can trigger catastrophic failure.

- **Seepage Control**: Seepage through the dam or foundation can erode materials and increase pore pressures, weakening the shear strength of both the tailings and the foundation soils. Effective seepage control systems (e.g., drainage layers, cutoff walls) are critical to maintaining shear strength and preventing failure.

#### 4. **Consolidation and Time-Dependent Behavior**

- **Consolidation of Tailings**: Over time, fine-grained tailings undergo consolidation as water is expelled and pore pressures reduce. As consolidation progresses, the shear strength of the material increases due to densification and increased effective stress. However, the rate of consolidation depends on the permeability of the tailings and the drainage conditions.

- **Long-Term Shear Strength**: Tailings dams must be designed to accommodate changes in shear strength over time. The shear strength may initially be low due to high pore pressures but can increase as the tailings consolidate. Long-term monitoring and maintenance are crucial for assessing the evolving stability of the structure.

#### 5. **External Loading and Dynamic Effects** - **Seismic Loading**: Tailings dams located in seismic zones must be designed to withstand dynamic loads from earthquakes. Under seismic conditions, the shear strength of the tailings and foundation may be temporarily reduced, especially in saturated or loose tailings, which can lead to liquefaction or slope failure.

- **Cyclic Loading**: Repeated loading (such as from waves or operational machinery) can cause a gradual reduction in shear strength due to cumulative deformations. Evaluating the dam’s response to cyclic loading is important for predicting potential failure mechanisms.

- **Construction Stages**: Shear strength can vary throughout the construction process. For dams constructed in stages (common in tailings dams), it’s important to evaluate the shear strength of each layer and ensure that it meets design requirements as the dam height increases. ### Enhancing Shear Strength for Stability

#### 1. **Proper Compaction**

- Compaction of tailings is essential to increase density, reduce void ratios, and improve shear strength. Proper moisture control during compaction ensures that the material reaches its optimum density and shear strength.

#### 2. **Drainage Systems**

- Effective drainage is critical to prevent the buildup of pore pressures that could reduce shear strength. Installing drainage layers within the dam and maintaining low water levels in the tailings pond can help control pore pressures and enhance the overall stability of the dam.

#### 3. **Stabilization Measures**

- **Reinforcement**: Techniques such as incorporating geotextiles, geogrids, or rockfill buttresses can increase the overall shear strength of the dam by providing additional stability and reinforcing weak zones.

- **Berm Construction**: Constructing stability berms at the base of the dam can increase the shear resistance by adding weight and preventing slope failures.

#### 4. **Real-Time Monitoring**

- Monitoring pore pressures, slope movements, and settlement can provide early warning of shear strength issues. Instruments such as piezometers, inclinometers, and settlement gauges help in assessing the performance of the dam and detecting potential failures before they occur. By ensuring that both the tailings and the foundation soils possess sufficient shear strength, engineers can prevent shear failure and maintain the long-term stability of the tailings dam. Proper design, material management, drainage, and real-time monitoring are essential to achieving this goal.

Consolidation in Tailings Dam Design

**Consolidation** refers to the gradual process by which tailings materials settle and become denser over time as pore water is expelled from the void spaces within the material. This process significantly influences both the **stability** and **long-term settlement behavior** of the dam. As consolidation occurs, the volume of the tailings decreases, shear strength increases, and pore water pressures dissipate, which affects both the dam’s performance and its maintenance requirements over time.

### Key Factors in Tailings Consolidation

#### 1. **Primary and Secondary Consolidation**

- **Primary Consolidation**: This phase occurs as the excess pore water pressure, generated by the weight of the tailings and the dam, dissipates over time. During this phase, water is squeezed out of the tailings, causing settlement. The rate of consolidation depends on the **permeability** of the tailings material and the effectiveness of drainage systems.

- **Secondary Consolidation (Creep)**: After most of the excess pore water has been expelled during the primary phase, secondary consolidation occurs more slowly. It is driven by the ongoing rearrangement of particles and compression of the material, even in the absence of significant additional loading. This phase can continue for years or even decades, leading to long-term settlement.

#### 2. **Permeability of Tailings**

- **Coarse-Grained Tailings**: Coarser materials like sand have higher permeability, allowing water to drain more quickly and consolidation to occur faster. This generally leads to more stable conditions in a shorter timeframe.

- **Fine-Grained Tailings**: Fine-grained materials, such as silts and clays, have low permeability, meaning water drains out slowly, causing consolidation to occur over a longer period. This prolonged consolidation can result in delayed settlement and stability improvements.

#### 3. **Pore Water Pressure**

- **Excess Pore Water Pressure**: As tailings are deposited, they are often in a saturated state. The initial high pore water pressure reduces the effective stress in the tailings, weakening the material’s shear strength. As consolidation proceeds and pore water pressures dissipate, effective stress increases, leading to improved stability.

- **Drainage and Pore Pressure Dissipation**: Installing proper drainage systems within the dam, such as horizontal drains, wick drains, or underdrain systems, is crucial to accelerate the dissipation of excess pore pressures and promote faster consolidation, especially in fine-grained tailings.

### Effects of Consolidation on Stability

#### 1. **Increased Shear Strength**

- As consolidation progresses, the effective stress in the tailings increases as pore water pressures are reduced. This leads to a significant increase in the material’s **shear strength**, improving the overall stability of the dam. Coarse tailings consolidate faster, resulting in a quicker increase in shear strength, while fine tailings take longer to achieve stable conditions.

- **Staged Construction Considerations**: For tailings dams constructed in stages (commonly used in upstream, downstream, or centerline methods), understanding the consolidation rate is critical. Each stage must account for the shear strength gained in the previously deposited material to ensure stability.

#### 2. **Long-Term Settlement Behavior**

- **Settlement**: As the tailings consolidate, the volume reduces, causing settlement. This is particularly important for the long-term stability of the dam. Uneven settlement can lead to differential stresses in the dam structure, potentially causing cracking, localized failures, or deformation.

- **Primary Settlement**: The bulk of settlement occurs during the primary consolidation phase, but it continues at a slower rate during secondary consolidation.

- **Differential Settlement**: Uneven settlement across the dam foundation or within the tailings can lead to structural instability. Managing this through careful deposition techniques, compaction, and drainage control is critical for preventing damage.

- **Implications for Tailings Dam Design**: Designers must account for settlement in the overall dam height and capacity. Failure to plan for settlement could result in the dam being lower than intended, reducing its storage capacity or even leading to overtopping in extreme cases.

#### 3. **Pore Pressure-Induced Failures**

- **Liquefaction Risk**: If pore water pressures remain elevated for too long, especially in saturated, fine-grained tailings, the risk of liquefaction increases under dynamic loading, such as during an earthquake. Liquefaction leads to a sudden loss of shear strength, causing the tailings to behave like a liquid, which could trigger catastrophic dam failure.

- **Seepage-Induced Instability**: Slow drainage of pore water could lead to prolonged periods of high pore pressures, which weaken the tailings and could result in slope failure or internal erosion (piping). Effective drainage systems help to mitigate this risk.

### Factors Influencing the Rate of Consolidation

#### 1. **Thickness of Tailings Deposit**

- **Thicker Tailings Layers**: When tailings are deposited in thick layers, consolidation takes longer, as the water from the deeper layers has a longer drainage path to escape. The rate of consolidation is slower, particularly for fine-grained tailings.

- **Thinner Layers**: Depositing tailings in thinner layers allows for faster drainage and quicker consolidation, as the drainage path is shorter. This is a common practice to speed up the consolidation process.

#### 2. **Drainage Systems**

- **Surface and Subsurface Drainage**: Effective surface and subsurface drainage systems are critical to speeding up the consolidation process by promoting the rapid dissipation of pore pressures. Drains also help prevent excessive buildup of pore water pressure, reducing the risk of liquefaction and improving shear strength.

- **Wick Drains (Vertical Drains)**: Installing vertical wick drains in fine-grained tailings can significantly accelerate consolidation by providing additional pathways for water to escape, reducing the consolidation time from decades to years or even months.

#### 3. **Type of Tailings**

- **Fine-Grained Tailings**: Silts and clays are more compressible and exhibit longer consolidation times due to their lower permeability. Fine tailings often consolidate slowly, and secondary consolidation (creep) can be significant over long periods.

- **Coarse-Grained Tailings**: Sandy or gravely tailings consolidate quickly due to their high permeability, allowing water to drain out more easily. Their consolidation behavior is often completed within a shorter timeframe, leading to quicker stabilization.

#### 4. **External Loading**

- **Construction Loads**: The rate and sequence of construction impact consolidation. The additional load from dam construction accelerates consolidation by increasing the stress on the tailings. However, if loading occurs too rapidly, excess pore water pressures may develop, potentially leading to failure before sufficient consolidation has occurred.

- **Post-Construction Settlements**: External factors like ongoing deposition, increases in water content due to changes in pond management, or seismic loading may continue to influence consolidation even after the dam is operational.

### Management of Consolidation

#### 1. **Monitoring**

- **Real-Time Pore Pressure Monitoring**: Piezometers are used to measure pore water pressures within the tailings mass. This data provides insights into the rate of consolidation and helps determine if additional drainage measures are needed.

- **Settlement Gauges**: Instruments such as settlement plates and inclinometers are used to track vertical and lateral displacements in the tailings mass, providing early warning of potential stability issues related to uneven settlement.

#### 2. **Controlled Deposition**

- **Layered Deposition**: Tailings dams are often constructed in layers, with each layer being compacted before the next is deposited. This promotes faster consolidation by minimizing void spaces and improving drainage conditions.

- **Dry Stacking**: In cases where water management is critical, dewatered tailings (dry stacking) can be used. This method reduces the amount of water that must be managed during consolidation, leading to faster stabilization.

#### 3. **Stability Berms and Reinforcements**

- **Berms**: Berms constructed at the base of the dam add weight and stability to resist sliding or shear failures that could be triggered by uneven consolidation.

- **Geotechnical Reinforcements**: Geosynthetics, geogrids, or other reinforcement techniques can be used to increase the overall stability of the dam during the consolidation process, especially in cases where long-term settlement is expected.

### Conclusion

**Consolidation** is a key factor in determining the **long-term stability** and **settlement behavior** of a tailings dam. The rate and extent of consolidation depend on the **permeability** and **compressibility** of the tailings material, the effectiveness of **drainage systems**, and the **loading conditions**. Proper management of consolidation through controlled deposition, drainage, and monitoring systems is essential to ensuring that pore water pressures dissipate safely, shear strength increases over time, and settlement is controlled. Managing these factors is critical for both the short-term stability during construction and the long-term performance of the dam.

Permeability in Tailings Dam Design

**Permeability** is a measure of how easily fluids can flow through a material. In the context of tailings dams, the permeability of both the tailings and the foundation materials is a crucial factor influencing seepage, pore pressure buildup, and overall dam stability. While **low permeability** is often desirable to minimize seepage, it also introduces challenges related to **pore pressure buildup** if not properly managed. Conversely, materials with high permeability allow better drainage but may be more prone to erosion and seepage-related failures. Managing permeability requires a careful balance between reducing seepage and allowing enough drainage to prevent excessive pore pressure.

### Key Aspects of Permeability in Tailings Dam Design

#### 1. **Low Permeability to Minimize Seepage**

- **Tailings as a Barrier**: Fine-grained tailings, such as silts and clays, typically have low permeability and can act as an effective barrier to fluid flow. This reduces the amount of seepage through the dam and prevents contamination of surrounding environments. Low permeability materials help in retaining water within the impoundment, reducing the risk of contaminating groundwater or nearby water bodies.

- **Impermeable Liners**: Many tailings dams are constructed with impermeable liners (such as compacted clay or synthetic geomembranes) at the base to further minimize seepage. These liners are often used in conjunction with low-permeability tailings to create an effective barrier to fluid flow.

- **Seepage Control**: Low permeability layers help to control seepage through the dam body and foundation. Controlling seepage is critical for preventing internal erosion or piping, which can lead to dam failure over time.

#### 2. **Challenges of Low Permeability: Pore Pressure Buildup**

- **Pore Pressure and Effective Stress**: One major challenge with low permeability tailings is the potential for **pore pressure buildup**. When tailings are deposited, especially in a saturated condition, water within the voids cannot escape easily if the material has low permeability. This results in the development of high pore water pressures, which reduce the **effective stress** in the material, thereby lowering its **shear strength**.

- **Risk of Liquefaction**: In fine-grained, low permeability tailings, the slow dissipation of pore pressure can increase the risk of **liquefaction**, particularly during dynamic events such as earthquakes. Liquefaction occurs when the pore water pressure approaches the total stress, causing a sudden loss of strength in the tailings, potentially leading to catastrophic dam failure.

- **Seepage-Induced Instability**: Low permeability alone does not eliminate the risk of seepage entirely. Poorly managed seepage paths, such as through cracks or interfaces between layers of different permeability, can result in concentrated flow and erosion (piping). If pore pressures remain high for extended periods, this can weaken the structure and trigger slope failure.

### Managing Permeability and Pore Pressure

#### 1. **Drainage Systems**

- **Horizontal and Vertical Drains**: Installing **horizontal drains** or **vertical wick drains** in low-permeability tailings can help alleviate pore pressure buildup by providing additional drainage paths. These systems promote the rapid dissipation of excess pore water pressure, allowing for faster consolidation and increasing the material’s shear strength.

- **Underdrains**: Tailings dams often incorporate **underdrain systems** beneath the tailings impoundment to capture and redirect seepage water away from the dam. These systems help reduce water pressure at the base of the dam and prevent the migration of pore pressure into the foundation, reducing the risk of sliding or liquefaction.

- **Relief Wells**: In some designs, relief wells are installed to allow pressurized water to escape from the foundation or within the dam body, reducing pore pressures and helping to maintain stability.

#### 2. **Controlled Deposition**

- **Layered Deposition**: Deposition of tailings in thin, well-compacted layers rather than large volumes at once can help manage permeability and pore pressures. Thinner layers allow better drainage and help reduce pore pressure buildup, while also promoting faster consolidation.

- **Deposition Techniques**: **Cycloning** and other methods of separating fine and coarse tailings can be used to create zones with different permeability. For example, coarse material (higher permeability) can be placed on the outer shell of the dam, while fine-grained, low-permeability tailings are deposited in the center to control seepage.

#### 3. **Permeability in the Foundation**

- **Permeability Contrast**: A significant difference in permeability between the tailings and the foundation soils can lead to seepage issues. For instance, if the foundation is highly permeable and the tailings have low permeability, water may seep into the foundation, causing pore pressure buildup and potentially leading to liquefaction or sliding.

- **Impermeable Cutoffs and Seepage Barriers**: In cases where the foundation has high permeability, seepage control measures such as **cutoff walls** or **slurry trenches** are often used. These barriers prevent water from migrating through the foundation and reduce the risk of seepage-induced instability.

#### 4. **Tailings Densification**

- **Compaction**: Proper compaction of tailings during deposition is critical for reducing the permeability of the material. Well-compacted tailings are less likely to develop significant pore pressure and will exhibit lower permeability, which improves stability.

- **Cemented Tailings**: In some cases, **cemented tailings** (using a mix of tailings and cement) are used to create a more stable, low-permeability structure. This approach reduces both seepage and the potential for pore pressure buildup, but it is typically more expensive and reserved for critical applications. ### Balancing Permeability for Dam Safety

#### 1. **Balancing Low Permeability and Drainage**

- **Seepage Control vs. Pore Pressure Management**: While low permeability is desirable for minimizing seepage, it must be balanced with adequate drainage to prevent excessive pore pressure buildup. Without sufficient drainage systems, even low-permeability materials can become unstable due to elevated pore pressures. Thus, the design must integrate drainage systems that ensure pore water pressure dissipates at a safe rate while still maintaining low seepage through the dam structure.

- **Graded Zoning**: A common approach in tailings dam design is to create a zoned structure where materials of different permeabilities are strategically placed. For example, a **high-permeability shell** (such as coarse tailings or rockfill) can be used to facilitate drainage, while **low-permeability tailings** or liners in the core or upstream zone are used to minimize seepage.

#### 2. **Permeability Testing and Monitoring**

- **Permeability Testing**: Before construction, detailed **permeability testing** of both the tailings and the foundation materials is essential to inform the design. Laboratory tests (e.g., constant head or falling head permeability tests) and field permeability tests (e.g., in-situ borehole tests) are typically conducted to quantify the permeability of different materials and ensure they meet design criteria.

- **Monitoring Seepage and Pore Pressure**: Post-construction monitoring using piezometers and seepage flow meters is crucial for assessing the performance of the dam’s permeability and drainage systems. Monitoring systems help detect changes in pore pressures and seepage rates, providing early warning of potential failures.

### Conclusion While **low permeability** is often targeted in tailings dam design to minimize seepage and protect the environment, it must be carefully managed to avoid issues with **pore pressure buildup**. Excessive pore pressure can weaken the dam and increase the risk of failure through mechanisms like liquefaction or slope instability. Proper drainage systems, controlled deposition, and permeability management are essential to balance seepage control with the need to dissipate pore pressures safely. By carefully balancing these factors, engineers can ensure the long-term stability and safety of the tailings dam.

Drainage Design in Tailings Dams

**Drainage design** is a critical component in tailings dam construction, as it directly influences the stability of the structure by managing **pore water pressure**. High pore pressures can reduce the **shear strength** of the tailings and surrounding soils, which can lead to slope instability, **liquefaction**, or even catastrophic dam failure. Effective drainage systems are essential to dissipate excess pore pressure, minimize seepage, and ensure the long-term safety of the dam.

### Key Elements of Drainage Design

#### 1. **Pore Water Pressure and Its Impact**

- **Reduced Shear Strength**: High pore water pressure reduces the **effective stress** in tailings material, which weakens its ability to resist shear forces. This reduction in shear strength increases the risk of slope failures, particularly in dams with steep slopes or in areas with seismic activity.

- **Liquefaction Risk**: Saturated, loose tailings are at risk of **liquefaction** under dynamic loading (e.g., during an earthquake). Liquefaction occurs when pore water pressures build up to a point where the tailings temporarily lose strength and behave like a liquid. Effective drainage systems are essential to dissipate pore water pressure and mitigate this risk.

#### 2. **Internal Drainage Systems**

- **Horizontal Drains**: Horizontal drains are installed within the dam or its foundation to intercept and channel water away from areas where it could cause pore pressure buildup. These drains are typically made from permeable materials (e.g., sand, gravel) and are used to improve drainage along critical sections of the dam.

- **Drainage Blankets**: These are wide layers of permeable material placed at the base of the dam or tailings impoundment to collect and convey seepage water away from the structure. Drainage blankets are particularly effective in controlling seepage through the dam foundation and promoting rapid dissipation of pore water pressure.

- **Underdrains**: Installed beneath the tailings deposit or the dam itself, underdrains are designed to collect seepage water from the tailings and channel it out of the dam structure. By lowering the water table, underdrains reduce pore water pressure in the tailings mass, improving stability.

- **Vertical Drains (Wick Drains)**: In fine-grained, low-permeability tailings, pore water tends to dissipate slowly. Vertical wick drains can be installed to provide additional pathways for water to escape, accelerating the consolidation process and reducing pore pressure. These drains are often used in combination with staged loading to enhance stability in fine-grained tailings dams.

#### 3. **Filter Layers**

- **Purpose of Filters**: Filter layers are critical components of the drainage system, designed to allow water to pass through while preventing the migration of fine particles that could clog the drains. Filters help maintain the permeability of the drainage system and prevent internal erosion or piping, which could weaken the dam.

- **Graded Filter Design**: Filters are typically constructed from **graded sand, gravel, or geotextiles**, which are chosen to match the particle size distribution of the surrounding tailings or soils. The goal is to provide a balance between preventing fines from entering the drainage system while allowing water to flow freely.

- **Primary Filters**: These are placed directly adjacent to the tailings material to filter out fine particles while allowing seepage water to pass.

- **Secondary Filters**: These are often used in multi-layered drainage systems to provide additional protection against clogging and to ensure the long-term effectiveness of the primary drainage elements.

#### 4. **Seepage Control Measures**

- **Upstream Drainage Systems**: In tailings dams, **upstream drainage** can be used to control water levels in the tailings impoundment. These systems help lower the phreatic surface (the saturated zone within the dam) and prevent pore pressures from reaching critical levels. By controlling seepage from the tailings impoundment into the dam structure, upstream drainage systems help maintain stability.

- **Toe Drains and Cutoff Trenches**: **Toe drains** are installed at the base (toe) of the dam to capture and remove seepage water that might flow through the dam body or foundation. In some cases, **cutoff trenches** or slurry walls are used to prevent water from seeping into permeable foundations, further enhancing dam stability by controlling seepage pathways.

#### 5. **Permeability and Drainage Zoning**

- **Zoned Dams**: Tailings dams are often constructed with different zones of materials, each with specific permeability characteristics to control water flow. Typically, the outer shell of the dam is made from more permeable materials (such as coarse tailings or rockfill) to facilitate drainage, while the core or upstream sections may use low-permeability tailings or liners to minimize seepage.

- **Drainage Layers within the Dam**: Drainage layers are incorporated within the dam’s body to direct water toward the designated drainage outlets. These layers typically consist of gravel, sand, or geosynthetic materials, which provide high-permeability pathways to move water away from critical areas where pore pressure could build up.

#### 6. **Seepage Collection and Monitoring**

- **Seepage Collection Systems**: In some designs, water that seeps through the dam or foundation is collected in **seepage collection ponds** or trenches. From here, water can be pumped away or treated if necessary. These systems ensure that any uncontrolled seepage does not compromise the dam’s structural integrity.

- **Piezometers and Pore Pressure Monitoring**: **Piezometers** are instruments used to measure pore water pressures within the dam body and foundation. Real-time monitoring of pore pressure provides essential data to detect high-risk conditions and assess whether drainage systems are functioning as intended.

- **Real-Time Monitoring**: Advanced tailings dams often use real-time monitoring systems to track pore pressure, seepage rates, and settlement. These systems provide early warnings of potential issues such as excessive pore pressure buildup, allowing for proactive management and maintenance.

### Design Considerations for Effective Drainage

#### 1. **Material Selection**

- **Permeability**: Materials used in the drainage system must have sufficient permeability to handle the expected water flow. Coarse materials, such as gravel and sand, are typically used in drainage zones, while finer materials are used in filter layers to prevent clogging.

- **Durability**: Drainage materials must also be durable enough to resist degradation over time. The geochemical compatibility of drainage materials with the tailings and the surrounding environment must be considered to avoid issues like chemical clogging or corrosion.

#### 2. **Slope and Drainage Gradients**

- **Optimizing Gradients**: The slope of drainage layers must be designed to optimize water flow. Steeper gradients increase the rate at which water is removed, reducing pore pressure more rapidly. However, gradients must also be carefully balanced to avoid excessive erosion of drainage materials.

- **Maintaining Stability**: While drainage systems help dissipate pore pressure, they must not destabilize the dam. Poorly designed drainage systems can lead to localized areas of high hydraulic gradients, which could trigger erosion or piping within the dam structure.

#### 3. **Staged Construction and Drainage**

- **Staged Loading**: For tailings dams constructed in stages, drainage systems must be designed to handle increasing pore pressure as new layers of tailings are deposited. Drainage pathways must be extended as the dam height increases, and additional drainage systems may be required to handle the higher loads and water volumes associated with each stage.

- **Consolidation Management**: In dams built using the upstream method, drainage systems must ensure that pore water pressures in the underlying tailings are sufficiently dissipated between each stage of construction to prevent liquefaction or instability.

#### 4. **Climate and Water Management**

- **Rainfall and Surface Water Management**: Drainage systems must account for precipitation and potential runoff from the dam surface. In high-rainfall areas, surface drainage systems (such as ditches and channels) are necessary to prevent water from infiltrating the tailings and increasing pore pressure. Proper water management also reduces the risk of erosion on the dam surface.

- **Seepage Control under Variable Conditions**: Seasonal variations in water levels or unexpected increases in water inflow (e.g., from flooding or snowmelt) can affect pore pressure. Drainage systems must be robust enough to handle fluctuating conditions without compromising the dam’s stability.

### Conclusion

Effective **drainage design** in tailings dams is essential for managing **pore water pressure**, reducing the risk of **liquefaction**, and ensuring the overall stability of the structure. Drainage systems, including internal drains, filter layers, and seepage control measures, must be carefully designed to dissipate pore pressure while preventing erosion or clogging. Continuous **monitoring** and **maintenance** of these systems are also critical for long-term safety, ensuring that pore pressures remain within safe limits throughout the dam’s lifecycle.

Phreatic Surface Control in Tailings Dams

**Phreatic surface control** is a critical aspect of tailings dam design and operation. The **phreatic surface** refers to the level within a dam or tailings impoundment at which the soil or tailings material is fully saturated with water. If the phreatic surface is too high, it can lead to increased **pore water pressures**, reducing the effective stress of the material, which, in turn, lowers the **shear strength** of the dam and increases the risk of **slope failure**, **piping**, and **liquefaction**. Managing the phreatic surface is essential for maintaining the structural integrity of the dam and ensuring the long-term stability of the impoundment.

### Why Phreatic Surface Control is Important

1. **Pore Pressure and Stability**:

- As the phreatic surface rises, **pore water pressures** increase within the tailings or dam body. This reduces the **effective stress** (the stress carried by the solid particles), which weakens the structure’s ability to resist shear forces and increases the risk of **slope instability** and failure.

- High pore pressures can also lead to **piping**, where water channels through the dam body, eroding material and potentially leading to internal erosion and collapse.

2. **Liquefaction Risk**:

- In saturated conditions, tailings are at higher risk of **liquefaction**, especially under seismic loading. When pore pressures are too high, the tailings can lose their strength and behave like a liquid, which can lead to a rapid failure of the dam structure.

3. **Seepage and Erosion**:

- A high phreatic surface can result in excessive **seepage** through the dam. Seepage paths, if not properly controlled, can cause internal erosion and weaken the dam over time. Controlling the phreatic surface helps minimize seepage and the associated risks of internal erosion.

### Key Methods for Controlling the Phreatic Surface

#### 1. **Effective Drainage Systems**

- **Drainage Layers**: One of the most effective methods of controlling the phreatic surface is through the use of permeable drainage layers or zones within the dam. These layers allow water to drain out of the dam, lowering the phreatic surface and reducing pore pressures.

- **Gravel and Sand Filters**: These materials are commonly used as drainage layers due to their high permeability, which helps to move water away from the core of the dam. Proper design and placement of these layers are critical to ensure they capture seepage and allow water to escape efficiently.

- **Horizontal and Vertical Drains**: Drains installed within the dam’s body and foundation can effectively lower the phreatic surface by directing water out of the structure.

**Horizontal drains** are typically used to capture water within the dam, while

**vertical drains** (such as wick drains) can help dissipate pore water pressure in fine-grained tailings materials.

- **Toe Drains**: Placed at the base of the dam, **toe drains** help capture and remove seepage water that reaches the lower part of the dam. These systems lower the phreatic surface at the downstream toe, preventing water from saturating the slope and causing instability.

#### 2. **Upstream and Downstream Zoning**

- **Zoned Dams**: In many tailings dams, different zones are constructed using materials with varying permeability. The upstream zone, in contact with the tailings, is often made of lower-permeability materials (e.g., fine-grained tailings or compacted earth) to minimize seepage into the dam body. The downstream zone is made from more permeable materials (e.g., gravel or rockfill) to allow for drainage and to control the phreatic surface.

- **Permeable Downstream Shell**: A permeable shell on the downstream face of the dam can effectively lower the phreatic surface by allowing water to flow out of the dam body. This helps keep the phreatic surface below the critical zone where slope instability is most likely to occur.

#### 3. **Filter and Drainage Blankets**

- **Filter Layers**: These layers are designed to filter out fine particles while allowing water to pass through. By preventing the migration of fines into the drainage system, filter layers help maintain the permeability of the drainage system, ensuring the phreatic surface remains low.

- **Drainage Blankets**: A **drainage blanket** is a highly permeable layer installed at the base of the tailings dam or tailings impoundment. It captures and directs water away from the dam, reducing the phreatic surface. Drainage blankets are particularly effective in controlling seepage from the tailings impoundment and preventing the buildup of water pressure in the foundation soils.

#### 4. **Seepage Cutoff Systems**

- **Cutoff Walls**: These are impermeable barriers installed vertically within the dam or its foundation to block seepage paths and lower the phreatic surface. Cutoff walls can be made of materials such as compacted clay, cement-bentonite, or concrete, and they are typically installed in areas where the foundation is permeable.

- **Upstream Liners**: Impermeable liners placed on the upstream face of the dam or beneath the tailings impoundment can reduce seepage into the dam body, effectively lowering the phreatic surface. Liners are typically made from materials such as **geomembranes**, **clay**, or **bentonite**.

#### 5. **Surface Water Management**

- **Surface Drainage Channels**: Proper surface water management systems, such as drainage channels, ditches, and diversion structures, help prevent rainwater and surface runoff from infiltrating the dam and tailings impoundment. By keeping surface water away from the dam, these systems help maintain a low phreatic surface and reduce the risk of water saturation.

- **Stormwater Control**: In regions with high rainfall or snowmelt, managing stormwater is critical. Stormwater control measures, including collection ponds and drainage systems, help capture and divert water away from the tailings impoundment to prevent the phreatic surface from rising during wet conditions.

#### 6. **Monitoring and Instrumentation**

- **Piezometers**: Piezometers are devices used to measure **pore water pressure** and monitor the phreatic surface within the dam and tailings impoundment. These instruments provide real-time data on pore pressures and allow engineers to track changes in the phreatic surface over time. If the phreatic surface begins to rise, drainage systems can be adjusted or additional measures can be implemented to control it.

- **Water Balance Modeling**: Engineers use water balance models to simulate how water moves through the dam and tailings impoundment. These models help predict the phreatic surface's behavior under different conditions (e.g., changes in tailings deposition rates, rainfall, or seepage control measures) and inform decisions about drainage design.

### Best Practices for Phreatic Surface Control

1. **Design for Long-Term Stability**:

- Phreatic surface control should be integrated into the initial design of the tailings dam. Using a combination of drainage systems, zoned construction, and seepage barriers helps ensure that the phreatic surface remains low and stable throughout the life of the dam.

2. **Ongoing Monitoring and Adjustments**:

- Monitoring pore pressures and phreatic surface levels throughout the dam's lifecycle is essential for maintaining stability. If the phreatic surface rises unexpectedly due to changes in tailings deposition or water management, engineers must be prepared to implement corrective measures, such as installing additional drains or upgrading surface water management systems.

3. **Adapt to Changing Conditions**:

- Tailings dams are dynamic structures, with water pressures changing over time due to tailings deposition, consolidation, and environmental factors. Drainage systems and seepage control measures should be flexible enough to adapt to these changes, ensuring the phreatic surface is managed effectively under varying conditions.

4. **Emergency Preparedness**:

- If monitoring indicates that the phreatic surface is rising to dangerous levels, emergency measures such as dewatering or temporary water diversion systems should be in place to quickly mitigate the risk of dam failure.

### Conclusion **Phreatic surface control** is vital for preventing tailings dam failures related to **slope instability**, **liquefaction**, and **seepage**. Through the use of effective drainage systems, seepage barriers, surface water management, and real-time monitoring, the phreatic surface can be kept at a safe level. Careful design, regular monitoring, and adaptive management strategies ensure the long-term stability and safety of the dam structure.

Static Stability in Tailings Dams: Analyzing Slope Stability Under Normal Loading Conditions

**Static stability** refers to the stability of a tailings dam under normal (non-dynamic) conditions, where no external forces like earthquakes or blasting are present.

**Slope stability** analysis under static loading focuses on the resistance of the dam to failure due to the weight of the tailings, water, and external environmental factors. Ensuring static stability is critical to prevent failures, such as **slope collapse**, **sloughing**, or **slip failures**, which can lead to catastrophic breaches of the tailings dam.

### Key Factors Influencing Static Stability

1. **Slope Angle**:

- The angle of the dam’s slope is one of the primary factors affecting stability. **Steeper slopes** tend to be more susceptible to failure, as the gravitational forces acting on the material are greater.

**Gentler slopes** distribute the load more evenly and reduce the risk of slope failure.

- Slope angles are typically determined based on the strength of the construction materials and the tailings. In practice,

**flattened slopes** (lower angles) are often used to enhance stability, especially in larger dams or those built with weaker materials.

2. **Shear Strength of Materials**:

- The **shear strength** of both the tailings and the dam construction materials (e.g., fill, rockfill, or compacted earth) is critical to resisting slope failure. Shear strength is determined by factors such as:

- **Cohesion**: The bonding between particles.

- **Internal friction angle**: The resistance of the material to sliding, influenced by particle size, shape, and interlocking.

- A thorough understanding of the **tailings' geotechnical properties** (particle size, density, and moisture content) and the material used for dam construction is essential for accurate slope stability analysis.

3. **Loading from Tailings and Water**:

- **Weight of Tailings**: As more tailings are deposited in the impoundment, the **loading on the dam increases**, which can reduce stability over time. The dam must be designed to safely support the additional weight, taking into account both vertical (compressive) and horizontal (lateral) forces.

- **Water Loading**: Water stored within the dam and in the tailings impoundment adds to the overall load, significantly affecting stability. Water exerts **hydrostatic pressure** and can raise the **phreatic surface**, increasing pore water pressures and reducing shear strength. Proper water management and **phreatic surface control** are therefore crucial.

4. **Pore Water Pressure**:

- High **pore water pressures** within the tailings or dam materials can reduce the **effective stress**, which is the stress carried by the solid particles. This weakens the material’s resistance to shear forces and increases the likelihood of slope failure.

- Controlling the **phreatic surface** and ensuring effective drainage helps dissipate pore water pressures, contributing to static stability.

5. **Foundation Conditions**:

- The stability of the dam depends significantly on the strength and integrity of the **foundation soils** or **bedrock**. Weak or highly compressible foundation materials can lead to excessive settlement, differential movement, or even **foundation failure**, compromising the dam’s overall stability.

- A thorough geotechnical investigation is necessary to assess the foundation conditions, and **foundation improvements** (e.g., compaction, grouting) may be required to enhance stability.

6. **Seepage and Drainage**:

- **Seepage** through the dam body or foundation can reduce stability by eroding material or raising the phreatic surface. Effective **seepage control measures**—such as internal drains, filters, and impermeable barriers—are essential for maintaining slope stability.

- **Internal erosion** or **piping**, where water transports fine particles out of the dam body, can undermine the dam’s structure and lead to failure. Proper drainage systems prevent this by reducing seepage paths and controlling water flow.

7. **External Conditions**:

- **Environmental Factors**: Weather and climate conditions, such as heavy rainfall or rapid snowmelt, can affect the stability of tailings dams. These factors can increase water infiltration, raise pore water pressures, and weaken the dam materials.

- **Vegetation**: While vegetation on the dam face can reduce surface erosion, excessive root growth may also penetrate drainage systems and affect seepage control, potentially impacting stability.

8. **Construction Method**:

- The construction method used for the tailings dam plays a significant role in its static stability. The three primary methods are:

- **Upstream Method**: Dams built using the upstream method are more susceptible to stability issues because the dam is constructed on top of deposited tailings, which may have lower strength.

- **Downstream Method**: This method offers higher stability because each new dam lift is supported by previous layers of dam material rather than tailings.

- **Centerline Method**: This method combines features of both upstream and downstream methods and provides a balance between cost and stability. ### Slope Stability Analysis Methods Several methods are used to evaluate the static stability of tailings dam slopes. These methods assess the balance of forces acting on the dam to determine the **factor of safety (FoS)**, which measures how much stronger the system is compared to the loads applied to it. A **FoS** greater than 1.0 indicates stability, with typical design targets ranging from 1.3 to 1.5 for static conditions.

#### 1. **Limit Equilibrium Methods (LEM)**

- **Limit equilibrium analysis** is one of the most common approaches for analyzing slope stability. It assumes that the slope is on the verge of failure and calculates the ratio of resisting forces (shear strength) to driving forces (weight and pore pressures).

- Various methods are used within LEM, including:

- **Simplified Bishop Method**: Assumes circular failure surfaces and is suitable for homogenous material analysis.

- **Janbu Method**: Can be applied to non-circular failure surfaces, useful for analyzing layered materials or dams with complex geometry.

- **Spencer Method**: Provides a more rigorous analysis by considering both force and moment equilibrium.

- These methods divide the slope into slices and analyze the equilibrium of each slice, summing the results to determine the overall factor of safety.

#### 2. **Finite Element Analysis (FEA)**

- **Finite element analysis** is a more advanced method that provides a detailed understanding of the stress and strain distribution within the dam body and foundation. FEA is used to model complex geometry, non-homogeneous materials, and the effects of pore water pressure.

- FEA considers the entire dam structure as a continuum, dividing it into smaller elements and analyzing how each element interacts with its neighbors under applied loads. This method is particularly useful for assessing **deformation** and **failure mechanisms** in large or complex dams.

#### 3. **Shear Strength Reduction (SSR) Method**

- The **shear strength reduction method** is a numerical approach that progressively reduces the material’s shear strength until failure occurs. This method is often used in conjunction with finite element modeling to determine the critical factor of safety.

- The SSR method allows for a more detailed understanding of how specific weak zones within the dam might contribute to failure, and it can provide insights into the potential failure mode and location.

#### 4. **Empirical Approaches**

- **Empirical methods** are based on observations from past dam performance and failures. These methods use established relationships between factors like slope angle, dam height, and material properties to provide an estimate of stability.

- Empirical approaches are often used for preliminary design and can serve as a starting point for more detailed analysis.

### Best Practices for Ensuring Static Stability

1. **Optimized Slope Design**:

- Design slopes with a balance between **stability** and **cost-effectiveness**. While flatter slopes provide greater stability, they may require more material and space. Adjusting slope angles based on the material’s shear strength and foundation conditions ensures long-term stability.

2. **Comprehensive Site Investigations**:

- Conduct thorough **geotechnical investigations** to assess the properties of the tailings, dam construction materials, and foundation soils. Accurate data on shear strength, permeability, and compressibility are essential for reliable slope stability analysis.

3. **Phreatic Surface and Seepage Control**:

- Design effective **drainage systems** to control the phreatic surface and minimize pore water pressure. Regular maintenance and monitoring of drains, filters, and seepage paths are critical to prevent erosion, piping, and slope instability.

4. **Regular Monitoring and Maintenance**:

- Continuously monitor **pore pressures**, **settlement**, and **seepage** using instruments like **piezometers** and **inclinometers**. Early detection of rising pore pressures or slope movement allows for timely corrective actions.

5. **Reinforcement of Weak Areas**:

- If the analysis reveals potential weak zones, reinforce these areas with **geosynthetic materials**, **rockfill**, or **compacted earth** to enhance stability. In some cases, installing **buttresses** or **berms** can provide additional support for the dam slope.

6. **Phased Construction**:

- For large tailings dams, phased construction with regular assessments of stability is recommended. **Staged loading** allows pore pressures to dissipate between construction phases, ensuring that the dam remains stable as the height increases.

### Conclusion

**Static slope stability analysis** is a crucial component of tailings dam design and maintenance. By considering factors such as **slope angle**, **material properties**, **loading conditions**, and **pore pressures**, engineers can ensure that

Seismic Stability in Tailings Dams: Designing for Seismic Loading

### Key Seismic Hazards for Tailings Dams

1. **Liquefaction**:

- **Liquefaction** occurs when saturated, loose tailings or dam materials lose strength and stiffness due to earthquake-induced shaking. This happens when seismic loading causes the **pore water pressures** to increase, reducing the material’s **effective stress** and turning it into a fluid-like state. Liquefaction can lead to rapid failure, especially if the tailings impoundment or dam itself is constructed with loose, unconsolidated materials. - Tailings dams that use the **upstream construction method**, where the dam is built over loose tailings, are particularly vulnerable to liquefaction.

2. **Slope Failure**:

- Earthquake-induced shaking generates additional **dynamic loads** on the dam structure, which can cause **slope instability**. Inadequate resistance to these loads may result in the **slip failure** of the dam's slopes. Seismic-induced slope failure can lead to partial or total dam collapse, especially in dams with steep slopes or weak foundation conditions.

3. **Overtopping**:

- Seismic shaking can cause **displacements** in the dam structure, which may lower the crest of the dam or cause the dam body to settle unevenly. These displacements, combined with potential seismically-induced waves in the impoundment (known as **seiche** waves), can lead to **overtopping**. Overtopping poses a serious risk as it can rapidly erode the dam and lead to catastrophic failure.

4. **Dam Deformation and Settlement**:

- Even if a dam does not fail during an earthquake, it may experience significant **deformation** or **settlement**. The tailings or dam materials can shift under seismic loading, altering the geometry of the structure and reducing stability. Post-earthquake assessments are critical to ensure that deformations have not compromised the dam’s integrity.

### Key Factors in Seismic Stability Design

1. **Seismic Hazard Assessment**:

- Before designing a tailings dam in a seismically active area, a detailed **seismic hazard assessment** must be performed. This includes analyzing the site’s seismic history, proximity to faults, and potential earthquake magnitudes. Key inputs for seismic design include:

- **Peak Ground Acceleration (PGA)**: A critical parameter representing the highest ground acceleration likely to occur at the site during an earthquake. - **Earthquake Magnitude**: The magnitude of the design earthquake, often selected based on the Maximum Credible Earthquake (MCE) or the Operating Basis Earthquake (OBE).

- **Ground Motion Duration**: The length of time the earthquake shaking will persist, which affects the potential for liquefaction and failure.

- **Seismic design parameters** must be chosen conservatively, accounting for the worst-case scenarios to ensure the dam remains stable even under extreme earthquake conditions.

2. **Liquefaction Potential**:

- Assessing the potential for liquefaction is essential, especially in areas where the tailings or foundation soils are loose, saturated, and susceptible to pore pressure buildup during seismic events.

- Key factors influencing liquefaction potential include:

- **Grain Size Distribution**: Fine-grained, saturated soils or tailings are more likely to liquefy under seismic shaking.

- **Saturation Level**: Fully saturated tailings are at greater risk of liquefaction than partially saturated materials.

- **Compaction Level**: Densely compacted materials are less susceptible to liquefaction.

- **Cyclic Stress Ratios (CSR)** and **Cyclic Resistance Ratios (CRR)** are commonly used in liquefaction assessments to compare the seismic demand on the soil versus its capacity to resist liquefaction.

3. **Shear Strength and Deformation**:

- The **dynamic shear strength** of the tailings and dam materials must be sufficient to resist seismic forces. During earthquakes, the dam’s materials are subjected to both vertical and horizontal shear stresses, and their ability to resist deformation under these loads is critical for stability.

- **Nonlinear deformation analysis** using methods such as **finite element analysis (FEA)** or **dynamic limit equilibrium analysis** helps predict how the dam will behave during seismic events, including potential **displacements**, **slip surfaces**, and **failure zones**.

4. **Seismic Slope Stability**:

- Seismic slope stability is evaluated similarly to static stability, but with the additional consideration of dynamic forces from seismic loading. **Pseudo-static analysis** is often used, where an equivalent static force is applied to simulate earthquake effects. This method calculates the **factor of safety (FoS)** under seismic conditions.

- The factor of safety under seismic loading should generally be greater than 1.0, but often, a target FoS of around 1.1 to 1.3 is used depending on the dam’s criticality and location.

5. **Seismic Deformation Analysis**:

- In addition to evaluating potential failures, it is important to assess how much the dam will deform during and after an earthquake. **Newmark’s Sliding Block Method** is commonly used to estimate permanent displacements in the dam during an earthquake. This approach models the dam as a rigid block on an inclined plane and estimates how much it will move based on the ground motion.

- If the predicted deformations exceed safe limits, additional design measures must be taken to reduce the risk of failure.

### Key Design Strategies for Seismic Stability

1. **Foundation and Site Preparation**:

- Ensure that the foundation soils or bedrock are stable and free from **weak layers** that could amplify seismic shaking or lead to **foundation failure**. Techniques such as **soil compaction**, **grouting**, or **ground improvement** can enhance foundation stability.

- In cases where weak soils are present, **deep foundation systems** (e.g., piles) may be necessary to transfer loads to more stable ground.

2. **Zoned Embankment Design**:

- Tailings dams should be designed with different zones of material to optimize seismic stability.

For example:

- A **low-permeability core** can help reduce seepage and limit pore pressure buildup during an earthquake.

- A **free-draining downstream shell** helps dissipate pore water pressures generated by seismic shaking, reducing the risk of liquefaction and slope failure.

- The **downstream construction method** is generally preferred in seismic regions due to its inherent stability, as each new layer of the dam is supported by previously compacted layers of the embankment rather than loose tailings.

3. **Liquefaction Mitigation**:

- To mitigate liquefaction risks, tailings and embankment materials should be **densified** through **compaction** or **vibro-compaction** techniques. Densification increases the material's resistance to liquefaction by improving its shear strength and reducing the likelihood of pore pressure buildup. - **Drains** and **cutoff walls** can be installed to reduce the saturation level of tailings and prevent pore pressure buildup during seismic shaking.

4. **Seismic Drainage Systems**:

- Tailings dams in seismic zones must be equipped with drainage systems that can handle increased pore pressures during earthquakes. **Horizontal drains**, **chimney drains**, and **toe drains** are common features designed to dissipate pore water pressures and lower the phreatic surface during seismic events.

- In regions prone to liquefaction, **wick drains** can be installed to expedite the consolidation of loose, saturated tailings, reducing the risk of pore pressure buildup during an earthquake.

5. **Freeboard and Crest Design**: