Developing an audit procedure for metallurgical accounting involves several steps. Here's a possible approach:

- Define the scope of the audit: Start by defining the scope of the audit, including the types of processes, products, and materials that will be audited. Consider the specific needs of the organization and the risks associated with metallurgical accounting.

- Identify the key performance indicators (KPIs): Identify the key performance indicators (KPIs) that are relevant to metallurgical accounting. These could include metrics such as recovery rates, yield, quality control, and efficiency.

- Review documentation and procedures: Review the organization's metallurgical accounting documentation and procedures, including its accounting policies, operating procedures, and technical specifications. Evaluate the adequacy of the system in ensuring accurate accounting.

- Inspect physical equipment: Inspect the physical equipment used in metallurgical accounting, including sampling equipment, laboratory instruments, and data collection systems. Ensure they are functioning correctly and produce accurate data.

- Verify calculations and data accuracy: Verify the accuracy of metallurgical accounting calculations and data by cross-checking data from various sources and comparing it to industry standards.

- Test internal controls: Test the effectiveness of the organization's internal controls in preventing errors and fraud in metallurgical accounting. Ensure there is segregation of duties, regular review of transactional data, and verification of results.

- Assess risks and evaluate findings: Assess the risks identified during the audit and evaluate the findings to determine the impact of any deficiencies. Provide recommendations for improvements where necessary.

- Report and follow up: Finally, report on the findings of the audit and provide recommendations for corrective action. Follow up to ensure that corrective action has been taken, and continue to monitor the system to ensure continued accuracy and effectiveness.

By following these steps, you can develop an audit procedure for metallurgical accounting that is thorough, effective, and tailored to the needs of the organization.

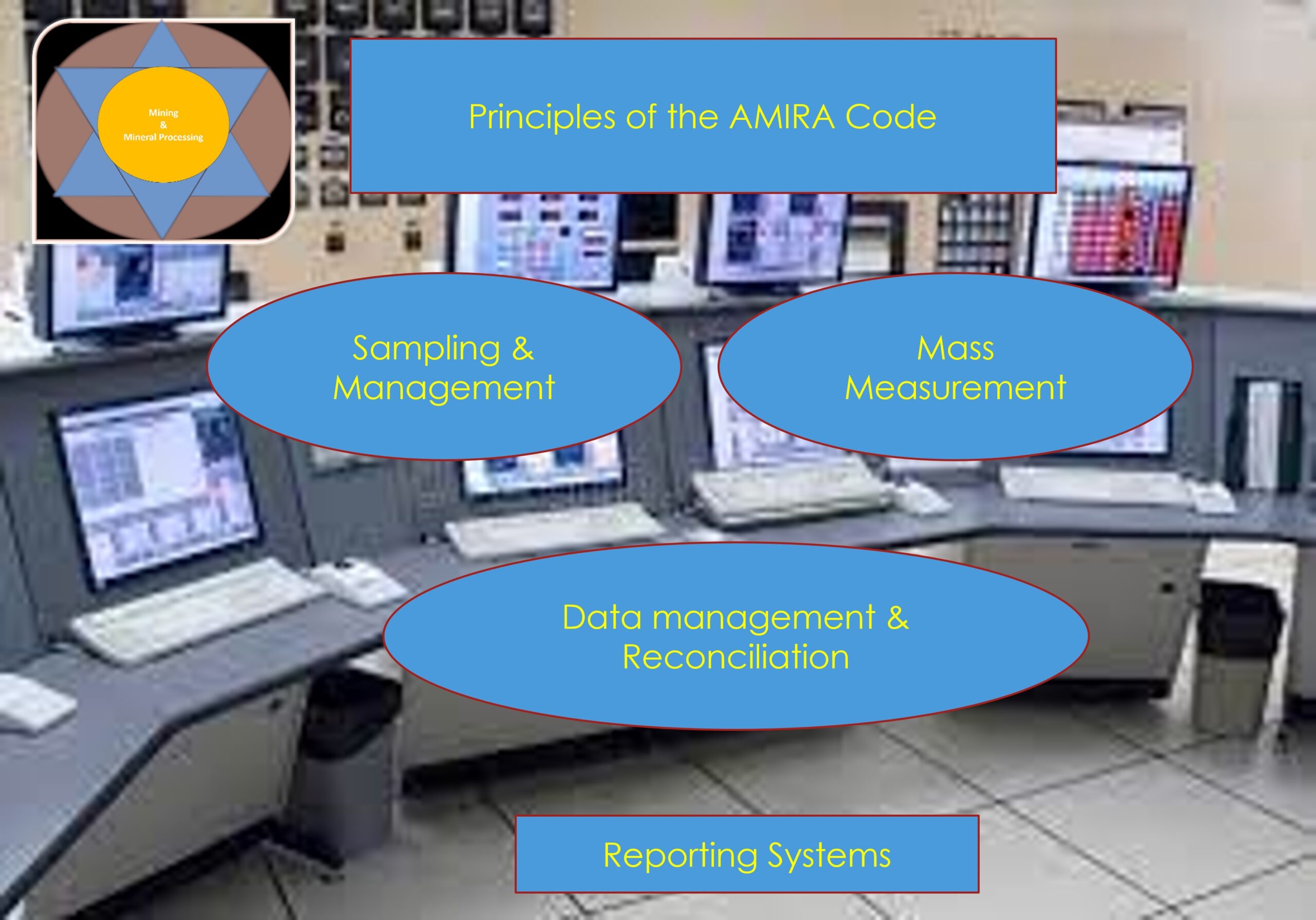

AMIRA Code of Practice

Auditing a metallurgical operation to assess its compliance with the requirements of the AMIRA Code of Practice is not a trivial matter and will require a significant amount of time and resources from a multi-disciplined team.

The AMIRA Code of Practice provides a framework for the accurate measurement and reporting of metallurgical data, including sampling, assaying, and data interpretation. It is essential to ensure that the organization is compliant with these requirements to maintain accuracy and integrity in the metallurgical data.

A comprehensive audit of a metallurgical operation to assess compliance with the AMIRA Code of Practice will likely require the involvement of experts in several areas, including:

- Metallurgical engineering: To evaluate the processes, equipment, and materials used in the metallurgical operation and assess their compliance with the code.

- Sampling and assaying: To evaluate the sampling procedures and analytical methods used to measure metallurgical data and assess their compliance with the code.

- Quality control: To evaluate the quality control measures in place to ensure the accuracy and consistency of metallurgical data and assess their compliance with the code.

- Data management: To evaluate the data management systems used to collect, store, and report metallurgical data and assess their compliance with the code.

The audit team will need to conduct a detailed review of the organization's documentation and procedures, inspect physical equipment, verify calculations and data accuracy, test internal controls, and assess risks and evaluate findings. The team will also need to report on the findings of the audit and provide recommendations for corrective action.

Overall, auditing a metallurgical operation to assess compliance with the AMIRA Code of Practice is a complex and time-consuming process that requires a multi-disciplined team with specialized knowledge and skills. However, it is essential to ensure the accuracy and integrity of metallurgical data, and the benefits of a thorough audit can outweigh the costs.

Mass measurement

Checking every mass measurement used for metal accounting purposes on each of the separate plants is a critical part of ensuring the accuracy and integrity of the metallurgical data. This involves inspecting the actual measurement procedures and equipment used, as well as checking all the calibration procedures, both internal and external, and records of each item of mass measurement equipment. Here are some steps that can be taken to carry out this task:

- Identify all mass measurement equipment: Start by identifying all the mass measurement equipment used in each plant, including scales, weighbridges, and other measurement devices.

- Review the calibration procedures: Review the calibration procedures used for each piece of mass measurement equipment, including both internal and external calibrations. Ensure that they are up to date and are performed regularly.

- Inspect the measurement procedures: Inspect the actual measurement procedures used for each piece of equipment to ensure that they are being used correctly and consistently. Check for any deviations from the established procedures and assess their impact on the accuracy of the measurements.

- Verify the accuracy of the measurements: Verify the accuracy of the measurements by cross-checking data from various sources and comparing it to industry standards. Evaluate the adequacy of the system in ensuring accurate accounting.

- Review the records: Review the records of each item of mass measurement equipment, including calibration records, maintenance logs, and any other relevant documentation. Ensure that they are complete, accurate, and up to date.

- Assess risks and evaluate findings: Assess the risks identified during the review and evaluation of the mass measurement equipment and evaluate the findings to determine the impact of any deficiencies. Provide recommendations for improvements where necessary.

- Report and follow up: Finally, report on the findings of the audit and provide recommendations for corrective action. Follow up to ensure that corrective action has been taken and continue to monitor the system to ensure continued accuracy and effectiveness.

By following these steps, you can check every mass measurement used for metal accounting purposes on each of the separate plants, including inspections of the actual measurement procedures and the equipment used, as well as checking all the calibration procedures, both internal and external, and records of each item of mass measurement equipment. This will help ensure the accuracy and integrity of the metallurgical data and provide assurance to stakeholders that the organization is complying with the relevant standards and regulations.

Accounting sample

Checking every accounting sample taken on each plant is essential to ensure the accuracy and integrity of the metallurgical data. This involves inspecting the sampling equipment and schedules, as well as the sample management procedures for delivering the accounting sample to the analytical laboratory, storing it on receipt at the laboratory, and preparing the analytical sample. Here are some steps that can be taken to carry out this task:

- Identify all accounting sample points: Start by identifying all the accounting sample points in each plant, including locations where samples are taken and analyzed.

- Review the sampling equipment and schedules: Review the sampling equipment and schedules used for each accounting sample point. Ensure that the equipment is properly maintained, calibrated, and suitable for the purpose, and that the schedules are appropriate for the process.

- Inspect the sample management procedures: Inspect the procedures used for delivering the accounting sample to the analytical laboratory, storing it on receipt at the laboratory, and preparing the analytical sample. Ensure that they are being followed correctly and consistently.

- Evaluate the adequacy of the system: Evaluate the adequacy of the system in ensuring accurate and representative sampling and analysis, such as verifying the number of samples taken per tonnage, which can impact the statistical reliability of the results.

- Review the records: Review the records of each accounting sample, including the sample collection record, sample transfer record, sample receipt record, and any other relevant documentation. Ensure that they are complete, accurate, and up to date.

- Assess risks and evaluate findings: Assess the risks identified during the review and evaluation of the accounting sample system and evaluate the findings to determine the impact of any deficiencies. Provide recommendations for improvements where necessary.

- Report and follow up: Finally, report on the findings of the audit and provide recommendations for corrective action. Follow up to ensure that corrective action has been taken and continue to monitor the system to ensure continued accuracy and effectiveness.

By following these steps, you can check every accounting sample taken on each plant, including inspecting the sampling equipment and schedules and the sample management procedures for delivering the accounting sample to the analytical laboratory, storing it on receipt at the laboratory, and preparing the analytical sample. This will help ensure the accuracy and integrity of the metallurgical data and provide assurance to stakeholders that the organization is complying with the relevant standards and regulations.

Reviewing the existing analytical procedures

Reviewing the existing analytical procedures against the prescribed procedures and comparing them with accepted best practices is a critical aspect of the metallurgical accounting audit. This includes inspecting the laboratory as a whole, as well as its records, calibration standards, and procedures for preparing, storing, and using them. Here are some steps that can be taken to carry out this task:

- Identify all analytical procedures: Start by identifying all the analytical procedures used in the laboratory, including sample preparation, sample analysis, and data interpretation.

- Review the prescribed procedures: Review the prescribed procedures for each analytical procedure, including those outlined in the AMIRA Code of Practice, and ensure that they are being followed correctly and consistently.

- Evaluate best practices: Evaluate accepted best practices for each analytical procedure and compare them to the laboratory's current practices. Determine if there are any areas for improvement.

- Inspect the laboratory: Inspect the laboratory to ensure that it is being maintained at an appropriate level of cleanliness, organization, and safety. Ensure that equipment is properly calibrated and maintained, and that supplies are adequate and stored appropriately.

- Review calibration standards and procedures: Review the laboratory's calibration standards and procedures, including both internal and external calibrations, and ensure that they are up to date and being followed correctly.

- Evaluate sample preparation and analysis procedures: Evaluate the laboratory's sample preparation and analysis procedures to ensure that they are being carried out correctly and consistently. Evaluate the accuracy and precision of the results.

- Assess risks and evaluate findings: Assess the risks identified during the review and evaluation of the laboratory's analytical procedures and practices and evaluate the findings to determine the impact of any deficiencies. Provide recommendations for improvements where necessary.

- Review records: Review the laboratory's records, including sample analysis records, calibration records, and any other relevant documentation. Ensure that they are complete, accurate, and up to date.

- Report and follow up: Finally, report on the findings of the audit and provide recommendations for corrective action. Follow up to ensure that corrective action has been taken and continue to monitor the laboratory to ensure continued accuracy and effectiveness.

By following these steps, you can review the existing analytical procedures against the prescribed procedures and compare them with accepted best practices. You can also inspect the laboratory as a whole, as well as its records, calibration standards, and procedures for preparing, storing, and using them. This will help ensure the accuracy and integrity of the metallurgical data and provide assurance to stakeholders that the organization is complying with the relevant standards and regulations.

Comparing the physical stockpiles

Comparing the physical stockpiles of concentrate, reverts, cast metal, and furnace inventories against the book stocks is an important aspect of the metallurgical accounting audit for smelters. Here are some steps that can be taken to carry out this task:

- Identify the stockpiles: Start by identifying all the physical stockpiles of concentrate, reverts, cast metal, and furnace inventories.

- Compare to book stocks: Compare the physical stockpiles to the book stocks, including accounting records and production reports, to identify any discrepancies.

- Investigate discrepancies: Investigate any discrepancies found between the physical stockpiles and the book stocks. Determine the cause of the discrepancy and whether there is any potential loss of metal or material.

- Verify stockpile weights: Verify the weights of the physical stockpiles by using weighing scales and other measuring devices. Ensure that the weighing scales are calibrated and maintained according to the prescribed procedures.

- Assess accuracy of measurements: Assess the accuracy of the measurements taken by comparing them to the book stocks and any other relevant data.

- Verify smelting processes: Verify that the smelting processes are being carried out correctly and consistently. Ensure that the appropriate amounts of concentrate, reverts, and other materials are being added to the furnaces.

- Review inventory procedures: Review the inventory procedures, including procedures for recording and tracking inventory levels, and ensure that they are being followed correctly and consistently.

- Report and follow up: Finally, report on the findings of the audit and provide recommendations for corrective action. Follow up to ensure that corrective action has been taken and continue to monitor the smelter to ensure continued accuracy and effectiveness.

By following these steps, you can compare the physical stockpiles of concentrate, reverts, cast metal, and furnace inventories against the book stocks. You can also investigate discrepancies found, verify the weights of the physical stockpiles, assess the accuracy of the measurements, verify the smelting processes, review inventory procedures, and report on the findings of the audit. This will help ensure the accuracy and integrity of the metallurgical data and provide assurance to stakeholders that the organization is complying with the relevant standards and regulations.

Conducting a review of the metal accounting records

Conducting a review of the metal accounting records is an important step in the metallurgical accounting audit. Here are some steps that can be taken to carry out this task:

- Identify the metal accounting records: Start by identifying all the metal accounting records for the plant, including the accounting books, production reports, and other relevant documents.

- Review the records for the current year: Review the metal accounting records for each accounting period in the current year. Ensure that the records are complete, accurate, and consistent with the prescribed procedures.

- Review the records for previous years: Review the metal accounting records for several previous years to identify any trends or patterns that may indicate problems or inconsistencies.

- Verify the accuracy of the records: Verify the accuracy of the metal accounting records by cross-checking them with other relevant data, such as production reports, laboratory results, and physical inventories.

- Investigate discrepancies: Investigate any discrepancies found between the metal accounting records and other relevant data. Determine the cause of the discrepancy and whether there is any potential loss of metal or material.

- Assess compliance with standards: Assess compliance with the relevant standards and regulations, including the AMIRA Code of Practice and accepted best practices.

- Report and follow up: Finally, report on the findings of the audit and provide recommendations for corrective action. Follow up to ensure that corrective action has been taken and continue to monitor the plant to ensure continued accuracy and effectiveness.

By following these steps, you can conduct a complete review of the metal accounting records for the plant for each accounting period in the current year as well as the figures for several previous years. This will help ensure the accuracy and integrity of the metallurgical data and provide assurance to stakeholders that the organization is complying with the relevant standards and regulations.

Checking the metal accounting records

Checking the metal accounting records of all the individual plants and the way in which these individual accounting reports are used to compile the overall metal accounting report for the entire operation is an important aspect of the metallurgical accounting audit. Here are some steps that can be taken to carry out this task:

- Identify the metal accounting reports: Start by identifying all the metal accounting reports for each individual plant, including the accounting books, production reports, and other relevant documents.

- Review the individual plant reports: Review the metal accounting records for each individual plant to ensure that they are complete, accurate, and consistent with the prescribed procedures.

- Verify the accuracy of the individual plant reports: Verify the accuracy of the metal accounting records for each individual plant by cross-checking them with other relevant data, such as production reports, laboratory results, and physical inventories.

- Review the overall metal accounting report: Review the overall metal accounting report for the entire operation to ensure that it has been compiled correctly using the individual plant reports.

- Verify the accuracy of the overall metal accounting report: Verify the accuracy of the overall metal accounting report by cross-checking it with the individual plant reports and other relevant data.

- Investigate discrepancies: Investigate any discrepancies found between the individual plant reports and the overall metal accounting report. Determine the cause of the discrepancy and whether there is any potential loss of metal or material.

- Assess compliance with standards: Assess compliance with the relevant standards and regulations, including the AMIRA Code of Practice and accepted best practices.

- Report and follow up: Finally, report on the findings of the audit and provide recommendations for corrective action. Follow up to ensure that corrective action has been taken and continue to monitor the operation to ensure continued accuracy and effectiveness.

By following these steps, you can check the metal accounting records of all the individual plants and the way in which these individual accounting reports are used to compile the overall metal accounting report for the entire operation. This will help ensure the accuracy and integrity of the metallurgical data and provide assurance to stakeholders that the organization is complying with the relevant standards and regulations.

Handling errors and correcting interim assay results

Handling errors and correcting interim assay results, reconciling accounting figures at custody transfer points, measuring inventory figures, and establishing authority levels for signing off on various reports are all important aspects of metallurgical accounting. Here are some specific procedures that can be used to address each of these areas:

- Handling errors and correcting interim assay results: Procedures should be in place for handling errors in assay results and correcting them in a timely manner. This may involve reviewing assay results for outliers, verifying sample preparation and analysis methods, and re-analyzing samples if necessary. Corrective action should be documented and communicated to all relevant parties.

- Reconciliation of accounting figures at custody transfer points: Custody transfer points are locations where ownership of the material changes hands. Procedures should be in place to ensure that accounting figures are reconciled at these points to prevent loss or gain of material. This may involve verifying the accuracy of measuring equipment, confirming that the correct material is being transferred, and reconciling data from both the sending and receiving locations.

- Measurement of inventory figures: Procedures should be in place to ensure that inventory figures are measured accurately and consistently. This may involve regularly calibrating measuring equipment, conducting physical inventory counts, and reconciling inventory data with accounting records.

- Authority levels for signing off on various reports: Procedures should be in place to establish authority levels for signing off on various reports, such as production reports and metal accounting reports. These levels should be clearly defined, documented, and communicated to all relevant parties.

In addition to these specific procedures, it is also important to assess compliance with relevant standards and regulations, such as the AMIRA Code of Practice and accepted best practices. Auditors should review all relevant documentation, such as standard operating procedures and training records, to ensure that the organization is following established procedures and that employees are properly trained.

By paying particular attention to the handling of errors and correction of interim assay results, reconciling accounting figures at custody transfer points, measuring inventory figures, and establishing authority levels for signing off on various reports, auditors can help ensure the accuracy and integrity of metallurgical accounting data.

Overall accounting report

It is important to audit the way in which the overall accounting report informed the operation's financial accounting reports. This will help ensure that the financial statements accurately reflect the company's financial position and performance.

To audit this aspect of the accounting process, the auditors should review the accounting policies and procedures in place, as well as the system for integrating the metallurgical accounting data into the financial accounting system. This may involve examining the software and technology used to collect, store, and report financial data, as well as reviewing documentation related to financial transactions and accounting entries.

Auditors should also verify that the metallurgical accounting data is accurately reflected in the financial accounting reports, such as the balance sheet and income statement. This may involve comparing the metallurgical accounting data to the financial data reported in the company's financial statements, as well as reviewing the methodology used to calculate the costs of production and inventory valuation.

Additionally, the auditors should assess whether any adjustments or reclassifications were made to the metallurgical accounting data in order to conform to financial accounting standards or principles. If such adjustments were made, the auditors should review the rationale for these adjustments and ensure that they are properly disclosed in the financial statements.

Overall, auditing the integration of metallurgical accounting data into the financial accounting system requires a thorough understanding of both the metallurgical and financial accounting processes. By reviewing accounting policies and procedures, examining software and technology, verifying the accuracy of financial reports, and assessing adjustments made to the metallurgical accounting data, auditors can help ensure that the company's financial statements are accurate and reliable.

Classify the risks

A general framework for classifying risks associated with non-compliance are as follows:

- Financial risk: Non-compliance with accounting standards and regulations can result in financial risks such as penalties, fines, litigation, and reputational damage.

- Operational risk: Non-compliance with operational procedures and standards can result in risks such as production shutdowns, equipment failures, quality issues, and supply chain disruptions.

- Legal and regulatory risk: Non-compliance with laws and regulations can result in legal and regulatory risks such as fines, penalties, and legal action.

- Reputational risk: Non-compliance with ethical and social standards can result in reputational risks such as loss of customer trust, negative publicity, and reduced brand value.

- Information security risk: Non-compliance with information security standards can result in risks such as data breaches, loss of confidential information, and damage to company reputation.

- Environmental risk: Non-compliance with environmental regulations can result in risks such as fines, penalties, and reputational damage.

- Health and safety risk: Non-compliance with health and safety standards can result in risks such as accidents, injuries, and health issues for employees, customers, and the general public.

Classifying risks associated with non-compliance can help the organization prioritize and manage the risks effectively.

A description of problems that can be encountered using a traditional excel based spreadsheet system

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article. https://accounts.binance.info/pt-PT/register-person?ref=KDN7HDOR

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.com/register?ref=IHJUI7TF

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article. https://accounts.binance.info/de-CH/register?ref=UM6SMJM3

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

As a Newbie, I am continuously searching online for articles that can benefit me. Thank you

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.info/de-CH/register-person?ref=UM6SMJM3

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.info/si-LK/register?ref=V2H9AFPY

Some truly nice and useful information on this web site, as well I believe the design and style has good features.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.com/en/register?ref=JHQQKNKN

yes

1. https://www.mineralprocessing.co.za/2531/what-is-metallurgical-accounting-and-how-can-we-use-it-to-improve-productivity/metal-accounting/basdew/

2. https://www.mineralprocessing.co.za/312/plant-sampling-plan-for-metallurgical-accounting/metal-accounting/basdew/

3. https://www.mineralprocessing.co.za/505/are-you-upto-date-with-metallurgical-accounting-best-practice-and-current-trends/tsf/basdew/

4. https://www.mineralprocessing.co.za/268/sampling-for-mineral-processing/metal-accounting/basdew/

5. https://www.mineralprocessing.co.za/274/mass-balancing-in-mineral-processing/metal-accounting/basdew/

6. https://www.mineralprocessing.co.za/1519/robotics-and-process-automation-rpa-in-mining-mineral-processing/tsf/basdew/

7. https://www.mineralprocessing.co.za/1456/digital-transformation-in-the-mineral-processing-industry/tsf/basdew/

8. https://www.mineralprocessing.co.za/1407/management-challenges-with-regards-to-sampling-and-analysis/tsf/basdew/

9. https://www.mineralprocessing.co.za/1372/productivity-enhancements-industry-trends-and-best-practice/tsf/basdew/

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.com/pt-PT/register?ref=DB40ITMB

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.com/ru/register?ref=V3MG69RO

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Wonderful blog! I found it while browsing on Yahoo News. Do you have any suggestions on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Appreciate it

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your place is valueble for me. Thanks!…

You are a very capable individual!

Thank you for some other informative web site. Where else could I get that type of information written in such an ideal means? I have a undertaking that I am just now running on, and I’ve been at the glance out for such information.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

You are my aspiration, I have few blogs and occasionally run out from to brand.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

It is a pleasure to read this weblog, thanks to its up-to-date information and interesting posts. Look into my web page YW9 for some really good points and find out more about Thai-Massage.

Thank you for your feedback. Much appreciated.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you for your feedback. Much appreciated. You can contact me on whattsapp 027728602564

Your article helped me a lot, is there any more related content? Thanks!

Thank you. Check out the following:

1. https://www.mineralprocessing.co.za/312/plant-sampling-plan-for-metallurgical-accounting/metal-accounting/basdew/

2.https://www.mineralprocessing.co.za/505/are-you-upto-date-with-metallurgical-accounting-best-practice-and-current-trends/tsf/basdew/

3.https://www.mineralprocessing.co.za/274/mass-balancing-in-mineral-processing/metal-accounting/basdew/

4.https://www.mineralprocessing.co.za/268/sampling-for-mineral-processing/metal-accounting/basdew/

Elias Pobe

Executive Head: Metallurgy SA at Harmony Gold Limited

Hi Besdew. We must catch up on your work sometime.

Basdew Rooplal

Managing Director at Supergold

Hi Elias, hope you are keeping well. Thank you. Have a 3 day workshop on Metallurgical Accounting. Really appreciate your comments.