Sensor based Ore sorting - An introduction

Trending

**Sensor-Based Ore Sorting: A Game Changer in Mineral Processing**Sensor-based ore sorting (SBOS) is transforming the mining industry by enabling smarter, more efficient, and environmentally responsible operations. By using advanced sensing technologies to analyze and separate ore from waste in real time, this approach delivers major improvements in grade control, throughput, and resource utilization.

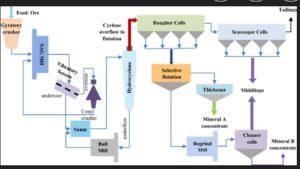

### How It Works

Sensor-based sorting uses technologies such as X-ray transmission (XRT), near-infrared (NIR), laser-induced breakdown spectroscopy (LIBS), and optical cameras to assess the composition or properties of individual rocks on a conveyor belt. Once a target mineral signature or density threshold is detected, high-speed air jets or mechanical devices divert the valuable material from the waste stream.

### Benefits *

**Improved Resource Recovery**:

Valuable ore can be extracted earlier in the process, improving recovery rates.

* **Reduced Energy and Water Use**:

Pre-concentration at an early stage means downstream crushing, grinding, and flotation circuits process less waste.

* **Lower Operating Costs**:

Sorting reduces transport, grinding, and tailings disposal costs.

* **Smaller Environmental Footprint**:

Less waste generated and a reduced need for chemicals, water, and energy.

* **Increased Throughput**:

Plants can handle more feed while maintaining or improving concentrate quality.

### Ideal Applications

* Low-grade ore bodies or marginal deposits.

* Operations where haulage and processing costs are high.

* Mines aiming to extend life of deposit through better resource utilization.

* Projects seeking ESG (Environmental, Social, and Governance) improvements.

### Challenges

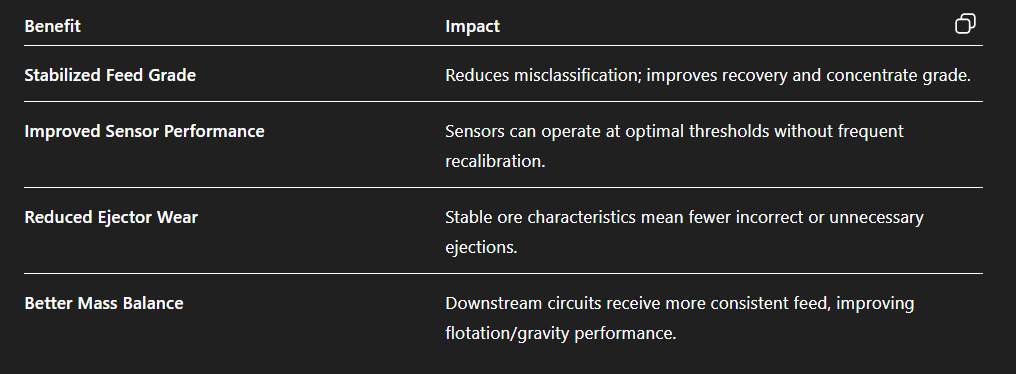

* Requires consistent ore characteristics for optimal performance.

* Capital cost for installation can be significant.

* Needs careful calibration and maintenance to avoid sorting losses.

* Fine particles (<10 mm="mm">

How Sensor based Ore sorting works?

Trending

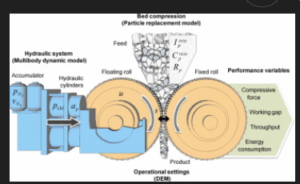

High Pressure Grinding Roll Crushers – HPGR: Trends and Best Practice

### 🔍 **How Sensor-Based Ore Sorting Works**Sensor-Based Ore Sorting (SBOS) is a dry, automated process that detects and separates ore from waste rock based on measurable physical or chemical properties.

Here's a step-by-step breakdown:

--- ### **1. Feed Preparation**

* **Crushing and Screening**:

ROM (run-of-mine) material is crushed and screened to a specific particle size—usually between **10 mm and 100 mm**—optimal for sorting.

* **Feed Uniformity**: Material must be evenly spread on a fast-moving **conveyor belt** in a single layer for accurate scanning.

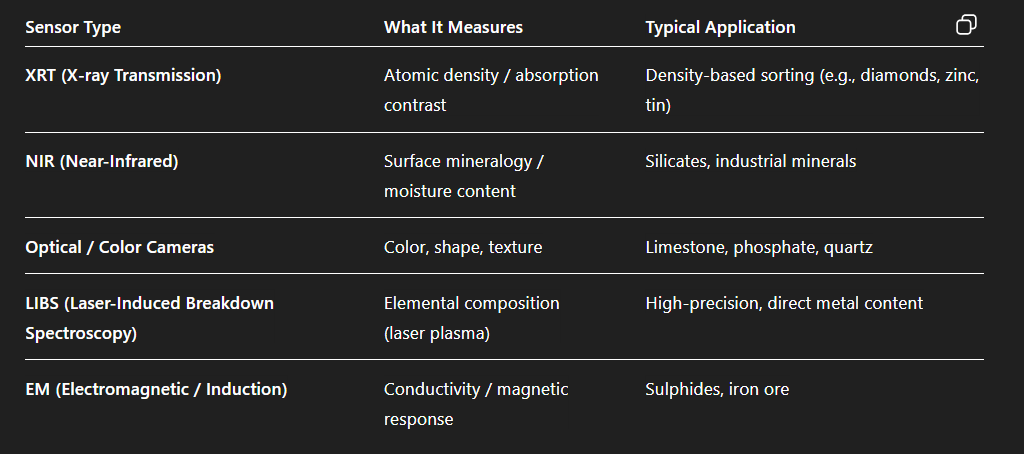

--- ### **2. Sensing/Detection** As the rocks move along the conveyor, one or more types of **sensors** scan each particle:

The sensors create a digital profile of each rock in milliseconds.

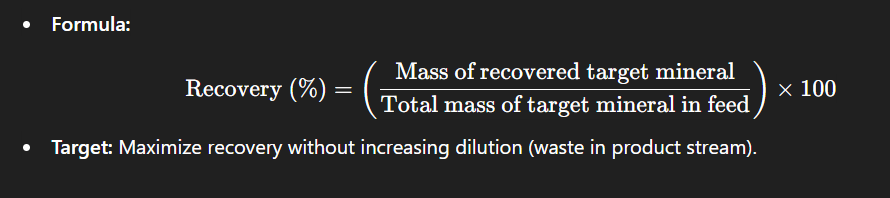

--- ### **3. Decision-Making (AI or Rule-Based Algorithms)** * Software compares the detected signatures against pre-set thresholds for valuable ore vs. waste.

* Real-time classification is performed using AI or rule-based decision logic.

* Each rock is tagged for either **accept** (ore) or **reject** (waste).

--- ### **4. Physical Separation**

* **Air Jets** (or mechanical deflectors) activate in precise timing to eject selected rocks into different chutes.

* High-speed valves blow air bursts to deflect rocks from the waste stream into the ore stream—or vice versa.

* This separation happens at line speeds of **2–3 m/s**, handling up to **150–300 tons/hour** per sorter.

--- ### **5. Post-Sorting Handling** * Sorted fractions (concentrate and reject) are conveyed to different downstream processes—either sent for further processing or discarded.

--- ### ✅ **Key Success Factors**

* Uniform feed presentation.

* Accurate sensor calibration.

* Regular maintenance and cleaning of sensors.

* Integration with upstream and downstream plant control systems. -

Ideal Application for sensor baed ore sorting

Sensor-based ore sorting isn’t a one-size-fits-all solution—it thrives under specific geological and operational conditions.

Here’s where it truly shines:

--- ### **1. Low-Grade or Marginal Ore Bodies**

* **Why**: Sorting allows early removal of waste, upgrading the feed grade before costly processing.

* **Example**: Processing low-grade copper or gold ores where traditional methods are uneconomical.

--- ### **2. Operations with High Haulage or Processing Costs**

* **Why**: Removing waste rock early reduces transport, crushing, milling, and tailings disposal costs.

* **Example**: Remote open-pit mines where trucking costs are high.

--- ### **3. Orebodies with Strong Physical or Chemical Contrast**

* **Why**: Effective sorting requires clear differences in properties (e.g., density, color, elemental content) between ore and waste.

* **Example**: Tin vs. quartz, chromite vs. serpentine, or limestone vs. shale.

--- ### **4. Brownfield Expansions & Plant Debottlenecking**

* **Why**:

Installing a sorter upstream of an overloaded plant can increase throughput by removing waste.

* **Example**:

Existing plant running at capacity—sorting reduces load on grinding and flotation circuits.

--- ### **5. Tailings Reprocessing**

* **Why**: Historical tailings may contain recoverable metals. Sorting can selectively recover value from what was once discarded.

* **Example**:

Legacy gold tailings with coarse residuals.

--- ### **6. ESG-Driven Projects**

* **Why**:

Sorting reduces energy, water, and chemical use, helping miners meet sustainability targets and permitting requirements.

* **Example**:

Greenfield projects in environmentally sensitive regions. --

- ### **7. Life-of-Mine Extension**

* **Why**: Marginal zones or lower-grade material that was previously subeconomic can be profitably mined.

* **Example**:

Reassessing cut-off grades using sorting to upgrade material.

Sensor based ore sorting for Low grade ore bodies

Sensor-based ore sorting offers a powerful solution for unlocking value from **low-grade or marginal ore bodies**—deposits that might otherwise be uneconomic to mine using conventional methods.

--- ### 🔎 **Why It Works** In low-grade deposits, a large portion of the mined material is waste.

Traditional processing treats the entire ore stream, resulting in:

* High energy and water use

* Low metal recovery

* Elevated operating costs **Sensor-based sorting** allows for **early removal of waste** before it reaches the grinding and flotation circuits.

This pre-concentration:

* Increases the average grade of the material being processed * Reduces wear and energy demand in downstream equipment

* Improves the economics of processing lower-grade material

--- ### 💡 **Key Benefits**

* **Boosts Economic Viability**:

Turns previously unprofitable resources into viable operations.

* **Reduces Cut-Off Grade**: More material can be mined and processed profitably, extending the mine’s life.

* **Defers Major Capital**:

Sorting can reduce load on existing plants, postponing the need for expensive expansions.

* **Improves Mill Feed Quality**:

Higher-grade feed improves recovery and reduces reagent consumption.

--- ### ✅ **Success Factors**

* Sufficient **physical or chemical contrast** between ore and waste (e.g., density, color, elemental content).

* Coarser particles present (ideally 10–100 mm range).

* Well-characterized orebody with minimal variability.

--- ### 📍 **Real-World Example**

At the **Tungsten mine at Wolfram Camp (Australia)**, TOMRA’s XRT sorting technology was used to upgrade low-grade feed. Sorting removed barren quartz before milling, significantly boosting feed grade and making the operation viable where conventional methods would fail.

--- Sensor-based sorting gives operators a strategic edge—especially in tight-margin scenarios—by converting subeconomic ore into profitable product.

Real World Exmple

TOMRA XRT Sorting at San Rafael Tin Mine (Peru)**

One of the most cited success stories of sensor-based ore sorting comes from the **San Rafael tin mine** in southern Peru, operated by MINSUR. It illustrates how SBOS can **transform a mature, declining-grade operation** into a more efficient and profitable one.

--- ### 🛠️ **Project Background**

* **Mine**: San Rafael Tin Mine

* **Operator**:

MINSUR * **Commodity**:

Tin * **Challenge**:

Declining head grade and increasing operational costs

* **Solution**: Install a sensor-based ore sorting plant using **TOMRA X-ray Transmission (XRT) technology**

--- ### ⚙️ **How the System Was Implemented**

* ROM material is crushed and screened to a sortable size fraction (\~10–80 mm).

* XRT sorters detect differences in **atomic density** between tin-bearing cassiterite and barren waste rock (e.g., quartz).

* Rocks are automatically separated by air jets into ore and waste streams before reaching the main processing plant.

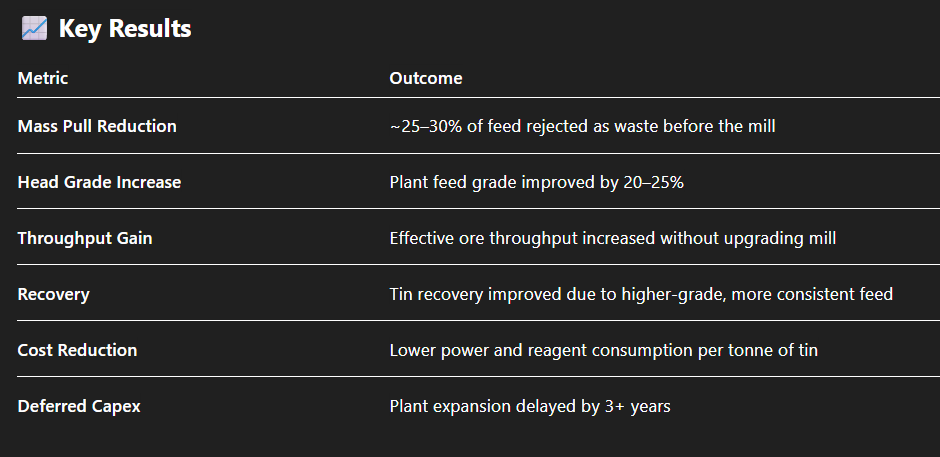

--- ### 📈 **Key Results**

* **Tin Recovery Increased** by \~6% in the fine circuit.

* **Waste Rejection** of up to 20% from the ROM feed.

* **Operational Cost Reduction** by lowering load on crushing, milling, and flotation circuits.

* **Extended Mine Life** through processing of previously uneconomic material.

* **Improved Water and Energy Efficiency** due to lower tonnage processed downstream.

--- ### ✅ **Why It Worked**

* Strong **density contrast** between cassiterite (high-density) and gangue (low-density).

* Consistent particle size and mineralogy in the sortable fraction.

* Integration with existing plant infrastructure and automation systems.

--- This case proves that **sensor-based sorting is not just for greenfield projects**—it’s a viable, retrofit-ready solution that **adds immediate value** to aging operations and marginal deposits.

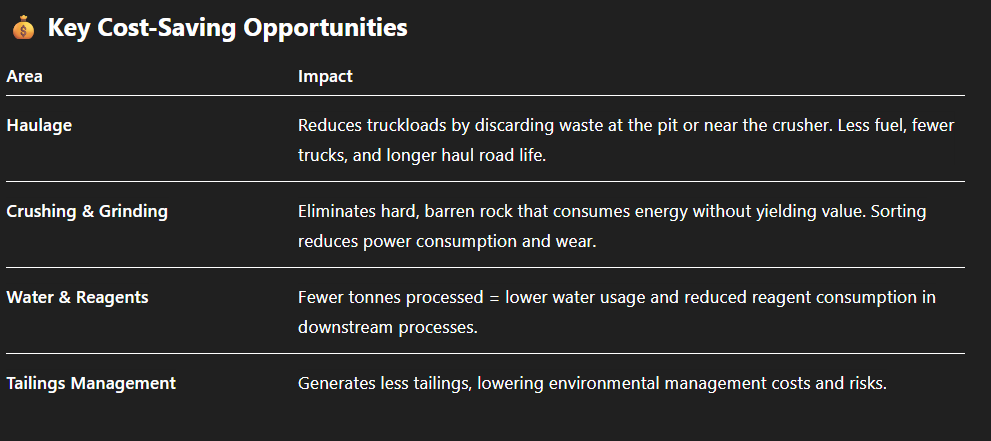

Operations with High Haulage or Operational Cost

Sensor-based ore sorting is a highly strategic tool for **mines where logistics, energy, and processing costs are major cost drivers**—especially in **remote locations**, **deep pits**, or **operations with expensive grinding circuits**.

--- ### 🔍 **Why It's Effective** In operations where moving or processing every tonne is costly, it’s far more economical to **reject waste early**.

Sensor-based sorting does just that—**removing barren or low-value rock before transport or full beneficiation**, which drastically cuts overall costs.

--- ### 💰 **Key Cost-Saving Opportunities**

--- ### 🏔️ **Ideal Settings**

* **Remote open-pit mines** with long haul distances.

* **Underground mines** with costly hoisting limits.

* **Mines with hard host rock** that strains comminution equipment.

* **Operations with tight energy or water constraints**.

--- ### 📍 **Example: Renison Bell Tin Mine (Australia)**

* **Problem**: High underground mining and processing costs limited economic viability.

* **Solution**: Installed TOMRA XRT sorters at surface to pre-concentrate ore before sending it to the processing plant.

* **Outcome**: Reduced haulage and mill tonnage by removing up to 30% barren rock. Cut costs, extended mine life, and improved tin recovery.

--- ### ✅ **Bottom Line** In high-cost operations, **every tonne of waste processed is wasted money**. Sensor-based sorting removes that burden early, improving net metal production per dollar spent.

Real World Example

--- ### 🏗️ **Background**

* **Mine**: Renison Bell Tin Mine

* **Location**: Tasmania, Australia

* **Operator**: Metals X (through Bluestone Mines Tasmania JV)

* **Commodity**: Tin (Sn)

* **Challenge**:

* High **underground mining and hoisting costs**

* Rising **energy and reagent consumption** in processing

* Ore dilution leading to reduced feed grades

* Need to extend mine life and improve profitability

--- ### 🛠️ **Solution:

TOMRA XRT Ore Sorters** To improve operational efficiency, **sensor-based XRT sorting units** were installed at the surface to treat ore from underground before it reached the mill.

#### ✨ XRT Sorting Highlights:

* Utilized **X-ray transmission (XRT)** to distinguish high-density cassiterite (tin ore) from low-density waste like quartz and host rock.

* Crushed ore (16–80 mm fraction) was passed through the sorter.

* Waste was ejected via high-speed air jets before the material entered the mill.

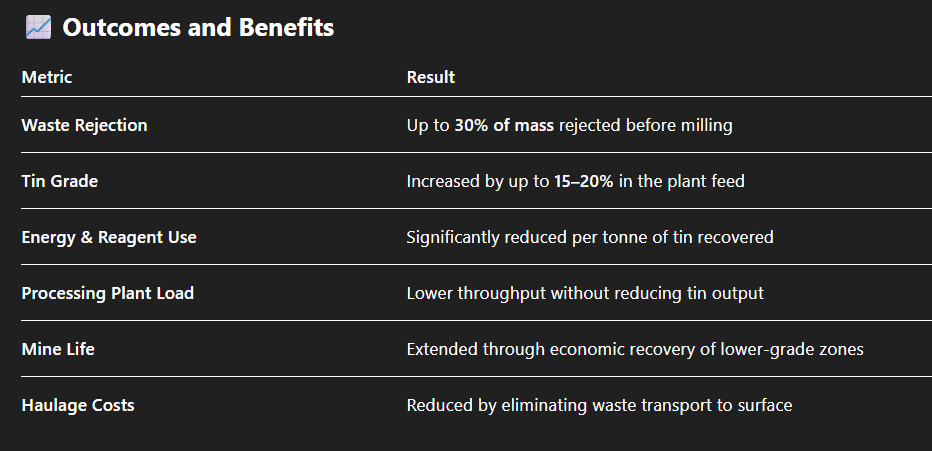

--- ### 📈 **Outcomes and Benefits**

--- ### ✅ **Why It Worked**

* Strong **density contrast** between cassiterite and gangue made XRT sorting ideal.

* Tight **underground logistics and hoisting limitations** created urgency to reduce transported tonnage.

* Flexible installation that complemented existing flowsheet with minimal disruption.

--- ### 🧠 **Key Takeaway** Renison Bell proves that **sensor-based sorting isn't just about grade—it's about cost control and smart logistics**.

When mining, transport, or energy costs are high, **rejecting waste early saves exponentially downstream**.

Orebodie with strong Physical or Chemical contrast

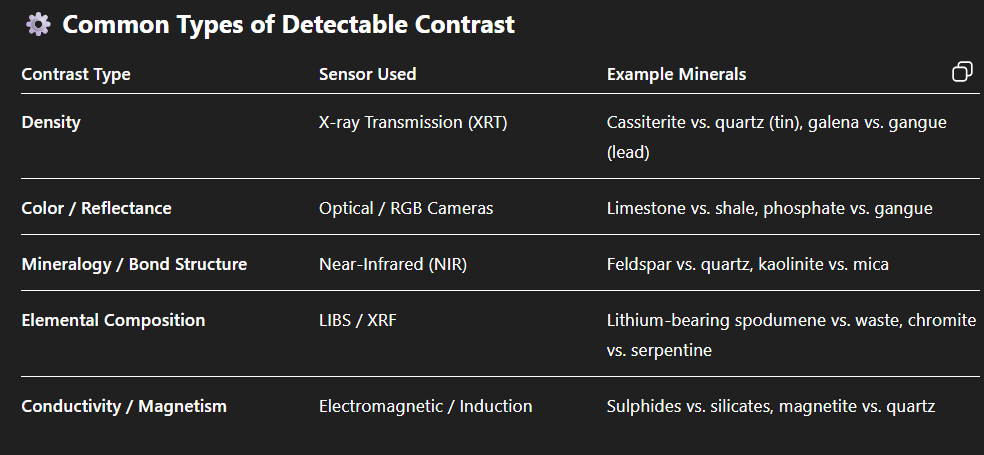

--- ### 🔍 **Why It Works** Sorting technologies rely on sensors that detect specific material properties. When the **ore and gangue exhibit distinct physical or chemical signatures**, the system can classify and separate them with high accuracy and efficiency.

--- ### ⚙️ **Common Types of Detectable Contrast**

--- ### 🏔️ **Ideal Geological Scenarios**

* High-contrast ore bodies where waste is compositionally distinct from ore.

* Visually distinct ores, such as **colored copper oxides**, **black chromite**, or **bright white quartz**.

* Deposits where **density** or **elemental differences** can be leveraged at coarse particle sizes (10–100 mm).

--- ### 📍 **Example: Wodgina Lithium Mine (Australia)**

* **Ore**: Spodumene (LiAlSi₂O₆)

* **Challenge**:

Host rock contained quartz and feldspar, visually and chemically different from spodumene.

* **Solution**:

Optical and XRF sorting used to identify spodumene based on color and lithium content.

* **Result**: Increased feed grade, reduced energy use in milling, and lower acid consumption during downstream processing.

--- ### ✅ **Key Advantages**

* High **sorting precision** with minimal misclassification.

* Effective **pre-concentration** before crushing and grinding.

* Improved downstream **recovery rates** and **plant efficiency**.

* Better ability to exploit **selective mining** and **low-grade zones**.

--- When a deposit offers clear, sensor-detectable contrasts, sensor-based sorting becomes a **low-risk, high-reward upgrade** to the flowsheet.

Real World Example

--- ### 🏗️ **Background**

* **Mine**: Wodgina Lithium Mine

* **Location**: Pilbara region, Western Australia

* **Operator**: Initially Mineral Resources Ltd; later a joint venture with Albemarle

* **Commodity**:

Lithium (primarily as **spodumene**, LiAlSi₂O₆)

* **Challenge**:

* Processing **low- to medium-grade pegmatite ore** containing significant barren minerals (e.g., quartz, feldspar)

* High energy consumption in comminution

* Maximizing concentrate grade and recovery before flotation and conversion

--- ### ⚙️ **Sorting Solution** To enhance ore quality before downstream processing, **sensor-based sorting** was introduced—particularly **optical and XRF-based systems**—to separate lithium-bearing spodumene from non-lithium-bearing gangue.

#### ✨ Key Sorting Features:

* **Optical Sorting**:

Used to detect color differences between pink/green spodumene and white/grey quartz/feldspar.

* **XRF or LIBS (in later testwork)**: Used to detect elemental **lithium signatures** or associated indicators like aluminum.

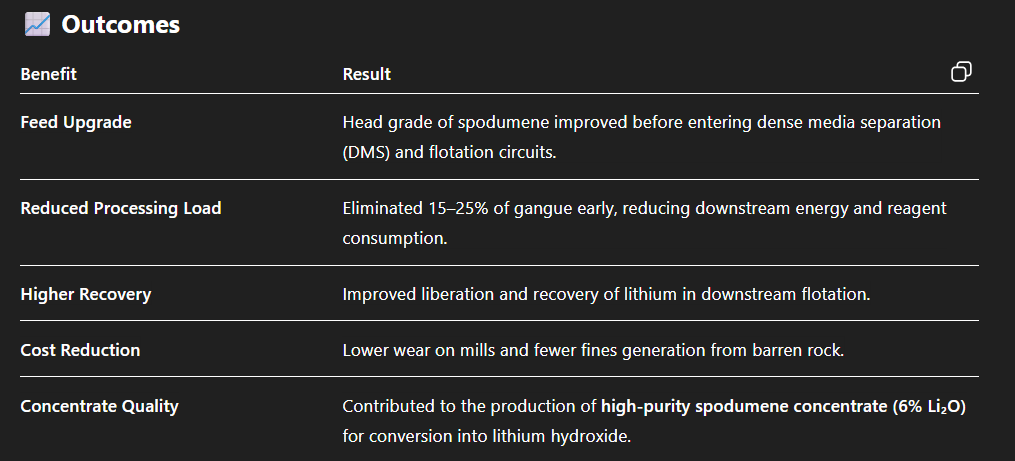

--- ### 📈 **Outcomes**

--- ### ✅ **Why It Worked**

* **Strong visual and chemical contrast** between spodumene and gangue minerals.

* Ore particles remained **coarse enough (10–80 mm)** for effective sorting.

* Technology provided **high-speed decision-making** and accurate rejection at commercial scale.

--- ### 🧠 **Key Takeaway** Wodgina demonstrates how sensor-based sorting in lithium operations can **optimize front-end feed quality**, improve plant economics, and support the push for **sustainable, high-efficiency battery mineral production**.

Brownfield expansion and debottlenecking

Sensor-based ore sorting is a **high-impact tool** for brownfield operations facing **capacity constraints**, **diminishing ore quality**, or **rising operating costs**. It allows mines to **improve feed quality and throughput** without the massive capital investment of a full plant expansion.

--- ### 🔍 **Why It Works** In brownfield or mature operations, the **plant infrastructure is often the bottleneck**—especially grinding and flotation circuits.

Installing ore sorters **upstream** of these units removes barren material, effectively:

* **Freeing up capacity**

* **Reducing processing load**

* **Allowing higher tonnage to be mined and processed without plant upgrades**

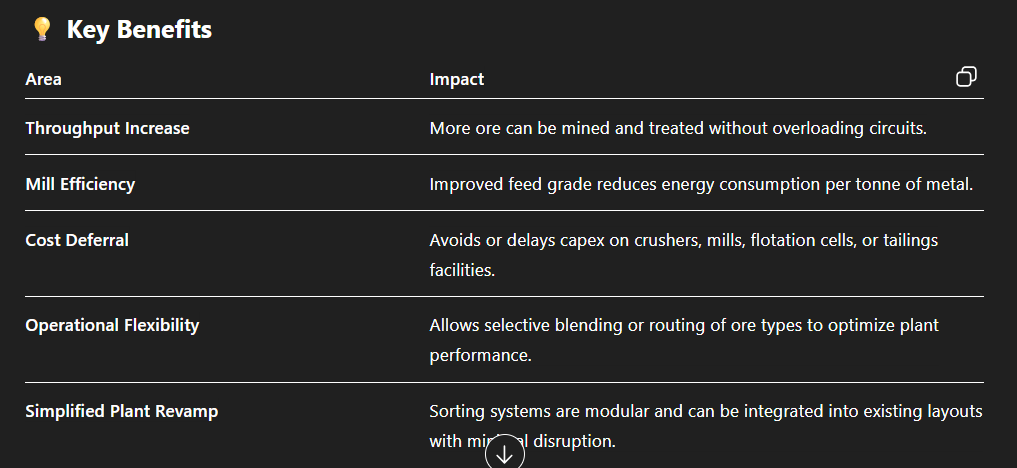

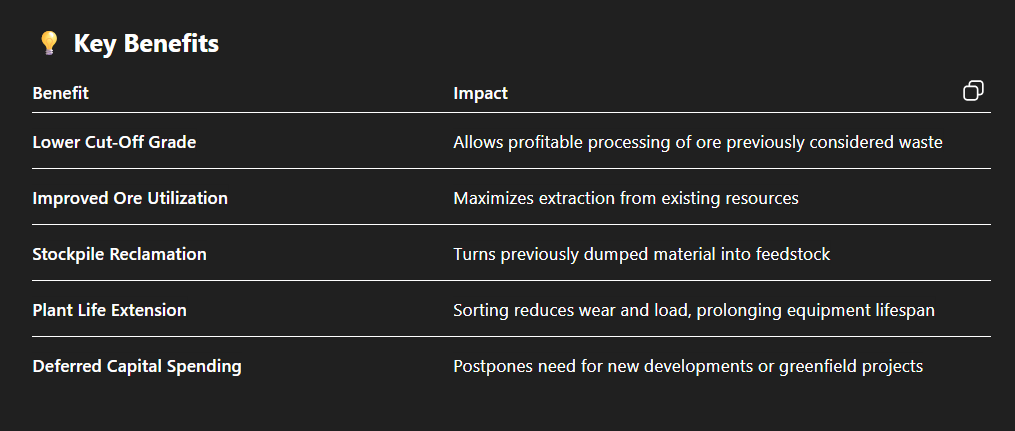

--- ### 💡 **Key Benefits**

| --- ### 📍 **Example: COMINIERE Tin Project (DRC)**

* Faced with limited mill capacity and rising dilution from deeper mining zones.

* Deployed XRT sorters at the front end.

* Sorting removed \~20–30% of mass as waste.

* Debottlenecked the mill by reducing tonnage while **maintaining metal output**.

* Postponed the need for grinding circuit expansion by several years.

--- ### 🧠 **Use Case Triggers**

* Your plant is **maxed out** but more ore is available from the mine.

* You're processing **lower-grade** ore and want to keep production stable.

* You're trying to **avoid the costs and delays** of a major expansion.

* You want to **improve ESG performance** by reducing energy, water, and tailings volume.

--- ### ✅ **Bottom Line** Sensor-based sorting provides a **scalable, bolt-on solution** for existing plants—perfect for **incremental capacity gains** and **cost-effective modernization** of aging operations.

Real World example

--- ### 🏗️ **Project Overview**

* **Mine**: COMINIERE Tin Project

* **Location**: Democratic Republic of the Congo (DRC)

* **Operator**: COMINIERE (state mining company) in partnership with international tin developers

* **Commodity**: Tin (Cassiterite – SnO₂)

* **Challenge**:

* Increasing **ore dilution** from deeper zones

* Aging **mill infrastructure** with limited expansion potential

* Escalating **processing costs per tonne**

* Environmental pressure to reduce energy and tailings volume

--- ### ⚙️ **Sorting Intervention** To manage these challenges without major capital outlay, the operation integrated **X-ray Transmission (XRT) sorting** into the front end of the processing flowsheet.

#### 🔧 Implementation Details:

* ROM ore was screened and crushed to a sortable fraction (typically 10–60 mm).

* **TOMRA XRT sorters** were deployed to detect cassiterite (high-density) from quartz-rich gangue.

* Air jets ejected barren material before it reached the grinding and gravity recovery circuits.

--- ### 📈 **Key Results**

--- ### ✅ **Why It Worked**

* Cassiterite's **distinct density** signature made it ideal for XRT sorting.

* The sorter was installed **in a modular unit** with minimal disruption to existing infrastructure.

* Sorting enabled **mine-to-mill optimization**, allowing blending strategies and more flexible mine planning.

--- ### 🧠 **Key Takeaway** COMINIERE’s use of sensor-based sorting showcases how **brownfield operations can unlock extra capacity and value** without heavy capital spend—**turning operational constraints into opportunities**.

Tailings reprocessings

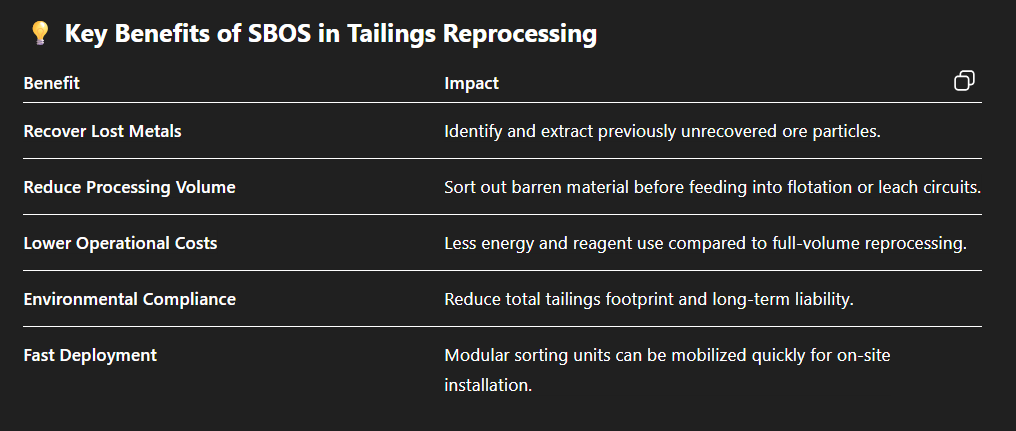

Tailings reprocessing is becoming a **strategic growth opportunity** in the mining industry—driven by rising metal prices, improved technologies, and environmental regulations.

**Sensor-based ore sorting (SBOS)** is playing a key role in recovering value from legacy tailings with minimal additional processing cost.

--- ### 🔍 **Why Sensor Sorting Makes Sense for Tailings** Many tailings dumps from older operations contain significant **residual metal values**—left behind due to:

* Poor historical recovery techniques

* Changing economic cut-off grades

* Inefficient classification or fine losses Sensor sorting can **pre-concentrate tailings material**—even decades old—by identifying and recovering coarse, high-grade particles, especially in dumps where early operations lacked fine control or operated at lower resolution.

--- ### 💡 **Key Benefits of SBOS in Tailings Reprocessing**

--- ### 📍 **Example:

Retreatment of Gold Tailings in South Africa**

* Historical gold tailings were screened to 10–100 mm.

* Sensor sorters (optical and XRT) removed barren gangue from coarse tailings fraction.

* Upgraded fraction fed into CIL (carbon-in-leach) for enhanced recovery. * Improved overall gold yield while reducing cyanide consumption and plant load. --- ### ✅ **Sorting Works Best When:** * Tailings contain **coarse liberated ore particles** (>10 mm). * Strong **density, color, or elemental contrast** remains between ore and gangue. * There’s a need for **low-footprint solutions** due to space or ESG constraints. * The operation seeks to **avoid full-scale regrinding or flotation**. --- ### ⚠️ **Limitations** * Fine tailings (<5 mm="mm">

Real World Example

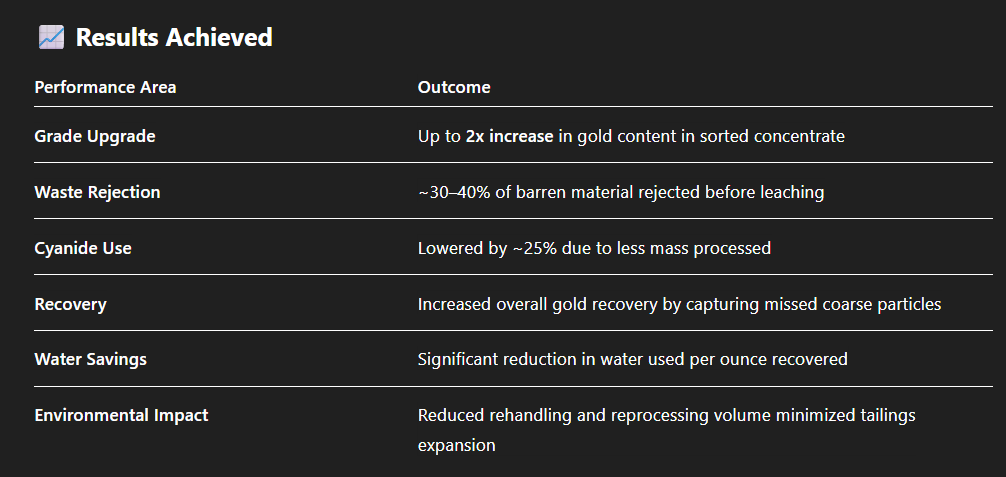

--- ### 🏗️ **Project Overview**

* **Location**: Witwatersrand Basin, South Africa

* **Material**: Historical gold tailings from century-old operations

* **Challenge**:

* Tailings contained residual gold due to **inefficient historical recovery methods**

* Reprocessing full volumes was **costly and energy-intensive** * Need to reduce **cyanide and water consumption**, while recovering gold economically

--- ### ⚙️ **Sorting Solution** As part of a broader tailings retreatment program, **sensor-based sorting** was piloted and deployed to:

* Pre-screen and treat the **coarse fraction** (typically 10–50 mm) of tailings

* Use **optical and XRT sensors** to distinguish between gold-bearing rock and barren quartz/silt

* Upgrade the feed grade **before CIL (carbon-in-leach)** or **heap leaching**

#### Technologies Used:

* **XRT Sorting** for identifying dense, mineralized particles

* **Optical Sorting** for visual color/texture differences in mineralized rocks

--- ### 📈 **Results Achieved**

--- ### ✅ **Why It Worked**

* Residual gold was often associated with **coarse, visible mineralized fragments** that had escaped earlier recovery due to outdated gravity or stamp mill systems.

* The coarse tailings were amenable to **dry handling and pre-screening**, a key requirement for SBOS.

* **Strong color and density contrast** between mineralized and non-mineralized material made sorting accurate and efficient.

--- ### 🧠 **Key Takeaway** In gold operations like those in South Africa, **sensor-based sorting unlocks hidden value in tailings**, turning waste into revenue while reducing the environmental footprint and chemical use of retreatment operations.

ESG-Driven Mining Projects

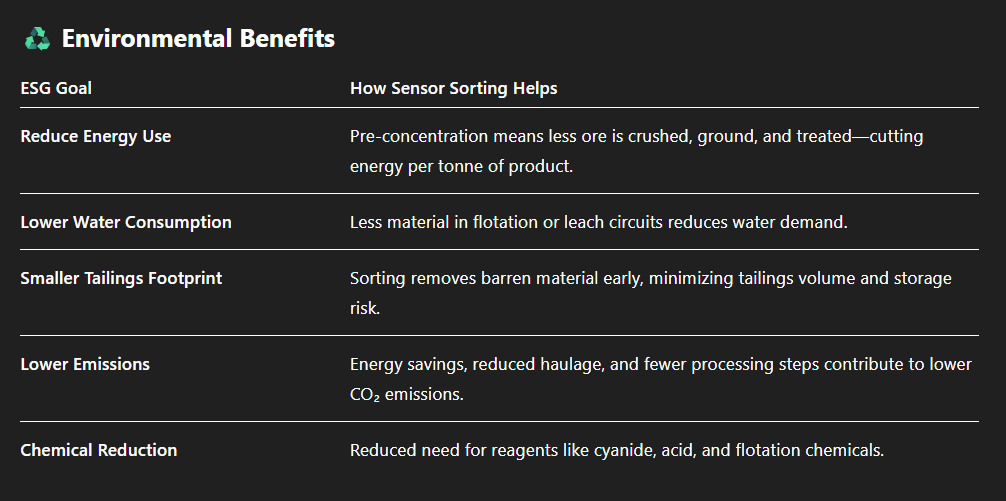

As Environmental, Social, and Governance (ESG) performance becomes central to mining strategy and investment decisions, **sensor-based ore sorting (SBOS)** offers a practical and impactful way to meet ESG objectives while boosting operational efficiency.

--- ### ♻️ **Environmental Benefits**

| --- ### 👥 **Social Responsibility Benefits**

* **Reduced Surface Impact**:

Smaller waste dumps and tailings dams mean less land disturbance and lower risk of catastrophic failures.

* **Improved Community Perception**:

Demonstrates commitment to responsible mining, helping maintain a social license to operate.

* **Job Quality over Quantity**:

Introduces automation and tech skills into local workforces—boosting training and employment value.

--- ### 💼 **Governance & Compliance Advantages**

* Supports adherence to **global ESG reporting frameworks** like: * GRI (Global Reporting Initiative)

* SASB (Sustainability Accounting Standards Board)

* ICMM performance expectations

* Enhances ESG metrics for **investor relations**, **ESG audits**, and **green financing eligibility**

* Enables **data-driven tracking** of sustainability KPIs through integrated monitoring systems

--- ### 📍 **Example: Tungsten Sorting in Spain (Barruecopardo Project)**

* Operator used TOMRA XRT sorting to reduce waste tonnage by 30% at the mine gate.

* Cut water consumption by 20% and improved energy intensity per tonne of concentrate.

* Achieved key ESG goals that supported project financing and permitting in a sensitive region.

--- ### 🧠 **Key Takeaway** Sensor-based sorting is more than a cost-cutting tool—it's a **technology of transformation** for miners seeking to **future-proof operations**, comply with **ESG regulations**, and win **stakeholder trust** in an era of heightened environmental scrutiny.

Real Word Example

**Using Sensor-Based Sorting to Meet ESG and Economic Goals**

--- ### 🏗️ **Project Overview**

* **Mine**: Barruecopardo Tungsten Mine

* **Location**: Salamanca Province, Spain

* **Operator**:

Saloro SLU (a subsidiary of Oaktree Capital)

* **Commodity**: Tungsten (as scheelite – CaWO₄)

* **Challenge**:

* Balancing economic viability with strict environmental regulations

* High dilution in ore feed due to weathered near-surface material

* Community and regulatory expectations for low-impact operations

--- ### ⚙️ **Sensor-Based Sorting Solution**

To improve concentrate quality and reduce environmental impact, **TOMRA X-ray Transmission (XRT) sorters** were installed in the plant’s pre-concentration stage.

#### ✨ How It Worked:

* Crushed ore (typically 10–60 mm) passed through XRT sorters.

* XRT technology distinguished dense scheelite particles from lighter gangue (quartz, feldspar).

* Waste was rejected **before grinding and flotation**, improving both recovery and sustainability metrics.

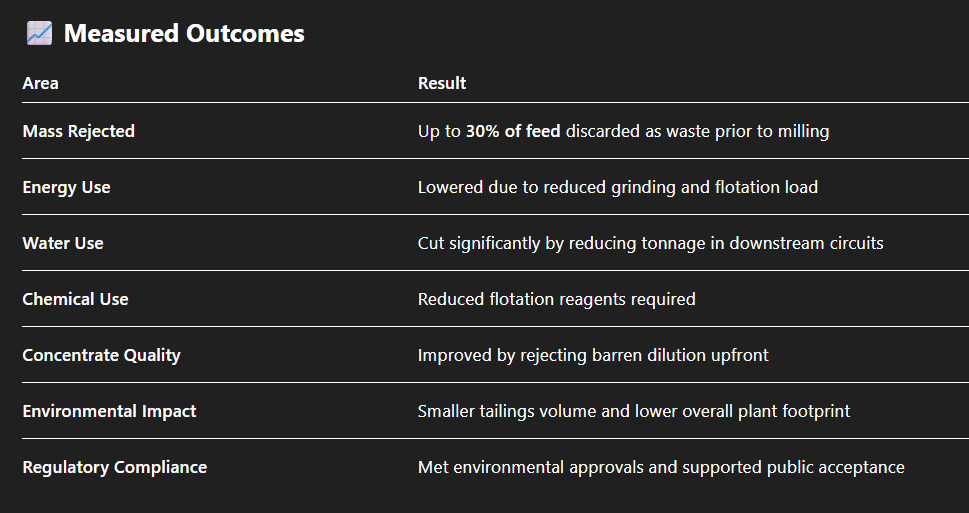

--- ### 📈 **Measured Outcomes**

--- ### ✅ **Why It Was ESG-Aligned**

* Spain’s permitting environment is highly sensitive to **waste, water use, and local impact**.

* XRT sorting aligned perfectly with Saloro’s goals to **minimize footprint**, **optimize resource use**, and **demonstrate best-practice environmental stewardship**.

* Enhanced ESG performance supported **investor confidence** and **long-term project viability**.

--- ### 🧠 **Key Takeaway** At Barruecopardo, sensor-based sorting was not just about ore quality—it was **instrumental in building a socially and environmentally acceptable operation** in a modern European context.

It’s a clear example of how SBOS can support both **performance and sustainability in harmony**.

Life of Mine Extension

As mines mature and ore grades decline, extending the life of mine (LoM) becomes both a **strategic priority and a technical challenge**.

Sensor-based ore sorting offers a powerful, cost-effective method to **upgrade marginal ores**, **lower cut-off grades**, and **reprocess stockpiles**, all of which help **unlock additional years of production** without new discoveries.

--- ### 🔍 **Why It Works for Life-of-Mine Extension**

Sensor-based sorting allows operations to:

* **Pre-concentrate lower-grade zones**, making them economically viable

* **Treat mineralized waste dumps or stockpiles** that were previously uneconomic

* **Optimize blending strategies** to maintain mill feed quality

* Reduce the need for costly **plant upgrades** by easing bottlenecks

--- ### 💡 **Key Benefits**

--- ### 📍 **Example: Kemi Chrome Mine (Finland)**

* As higher-grade zones declined, Outokumpu introduced **XRT-based sorting** at Kemi to pre-concentrate lower-grade chromite ore.

* Sorting upgraded marginal zones enough to sustain plant feed rates and quality.

* Result: **Mine life extended by several years** without expanding the mine footprint.

--- ### ✅ **When to Use SBOS for LoM Extension**

* Your deposit includes **large volumes of sub-economic or diluted ore**

* You have **historical stockpiles** with known metal content

* Your plant is reaching **design limits**, but ore supply isn’t

* You want to **defer capex** while maximizing existing resource value

* You need to **demonstrate long-term sustainability** for permitting or investors

--- ### 🧠 **Key Takeaway** Sensor-based sorting gives miners the **technical edge** to recover more from less. By upgrading marginal material and unlocking “hidden ore” from stockpiles and dumps, it transforms **what was once uneconomic into viable production**—delivering value, sustainability, and resilience to your mine’s future.

Real World example

**Extending Mine Life with Sensor-Based Ore Sorting**

--- ### 🏗️ **Project Overview**

* **Mine**: Kemi Chrome Mine

* **Location**: Kemi, northern Finland

* **Operator**: Outokumpu Chrome Oy

* **Commodity**: Chromite (FeCr₂O₄), used in stainless steel production

* **Challenge**:

* Declining head grades and increasing ore dilution from deeper sections of the deposit

* Desire to **extend mine life** without new major capital expenditure

* Need to **maintain plant throughput and concentrate quality**

--- ### ⚙️ **Sensor-Based Sorting Integration** To address these issues, Outokumpu installed **X-ray Transmission (XRT) sensor-based sorting** at the front end of the processing circuit.

#### 🔧 How It Worked:

* Coarse ore (10–80 mm) was passed through XRT sorters.

* Chromite, with its **high atomic density**, was distinguished from waste material (e.g., talc, serpentine).

* Waste was diverted before entering the crushing and grinding circuits.

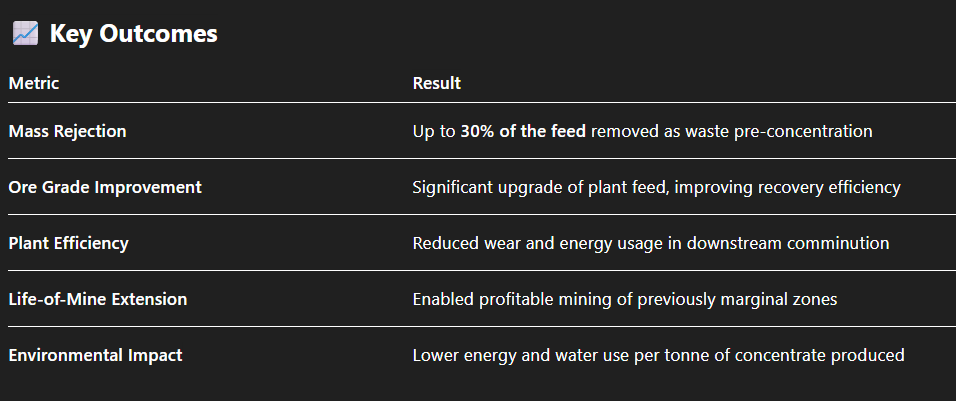

--- ### 📈 **Key Outcomes**

--- ### ✅ **Why It Worked**

* Chromite has a **very distinct density profile**, making it ideal for XRT sorting.

* The mine had well-defined **lower-grade extensions** that became viable once upgraded by sorting.

* Modular sorting units allowed for **cost-effective integration** into the existing flowsheet.

--- ### 🧠 **Key Takeaway** At Kemi, sensor-based sorting didn’t just solve a grade problem—it **changed the mine’s economic horizon**.

By recovering value from marginal ore and easing the burden on downstream circuits, it delivered a **sustainable path to production extension** and operational resilience.

Types of Sensors used

**Matching Sensor Technology to Ore Characteristics**

Sensor-based ore sorting relies on advanced sensors that detect **physical or chemical differences** between ore and waste. The selection of sensor type is **critical** to achieving high accuracy, recovery, and waste rejection.

Here are the most commonly used sensor types:

--- ### 1. 🩻 **X-ray Transmission (XRT)** * **What it measures**: Atomic density (bulk density differences)

* **How it works**:

X-rays pass through particles; denser materials absorb more, creating contrast.

* **Applications**:

* High-density ores like **cassiterite (tin)**, **chromite**, **wolframite (tungsten)**, **galena (lead)**

* Diamond, zinc, and some base metal ores

* **Advantages**:

* Works well on coarse particles * Can detect hidden (non-visible) minerals

* **Limitations**:

* Requires dry material * Doesn’t detect chemical composition directly

--- ### 2. 🎨 **Optical/RGB Cameras**

* **What it measures**: Visible color, brightness, shape, and texture

* **How it works**:

High-resolution cameras capture images of rocks; pattern recognition used for sorting

* **Applications**: * **Limestone**, **phosphate**, **quartz**, **feldspar**

* Visually distinctive ores like oxidized copper or manganese

* **Advantages**:

* Inexpensive and fast

* Effective on color-contrasting ores

* **Limitations**:

* Only works if visual differences exist * Dust and moisture can affect performance

--- ### 3. 🌈 **Near-Infrared (NIR)**

* **What it measures**:

Surface mineralogy, moisture, and reflectance in the NIR spectrum

* **How it works**:

NIR light reflects differently based on molecular structures (e.g., OH-, CO₃²⁻ groups)

* **Applications**:

* **Feldspar vs. quartz**, **kaolinite vs. muscovite**

* Industrial minerals and alteration zones

* **Advantages**:

* Good for subtle mineralogical differences

* Works with weathered materials

* **Limitations**:

* Surface-based—can’t detect deep or fine-grained inclusions

* Limited for metallic ores

--- ### 4. 🔬 **Laser-Induced Breakdown Spectroscopy (LIBS)**

* **What it measures**:

Elemental composition (real-time chemical fingerprint)

* **How it works**:

A laser vaporizes a micro-layer of material; plasma light is analyzed spectroscopically

* **Applications**:

* **Lithium-bearing minerals**, **rare earths**, **complex polymetallic ores**

* **Advantages**:

* Very precise elemental detection

* Can detect light elements (e.g., Li, B, Be)

* **Limitations**:

* More complex and expensive

* Slower than bulk detection methods

--- ### 5. ⚡ **Electromagnetic (EM) / Induction Sensors**

* **What it measures**:

Electrical conductivity or magnetic susceptibility

* **How it works**:

Particles induce a current or magnetic signal when exposed to EM fields

* **Applications**:

* **Sulfide ores**, **magnetite**, **nickel**, **cobalt**, **pyrrhotite**

* **Advantages**:

* Very effective for conductive or magnetic minerals

* Rapid response time

* **Limitations**:

* Not effective on non-conductive/non-magnetic material * Often used in conjunction with other sensors

--- ### 🔧 **Multisensor Systems**

* Combine multiple technologies (e.g., **XRT + RGB**, **NIR + LIBS**)

* Allow more complex sorting decisions for **heterogeneous ores**

--- ### 🧠 **Key Takeaway**

Selecting the right sensor depends on the **ore’s distinguishing properties**.

A well-matched sensor system can **maximize recovery, reject more waste, and improve downstream efficiency**—but the wrong choice can lead to poor performance and economic loss.

X-Ray transmitters XRT

--- ### **What is XRT?** X-ray Transmission (XRT) is a sensor technology that uses **X-rays to measure the atomic density** of particles passing through the sorter.

Since different minerals have different densities and atomic structures, XRT can distinguish ore from waste based on how much the material absorbs or transmits X-rays.

--- ### **How Does It Work?**

* An X-ray source emits beams through the falling ore particles on a conveyor.

* A detector measures the intensity of X-rays that pass through each particle.

* Denser particles absorb more X-rays, producing a lower transmission signal.

* The system processes this data in real time to identify high-density ore (e.g., cassiterite, chromite) vs. lower-density waste (e.g., quartz, feldspar).

* High-speed air jets then eject waste particles before they reach the processing plant.

--- ### **Applications of XRT Sorting**

* **Tin (cassiterite)**

* **Tungsten (wolframite, scheelite)**

* **Chromite**

* **Lead (galena)**

* **Diamond (kimberlite rejection)**

* **Zinc** and other dense base metals

--- ### **Advantages**

* Works well on **coarse particles** (typically 10–80 mm) with clear density differences.

* Can detect ore **even if not visually distinguishable** (e.g., hidden in host rock).

* Suitable for **dry, free-flowing material**; no need for wet processing.

* High sorting speed and accuracy.

--- ### **Limitations**

* Requires dry feed material; moisture reduces X-ray transmission quality.

* Less effective on ores where density contrast between ore and gangue is low.

* Limited chemical specificity; cannot identify elemental composition directly.

--- ### **Typical Setup**

* Feed material passes over a chute or conveyor under an X-ray source.

* Detectors record transmission data.

* Computer algorithms analyze density profiles in real time.

* Air jets selectively remove waste particles.

--- ### **Key Takeaway** XRT sorting is a **proven, efficient, and versatile technology** for pre-concentrating dense mineral ores, reducing downstream load, and improving plant economics, especially when the ore and waste differ strongly in density.

Optical / RGB Camera sensors

--- ### **What Are Optical/RGB Sensors?** Optical or RGB cameras use **visible light imaging** to capture the **color, shape, texture, and brightness** of particles. These cameras analyze images of ore fragments on a conveyor to differentiate valuable minerals from waste based on their visual characteristics.

--- ### **How Do They Work?**

* High-resolution cameras take real-time pictures of particles as they pass along the sorter.

* Image-processing software analyzes color variations, patterns, and surface features.

* Particles matching ore “signatures” (color or texture) are identified as valuable.

* Air jets eject particles identified as waste before they enter the processing plant.

--- ### **Applications**

* **Phosphate vs. silica**

* **Limestone vs. shale**

* **Oxidized copper minerals (e.g., malachite, azurite)**

* **Manganese ores**

* **Iron ore (hematite vs. goethite)**

* **Colored gemstones and industrial minerals**

--- ### **Advantages**

* **Fast and inexpensive** compared to other sensor types.

* Works well when there is **strong color or texture contrast** between ore and waste.

* Can be combined with other sensors for **multi-parameter sorting**.

* Non-destructive and requires no special preparation.

--- ### **Limitations**

* Only effective when **visual differences exist**; invisible or subtle mineralogical differences are hard to detect.

* Performance can be affected by **dust, moisture, lighting conditions**, and particle orientation.

* Limited to surface features—cannot detect internal mineralogy or elemental composition.

--- ### **Typical Setup**

* Particles spread thinly on a conveyor belt under controlled lighting.

* One or more cameras capture images from various angles.

* Software algorithms classify particles based on color thresholds and pattern recognition.

* Sorting decisions trigger air jets to reject waste.

--- ### **Key Takeaway**

Optical/RGB sorting is a **cost-effective, rapid solution** best suited for deposits where ore and gangue have **distinct visual appearances**.

It’s often used in combination with other sensors for improved accuracy.

Near Infrared Sensors (NIR)

--- ### **What is NIR?**

Near-Infrared (NIR) sensors detect the way materials **reflect and absorb light in the near-infrared spectrum** (typically wavelengths from about 700 nm to 2500 nm). Different minerals have unique NIR signatures due to their molecular bonds and structures, allowing identification based on surface mineralogy.

--- ### **How Does NIR Sorting Work?**

* NIR light sources illuminate ore particles on a conveyor belt.

* Sensors measure the reflected NIR light from each particle.

* The reflectance spectra are analyzed in real time to identify mineral types or surface compositions.

* Particles matching target mineral signatures are separated from waste using air jets.

--- ### **Applications**

* Distinguishing **feldspar vs. quartz**

* Differentiating clay minerals like **kaolinite, illite, and muscovite**

* Sorting **phosphates**, **limestones**, and other industrial minerals

* Identifying alteration zones in ore deposits

* Sometimes used in **coal cleaning** and **industrial mineral sorting**

--- ### **Advantages**

* Sensitive to **subtle mineralogical differences** not visible in RGB imaging.

* Can detect **chemical bonds** like hydroxyl (OH), carbonate (CO₃), and water content.

* Effective for sorting weathered or partially altered ores.

* Non-destructive and fast.

--- ### **Limitations**

* Mainly surface-sensitive; can be less effective if surface coatings obscure mineralogy.

* Less suitable for metallic ores where density or elemental composition differences dominate.

* Requires **dry, clean, and well-spread particles** for optimal performance.

* Limited depth penetration—cannot detect internal particle composition.

--- ### **Typical Setup**

* Ore particles spread in a single layer on a conveyor.

* NIR light sources illuminate the feed area.

* Reflectance spectra are collected by sensors and processed by software.

* Air jets reject waste particles based on classification.

--- ### **Key Takeaway** NIR sorting excels when distinguishing **minerals with subtle but distinct chemical compositions**—especially in industrial minerals and some oxide ores—making it a valuable complement to other sensor types in multi-sensor ore sorting setups.

Laser - Induced Breakdown Sprectroscopy (LIBS(

--- ### **What is LIBS?** LIBS is an advanced sensor technology that uses a **high-powered laser pulse to vaporize a tiny portion of a particle’s surface**, creating a plasma. The light emitted by this plasma is analyzed spectroscopically to determine the **elemental composition** of the material in real time.

--- ### **How Does LIBS Sorting Work?**

* A focused laser pulse hits each particle on a conveyor belt, vaporizing a micro-sample.

* The plasma generated emits light with wavelengths characteristic of the elements present.

* A spectrometer collects and analyzes this light to identify elemental signatures (e.g., lithium, rare earths, metals).

* Based on elemental analysis, particles are classified as ore or waste.

* Air jets remove waste particles before further processing.

--- ### **Applications**

* Sorting of **lithium-bearing minerals** (e.g., spodumene)

* Recovery of **rare earth elements (REEs)**

* Complex **polymetallic ores** with subtle elemental differences

* Identification of **valuable trace elements** not detectable by other sensors

--- ### **Advantages**

* Provides **precise elemental identification**, including light elements (Li, Be, B) that are difficult to detect by XRF.

* Can detect **complex mineralogical assemblages** with overlapping physical properties.

* Real-time, particle-level chemical analysis enables very **high sorting accuracy**.

* Useful for ores with **minimal physical contrast** but clear chemical differences.

--- ### **Limitations**

* More **complex and expensive** than other sensor types.

* Requires stable, dust-free environments and consistent sample presentation.

* Sorting speed can be slower due to the detailed analysis required.

* Typically used in **specialized applications** or combined with other sensors.

--- ### **Typical Setup**

* Particles pass individually through a LIBS laser station.

* The laser pulses and spectrometer capture plasma emission spectra.

* Data processing algorithms classify particles in real time.

* Waste particles are rejected via air jets.

--- ### **Key Takeaway** LIBS offers **cutting-edge elemental sorting** where physical properties fail to differentiate ore and waste, making it ideal for **high-value, chemically complex deposits** like lithium and rare earths.

Electromagnetic (EM) / Induction sensors

--- ### **What Are EM / Induction Sensors?** Electromagnetic or induction sensors detect the **electrical conductivity or magnetic susceptibility** of ore particles. They sense how particles respond to electromagnetic fields, enabling separation based on conductive or magnetic properties.

--- ### **How Do They Work?**

* An alternating electromagnetic field is generated near the conveyor carrying ore particles.

* Conductive or magnetic particles induce secondary currents or magnetic fields.

* Sensors measure these induced signals to distinguish ore from non-conductive or non-magnetic waste.

* Waste particles are rejected by air jets before further processing.

--- ### **Applications**

* Sorting **sulfide ores** such as chalcopyrite, pyrite, and pentlandite.

* Separating **magnetic minerals** like magnetite and ilmenite from non-magnetic gangue.

* Beneficiation of **nickel**, **cobalt**, and other base metals with conductive phases.

--- ### **Advantages**

* Very effective for ores with strong **magnetic or conductive properties**.

* Non-contact and fast measurement suitable for high throughput. * Often used in conjunction with other sensors (e.g., XRT or optical) for improved accuracy.

--- ### **Limitations**

* Not effective for **non-conductive and non-magnetic minerals** (e.g., quartz, feldspar).

* Conductivity can be affected by moisture and surface conditions.

* Requires calibration for different ore types and mineral assemblages.

--- ### **Typical Setup**

* Ore particles pass under or through coils generating electromagnetic fields.

* Sensors detect induced signals from particles on a conveyor.

* Signal processing units classify particles in real time.

* Air jets remove particles classified as waste.

--- ### **Key Takeaway** EM and induction sensors excel in **sorting ores with distinct magnetic or conductive characteristics**, providing a fast, contactless, and efficient pre-concentration step in mineral processing.

Typical Sensor Based Ore sorting Setup

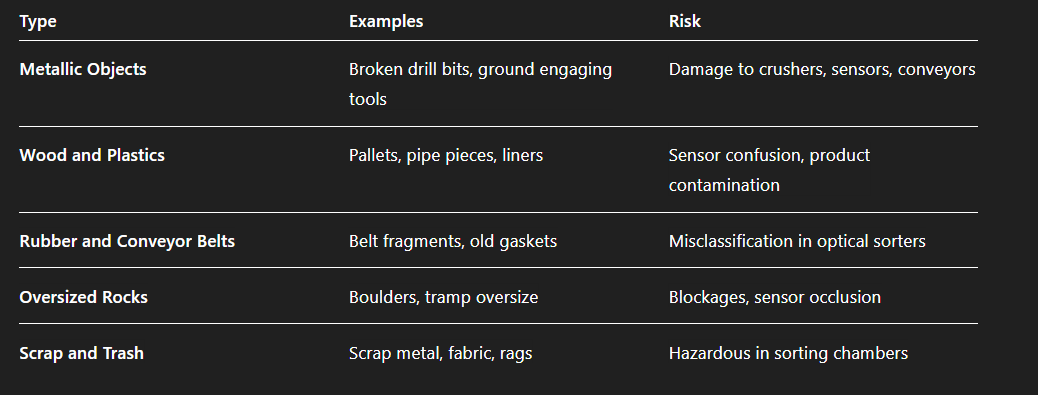

A sensor-based ore sorting (SBOS) system is a combination of mechanical, optical/electronic, and pneumatic components designed to **analyze and separate ore particles from waste** in real time. Here’s how a typical setup looks and works:

--- ### 1. **Feed Preparation**

* **Crushing and Screening:** Ore is crushed and screened to the target particle size range (usually 10–80 mm) for optimal sensor detection and sorting efficiency.

* **Drying (if necessary):** Moisture can interfere with sensor accuracy, especially for XRT and optical systems, so feed material may be dried or dewatered.

--- ### 2. **Material Presentation**

* **Single Particle Layer:** Material is spread in a thin, single-particle layer on a chute or conveyor belt to ensure each particle is individually visible to sensors.

* **Controlled Feed Rate:** A steady, controlled feed ensures sensors can analyze each particle with high precision.

--- ### 3. **Sensing Module**

* Depending on the sensor type (XRT, optical, NIR, LIBS, EM), one or multiple sensor arrays scan the particles as they pass by.

* Sensors detect physical or chemical properties, generating data for classification.

--- ### 4. **Data Processing & Classification**

* Real-time software analyzes sensor data using advanced algorithms (machine learning or rule-based) to classify particles as **ore** or **waste**.

* Thresholds and sorting criteria are adjustable based on ore characteristics and operational goals.

--- ### 5. **Separation Module**

* **Air-Jet Ejectors:** High-speed air jets are positioned downstream to precisely blow away particles identified as waste, diverting them from the ore stream.

* Ejection timing is critical and synchronized with sensor detection to target individual particles accurately.

--- ### 6. **Sorted Material Handling**

* **Ore Stream:** Particles identified as ore continue to downstream processing circuits (e.g., milling, flotation).

* **Waste Stream:** Rejected particles are sent to waste dumps or tailings facilities, reducing plant load.

--- ### 7. **Control & Monitoring**

* The entire system is monitored via control software, allowing operators to adjust parameters, track performance, and integrate data with plant-wide process control.

--- ### **Additional Features**

* **Multi-Sensor Integration:**

Combining sensors (e.g., XRT + RGB cameras) for higher accuracy on complex ores.

* **Modular Design:** Systems can be added or removed based on operational requirements and plant layout.

* **Dust and Lighting Controls:** Ensuring sensor accuracy and reliability.

--- ### 🧠 **Key Takeaway** An effective sensor-based sorting setup requires careful coordination of **feed preparation, precise sensing, intelligent classification, and accurate particle ejection**—all integrated to maximize recovery and waste rejection.

Setup and Installation Guide

Setting up and installing a sensor-based ore sorting system involves careful planning to ensure **optimal performance, integration with existing operations, and safety**. Below is a step-by-step overview of the typical process:

--- ### 1. **Site Assessment and Design**

* **Ore Characterization:** Analyze ore mineralogy, particle size distribution, moisture content, and physical/chemical contrasts to select the right sensor technology (XRT, Optical, NIR, etc.).

* **Plant Layout Review:** Identify space availability, feed source, and points of integration (usually after primary crushing or screening).

* **Environmental Conditions:** Assess dust, humidity, lighting, and power availability.

--- ### 2. **Equipment Selection**

* Choose sensor units, conveyors, air ejectors, and control systems sized for the expected throughput and ore characteristics.

* Decide on modular or fixed installations based on operational flexibility and future expansion plans.

* Specify auxiliary equipment such as feed spreaders, dust suppression, and drying if necessary.

--- ### 3. **Structural Installation**

* **Support Framework:** Install sturdy steel frames or modular skids to support sensors, conveyors, and ejectors with vibration isolation.

* **Conveyors and Feeders:** Install conveyors to deliver a consistent, single-layer feed of material to the sensor array.

* **Feed Preparation Equipment:** Include screening or crushing units upstream as needed for sizing.

--- ### 4. **Sensor System Installation**

* Mount sensors according to manufacturer specifications ensuring correct distance, angle, and lighting conditions.

* Integrate sensor arrays if multi-sensor systems are used.

* Shield sensors from dust, moisture, and electromagnetic interference.

--- ### 5. **Pneumatic Ejector Setup**

* Position air-jet nozzles precisely downstream of sensors.

* Connect to compressed air supply with proper filtration and regulation.

* Test air jets for response speed and accuracy in ejecting targeted particles.

--- ### 6. **Electrical and Control Systems**

* Install control panels and PLCs (Programmable Logic Controllers) to process sensor data and trigger ejectors.

* Integrate Human-Machine Interface (HMI) for operator control and monitoring.

* Connect to plant-wide SCADA or data management systems for real-time analytics.

--- ### 7. **Commissioning and Calibration**

* Perform dry runs to calibrate sensor thresholds, adjust feed rates, and synchronize ejectors.

* Run pilot batches with actual ore to validate sorting performance.

* Fine-tune algorithms and ejection timing for optimal recovery and waste rejection.

--- ### 8. **Operator Training and Maintenance Setup**

* Train plant personnel on operation, troubleshooting, and routine maintenance.

* Establish maintenance schedules for sensors, air jets, and mechanical components.

* Implement monitoring protocols for system health and performance metrics.

--- ### 9. **Safety and Environmental Compliance**

* Ensure all installations comply with site safety standards (electrical, mechanical, pneumatic).

* Install dust control systems and noise abatement where necessary.

* Verify environmental permits and community impact considerations.

--- ### 🧠 **Key Takeaway** Successful sensor sorting installation hinges on **thorough planning, precise mechanical and electrical setup, and rigorous commissioning**. Integration with existing plant infrastructure and ongoing operator support are critical for sustained benefits.

Site Assessment and Design

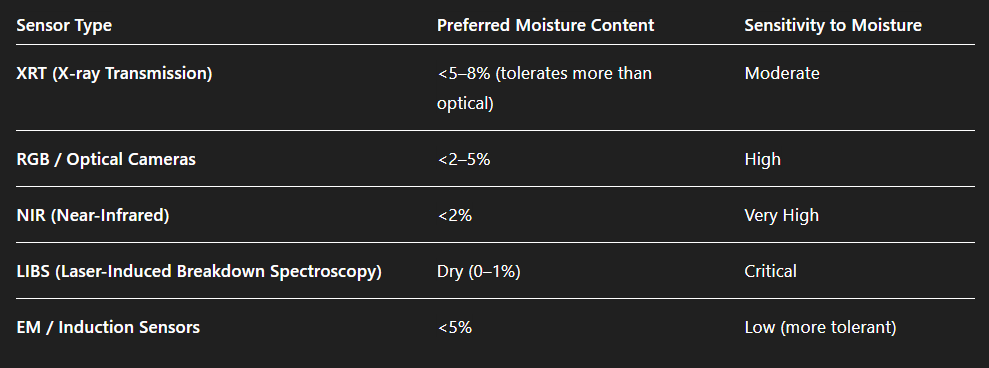

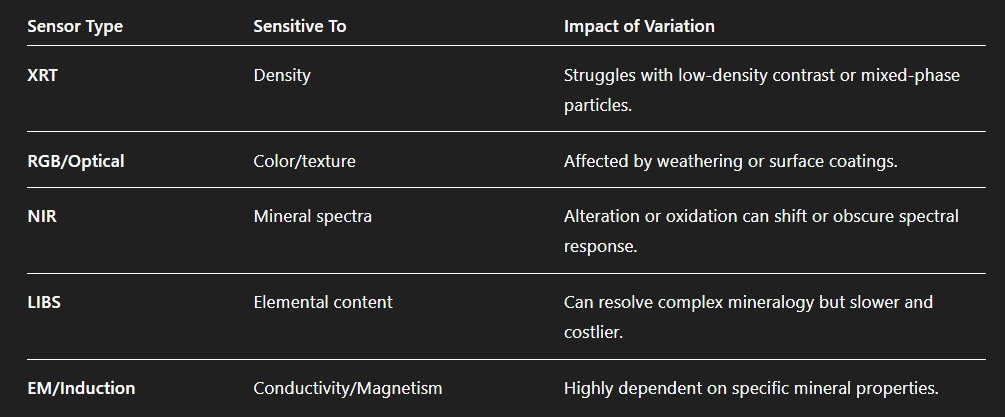

--- ### 1. **Ore Characterization**

* **Mineralogy & Physical Properties**

* Identify ore and gangue mineral types.

* Determine physical contrasts: density, color, texture, magnetic properties.

.* Analyze chemical composition relevant to sensor selection (e.g., elements detectable by LIBS).

* **Particle Size Distribution (PSD)**

* Assess size range suitable for sorting (typically 10–80 mm).

* Identify crushing and screening needs to prepare feed.

* **Moisture Content**

* Measure moisture levels; high moisture can degrade sensor accuracy, especially for XRT and optical systems.

--- ### 2. **Operational Data Review**

* **Throughput Requirements**

* Define tonnage targets to size equipment accordingly.

* **Feed Consistency**

* Evaluate variability in ore grade and material properties over time.

* **Existing Infrastructure**

* Map crushing, screening, conveyors, and plant layout to find integration points.

* **Material Handling**

* Assess space availability and material flow constraints.

--- ### 3. **Environmental and Site Conditions**

* **Dust and Humidity Levels**

* Plan for dust suppression and moisture control as required.

* **Power Availability**

* Confirm electrical supply capacity and stability.

* **Lighting and Space Constraints**

* Design sensor lighting and access for maintenance.

* **Safety Considerations**

* Identify hazards related to pneumatic systems, electrical equipment, and mechanical structures.

--- ### 4. **Sensor Technology Selection**

* Match ore characteristics to sensor type(s):

* **XRT** for dense ores with atomic density contrast. *

**Optical/RGB** for color/texture differences.

* **NIR** for mineralogy differences on particle surfaces.

* **LIBS** for elemental analysis.

* **EM/Induction** for conductive or magnetic minerals.

* Consider combining sensors for complex ores.

--- ### 5. **Preliminary Process Design**

* Develop conceptual layouts for feed preparation, sensor stations, ejectors, and downstream handling.

* Estimate space requirements and footprint.

* Identify key interfaces with existing plant equipment.

--- ### 6. **Economic and ESG Considerations**

* Evaluate expected recovery improvements, waste rejection rates, and operational cost savings.

* Assess environmental benefits: energy, water savings, tailings reduction.

* Consider social and regulatory factors influencing project design.

--- ### 🧠 **Key Takeaway** A comprehensive site assessment provides the foundation for a tailored sensor-based sorting solution—maximizing recovery, minimizing costs, and ensuring smooth integration with your mine’s unique conditions.

Equipment Selection

Selecting the right equipment is crucial to maximize sorting efficiency, throughput, and integration with your mineral processing plant.

Here’s a guide to help you choose the key components:

--- ### 1. **Sensor Units**

* **Type:**

Choose sensor technology based on ore characteristics (XRT, Optical/RGB, NIR, LIBS, EM).

* **Capacity:**

Ensure sensor throughput capacity matches expected feed tonnage (e.g., tons per hour).

* **Resolution & Sensitivity:** Higher resolution sensors improve detection of fine or subtle differences.

* **Multi-Sensor Options:** Consider combining sensor types for complex or variable ores.

* **Environmental Protection:**

Sensors should be rated for dust, moisture, and temperature conditions of your site.

--- ### 2. **Feed Preparation Equipment**

* **Crushers & Screens:** To reduce feed to appropriate particle size range (usually 10–80 mm) and remove fines.

* **Drying Equipment:** If moisture content is high, drying or dewatering systems may be required to improve sensor accuracy.

* **Feed Spreaders:** Devices to create a uniform, single-layer feed on the conveyor or chute.

--- ### 3. **Conveyors & Material Handling**

* **Feed Conveyors:** Sized for consistent, controlled feed rates compatible with sensor capacity.

* **Sorting Chutes / Conveyor Sections:** Designed to optimize particle exposure to sensors and ejectors.

* **Discharge Conveyors:** Separate ore and waste streams with appropriate routing to downstream processes or waste dumps.

--- ### 4. **Separation Equipment**

* **Air-Jet Ejectors:** High-speed air nozzles precisely timed to eject waste particles.

* **Compressed Air System:** Adequate volume, pressure, and filtration for reliable ejector operation.

* **Backup Systems:** Redundant ejectors or pneumatic lines to minimize downtime.

--- ### 5. **Control and Automation**

* **PLC / Control Systems:**

For real-time sensor data processing, decision-making, and ejector control.

* **HMI (Human-Machine Interface):**

Operator dashboard for monitoring performance and adjusting settings.

* **Integration Capability:** Interfaces for plant-wide SCADA or data analytics systems.

--- ### 6. **Auxiliary Systems**

* **Dust Suppression:**

Enclosures, sprays, or vacuum systems to minimize dust around sensors and conveyors.

* **Lighting Systems:** Controlled illumination for optical sensors. * **Safety Systems:** Guards, emergency stops, and access platforms for maintenance.

--- ### 🧠 **Key Takeaway**

Equipment should be **matched carefully to your ore’s characteristics and plant capacity**, with a focus on reliability, maintainability, and ease of integration.

Early collaboration with equipment suppliers ensures the best fit for your project.

Structural Installation

A solid and well-designed structural installation is essential to ensure **stable operation, accurate sensing, and easy maintenance** of the ore sorting equipment.

Here’s a detailed overview:

--- ### 1. **Support Framework**

* **Material:** Typically fabricated from structural steel (e.g., mild steel or stainless steel in corrosive environments).

* **Design:**

* Engineered to withstand dynamic loads from conveyors, sensors, and ejectors.

* Vibration isolation features to prevent sensor inaccuracies.

* Modular or skid-mounted frames for easier installation and relocation.

* **Access:** Include walkways, ladders, and platforms for safe operator and maintenance access.

--- ### 2. **Mounting of Sensors**

* **Positioning:** Sensors must be mounted rigidly at precise angles and distances as per manufacturer specifications.

* **Adjustability:**

Provision for fine-tuning sensor orientation and height to optimize detection.

* **Protection:** Enclosures or shields to protect sensors from dust, moisture, and mechanical damage.

* **Cable Management:**

Proper routing and securing of power and data cables to prevent damage or interference.

--- ### 3. **Conveyor and Chute Installation**

* **Feed Conveyor:** Designed to deliver a uniform, steady feed to the sensor zone with minimal particle overlap.

* **Sorting Chute/Conveyor:**

Optimized to ensure particles are well separated for accurate sensing and sorting.

* **Discharge Conveyors:**

Separate ore and waste streams cleanly with minimal spillage.

--- ### 4. **Air-Jet Ejector Installation**

* **Nozzle Positioning:**

Precisely aligned below the sorting zone to target individual particles based on sensor data.

* **Mounting Frames:** Secure and vibration-damped to maintain accuracy of ejection timing and direction.

* **Compressed Air Lines:**

Rigid and well-supported piping with filtration units installed upstream.

--- ### 5. **Structural Integration with Existing Plant**

* Assess and plan how the sorter structure will interface with existing conveyors, feed hoppers, and processing circuits.

* Minimize modifications to existing infrastructure to reduce downtime and cost.

* Plan for future expansion or modular upgrades.

--- ### 6. **Safety and Compliance**

* Install guardrails, safety gates, and emergency stop mechanisms according to site safety standards.

* Ensure clear signage and safe working zones around equipment.

* Comply with local electrical, mechanical, and occupational safety regulations.

--- ### 🧠 **Key Takeaway** Structural installation must provide **rigid, vibration-free support** for precision sensing and sorting while allowing **safe access for operation and maintenance**.

Early coordination between engineers, equipment suppliers, and site teams ensures smooth installation and commissioning.

Sensor System Installation

Below are the key steps and considerations:

--- ### 1. **Pre-Installation Preparation**

* **Review Manufacturer Guidelines:**

Carefully study the sensor manufacturer’s installation manual for mounting requirements, clearances, and calibration procedures.

* **Site Readiness:**

Ensure all structural supports, conveyors, power supplies, and environmental controls (dust, lighting) are in place.

--- ### 2. **Mounting Sensors**

* **Positioning:**

* Mount sensors at the exact height and angle specified to optimize the sensing field.

* For XRT: Position sensor arrays so particles pass through the X-ray beam correctly.

* For Optical/RGB or NIR: Install cameras with controlled, stable lighting and minimal reflections.

* For LIBS or EM sensors: Align laser or coils precisely with the particle flow path.

* **Secure Attachment:** Use vibration-damping mounts or brackets to avoid sensor movement that could degrade accuracy.

* **Enclosures & Protection:**

Install protective housings to guard against dust, moisture, and mechanical impacts, with easy access for maintenance.

--- ### 3. **Electrical Connections**

* **Power Supply:**

Connect sensors to stable and clean power sources as per specifications.

* **Data Cables:** Route sensor output cables to control systems using proper shielding to minimize electromagnetic interference.

* **Grounding:** Ensure proper grounding and bonding to avoid electrical noise.

--- ### 4. **Integration with Control Systems**

* Connect sensors to PLCs or data acquisition units responsible for real-time signal processing.

* Verify communication protocols (Ethernet, serial, proprietary) are correctly configured.

* Setup interfaces for Human-Machine Interface (HMI) and integration with plant SCADA systems.

--- ### 5. **Testing & Calibration**

* Perform initial power-up and diagnostics checks.

* Calibrate sensors using known standards or representative ore samples to establish detection thresholds.

* Adjust sensor sensitivity and settings to minimize false positives/negatives.

* Test real-time particle detection and sorting decisions.

--- ### 6. **Training & Documentation**

* Train operators and maintenance staff on sensor operation, troubleshooting, and calibration procedures.

* Maintain thorough documentation including wiring diagrams, calibration records, and maintenance schedules.

--- ### 🧠 **Key Takeaway** Precise sensor installation and calibration ensure the ore sorter delivers **accurate, repeatable particle classification**, which is the backbone of efficient sorting and plant optimization.

Pneumatic Ejector Setup

Pneumatic ejectors are critical components that physically remove waste particles identified by the sensor system.

Proper setup ensures **precise, reliable particle rejection** without disrupting ore flow.

--- ### 1. **Ejector Positioning**

* Install air-jet nozzles **just downstream of the sensor detection zone** on the conveyor or chute.

* Position nozzles at angles and distances optimized to target individual particles without disturbing neighboring material.

* Use adjustable mounts for fine-tuning nozzle direction and height.

--- ### 2. **Compressed Air Supply**

* Provide a **clean, dry, and stable compressed air source** with sufficient pressure (typically 5–8 bar) and flow rate to operate all ejectors effectively.

* Install air filtration (coalescing and particulate filters) and pressure regulators near ejector manifolds to maintain air quality and consistency.

* Include moisture traps and dryers if site humidity is high.

--- ### 3. **Piping and Manifolds**

* Use **rigid, corrosion-resistant piping** to connect compressed air supply to ejector nozzles, minimizing pressure drops.

* Design manifold systems to evenly distribute air to all ejectors with quick response times.

* Include valves or solenoids for individual nozzle control triggered by sensor data.

--- ### 4. **Ejector Valve Control**

* Use fast-acting **solenoid valves** or **piezoelectric valves** for precise timing, typically millisecond-scale, to ensure only targeted particles are ejected.

* Synchronize valve actuation with sensor detection via the control system/PLC.

--- ### 5. **Testing and Calibration**

* Test ejectors individually to verify air pressure, flow rate, and jet strength.

* Calibrate timing and jet duration to effectively remove waste particles without displacing ore.

* Adjust nozzle position and air pressure based on particle size, density, and conveyor speed.

--- ### 6. **Maintenance Considerations**

* Schedule regular inspection and cleaning of air filters and nozzles to prevent clogging.

* Monitor compressed air system pressure and flow continuously. * Replace worn or damaged valves and seals promptly.

--- ### 🧠 **Key Takeaway** Efficient pneumatic ejector setup ensures **accurate and responsive waste removal**, maximizing sorter performance and protecting downstream processing equipment.

Electrical And Control Systems

The electrical and control systems are the **brains and nerves** of a sensor-based ore sorting setup, responsible for processing sensor data, controlling ejectors, and integrating with plant-wide operations.

--- ### 1. **Power Supply**

* Ensure **stable, clean power** is supplied to all components, including sensors, PLCs, actuators, lighting, and auxiliary equipment. * Use **uninterruptible power supplies (UPS)** for critical control components to prevent downtime from power disturbances.

--- ### 2. **Programmable Logic Controllers (PLCs)**

* PLCs process real-time data from sensors, run classification algorithms, and send commands to ejectors.

* Select PLCs with sufficient input/output (I/O) channels and processing speed to handle sensor data volume and ejector control. * Incorporate redundancy for increased reliability in critical installations.

--- ### 3. **Human-Machine Interface (HMI)**

* Provides operators with real-time system status, diagnostics, and control options.

* Displays sensor readings, sorting statistics (recovery rates, waste rejection), alarms, and system health.

* Allows parameter adjustments such as sensor sensitivity, air jet timing, and feed rate control.

--- ### 4. **Communication and Networking**

* Connect sensors, PLCs, HMIs, and plant SCADA systems via industrial communication protocols (e.g., Ethernet/IP, Modbus TCP, Profibus).

* Enable remote monitoring, data logging, and integration with plant-wide process control and analytics.

* Secure networks against cyber threats with firewalls and access controls.

--- ### 5. **Signal Processing and Software**

* Use specialized software algorithms for **real-time classification** based on sensor inputs.

* Implement machine learning or rule-based models tailored to the ore characteristics.

* Support data analytics for performance optimization and predictive maintenance.

--- ### 6. **Safety Systems**

* Include emergency stop circuits and interlocks to safely shut down the sorter during faults or emergencies.

* Ensure compliance with local electrical and safety codes.

* Incorporate alarms and fault detection with operator notification. -

-- ### 7. **Installation Considerations**

* Proper cable management: Use shielded cables, conduits, and cable trays to prevent electromagnetic interference.

* Grounding and bonding: Ensure all electrical equipment is properly grounded to protect personnel and equipment.

* Environmental protection: Use enclosures rated for dust, moisture, and temperature extremes where required.

--- ### 🧠 **Key Takeaway** Robust electrical and control systems ensure **precise sensor data processing, responsive ejector control, operator visibility, and seamless plant integration**, which are critical for effective ore sorting operations.

Commissioning And Calibration

--- ### 1. **Pre-Commissioning Checks**

* Verify mechanical installation:

structural supports, conveyors, sensors, ejectors, and air systems are properly installed and secure.

* Confirm electrical wiring and connections meet design specifications.

* Check compressed air supply pressure, cleanliness, and flow.

* Ensure all safety systems and emergency stops are functional.

--- ### 2. **Initial Power-Up and Diagnostics**

* Power up control and sensor systems following manufacturer procedures.

* Run hardware diagnostics to confirm all sensors, PLCs, and actuators are communicating and operational.

* Verify sensor outputs are within expected ranges on test samples or blanks.

--- ### 3. **Calibration Procedures**

* Use **representative ore and waste samples** to calibrate sensor response thresholds:

* For XRT, calibrate density discrimination settings.

* For Optical/NIR, set color or spectral classification limits.

* For LIBS or EM, define elemental or conductivity detection parameters.

* Adjust sensor sensitivity to balance **maximizing ore recovery** and **minimizing waste rejection errors**.

* Synchronize ejector timing with sensor detection to ensure accurate particle ejection.

--- ### 4. **Test Runs and Performance Validation**

* Conduct controlled test runs with varying feed grades and particle sizes.

* Monitor sorter performance metrics: recovery rate, waste rejection, throughput, false positive/negative rates.

* Adjust calibration parameters iteratively based on test results. * Validate stable operation over extended periods.

--- ### 5. **Operator Training**

* Train operators on system controls, calibration procedures, and troubleshooting.

* Develop protocols for regular calibration checks and performance monitoring.

--- ### 6. **Documentation**

* Record all calibration settings, test results, and adjustments.

* Provide operation manuals and maintenance schedules.

--- ### 🧠 **Key Takeaway** Thorough commissioning and precise calibration ensure the sensor sorter delivers **optimal separation performance**, reduces operational risks, and supports consistent production outcomes.

Operator Training and Maintenance Setup

--- ### 1. **Operator Training**

* **System Overview:**

* Teach operators the basic principles of sensor-based ore sorting and how the specific system works.

* Explain sensor types, feed preparation, sorting logic, and ejector function.

* **Control Interface:**

* Train operators on using the Human-Machine Interface (HMI) to monitor system status, alarms, and key performance indicators (KPIs).

* Show how to adjust operational parameters such as sensor sensitivity, ejector timing, and feed rates.

* **Troubleshooting:**

* Provide guidance on identifying common faults like sensor misreads, air jet failures, or feed inconsistencies.

* Train on how to respond to alarms and perform basic resets or recalibration.

* **Safety Procedures:**

* Emphasize safe operation, including lockout/tagout, emergency stops, and personal protective equipment (PPE) requirements.

* Review site-specific safety protocols.

--- ### 2. **Maintenance Setup**

* **Routine Inspection Schedule:**

* Daily checks of sensors, air ejectors, conveyors, and compressed air systems.

* Monitor wear on nozzles, belts, and structural components.

* **Cleaning Procedures:**

* Regular cleaning of sensor lenses, cameras, and enclosures to prevent dust and dirt interference.

* Maintain compressed air filters and moisture traps.

* **Calibration Maintenance:**

* Establish a schedule for periodic sensor recalibration to maintain accuracy over time.

* Keep calibration logs for traceability.

* **Spare Parts Inventory:**

* Stock critical spares such as air valves, sensor components, filters, and cables to minimize downtime.

* **Predictive Maintenance:**

* Use monitoring data to anticipate component wear and schedule proactive maintenance.

* Integrate with plant-wide maintenance management systems if available.

--- ### 3. **Documentation and Support**

* Provide clear operating manuals, maintenance guides, and troubleshooting flowcharts.

* Set up a communication channel with equipment suppliers for technical support and software updates.

* Conduct refresher training sessions regularly or when system upgrades occur.

--- ### 🧠 **Key Takeaway** Effective operator training and a well-structured maintenance program are vital to **sustaining sensor sorter performance, minimizing downtime, and ensuring safe operation** over the system’s lifespan.

Safety and Environmental Compliance

--- ### 1. **Safety Compliance**

* **Electrical Safety:**

* Ensure all electrical installations comply with local and international standards (e.g., IEC, NEC).

* Proper grounding, insulation, and circuit protection to prevent shocks and fires.

* **Mechanical Safety:**

* Install guards, barriers, and emergency stops around moving conveyors, air jets, and crushing equipment.

* Use lockout/tagout procedures for maintenance.

* **Pneumatic System Safety:**

* Use pressure relief valves and safety shutoffs on compressed air lines.

* Prevent accidental air jet activation during maintenance.

* **Operator Safety Training:**

* Train workers on hazard recognition, PPE use, and emergency procedures.

* Maintain clear signage and restricted access zones.

* **Ergonomics and Access:**

* Design walkways, platforms, and ladders for safe and easy access to sensors and maintenance points.

* Provide adequate lighting and non-slip surfaces.

--- ### 2. **Environmental Compliance**

* **Dust Control:**

* Implement dust suppression methods such as water sprays, enclosures, and dust collectors to minimize airborne particles.

* Regularly monitor dust levels to comply with environmental regulations.

* **Noise Management:**

* Use noise dampening enclosures or barriers around air ejectors and conveyors to reduce workplace noise.

* **Water and Energy Efficiency:**

* Design sorter operations to minimize water usage (most sorting is dry).

* Optimize energy consumption of sensors, conveyors, and compressed air systems.

* **Waste Management:**

* Ensure proper handling and disposal of rejected waste materials according to environmental laws.

* Evaluate opportunities for tailings reprocessing or recycling.

* **Permitting and Reporting:**

* Obtain necessary environmental permits before installation and operation.

* Maintain records and report environmental performance as required.

--- ### 🧠 **Key Takeaway** Prioritizing safety and environmental compliance protects workers, reduces operational risks, and ensures sustainable, socially responsible mining practices.

Role of Ore Characterization

--- ### 1. **Mineralogical Composition**

* Identify key valuable minerals and gangue phases using techniques such as:

* **X-ray Diffraction (XRD)** for mineral identification

* **Scanning Electron Microscopy (SEM)** for texture and mineral associations

* **Mineral liberation analysis (MLA)** for liberation degree and particle composition

--- ### 2. **Physical Properties**

* **Particle Size Distribution (PSD):**

* Analyze the size range and shape of particles post-crushing to ensure compatibility with sensor detection limits (typically 10–80 mm).

* **Density and Specific Gravity:**

* Measure density contrasts between ore and waste, which are critical for sensors like X-ray Transmission (XRT).

* **Magnetic and Electrical Properties:**

* Determine magnetic susceptibility and electrical conductivity relevant for electromagnetic (EM) sensors.

* **Color and Texture:**

* Assess visual differences for Optical/RGB sensor suitability.

--- ### 3. **Chemical Composition**

* Use assays or elemental analysis (e.g., ICP-MS, LIBS) to determine:

* Major and trace elements relevant to sorting (e.g., Li, REEs, Cu, Sn).

* Chemical differences that sensors like LIBS can detect.

--- ### 4. **Surface vs. Bulk Properties**