AI in DMS: An overview

Trending

How can I use AI to enhance Metallurgical Performance of Mineral Processing Plants

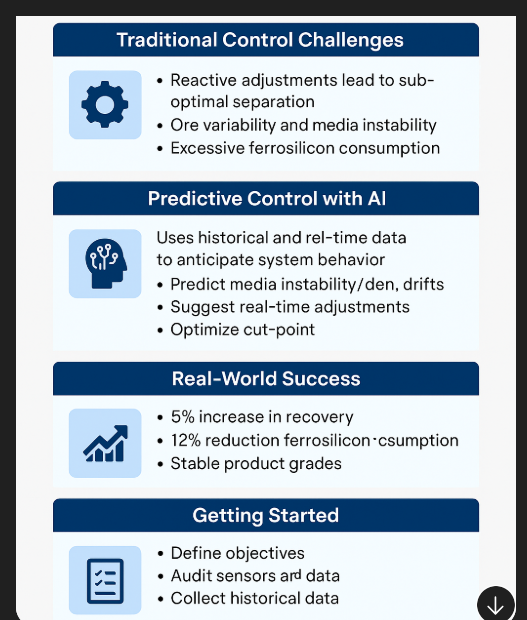

--- ## **AI in DMS: Predictive Control for Improved Separation**In modern mineral processing, Dense Media Separation (DMS) remains a trusted method for upgrading ores based on specific gravity. However, maintaining consistent performance in a DMS circuit is challenging due to ore variability, media instability, and equipment wear.

Enter **Artificial Intelligence (AI)**—a powerful tool that is redefining how we manage and optimize DMS operations.

### Why Traditional DMS Control Falls Short Conventional DMS control methods—such as manual density sampling, visual inspections, or basic PID controllers—are largely reactive. By the time a deviation in media density or cut-point is detected, losses may already be incurred. These reactive approaches struggle to handle dynamic changes in feed composition, flow rates, and equipment condition. The result? Sub-optimal separation, excessive ferrosilicon usage, and reduced recovery.

### Predictive Control with AI:

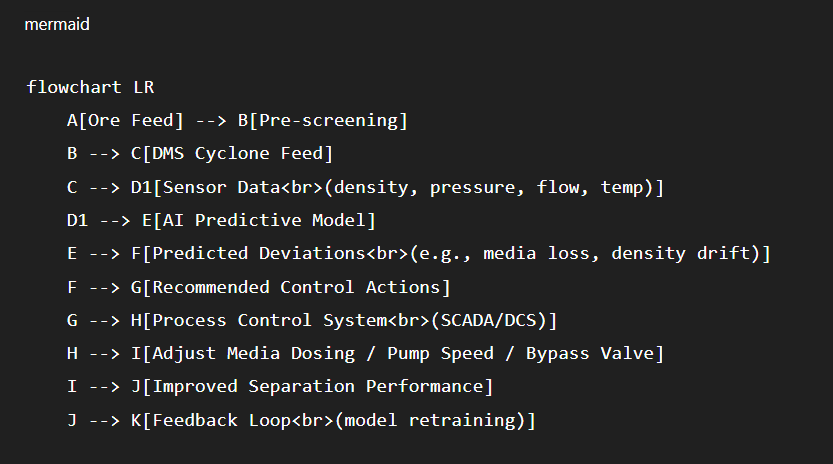

A Game Changer AI-based predictive control uses historical and real-time data to forecast system behavior and recommend pre-emptive actions. Machine learning models such as Random Forests, Gradient Boosting, or even Recurrent Neural Networks (RNNs) can detect complex patterns in process variables like cyclone pressure, slurry density, underflow/overflow quality, and media concentration.

By continuously learning from data, these models can:

* Predict media instability events or density drifts before they occur.

* Suggest real-time adjustments to media dosing, bypass valves, or pump speeds.

* Optimize the cut-point dynamically based on ore variability.

* Reduce operator guesswork and improve process consistency.

### Real-World Success At a southern African diamond plant, a machine learning pilot system successfully predicted density instability 30 minutes in advance. The AI platform recommended flow adjustments to the mixing tank, reducing media loss and improving sink/floats separation.

Over time, the plant recorded a **5% increase in recovery** and a **12% drop in ferrosilicon consumption**. Elsewhere, an iron ore concentrator in Brazil implemented reinforcement learning for real-time cut-point control, maintaining product grade consistency across fluctuating ore types—something manual control struggled to achieve.

### How to Get Started Implementing AI in DMS starts with a few key steps:

1. **Define clear objectives** (e.g., recovery improvement, media savings).

2. **Audit sensors and data infrastructure** to ensure reliable inputs.

3. **Collect and label historical data** to train initial models.

4. **Pilot the AI model in advisory mode**, then transition to closed-loop control.

5. **Continuously refine** the models with new data and operator feedback.

### The Future of Separation is Predictive AI-powered predictive control is no longer experimental—it’s fast becoming the new standard for high-performance DMS circuits. By moving from reactive to proactive decision-making, operations can achieve better recovery, reduced media costs, and improved stability in the face of variable feed conditions. At **mineralprocessing.co.za**, we’re tracking the frontier of digital transformation in mining.

If your plant is ready to explore predictive control in DMS or other circuits, let’s start the conversation.

--- **#AIinMining #DenseMediaSeparation #PredictiveControl #SmartPlant #MetallurgicalInnovation #MineralProcessingSA #ProcessOptimization #DigitalMining #RecoveryImprovement**

Why Traditional DMS Controls Falls short

Trending

--- ### **Why Traditional DMS Control Falls Short**Conventional Dense Media Separation (DMS) control methods—such as manual density checks, periodic visual inspections, and basic PID loops—are inherently reactive.

These approaches detect problems only after they’ve already impacted performance. By the time deviations in media density or cut-point are noticed, valuable material may already be lost to waste streams.

Moreover, traditional controls struggle to adapt to real-time fluctuations in feed composition, slurry flow, and equipment condition.

The consequences include inconsistent separation efficiency, excessive ferrosilicon consumption, and ultimately, reduced product recovery and profitability. -

What AI brings to DMS circuits

Artificial Intelligence (AI), particularly in the form of machine learning, transforms how DMS circuits are controlled by introducing

*predictive intelligence* into the process. Instead of reacting to problems after they occur, AI models forecast issues before they impact recovery or media stability.

By analyzing real-time sensor data—such as feed density, cyclone pressure, and slurry flow—AI systems can recognize early warning signs of process drift.

These models do more than detect; they **recommend or automate corrective actions** in real time. For example, if media density is trending outside optimal bounds, the AI can suggest adjusting ferrosilicon dosing or modifying bypass valve positions before separation efficiency drops. Over time, the system learns from historical data and outcomes, continually improving its accuracy and value to operators. With AI in place, DMS plants benefit from:

* 📈 **More consistent product quality**

* ⏱️ **Faster reaction to process changes**

* 💰 **Lower media consumption and operating cost**

* 🧠 **Enhanced decision-making support for metallurgists**

Getting Started with Your AI in DMS Circuit

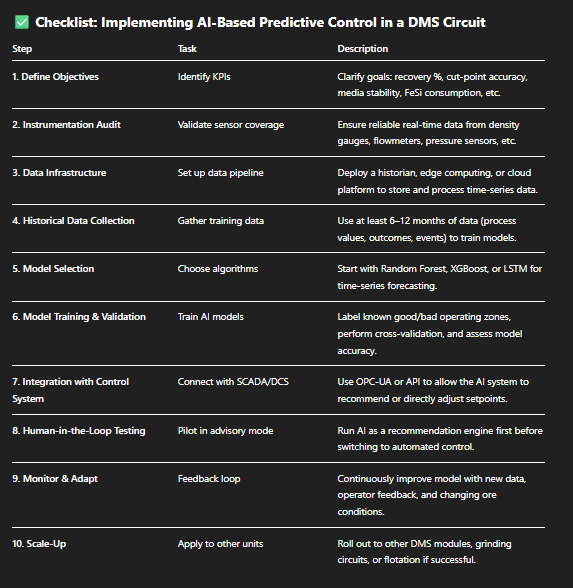

Adopting AI for Dense Media Separation doesn’t require a complete plant overhaul—it starts with a focused, data-driven strategy.

The goal is to move from reactive, manual interventions to a more proactive and intelligent control environment. Here’s how:

#### ✅ **1. Define Your Objectives** Start by identifying what success looks like: better recovery, tighter cut-point control, reduced ferrosilicon loss, or energy savings.

#### ⚙️ **2. Audit Instrumentation and Data** Ensure that your DMS circuit has reliable sensors capturing key metrics: media density, cyclone pressure, flow rates, and feed properties. Good data is the foundation of effective AI.

#### 📊 **3. Collect and Label Historical Data** Gather historical data covering both stable and unstable operating periods. Label events (e.g., density drift, media spike) to train predictive models accurately.

#### 🧠 **4. Train and Test Your Model** Use machine learning algorithms—such as Random Forest, XGBoost, or LSTM—to model process behavior and forecast deviations. Validate the models using recent plant data.

#### 🤖 **5. Deploy in Advisory Mode First** Run the AI model in parallel with your control room, offering real-time recommendations to operators. Once reliable, transition to automated control if desired.

#### 🔁 **6. Monitor, Learn, and Scale** Continue refining the system with new data and operator feedback. If successful, apply similar logic to other plant areas (e.g., grinding, flotation, or tailings).

--- ### 🌐 The Future is Predictive Dense Media Separation is too valuable a process to leave at the mercy of slow reaction times and manual control. With AI-powered predictive control, operations gain consistency, agility, and insight—transforming the plant from reactive to smart.

At **mineralprocessing.co.za**, we’re committed to helping the industry harness technology to drive smarter, safer, and more profitable processing. If your plant is ready to explore AI in DMS or other areas, let’s connect.

Check List: Impleementing AI based Predicttive controls in DMS

--- ### ✅ **Checklist: Implementing AI-Based Predictive Control in a DMS Circuit**

--- ### 📊 **Flow Diagram: AI in DMS Predictive Control**

Here’s a diagram showing how AI integrates with a DMS process: **\[DMS AI Flow Diagram]**

Real World Case studies - AI in DMS

--- ### 🟢 **Case Study 1:

Diamond Concentrator – Southern Africa**

**Goal:**

Reduce ferrosilicon consumption and improve sink-float separation

**AI Application:** Real-time media density prediction and automatic dosing control

**Background:**

A major diamond processing plant in Southern Africa experienced frequent media density fluctuations due to inconsistent ore feed quality and manual dosing adjustments.

These fluctuations often led to poor separation, material losses, and overuse of ferrosilicon.

**Solution:** An AI system was trained using 12 months of historical process data, including cyclone pressure, FeSi dosing rates, feed solids density, and product quality.

A gradient boosting model (XGBoost) was deployed in parallel with the plant’s SCADA system.

**Results:** * Predicted media instability 20–30 minutes in advance

* Recommended optimal FeSi dosing based on real-time ore density

* **5.3% increase in diamond recovery**

* **12% reduction in ferrosilicon usage** over 90 days

--- ### 🔵 **Case Study 2: Iron Ore Plant

– Minas Gerais, Brazil**

**Goal:** Stabilize cut-point under variable ore feed

**AI Application:** Reinforcement learning for dynamic cyclone setpoint control

**Background:** This iron ore operation processed multiple ore types with varying densities and clay content, leading to frequent misplacement of valuable ore to tailings. Manual intervention lagged behind the feed variability.

**Solution:** A reinforcement learning (RL) model was deployed, continuously learning the relationship between cyclone inlet pressure, underflow density, and ore quality.

The AI was integrated into the PLC system to adjust pump speed and underflow valve settings in real time.

**Results:**

* Maintained consistent cut-point within ±0.02 SG units

* Improved concentrate grade control without sacrificing throughput

* **3.8% reduction in misplacement losses**

* Stabilized product despite daily feed blend changes

--- ### 🟠 **Case Study 3: Coal Washing Plant

– Queensland, Australia**

**Goal:** Improve yield and product consistency in dense medium cyclone (DMC) circuit

**AI Application:

** Neural network prediction of separation inefficiencies

**Background:**

The coal plant struggled with fluctuating ash content in product due to manual washability adjustments and limited response to real-time variability.

**Solution:**

A deep neural network (DNN) model was trained to predict separation efficiency from parameters such as feed rate, magnetite density, differential pressure, and washability data. A dashboard was developed to visualize AI alerts and simulate operator responses.

**Results:**

* Early warning of magnetite recovery issues

* AI model recommended proactive feed dilution or DMC bypass to maintain yield

* **2.5% improvement in saleable product yield**

* Enhanced operator confidence in control room decisions

--- ### 🔍 **Key Takeaways Across All Cases**

* **AI thrives in dynamic conditions**

where manual control struggles

* **Predictive control**

reduces response time and stabilizes output

* **Data quality and instrumentation** are critical for success

* Human-in-the-loop systems (starting in advisory mode) help build trust before automation

DMS optimization using AI

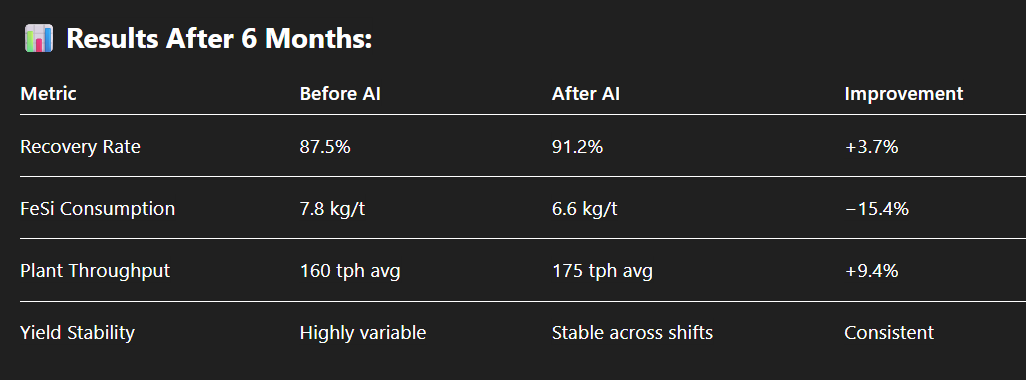

--- ## 🟢 **Case Study: Plant-Wide AI Optimization in a Manganese DMS Plant – Northern Cape, South Africa**

### 🎯 Objective: To improve overall plant performance by using AI to optimize **cut-point accuracy**, **ferrosilicon usage**, **throughput**, and **yield** simultaneously—rather than targeting only one variable at a time.

--- ### 🏭 **Background:**

The manganese DMS plant processes ROM ore through a two-stage crushing and screening circuit, followed by dense media separation using cyclone technology. The plant had consistent challenges:

* Inconsistent sink-float separation due to feed variability

* High ferrosilicon (FeSi) consumption

* Throughput limitations during feed surges

* Manual adjustments that were slow to respond to rapid process changes

The operation wanted to **stabilize performance and increase profitability** by using advanced AI tools that could monitor, predict, and optimize key process variables in real time.

--- ### 🤖 **AI Implementation Strategy:**

#### 1. **Instrumentation & Data Infrastructure Upgrade**

* Installed real-time density gauges on cyclone feed and overflow

* Added inline flowmeters, pressure transducers, and level sensors

* Centralized all plant data into a historian linked to a cloud-based machine learning platform

#### 2. **Data Training & Model Development**

* Used 18 months of historical plant data (inputs, outputs, and quality data)

* Labeled downtime events, yield loss incidents, and optimal operating periods

* Trained ensemble models (Random Forest + LSTM neural networks) to predict separation performance, media instability, and yield loss

#### 3. **Optimization Engine Deployment**

* AI models generated setpoint recommendations for cyclone pressure, media density, and pump speeds

* A supervisory optimizer (genetic algorithm) tested multiple combinations in real time to maximize recovery while minimizing media use and energy

#### 4. **Operator Integration & Phased Control Rollout**

* Started with AI in advisory mode (real-time recommendations only)

* After three months, moved to **semi-automated control** via SCADA integration

--- ### 📊 **Results After 6 Months:

--- ### ✅ **Key Features That Drove Success:**

* **Multi-variable optimization**: Rather than optimizing media density alone, the AI balanced multiple conflicting objectives simultaneously.

* **Predictive maintenance alerts**: The AI flagged abnormal pump vibration patterns, helping prevent cyclone failure.

* **Shift-based performance benchmarking**: The AI system gave operators feedback on performance against "digital twin" benchmarks, encouraging continuous improvement.

--- ### 🧠 **Lessons Learned:**

* Operator engagement and trust are critical—phased deployment ensured buy-in.

* Good instrumentation and clean, labeled data are prerequisites for success.

* AI is not a silver bullet—it’s a decision support and optimization tool, not a replacement for skilled metallurgists.

--- ### 🔚 **Conclusion:** This case demonstrates how AI can go beyond single-point control and become a powerful **plant optimization tool** in DMS circuits.

By integrating machine learning, real-time data, and multi-objective decision logic, the plant significantly boosted profitability and process stability in a short time.

Equipment Selection for DMS using AI

--- ## 🔵 **Case Study: AI-Assisted Equipment Selection for a New DMS Circuit – Lithium Mine, Western Australia**

### 🎯 Objective:

To use AI-based simulation and historical plant benchmarking to select optimal equipment — specifically cyclones, pumps, and screens — for a new Dense Media Separation (DMS) circuit during project design.

--- ### 🏗️ **Background:** A lithium mining company in Western Australia planned to build a modular pre-concentration plant using DMS to reject barren gangue before flotation. The ore body had **high variability in particle size and density**, making equipment selection for the DMS circuit especially critical. Conventional design relied heavily on OEM datasheets, pilot test data, and engineer experience.

However, the project team decided to incorporate AI to:

* Simulate multiple equipment configurations

* Predict their performance on variable feed blends

* Optimize CAPEX vs. OPEX trade-offs before committing to procurement

--- ### 🧠 **AI Implementation Strategy:**

#### 1. **Data Ingestion**

* Compiled data from 6 existing lithium DMS plants worldwide

* Included cyclone types, pump curves, screen deck parameters, ore characteristics, and performance data

* Augmented with 3D scan data of coarse particles and lab-scale separation results

#### 2. **Digital Twin & Simulation**

* Developed a **digital twin** of the proposed DMS circuit using physics-based models (e.g., flow dynamics, separation behavior)

* Integrated AI with simulation using **Bayesian optimization** to explore thousands of possible configurations

#### 3. **Performance Prediction Modeling**

* Trained a machine learning model to predict key outcomes: separation efficiency, FeSi losses, wear rates, and energy usage

* Ran simulations across 200+ ore blend scenarios to stress-test equipment under different mining phases

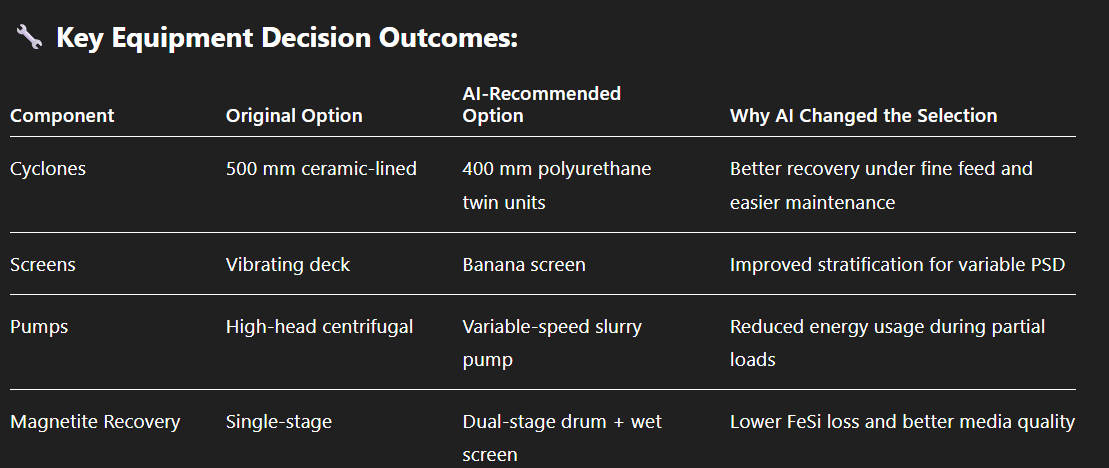

--- ### 🔧 **Key Equipment Decision Outcomes:**

--- ### 📊 **Predicted Benefits from AI-Guided Selection:**

* **8% higher projected recovery** under worst-case ore scenarios *

**22% lower estimated FeSi loss** compared to conventional design

* **17% reduction in lifetime energy cost**

* Deferred \$1.1M in CAPEX by selecting modular components with scalable capacity

--- ### ✅ **Key Takeaways:**

* **AI helped optimize the circuit before it was built**, reducing design risk and future retrofit costs

* The model evaluated **performance, energy, media consumption, and maintainability**, not just throughput

* This approach enabled **data-backed procurement decisions**, improving stakeholder confidence and long-term ROI

--- ### 📌 **Conclusion:** This case study showcases how **AI is now being used upstream**—not just to control or monitor a DMS plant, but to influence **design and equipment selection**. As digital twins and machine learning become more integrated in plant design workflows, AI-assisted decision-making will likely become standard in the **next generation of mineral processing plant design**.

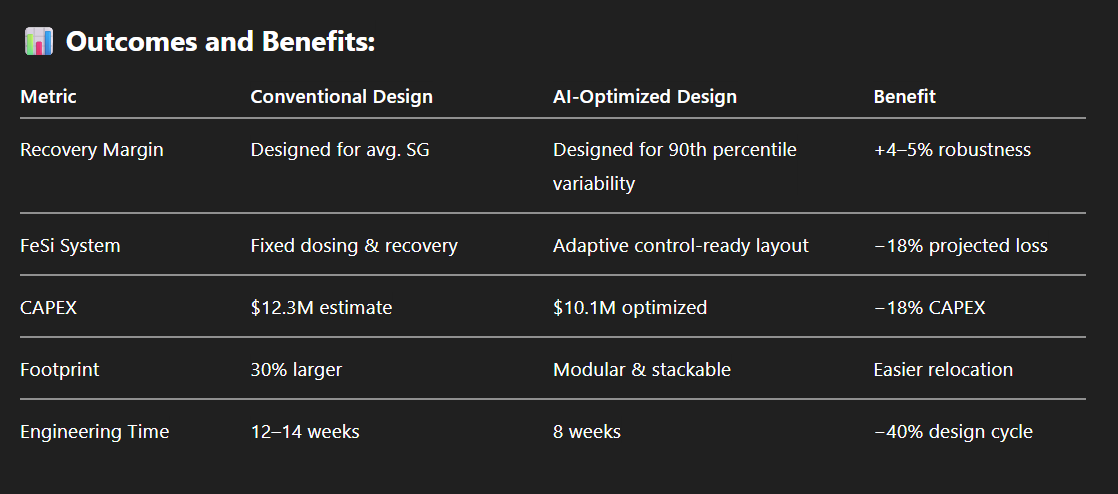

Design of DMS plants using AI

— integrating ore body data, simulation, and machine learning to **optimize layout, equipment sizing, and circuit configuration** before construction.

--- ## 🟠 **Case Study: AI-Driven Design of a Modular DMS Plant for a Polymetallic Ore Body – Central Africa**

### 🎯 Objective: To design a highly efficient, modular DMS plant using AI tools to optimize plant configuration, equipment sizing, and layout based on variable ore characteristics — reducing overdesign and improving flexibility.

--- ### 🏗️ **Background:

** A mining company developing a polymetallic ore deposit in Central Africa needed a pre-concentration DMS plant to upgrade material before downstream milling and flotation.

The ore body was geologically complex, with wide variability in:

* Density contrast between ore and gangue

* Particle size distribution (PSD)

* Abrasiveness and clay content

* Feed tonnage depending on pit phase Designing a one-size-fits-all DMS circuit posed high risks: overdesign could waste capital, while underdesign would limit future throughput.

To overcome this, the engineering team partnered with a digital engineering firm to apply **AI and simulation to the plant design phase.**

--- ### 🧠 **AI Implementation in Plant Design**

#### 1. **Ore Body Data Integration**

* AI ingested 3D block model data with grade, SG, hardness, and lithology

* Simulated 50+ ore scenarios over the life-of-mine (LoM), including extreme blends

* Used unsupervised learning (e.g., k-means clustering) to group ore into “process types”

#### 2. **Digital Twin and Process Simulation**

* Built a digital twin of the entire DMS circuit using METSIM and integrated it with Python-based AI tools

* Simulated behavior of feed bins, crushers, screens, mixing boxes, cyclones, and media recovery under various scenarios

#### 3. **Multi-Objective Optimization**

* Applied genetic algorithms to explore thousands of design combinations

* Simultaneously optimized recovery, media consumption, capital cost, and energy use

* Considered space constraints for modular units (e.g., containerized plant design)

#### 4. **AI-Guided Design Decisions**

* Identified optimal cyclone diameter range (450–500 mm) for most ore types

* Recommended hybrid pump sizing (variable speed) to accommodate fluctuating feed rates

* Suggested inclusion of automated media make-up and recovery units for FeSi stability

* Defined layout options for fast relocation and expansion based on LoM production phases

--- ### 📊 **Outcomes and Benefits:**

--- ### 🔍 **Key Lessons Learned:**

* **Ore body variability must drive design decisions**—not just average values

* **AI reduces uncertainty early**, minimizing change orders during construction

* **Digital twin + AI = faster iterations**, allowing engineers to explore more configurations in less time

* **Process engineers, data scientists, and metallurgists need close collaboration** for success

--- ### 🔚 **Conclusion:**

This project is a leading example of how AI and simulation can be embedded in **DMS plant design**, long before equipment is procured or concrete is poured.

By using AI to evaluate ore body dynamics and simulate plant behavior across realistic scenarios, the company built a **future-proof, scalable, and cost-effective solution** aligned with both operational and geological realities.

DMS plant management and Control using AI

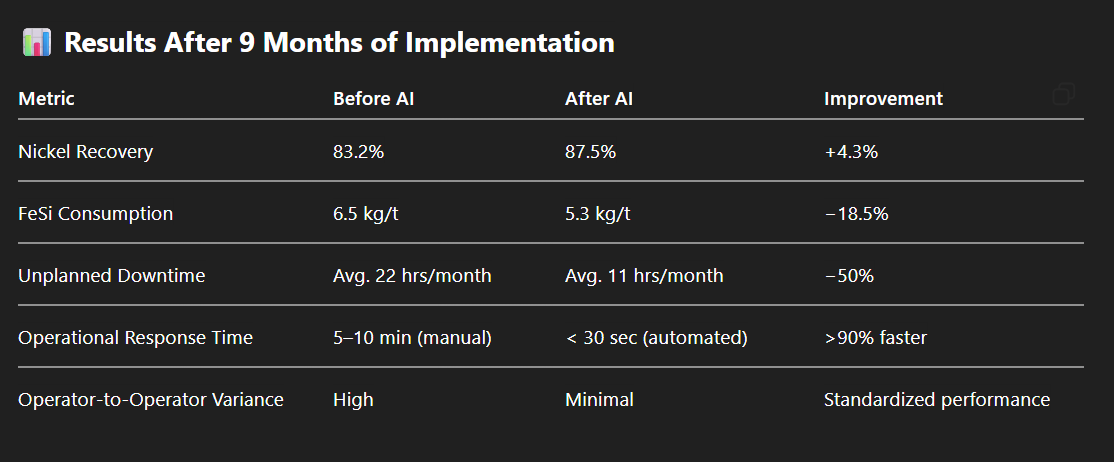

--- ## 🔵 **Case Study: AI-Powered Management and Control of a DMS Plant – Nickel Operation, Southeast Asia**

### 🎯 Objective:

To implement an AI-driven management and control system for a full-scale DMS plant to improve recovery, reduce media loss, stabilize operations, and assist shift supervisors and control room staff with real-time decision-making.

--- ### 🏭 **Background:**

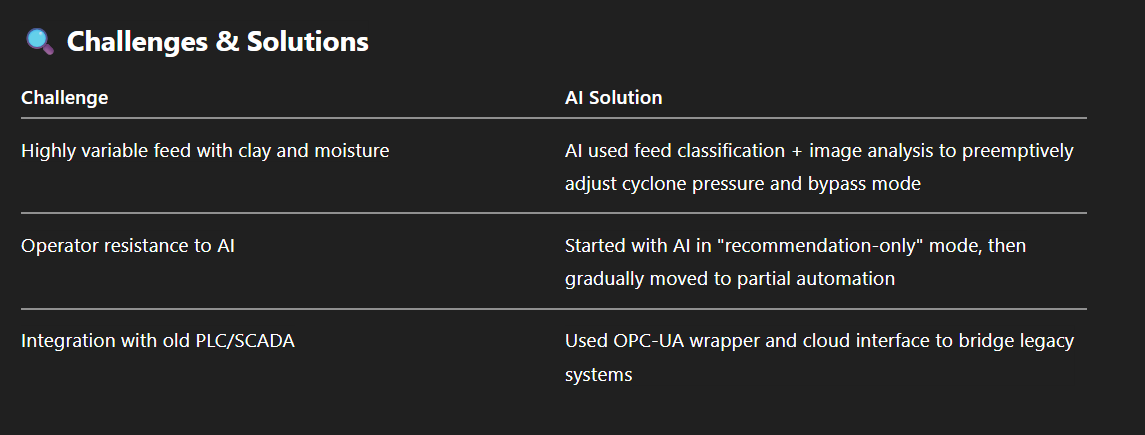

A large-scale nickel laterite mine operating a 300 tph Dense Media Separation (DMS) plant faced challenges in maintaining consistent cut-point performance and media stability due to:

* Rapid changes in feed composition and moisture

* Operator-to-operator variability in decision-making

* High ferrosilicon losses during peak loads or unstable conditions

* Delayed detection of performance issues, often after material loss Management wanted a **central AI system** to assist with **real-time process control, operational decisions, and plant reporting**—not just automation, but intelligent plant-wide management.

--- ### 🤖 **AI Deployment Strategy**

#### 1. **Real-Time Data Integration**

* Installed a unified data platform (based on OSIsoft PI + custom API layer) to pull live data from density gauges, flowmeters, cyclone pressures, pump speeds, and feed belt analyzers

* Integrated data from ERP and laboratory assays for closed-loop feedback

#### 2. **AI Engine Components**

**(a) Predictive Control Module**

* Used LSTM neural networks and ensemble models to predict media instability, misplacement risk, and separation inefficiencies up to 30 minutes in advance

* Automatically adjusted media dosing rate, cyclone bypass valve position, and feed rate in real time **(b) Plant Advisory Dashboard**

* Displayed AI-driven alerts, recommended actions, and root cause diagnostics to control room operators

* Suggested best control strategies based on current ore feed type (classified via real-time image + XRF analysis)

**(c) Management Reporting Tool**

* Auto-generated daily and weekly performance summaries including recovery, downtime causes, FeSi usage, and deviation from AI-optimal parameters

* Benchmarked operator performance and plant stability across shifts

--- ### 📊 **Results After 9 Months of Implementation**

--- ### ✅ **Key Benefits Realized**

* **Real-time predictive control** led to faster adjustments before losses occurred *

**AI decision support** reduced the cognitive burden on operators, improving shift consistency

* **Management had clearer visibility** into plant bottlenecks, media loss trends, and ore type behavior

* **FeSi savings alone paid for the system within 6 months**

--- ### 🔍 **Challenges & Solutions**

--- ### 🧠 **Lessons Learned**

* AI **augments**, not replaces, skilled metallurgists and control room staff * Start with AI as **a decision-support tool** before moving to full closed-loop control

* **Data governance and sensor calibration** are critical for reliable AI performance

* **Cross-functional collaboration** between metallurgists, AI engineers, and operators ensured success

--- ### 🔚 **Conclusion:**

This case study demonstrates that **AI-driven plant management and control in DMS operations is not theoretical—it's operational today.**

By combining real-time data, predictive modeling, and decision support, this nickel plant achieved measurable gains in recovery, stability, and cost efficiency.

AI helped unify people, equipment, and data into a system that is smarter, faster, and more resilient.

DMS operator Training Using AI

--- ## 🟢 **Case Study:

AI-Enhanced Operator Training for DMS Circuit – Platinum Group Metals (PGM) Plant, South Africa**

### 🎯 Objective:

To implement an AI-based operator training simulator and decision support system that improves DMS operator skill, response time, and decision consistency across all shifts—leading to better plant stability and performance.

--- ### 🏭 **Background:**

A major PGM producer in South Africa operated a two-stage Dense Media Separation (DMS) circuit for pre-concentration of chromite and PGM ores.

The plant experienced:

* **High variability between operator shifts**, particularly on night crews

* Inconsistent responses to density drift, feed surges, and cyclone overflow instability

* Frequent **media losses due to delayed reactions** to process deviations

* A skills gap between experienced metallurgists and new junior control room operators Rather than relying on traditional classroom or manual shadowing methods, the company adopted an **AI-driven training and decision-support approach** to accelerate skill development and standardize performance.

--- ### 🧠 **AI Training System Components**

#### 1. **Virtual Plant Simulator**

* Developed a **digital twin** of the DMS circuit using historic plant data and control logic

* Simulated dynamic process scenarios: e.g., feed variability, cyclone blockage, magnetite dilution, pump trips

* Enabled operators to practice responses in a **safe, real-time environment**

#### 2. **AI-Coached Learning Engine**

* AI monitored trainee actions during simulation and gave **instant feedback**

* Reinforcement learning-based model scored responses on timeliness, appropriateness, and outcome

* Provided personalized coaching: e.g., “Cyclone bypass activated too late – density instability worsened”

#### 3. **Shift Support Dashboard (Live Use)**

* After training, operators used a real-time AI dashboard in the actual control room

* Offered **real-time alerts, best-practice suggestions**, and “confidence scores” for key decisions * Logged decisions to build operator profiles and identify additional training needs

--- ### 📊 **Results After 6 Months**

--- ### ✅ **Key Features That Made It Work**

* **Realistic plant scenarios** using actual ore and equipment data

* **AI-powered feedback loops** helped operators self-correct and learn faster

* Built **“muscle memory”** for emergencies without risking real plant performance

* Used AI to **bridge the gap between theory and practice**, accelerating readiness

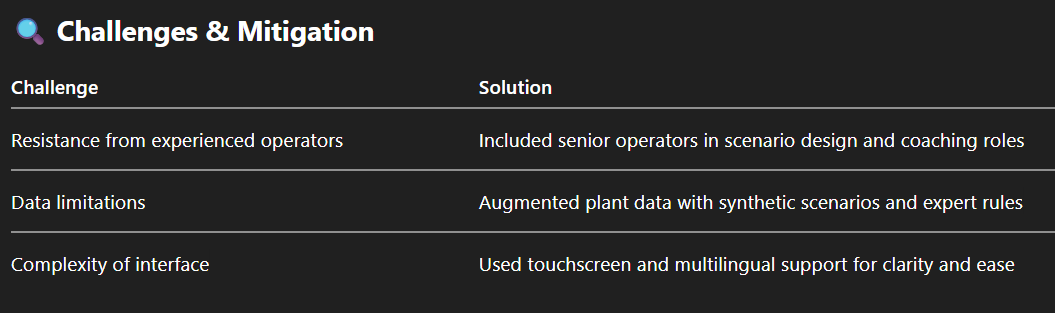

--- ### 🔍 **Challenges & Mitigation**

--- ### 🔚 **Conclusion:**

This case shows that AI is not only a control and optimization tool, but also a powerful **human learning accelerator** in complex mineral processing environments.

By combining real plant data, simulation, and real-time coaching, the platinum producer developed a new generation of confident, consistent, and high-performing DMS operators—faster and more effectively than with traditional methods.