Predictive Maintenace using Machine Learning - An Introduction

Here's an overview of the concept, key components, and common techniques:

--- ## 🔧 Predictive Maintenance Using Machine Learning

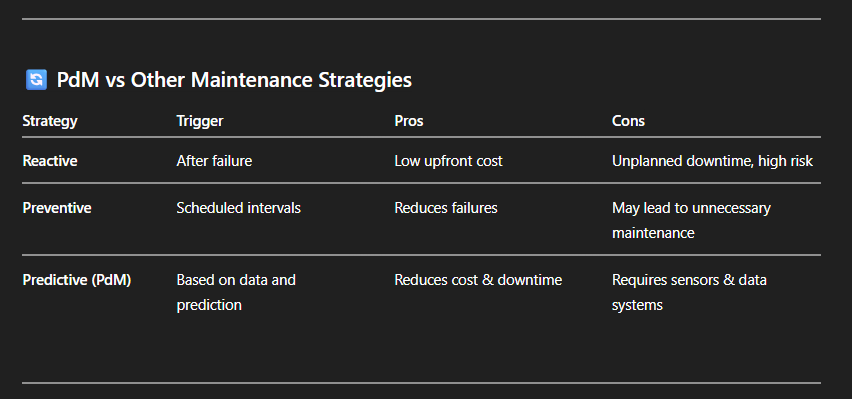

### 📌 What Is Predictive Maintenance (PdM)? Predictive maintenance is a data-driven approach to anticipate equipment failures by analyzing patterns from operational data. It differs from:

* **Reactive Maintenance:** Fixing equipment after it fails.

* **Preventive Maintenance:** Performing maintenance on a schedule regardless of equipment condition.

### 🧠 Role of Machine Learning (ML) Machine learning enables systems to learn from historical and real-time data to:

* Predict **when** a machine will likely fail.

* Identify **why** it is failing.

* Optimize **what** maintenance action to take and **when**.

--- ## ⚙️ Key Components

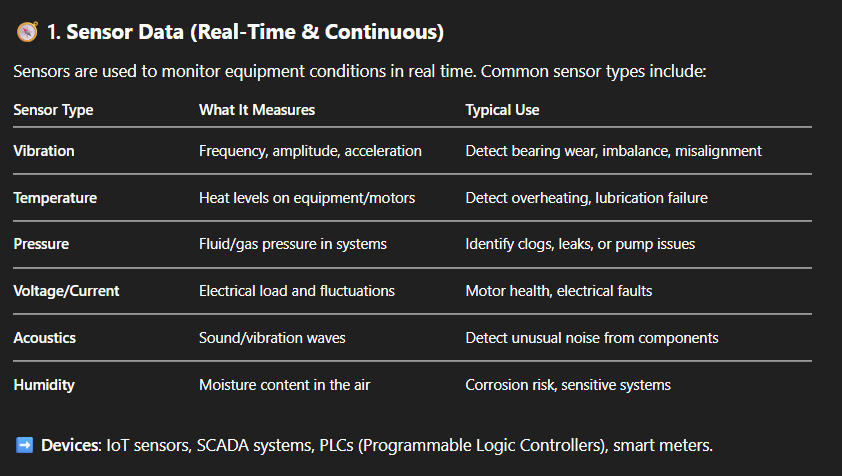

1. **Data Collection**

* Sensors: Vibration, temperature, pressure, voltage, current, acoustics, etc.

* Logs: Maintenance records, failure logs.

* Usage patterns: Operating hours, workload intensity.

2. **Data Preprocessing**

* Cleaning: Handle missing or corrupted data.

* Feature Engineering: Extract useful features (e.g., rolling mean, FFT of vibration).

* Labeling: Assign labels such as "Healthy", "Failing", "Critical", etc.

3. **Model Selection**

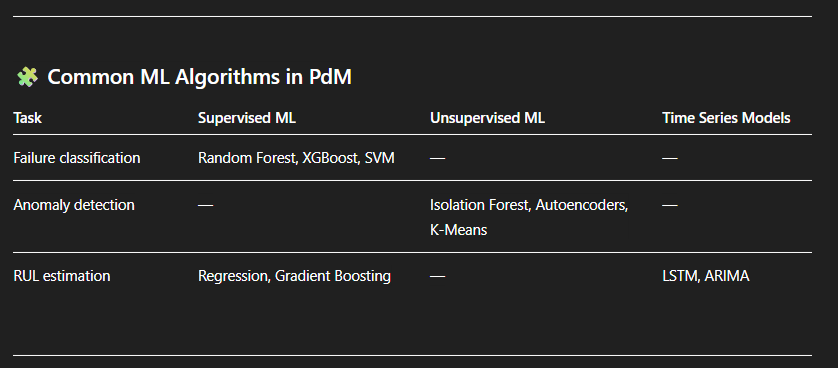

* **Supervised Learning:** Needs historical failure data.

* Algorithms: Random Forest, Gradient Boosting, SVM, Neural Networks.

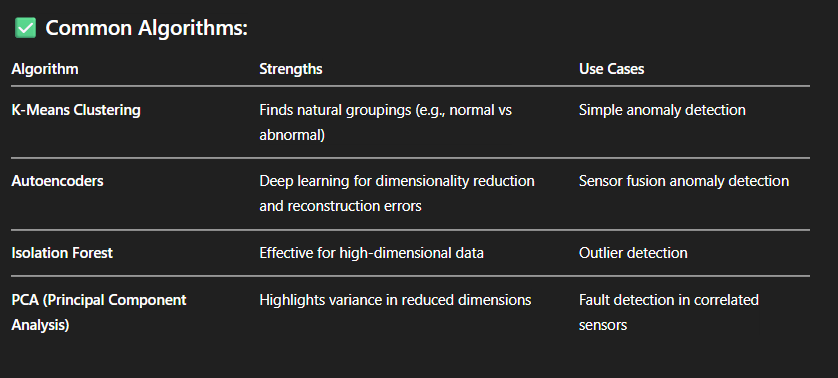

* **Unsupervised Learning:** Detect anomalies without labeled data.

* Algorithms: K-Means, Autoencoders, Isolation Forest, PCA.

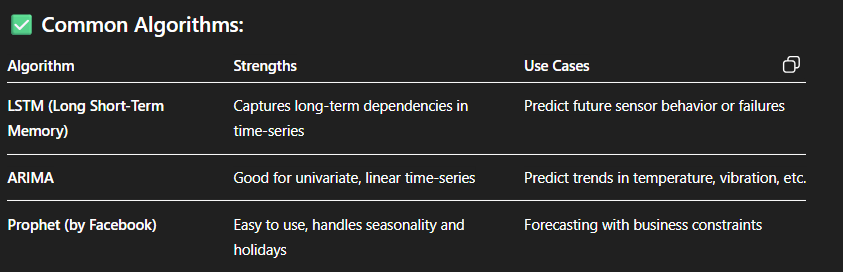

* **Time-Series Models:**

* LSTM (Long Short-Term Memory), ARIMA, Prophet.

4. **Model Deployment**

* Real-time prediction and alerting.

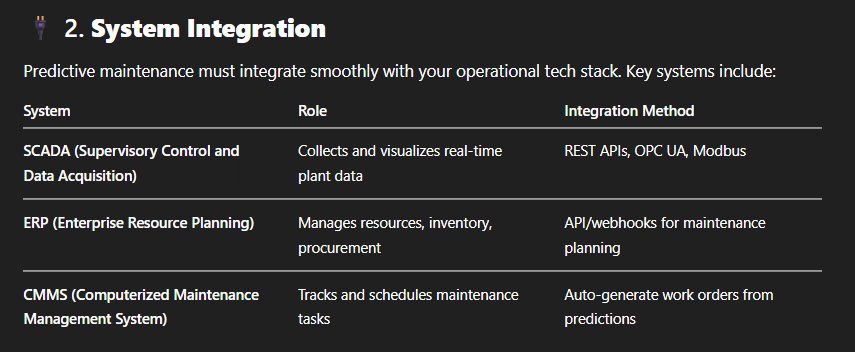

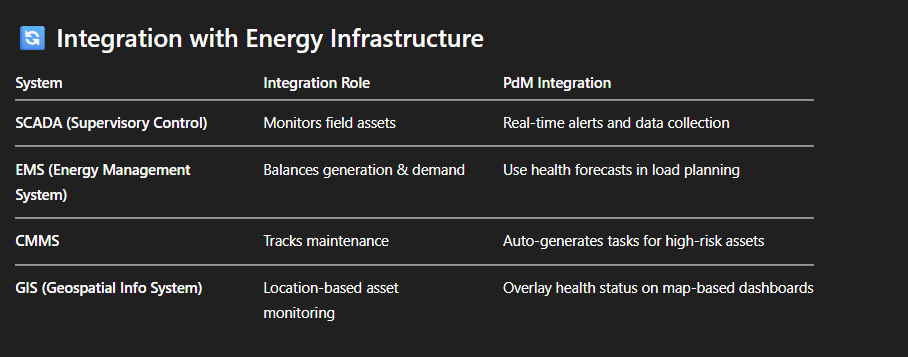

* Integration with SCADA, ERP, or CMMS systems.

5. **Feedback Loop**

* Continual model refinement based on new data and outcomes.

--- ## 📈 Common Use Cases

* **Manufacturing:** CNC machines, robotics, motors.

* **Energy Sector:** Wind turbines, transformers, pipelines.

* **Transportation:** Aircraft engines, train brakes, fleet management.

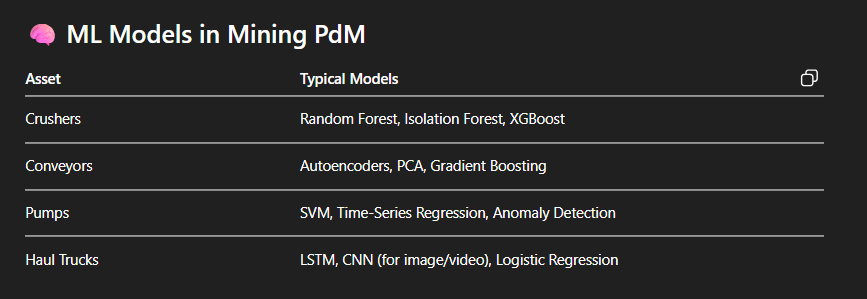

* **Mining:** Crushers, conveyors, pumps, haul trucks.

--- ## ✅ Benefits

* Reduced unplanned downtime

* Lower maintenance costs

* Extended equipment lifespan

* Safer operations

* Higher operational efficiency

--- ## 🛠 Example Workflow

1. Collect vibration and temperature data from a motor.

2. Label past failures and normal operation periods.

3. Train a Random Forest model to classify risk of failure.

4. Deploy the model to predict failure 48 hours in advance.

5. Send automated alerts to maintenance teams.

--- If you want, I can help you:

* Design a predictive maintenance model for a specific industry (e.g., mining or manufacturing).

* Implement sample code using Python and libraries like `scikit-learn`, `XGBoost`, or `TensorFlow`.

* Build a roadmap for integrating PdM into your current operations. Would you like a more technical deep dive or a case study example?

What is Predictive Maintenance?

**Predictive Maintenance (PdM)** is a **proactive maintenance strategy** that uses real-time data and machine learning to predict **when** equipment is likely to fail, so maintenance can be performed **just in time**—*not too early, not too late*.

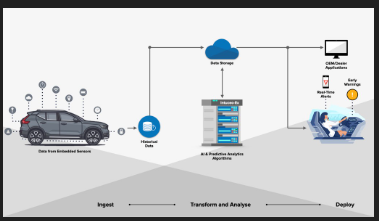

--- ### 🛠 How It Works PdM relies on:

* **Sensors** that monitor equipment conditions (e.g., vibration, temperature, noise, current).

* **Data analytics and machine learning** to detect patterns and trends.

* **Predictive models** that estimate the **Remaining Useful Life (RUL)** or risk of failure.

--- ### 🔄 PdM vs Other Maintenance Strategies

--- ### 🎯 Key Goals of PdM

* **Minimize unplanned downtime**

* **Extend equipment life**

* **Optimize maintenance scheduling**

* **Lower overall maintenance costs**

* **Improve safety and reliability**

--- ### 💡 Real-World Example

In a mining operation, sensors on a **vibrating screen motor** track temperature and vibration. A PdM system uses this data to detect early signs of bearing wear. When the risk of failure crosses a threshold, it sends an alert to maintenance before the motor breaks down—preventing a costly production halt.

--- Would you like an example of a PdM workflow, system architecture, or a basic ML model used in PdM?

The role of Machine Learning in Predictive Maintenance

--- ### 🧠 What Machine Learning Does in PdM

1. **Failure Prediction**

* Learns from historical sensor and maintenance data to predict **when a component will fail**.

* Example: Predicts that a pump is likely to fail within 3 days based on rising vibration patterns.

2. **Anomaly Detection**

* Identifies unusual behavior that may signal degradation or a fault. * Useful when labeled failure data is scarce or unavailable.

3. **Remaining Useful Life (RUL) Estimation**

* Estimates how long equipment will continue operating reliably. * Supports proactive maintenance planning.

4. **Root Cause Analysis** * Finds patterns that point to specific causes of repeated failures.

5. **Maintenance Optimization**

* Helps determine **what kind of maintenance** should be done and **when**, minimizing unnecessary interventions.

--- ### 🧩 Common ML Algorithms in PdM

--- ### 📊 Example Use Case In a fleet of industrial compressors:

* **Sensors** collect data like pressure, temperature, and vibration.

* A **Random Forest model** is trained on labeled data (normal vs failed states).

* The model predicts failure with 92% accuracy.

* The system sends alerts 24 hours before probable failure, allowing timely maintenance.

--- ### 📦 ML Workflow for PdM

1. **Data Collection**: Sensors, logs, usage patterns

2. **Preprocessing**: Clean, normalize, label, extract features

3. **Model Training**: Select and train the ML algorithm

4. **Evaluation**: Use metrics like accuracy, precision, recall, and ROC-AUC

5. **Deployment**: Integrate with real-time systems

6. **Feedback Loop**: Continuously improve the model with new data

--- Would you like help building a simple ML model for PdM using Python? Or would you like a sample dataset to try it on?

Data Collection for Predictive Maintenance

--- ### 🧭 1. **Sensor Data (Real-Time & Continuous)**

Sensors are used to monitor equipment conditions in real time. Common sensor types include:

--- ### 🗃 2. **Logs and Historical Records**

Historical data provides labeled examples that help ML models learn to distinguish between healthy and failing equipment.

* **Maintenance Logs**

* Records of what was fixed, when, and why

* Includes notes on parts replaced, technicians’ observations

* **Failure Logs**

* Specifics about failures: time, cause, symptoms

* Crucial for supervised learning models

* **Work Orders / CMMS Data**

* Data from Computerized Maintenance Management Systems

* Includes scheduling, cost, and type of maintenance performed

--- ### 🕒 3. **Usage and Operational Patterns** These describe how the equipment is used, which heavily influences wear and tear:

* **Operating Hours**

* Cumulative or time since last maintenance

* **Load/Stress Levels**

* How hard the equipment is working (e.g., tonnage, speed, RPM)

* **Cycle Count**

* Number of operational cycles (useful in repetitive operations like manufacturing)

* **Idle vs Active Time**

* Helps assess under-utilization or overuse

--- ### 💡 Why It Matters

* **Sensor data** detects *real-time symptoms*.

* **Logs** provide *context and ground truth*.

* **Usage patterns** give *degradation behavior* over time.

--- Would you like a visual diagram showing how these data sources flow into a predictive maintenance system?

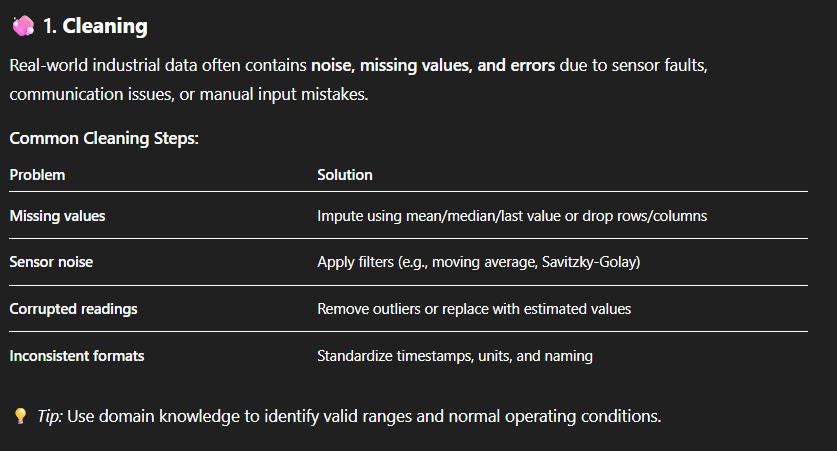

Data Preprocessing for Predictive Maintenance

--- ### 🧼 1. **Cleaning** Real-world industrial data often contains **noise, missing values, and errors** due to sensor faults, communication issues, or manual input mistakes.

#### Common Cleaning Steps:

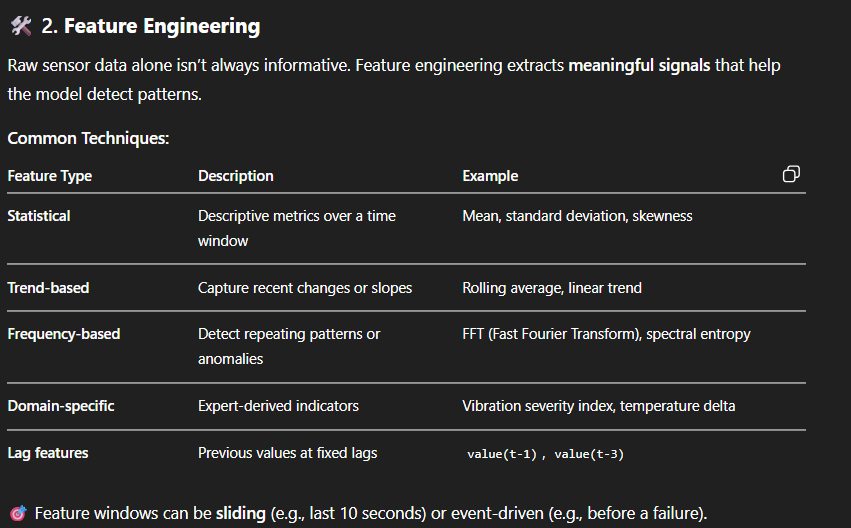

--- ### 🛠 2. **Feature Engineering** Raw sensor data alone isn’t always informative. Feature engineering extracts **meaningful signals** that help the model detect patterns.

#### Common Techniques:

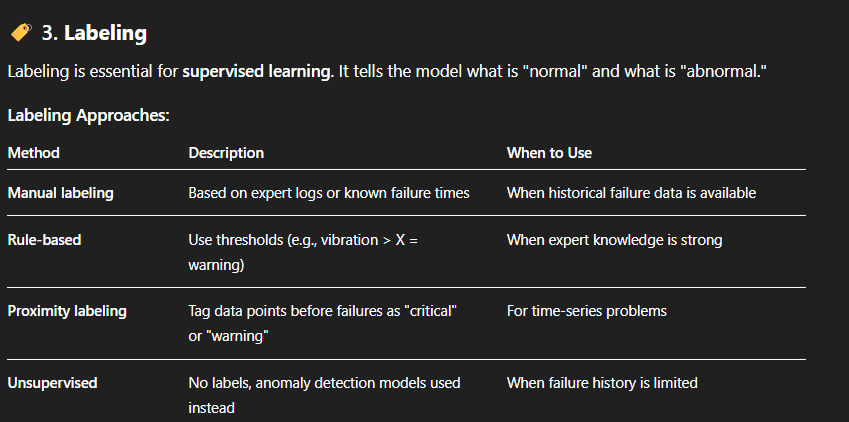

--- ### 🏷️ 3. **Labeling** Labeling is essential for **supervised learning**. It tells the model what is "normal" and what is "abnormal."

#### Labeling Approaches:

#### Example Labels: * `0`: Healthy * `1`: Degraded * `2`: Failing * `3`: Critical failure

--- ### 🧠 Importance Good preprocessing:

* Improves **model accuracy**

* Reduces **training time**

* Enables **early failure detection**

--- Would you like a sample Python code snippet showing how to preprocess time-series vibration data for predictive maintenance?

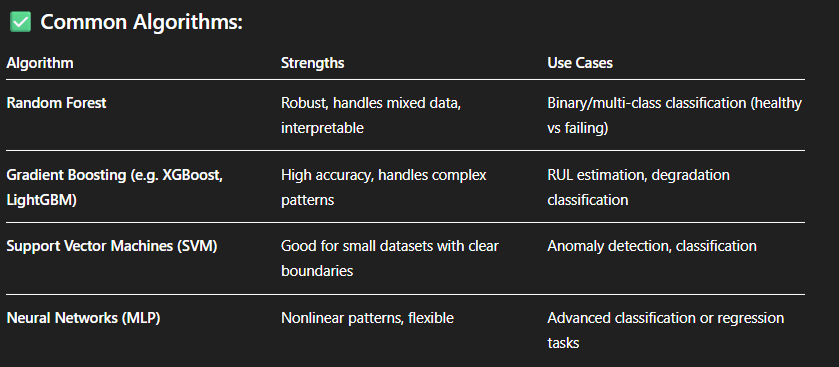

Model Selection for Predictive Maintenance

--- ## 🏷️ 1. **Supervised Learning** > Used when **historical failure data with labels** (e.g., healthy, failing) is available.

### 🔍 Goal: Classify the health status of equipment or predict **Remaining Useful Life (RUL)**.

### ✅ Common Algorithms:

--- ## ❓ 2. **Unsupervised Learning** > Used when **labeled failure data is unavailable** or scarce.

### 🔍 Goal: Detect **anomalies** or **outliers** that may indicate early signs of failure.

### ✅ Common Algorithms:

--- ## 🕒 3. **Time-Series Models** > Used when equipment behavior evolves over **time**, and **temporal patterns** are critical.

### 🔍 Goal: Forecast sensor readings, detect deviations, or estimate RUL from time-series data.

### ✅ Common Algorithms:

--- ## 🧠 Hybrid Approaches

* Combine models (e.g., LSTM + Random Forest) * Use unsupervised learning for anomaly detection, followed by supervised models for failure classification

* Stack multiple time-series and classification models

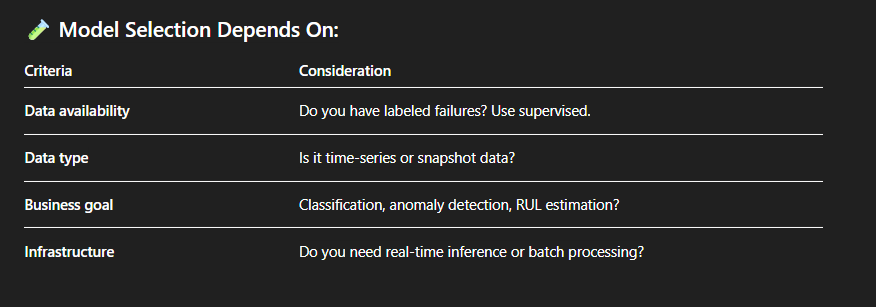

--- ### 🧪 Model Selection Depends On:

--- Would you like a model selection flowchart or example code for training one of these models?

Model Deployment for Predictive Maintenance

--- ## ⚡ 1. **Real-Time Prediction and Alerting**

### ✅ Objectives:

* Continuously monitor sensor data

* Run predictions as new data arrives

* Alert operators before failure occurs

### 🔧 Deployment Steps:

1. **Stream incoming sensor data** from machines (via MQTT, OPC UA, Kafka, etc.)

2. **Preprocess data in real time** (e.g., windowing, feature extraction)

3. **Feed into the ML model** (e.g., REST API, containerized microservice)

4. **Output prediction or RUL estimate**

5. **Trigger alerts** via:

* Email, SMS, dashboards

* SCADA HMI (Human-Machine Interface) pop-ups

* Mobile maintenance apps

--- ## 🔌 2. **System Integration** Predictive maintenance must integrate smoothly with your operational tech stack. Key systems include:

### 🔄 Example Workflow:

> LSTM model predicts conveyor motor failure risk at 85%

→ Triggers alarm in SCADA

→ Auto-creates work order in CMMS

→ ERP updates spare parts inventory

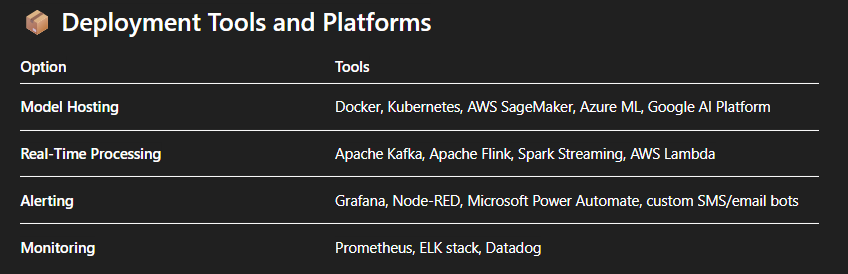

--- ## 📦 Deployment Tools and Platforms

--- ## 🧠 Best Practices * **Latency:**

Ensure low prediction latency (<5s) for real-time systems.

Scalability:

Use container orchestration (e.g., Kubernetes) for scalable ML APIs. Fail-safes:

Define fallback rules if the ML model fails or is offline.

Feedback loop:

Log prediction outcomes to continuously retrain and improve the model. Would you like:

A sample architecture diagram for PdM deployment?

Code for serving a model as an API using FastAPI or Flask?

Integration tips for a specific platform like SCADA or CMMS?

Feedback loop in Predictive Maintenance

--- ## 🎯 Why It Matters

* **Equipment degrades differently over time**

* **Sensor calibration may drift**

* **Operating conditions can change** (e.g., increased workload, climate, aging infrastructure) Without a feedback loop, even high-performing models can **degrade in accuracy** and start missing failures or triggering false alarms.

--- ## 🧠 What the Feedback Loop Does

1. **Monitors model performance**

* Tracks metrics like precision, recall, false positives/negatives over time

2. **Collects fresh data**

* New sensor readings, updated labels, logs from recent failures or maintenance events

3. **Captures real-world outcomes**

* Was the predicted failure real?

* Did the system miss anything?

* Was the prediction early enough?

4. **Retrains the model**

* Periodically (e.g., weekly, monthly)

* Automatically (if degradation is detected)

5. **Validates and redeploys**

* Ensures retrained models outperform current ones

* Uses CI/CD pipelines for deployment

--- ## 🔁 Feedback Loop Pipeline

``` 1. Data Ingestion

⟶ 2. Prediction

⟶ 3. Outcome Monitoring

⟶ 4. Logging

⟶ 5. Model Evaluation

⟶ 6. Retraining

⟶ 7. Testing

⟶ 8. Deployment ```

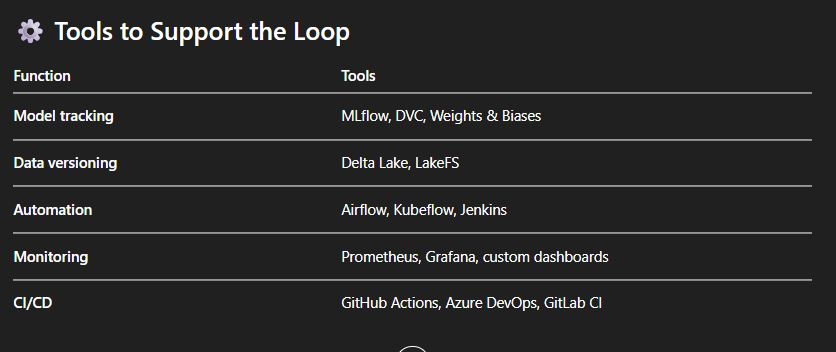

--- ## ⚙️ Tools to Support the Loop

--- ## ✅ Example Scenario

1. A Random Forest model predicts a gearbox is "healthy."

2. The gearbox fails 3 days later — this is logged as a **false negative**.

3. That failure instance is added to the training set.

4. Weekly retraining pipeline updates the model using the new labeled example.

5. Updated model is evaluated and redeployed if better.

--- Would you like:

* A diagram of the full PdM lifecycle including the feedback loop? * Sample code for automated retraining and validation?

* Guidelines on how often to retrain models in PdM systems?

Predictive Maintenance in Manufacturing

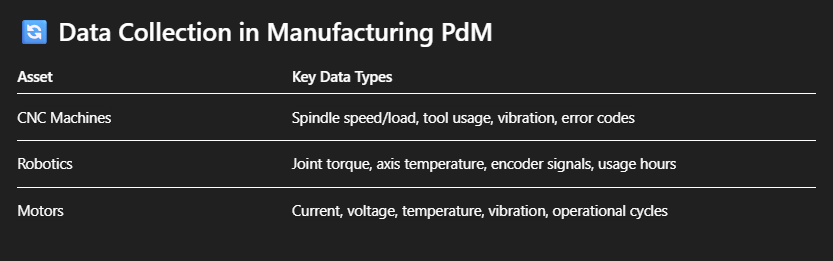

Key assets include **CNC machines**, **industrial robots**, and **electric motors**.

--- ## 🛠️ Key Applications in Manufacturing

### 1. **CNC Machines (Computer Numerical Control)**

* **What Fails:** Spindles, ball screws, tool changers, cooling systems

* **Sensors Used:** Vibration, temperature, spindle load, acoustic emission

* **PdM Value:**

* Detect tool wear or breakage

* Predict spindle bearing failure

* Reduce scrap due to sudden machine errors

> 📈 Example: Use vibration and spindle motor current to predict when spindle bearings will degrade, allowing replacement during scheduled downtime.

--- ### 2. **Robotics**

* **What Fails:** Joints, actuators, gearboxes, end effectors

* **Sensors Used:** Torque, current, encoder feedback, temperature

* **PdM Value:** * Detect drift or backlash in arms

* Prevent unplanned robot crashes

* Maintain precision in pick-and-place or welding

> 🧠 ML can learn the robot's baseline joint torque and identify deviations as early signs of wear.

--- ### 3. **Electric Motors and Drives**

* **What Fails:** Bearings, insulation, windings, couplings

* **Sensors Used:** Vibration, current signature, voltage, thermal imaging

* **PdM Value:**

* Identify early signs of rotor imbalance or bearing wear

* Avoid overheating or insulation breakdown

* Improve energy efficiency by detecting overloads

> 🧰 Techniques like **Motor Current Signature Analysis (MCSA)** are combined with ML for early fault detection.

--- ## 🔄 Data Collection in Manufacturing PdM

--- ## 🧠 ML Models Commonly Used

* **Supervised:** Random Forest, XGBoost, CNNs for image-based fault detection

* **Unsupervised:** Autoencoders for robotic joint anomalies, Isolation Forest

* **Time-Series:** LSTM for multi-sensor CNC health prediction, ARIMA for load forecasting

--- ## 📦 Integration with Manufacturing Systems

* **SCADA/HMI:** Real-time dashboard alerts for machine operators

* **CMMS:** Auto-generate maintenance tasks for flagged equipment

* **MES (Manufacturing Execution Systems):

** Track machine availability and condition

--- Would you like a manufacturing-specific PdM workflow diagram or example dataset (e.g., for CNC vibration data)?

Predictive Maintenance in Energy sector

Predictive maintenance (PdM) is critical for minimizing downtime, reducing failures, and optimizing performance across high-value infrastructure like **wind turbines**, **transformers**, and **pipelines**.

--- ## 🌬️ 1. **Wind Turbines**

### 🔧 Common Failure Points:

* Gearboxes

* Blades (erosion, cracking)

* Generators and bearings

* Pitch/yaw systems

### 📡 Sensor Data:

* Vibration (gearbox, nacelle)

* Temperature (gearbox oil, generator)

* Wind speed, power output

* Acoustic emissions

* SCADA system logs

### 💡 PdM Value:

* Detect bearing and gearbox wear early

* Forecast blade fatigue or pitch actuator faults

* Reduce maintenance trips in remote locations

> 🧠 ML Example: Use LSTM models to analyze turbine SCADA data and predict failures 5–7 days in advance.

--- ## 🔌 2. **Transformers (Power Grid)**

### 🔧 Common Failure Points:

* Insulation breakdown

* Bushing cracks

* Cooling system failure

* Tap changer degradation

### 📡 Sensor Data:

* Oil temperature, dissolved gas analysis (DGA)

* Load current, voltage, harmonics

* Ambient temperature

* Partial discharge signals

### 💡 PdM Value:

* Predict overheating or insulation failure

* Reduce risk of catastrophic outages

* Optimize asset life through condition-based maintenance

> 🔍 DGA + ML: Predict internal arcing faults using historical gas concentration trends and classification models like Random Forest.

--- ## 🛢️ 3. **Pipelines (Oil & Gas, Water, Hydrogen)**

### 🔧 Common Failure Points:

* Corrosion, leakage, cracking

* Valve failures

* Pump station anomalies

### 📡 Sensor Data:

* Pressure, flow rate, acoustic sensors

* Vibration, temperature

* Smart pig inspection data * Leak detection systems

### 💡 PdM Value:

* Detect micro-leaks and pressure drops before they escalate

* Reduce risk of environmental damage and fines

* Optimize pump and valve maintenance schedules

> 🛠️ Anomaly Detection: Use Isolation Forest or Autoencoders to flag unusual pressure-drop signatures or vibration spikes.

--- ## 🔄 Integration with Energy Infrastructure

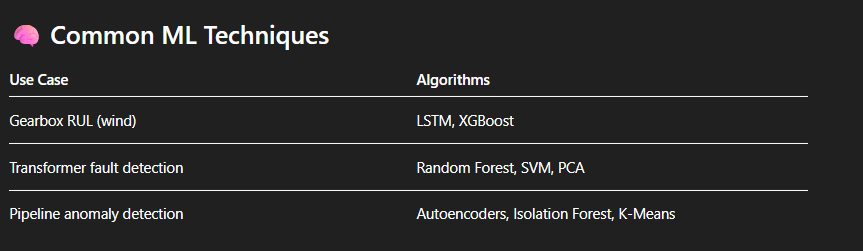

--- ## 🧠 Common ML Techniques

--- Would you like:

* A sample PdM architecture diagram for the energy sector?

* Code to analyze transformer DGA data using ML?

* A case study from a wind turbine or pipeline PdM system?

Predictive Maintenance in Transportation

Given the high stakes in passenger safety and logistics uptime, predictive maintenance is a key enabler of operational excellence.

--- ## ✈️ 1. **Aircraft Engines**

### 🔧 Common Failure Points:

* Turbines and compressors

* Bearings and fan blades

* Fuel injectors

* Vibration-related fatigue

### 📡 Sensor Data:

* Exhaust gas temperature (EGT)

* Oil pressure and temperature

* Vibration (accelerometers)

* Engine pressure ratio (EPR)

* Flight data recorder (FDR) logs

### 💡 PdM Value:

* Predict bearing or blade degradation

* Schedule proactive repairs between flights

* Avoid inflight shutdowns or emergency landings

> 🧠 ML Example: LSTM model analyzes flight-by-flight sensor logs to estimate engine RUL and prevent AOG (Aircraft on Ground) scenarios.

--- ## 🚄 2. **Train Brakes and Systems**

### 🔧 Common Failure Points:

* Brake pads and discs

* Air compressors and valves * Suspension components

* Motor and gearbox in electric locomotives

### 📡 Sensor Data:

* Brake pressure, pad wear sensors

* Wheel speed and vibration

* Ambient and brake system temperature

* Event logs from Train Control & Monitoring System (TCMS)

### 💡 PdM Value:

* Monitor braking force consistency

* Detect stuck or leaking brake valves

* Optimize overhaul intervals without compromising safety

> 📈 Autoencoder detects abnormal braking patterns by comparing real-time pressure behavior with historical norms.

--- ## 🚚 3. **Fleet Management (Trucks, Buses, Delivery Vehicles)**

### 🔧 Common Failure Points:

* Engine overheating

* Brake wear

* Battery degradation (in EVs)

* Tire pressure and suspension failures

### 📡 Sensor Data:

* OBD-II/ECU data (RPM, temperature, fuel, throttle position)

* GPS and telematics (speed, idling time, routes)

* Tire pressure monitoring system (TPMS)

* Driver behavior (braking, acceleration) ### 💡 PdM Value:

* Reduce roadside breakdowns and delays

* Lower fuel and maintenance costs

* Improve driver safety and compliance > 🛠️ Predictive models flag trucks showing early signs of fuel injector or alternator issues, allowing intervention before a service call is needed.

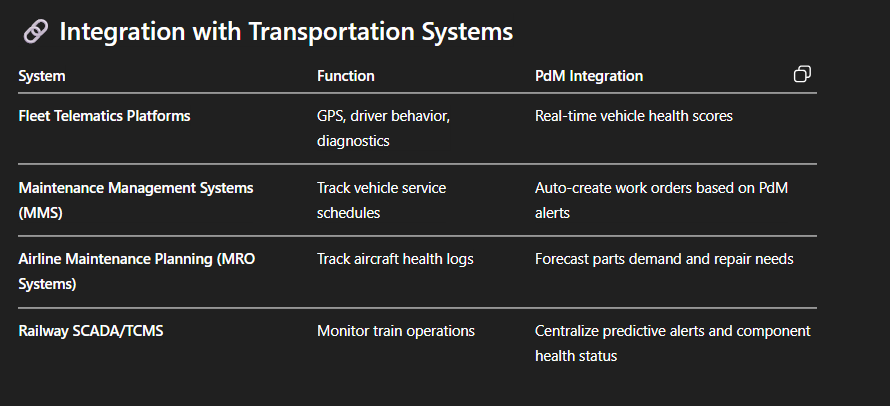

--- ## 🔗 Integration with Transportation Systems

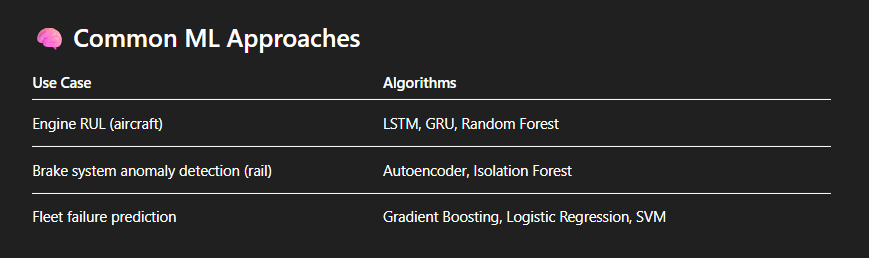

--- ## 🧠 Common ML Approaches

--- Would you like:

* A sample architecture for a fleet PdM system?

* Code for engine degradation prediction?

* A case study of PdM in aviation or rail?

Predictive Maintence in Mining

--- ## 🪨 1. **Crushers (Jaw, Cone, Impact)**

### 🔧 Common Failure Points:

* Bearings and shafts

* Jaw liners and wear plates

* Drive motors and gearboxes

* Hydraulic systems

### 📡 Sensor Data:

* Vibration sensors (bearing condition)

* Motor current/voltage

* Oil temperature and pressure

* Load sensor (tonnage throughput)

### 💡 PdM Value:

* Predict bearing or shaft misalignment

* Detect wear liner degradation

* Optimize shutdowns for reline planning

> 🛠️ Example: ML model flags a 30% increase in vibration RMS + 10°C oil temperature rise = early-stage bearing wear.

--- ## 📦 2. **Conveyors**

### 🔧 Common Failure Points:

* Idlers and rollers

* Drive motors and gearboxes

* Belt misalignment, slippage, or tears

* Pulley bearings

### 📡 Sensor Data:

* Belt speed and tension

* Motor current draw

* Vibration and acoustic signals (idler health)

* Belt position and alignment sensors

### 💡 PdM Value:

* Prevent catastrophic belt failures

* Detect overheating in gearboxes

* Reduce production stoppages from misalignment

> 📈 Unsupervised ML detects anomalies in current and vibration that precede gearbox failure.

--- ## 🚰 3. **Pumps (Slurry, Dewatering, Process Water)**

### 🔧 Common Failure Points:

* Impeller erosion or blockage

* Seal and bearing wear

* Motor failure or overheating

### 📡 Sensor Data:

* Suction/discharge pressure

* Flow rate

* Motor temperature and power usage

* Vibration and acoustic sensors

### 💡 PdM Value:

* Detect cavitation or dry-running early

* Optimize maintenance of seals and bearings

* Prevent pump failure and flooding of mining areas

> 🧠 Random Forest classifier predicts seal wear based on pressure differential + vibration signature.

--- ## 🚛 4. **Haul Trucks**

### 🔧 Common Failure Points:

* Tires, suspension, brakes

* Engine and cooling system

* Transmission and drivetrain

* Hydraulics and steering

### 📡 Sensor Data:

* Onboard diagnostics (CAN bus, OBD)

* Tire pressure and temperature (TPMS)

* Oil analysis (iron, viscosity, contamination)

* Fuel efficiency and engine load

### 💡 PdM Value:

* Reduce catastrophic engine or transmission failures

* Predict tire blowouts or overheating brakes

* Extend asset life and optimize fleet dispatching

> 📊 LSTM model analyzes load cycles and oil temperature to predict engine failure risk 72 hours in advance.

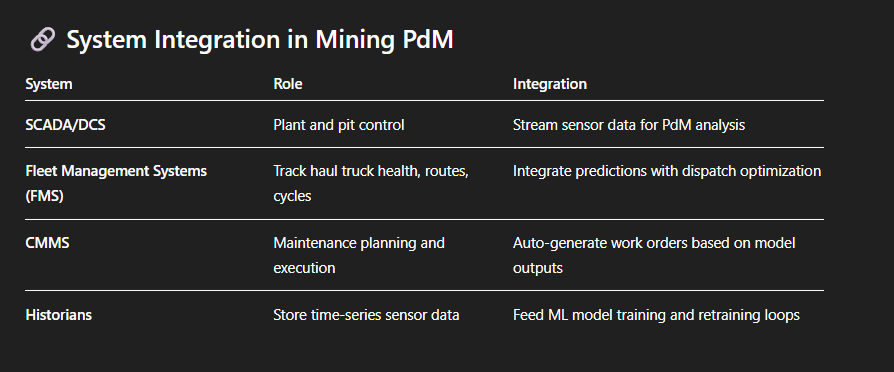

--- ## 🔗 System Integration in Mining PdM

--- ## 🧠 ML Models in Mining PdM

--- Would you like:

* A mining PdM system architecture diagram?

* Example Python code for pump fault classification?

* A checklist for deploying PdM in a mining operation?

Predictive Maintenace in Action - Workflow Example

--- ## 🔁 Step-by-Step Workflow

--- ### **1. Data Collection** Collect real-time and historical sensor data from the motor.

**Sensors used:**

* **Vibration** (e.g., axial, radial)

* **Temperature** (bearing housing, stator windings)

* **Optional:** Current, RPM, voltage **Tools/Devices:** IoT sensors, SCADA system, PLCs, data loggers

--- ### **2. Data Labeling** Identify and tag periods of normal and abnormal operation.

**Labels:**

* `0` → Healthy (normal operation)

* `1` → Warning or Degraded

* `2` → Failure (pre-failure or breakdown event)

**Sources for labeling:**

* Maintenance logs

* Failure reports

* Manual technician input

---

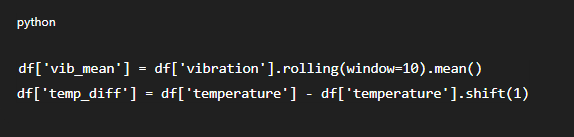

### **3. Feature Engineering & Preprocessing**

* Extract statistical features: mean, std, kurtosis, skew

* Time-domain features: rolling mean, RMS

* Frequency-domain features: FFT peaks

* Normalize/scale the data

* Handle missing values

**Feature Examples:

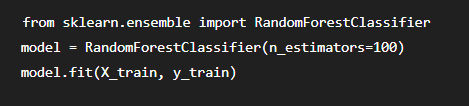

--- ### **4. Model Training**

Train a **Random Forest classifier** to predict failure risk.

**Steps:**

* Split data into training/test sets

* Use `RandomForestClassifier` from `scikit-learn`

* Tune parameters (e.g., n\_estimators, max\_depth)

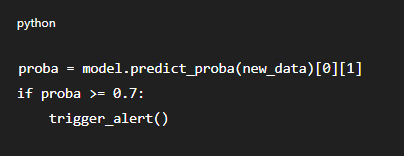

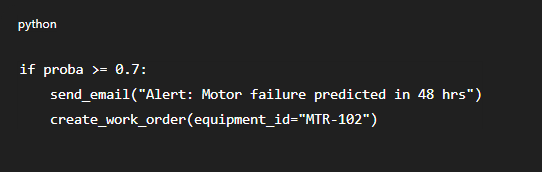

### **5. Prediction & Inference**

Use the trained model to **predict failure within the next 48 hours**.

* Apply the model in real time on incoming sensor data

* If probability of failure ≥ threshold (e.g. 0.7), flag it

### **6. Deployment**

Deploy the model as an **API** or integrate into an existing monitoring platform.

**Tools:**

* FastAPI or Flask for API

* Docker for containerization

* Stream processing with Kafka/Spark if needed

--- ### **7. Automated Alerting** When a high failure risk is predicted:

* Send alerts via:

* SMS

* Maintenance dashboard

* Auto-create a work order in the **CMMS**

--- ### ✅ Final Outcome:

* Maintenance team receives a warning **2 days before failure**

* The issue is investigated and resolved during scheduled downtime

* No unplanned shutdown occurs

--- Would you like a Python notebook template for this workflow, or a deployment diagram to visualize the system?