Introduction - Whats Real and Whats Hype?

Trending

How can I use AI to enhance Metallurgical Performance of Mineral Processing Plants

The use of **AI in plant monitoring**—especially in industrial, mining, manufacturing, and processing plants—is evolving rapidly. However, not all claims are grounded in reality. Here's a clear breakdown of **what’s real** versus **what’s hype** in the current AI landscape for plant monitoring:--- ### ✅ **What’s Real**

1. **Predictive Maintenance**

* **Reality**: AI models (especially ML) are reliably used to predict equipment failure before it happens using historical and real-time sensor data (vibration, temperature, pressure, etc.).

* **Examples**: Early warning systems for motor bearing failure, pump wear, and conveyor belt issues.

2. **Computer Vision for Safety & Quality**

* **Reality**: Vision AI can detect PPE compliance, product defects, spills, smoke, or anomalies in visual feeds.

* **Examples**: Cameras detect when a worker enters a hazardous zone or when product defects appear on a conveyor.

3. **Anomaly Detection in Process Data**

* **Reality**: Unsupervised learning models can identify deviations from normal operation patterns (e.g., energy use spikes, pressure drops).

* **Examples**: Spotting irregular flow patterns in pipelines or fluctuating DMS cyclone pressure.

4. **Energy Optimization**

* **Reality**: AI can recommend or automate control changes to reduce energy use while maintaining output.

* **Examples**: Smart HVAC, load scheduling, or real-time pump speed adjustments.

5. **Digital Twins**

* **Reality**: AI-powered digital twins simulate real-time plant operations for optimization, forecasting, and training.

* **Examples**: Virtual models of crushers, mills, or flotation circuits that mirror real-time behavior.

6. **Process Control Tuning**

* **Reality**: AI assists in PID loop tuning or advanced process control by learning dynamic relationships in the plant.

* **Examples**: Adjusting reagent dosing in flotation circuits or controlling lime addition in pH systems.

--- ### ❌ **What’s Hype**

1. **"Fully Autonomous" Plants**

* **Hype**: Claims of AI running entire plants with no human input are exaggerated. Full autonomy is rare and limited to very controlled environments.

* **Reality**: Human oversight and domain expertise are still critical, especially during abnormal conditions or maintenance.

2. **One-size-fits-all AI Platforms**

* **Hype**: Off-the-shelf AI solutions that claim to "work out of the box" for any plant often fail to account for site-specific complexities.

* **Reality**: Successful implementations require customization, integration with legacy systems, and quality data.

3. **AI That Replaces Experts**

* **Hype**: AI cannot replace the nuanced understanding of experienced plant operators or metallurgists.

* **Reality**: AI augments decision-making, not replaces it—especially in complex operations like DMS or flotation.

4. **Instant ROI**

* **Hype**: Vendors often promise ROI in weeks; in reality, AI deployment takes months of data gathering, tuning, and validation.

* **Reality**: ROI is possible but depends on data quality, infrastructure readiness, and change management.

5. **Chatbots for Deep Technical Troubleshooting**

* **Hype**: AI chatbots may help with documentation retrieval or basic FAQs but lack context for diagnosing intricate process issues.

* **Reality**: Human experts still lead root cause analysis in non-routine failures.

--- ### 🧠 Key Takeaways

* **Data is king**: The success of AI depends on sensor quality, data infrastructure, and contextual labeling.

* **Start small**: Begin with pilot projects (e.g., predictive maintenance on pumps or fans) before scaling.

* **Human-AI synergy**: The best outcomes come from combining AI tools with experienced operators and engineers.

* **Customization matters**: Industrial AI must be tailored to each plant's unique processes and goals. --- If you want, I can suggest AI tools or vendors relevant to your specific plant type (e.g., mining, processing, smelting).

Predcictive Maintenance

--- ### ✅ Predictive Maintenance

**Reality**: AI—particularly machine learning (ML)—is now reliably used to predict equipment failures before they occur. These systems analyze both historical and real-time data from sensors (e.g., vibration, temperature, acoustic signals, pressure) to detect patterns that precede failure.

**How it works**:

* ML models learn from past failure data and normal operating conditions.

* Real-time monitoring flags anomalies that match known failure signatures or deviate from normal behavior.

* Maintenance teams receive alerts well before actual failure, allowing for planned interventions.

**Examples**:

* Detecting **motor bearing degradation** through vibration analysis.

* Predicting **pump cavitation or impeller wear** from pressure and flow inconsistencies.

* Identifying **belt misalignment or wear** in conveyors using acoustic and thermal sensors. **Benefits**:

* Reduces unplanned downtime.

* Extends equipment life.

* Cuts maintenance costs by moving from reactive to proactive strategies. --- Would you like me to format this as part of a broader presentation or document on AI in plant monitoring?

Vision for Safety and Quality

**Computer Vision for Safety & Quality**

--- ### ✅ Computer Vision for Safety & Quality **Reality**:

Vision-based AI systems are increasingly effective in monitoring safety compliance and product quality. Using live camera feeds and machine learning models, these systems can detect a wide range of visual cues in real time to flag safety hazards or defects.

**How it works**:

* AI models are trained on thousands of labeled images to recognize patterns and anomalies.

* Integrated with CCTV or smart cameras, they can analyze live feeds continuously without fatigue.

* Alerts are generated instantly when predefined safety or quality thresholds are breached.

**Examples**:

* Detecting when a **worker enters a restricted or hazardous zone** without required PPE (e.g., hard hat, safety vest).

* Identifying **surface defects, cracks, or misalignments** on products moving along a conveyor.

* Spotting **smoke, liquid spills, or fires** before alarms are triggered by traditional sensors. **Benefits**:

* Enhances workplace safety through real-time hazard detection.

* Reduces quality control errors with consistent, non-stop inspection.

* Scales across multiple plant locations with centralized monitoring. --- Would you like to continue refining the other sections in the same style (e.g., Anomaly Detection, Energy Optimization, etc.)?

Anomoly detection in Process Data

--- ### ✅ Anomaly Detection in Process Data **Reality**: AI models—especially those using **unsupervised learning**—are highly effective at detecting anomalies in real-time process data. These systems learn what "normal" operation looks like and can automatically flag deviations without needing pre-labeled failure data.

**How it works**:

* Models analyze multivariate time-series data from sensors (e.g., temperature, flow, pressure, current).

* Unsupervised algorithms (e.g., autoencoders, clustering, statistical modeling) learn baseline patterns.

* Deviations from the baseline trigger alerts for investigation or action.

**Examples**:

* Identifying **irregular flow patterns** in slurry pipelines that may signal blockages or pump malfunction.

* Detecting **pressure fluctuations in DMS cyclones**, which could indicate worn components or media instability.

* Spotting **energy consumption spikes** that signal inefficiencies or equipment strain.

**Benefits**:

* Enables early detection of process drift or potential failures.

* Improves operational reliability by catching issues invisible to rule-based systems.

* Reduces false positives compared to threshold-based alerts. --- Would you like a visual (diagram or flowchart) to explain how this works in a processing plant context, or continue with the next section like **Energy Optimization**?

Energy Optimization

--- ### ✅ Energy Optimization **Reality**:

AI is increasingly used to optimize energy consumption across industrial plants by analyzing operational data and recommending—or even executing—control changes in real time. These systems help maintain production levels while minimizing energy waste.

**How it works**:

* AI models analyze historical and real-time data on equipment usage, process loads, environmental conditions, and utility rates.

* Algorithms identify patterns and inefficiencies, then suggest optimal control setpoints or schedules.

* In advanced setups, AI can **autonomously adjust controls** within defined limits for continuous optimization.

**Examples**:

* **Smart HVAC control** that dynamically adjusts airflow and temperature based on occupancy and ambient conditions.

* **Load scheduling** to shift non-critical operations to off-peak hours, reducing energy costs.

* **Real-time pump speed optimization** using AI to balance flow demand with minimum energy draw.

**Benefits**:

* Cuts operational energy costs without compromising throughput. * Supports sustainability and carbon reduction goals.

* Enables compliance with ISO 50001 and other energy management standards.

--- Would you like to wrap these sections into a full white paper or presentation format titled *"AI in Plant Monitoring: What’s Real and What’s Hype"*? I can prepare an executive summary, table of contents, and layout if needed.

Digital Twinsg

--- ### ✅ Digital Twins **Reality**:

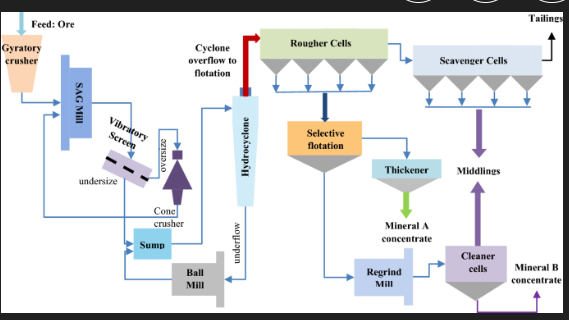

AI-powered **digital twins** are virtual replicas of physical plant systems that simulate real-time operations. These models continuously receive data from sensors and control systems, allowing for dynamic monitoring, optimization, forecasting, and operator training.

**How it works**:

* A digital twin integrates **real-time data** with physics-based and ML models to reflect the current state of equipment or processes.

* Operators and engineers can use the twin to **test scenarios**, optimize performance, or predict outcomes—without impacting actual operations.

* Feedback loops between the physical plant and digital twin improve accuracy over time.

**Examples**:

* Simulating a **crushing circuit** to forecast wear, optimize throughput, and reduce downtime.

* Modeling a **flotation plant** to optimize reagent dosing and recovery rates under varying feed conditions.

* Using a digital twin of a **grinding mill** to train operators on startup, shutdown, or upset scenarios in a risk-free environment.

**Benefits**:

* Improves decision-making with deeper process insight.

* Reduces trial-and-error in process optimization.

* Enhances operator readiness and plant uptime.

--- Let me know if you'd like this included in a report or if you want to continue with the next topic, like **Process Control Tuning**.

Process Control Tuning

--- ### ✅ Process Control Tuning **Reality**:

AI is proving valuable in improving **PID loop tuning** and implementing **advanced process control (APC)** strategies. By learning dynamic, non-linear relationships between variables, AI helps maintain stable, efficient operations—especially in processes with lag, noise, or complexity.

**How it works**:

* AI models analyze historical control loop data and live inputs to identify process dynamics.

* Algorithms suggest or automatically adjust PID parameters to minimize oscillations, lag, or overshoot.

* In more advanced applications, **model predictive control (MPC)** powered by AI can proactively optimize multiple inputs and constraints in real time.

**Examples**:

* **Tuning reagent dosing** in flotation circuits based on feed variability and recovery performance.

* **Controlling lime addition** in pH systems to maintain stable neutralization in variable ore conditions.

* **Optimizing temperature or pressure loops** in kilns, dryers, or reactors for energy efficiency and product consistency.

**Benefits**:

* Increases process stability and product quality.

* Reduces energy and reagent consumption.

* Decreases manual intervention and operator workload. --- Would you like a consolidated summary of all six sections for use in a briefing or investor deck on AI in plant operations?

Fully Automated Plants

--- ### ❌ “Fully Autonomous” Plants **Hype**:

Bold claims that AI can run entire industrial plants without human intervention are **overstated**. While some pilot projects exist—often in highly controlled environments—true full autonomy across complex, variable operations like mining, processing, or refining remains largely aspirational.

**Reality**:

AI can automate specific tasks or subsystems, but **human oversight is still essential**—especially for:

* Abnormal operating conditions

* Maintenance planning and execution

* Strategic decision-making

* Interpreting context beyond what AI systems can perceive **Limitations**: * AI models struggle with edge cases, novel failures, and unstructured problems.

* Safety, compliance, and process complexity often require experienced operators and engineers.

* Most successful implementations are **human-in-the-loop**, where AI augments but does not replace expert judgment. **Bottom line**:

Full autonomy is possible in theory, but in practice, **AI serves best as an assistant—not a replacement**—in most industrial settings today.

--- Would you like to follow this up with the next “Hype” topic, like **One-size-fits-all AI Platforms**?

One size Fits all Platforms

--- ### ❌ One-size-fits-all AI Platforms **Hype**: Many vendors promote off-the-shelf AI solutions that supposedly “work out of the box” across any industrial plant. In reality, these generic platforms often **fail to account for site-specific nuances**, legacy infrastructure, and unique process dynamics.

**Reality**: Effective AI implementations require:

* **Customization** to fit local process flows, control strategies, and equipment configurations.

* **Integration** with existing SCADA, PLCs, historians, and MES systems—which vary widely by site.

* **High-quality, contextualized data** to train reliable models; without it, even sophisticated AI underperforms.

**Limitations**:

* Generic platforms can generate irrelevant insights or false alarms if not properly tuned.

* Lack of plant-specific context reduces trust and adoption among operators and engineers.

* Successful use cases usually involve **collaboration between AI teams and domain experts** to tailor solutions.

**Bottom line**:

AI isn’t a plug-and-play solution—**real value comes from domain-driven, data-aware customization**, not one-size-fits-all promises.

--- Would you like to move on to the next hype topic, like **AI That Replaces Experts**?

Chatbots for deep troubleshooting

**Chatbots for Deep Technical Troubleshooting**

--- ### ❌ Chatbots for Deep Technical Troubleshooting **Hype**:

AI chatbots are often marketed as capable of handling complex troubleshooting tasks in industrial environments. While they can assist with **basic queries**, documentation retrieval, or standard operating procedures, they **lack the process context and judgment** needed for diagnosing nuanced technical problems.

**Reality**:

* Chatbots can support frontline teams with **quick access to manuals, sensor data summaries, or training materials**.

* However, **root cause analysis** of non-routine failures—such as intermittent equipment faults, process instability, or interdependent system issues—still requires **human expertise**.

* Even the most advanced AI lacks the practical, situational awareness of seasoned engineers and technicians.

**Limitations**:

* Chatbots often misinterpret ambiguous inputs or fail to grasp operational nuances.

* They can’t make reliable decisions under uncertainty or account for process variability without substantial oversight.

* Overreliance on bots may delay escalation to human experts when it matters most.

**Bottom line**:

Chatbots are a **useful support tool**, but **not a replacement for experienced technical personnel** in complex, real-world troubleshooting.

--- Would you like to wrap up with a final summary section or executive conclusion tying together all the "Real vs Hype" insights?

Data is Hing

--- ### 📌 Data is King

**The success of any AI initiative in plant monitoring begins and ends with data.

** Without high-quality, well-structured, and context-rich data, even the most advanced AI models will produce weak or misleading results.

**Key considerations**:

* **Sensor Quality**: Inaccurate, noisy, or poorly calibrated sensors lead to unreliable inputs and flawed predictions.

* **Data Infrastructure**:

Effective AI relies on real-time access to clean, timestamped, and integrated data streams—from SCADA systems, PLCs, historians, and more.

* **Contextual Labeling**:

Historical data must be annotated with operational context (e.g., maintenance events, process changes, anomalies) to train meaningful models.

**Bottom line**:

AI is not magic—it’s **only as good as the data it learns from**. Building a strong foundation of reliable, contextualized data is the most critical step toward any successful AI deployment in industrial operations.

--- Would you like me to compile all of these sections into a full document or slide deck titled *"AI in Plant Monitoring: What’s Real and What’s Hype"*?

Start Small

--- ### 📌 Start Small **AI success in plant operations rarely comes from large, top-down deployments.** The most effective approach is to start with focused, high-impact **pilot projects**—then scale based on results.

**Why it works**:

* **Low risk, high learning**:

Small-scale pilots help teams learn how AI interacts with existing systems, workflows, and data.

* **Quick wins**: Early successes—like reducing downtime on a critical pump or fan—build credibility and stakeholder buy-in.

* **Scalable foundation**:

Insights gained from pilots guide the development of scalable, site-specific solutions.

**Example pilots**:

* **Predictive maintenance** on pumps, compressors, or fans using vibration and temperature data.

* **Anomaly detection** in a single processing loop (e.g., flotation or DMS cyclone).

* **Energy optimization** in a specific system like HVAC or water pumping.

**Bottom line**:

Don’t try to automate the entire plant overnight.

**Prove value in small steps, then expand with confidence.**

--- Would you like to continue with another best practice like **“Human-AI synergy”** or move to compiling the full document?

Customization Matters

**Customization**:

--- ### 🛠️ Customization Matters **There’s no universal AI solution for industrial operations.

** Each plant has its own processes, constraints, equipment, data quality, and business goals—so effective AI systems must be **custom-tailored** to succeed.

**Why it’s critical**:

* **Process variability**:

Even plants using the same equipment can differ significantly in operating conditions, ore types, control strategies, and maintenance practices.

* **System integration**:

Legacy systems, data architecture, and instrumentation levels vary widely—requiring flexible AI designs.

* **Business objectives**:

Whether a site prioritizes recovery, energy efficiency, safety, or throughput, AI must align with **local KPIs** and constraints.

**What customization involves**:

* Close collaboration between AI developers and plant engineers.

* Configuration of models to specific process units (e.g., custom digital twins or tuned anomaly detection).

* Iterative tuning and feedback to adapt to real-world dynamics.

**Bottom line**: **AI delivers real value only when it reflects the plant it serves.** Tailored solutions—not generic ones—drive lasting impact.

--- You're now ready to compile a comprehensive, high-impact piece on

*AI in Plant Monitoring:

What’s Real and What’s Hype*.

Would you like it formatted as a:

* 📄 White paper (PDF) * 📊 Slide deck (PowerPoint style)

* 📝 Executive brief (one-pager)