Using AI to enhance Metallurgical Performance - What are the factors to be considered?

--- ## 🔧 1. **Process Optimization** AI can identify optimal process parameters for maximizing recovery and grade in real-time.

### Techniques:

* **Machine Learning (ML)** models trained on historical process data (temperature, feed grade, flow rate, pH, etc.)

* **Reinforcement Learning** for dynamic control of variables (e.g., reagent dosage, residence time, flotation air rate)

### Applications:

* Optimizing **Dense Media Separation (DMS)**, flotation, leaching, and smelting parameters

* Reducing energy and reagent consumption

* Predicting optimal setpoints to maximize throughput without sacrificing recovery

--- ## 📊 2. **Predictive Maintenance** Avoid downtime and improve equipment reliability.

### Techniques: * **Anomaly detection** using sensor data (vibration, temperature, current draw)

* Predictive models trained on maintenance logs and failure history ### Applications:

* Forecasting failure of pumps, crushers, cyclones, or flotation cells

* Scheduling maintenance activities proactively to prevent unplanned shutdowns

--- ## 🧪 3. **Ore Characterization & Feed Blending** Improve feed consistency to ensure stable metallurgical performance.

### Techniques:

* **Computer vision** for ore texture and size classification

* **Spectral analysis** (e.g., XRF, LIBS) integrated with AI to identify mineral composition in real-time

* AI-assisted **ore tracking** from mine to mill ### Applications:

* Automated grade control

* Real-time blending strategies to smooth feed variability

* Adjusting processing strategy to suit ore variability

--- ## ⚙️ 4. **Real-Time Monitoring & Control** Implement adaptive process control with AI integration. ### Techniques:

* **Digital Twins** that simulate and predict plant behavior

* **Advanced Process Control (APC)** enhanced with AI

* Real-time feedback loops using neural networks or decision trees

### Applications:

* Real-time adjustment of flotation air rates, DMS media density, grinding pressure

* Early detection of process inefficiencies

* Dynamic adjustment of cut points in DMS

--- ## 📈 5. **Recovery & Quality Prediction** Use AI models to predict metallurgical performance based on current inputs. ### Techniques:

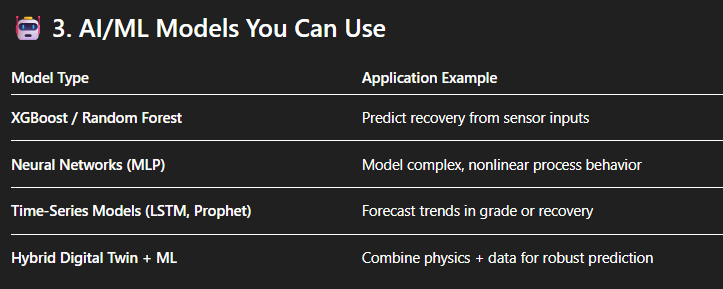

* Regression or ensemble models (Random Forest, XGBoost)

* Neural networks for complex nonlinear process behavior

### Applications:

* Predicting concentrate grade, tailing losses, or overall recovery

* Identifying root causes of poor metallurgical performance

* Suggesting operational changes to improve output

--- ## 📷 6. **Image and Video Analysis** Automate inspection and quality assurance.

### Techniques:

* Deep Learning (CNNs) for image classification

* Machine vision systems for real-time monitoring

### Applications:

* Froth analysis in flotation cells (bubble size, color, texture) * Particle size distribution in comminution circuits

* Slag or matte quality in smelting

--- ## 🔄 7. **Simulation & Scenario Planning** Test operational changes virtually before implementation.

### Techniques: * AI-integrated simulation tools (e.g., METSIM, HSC Chemistry)

* Scenario analysis with ML-enhanced process simulators

### Applications:

* Evaluating "what-if" scenarios for process changes

* Training operators using AI-based virtual environments

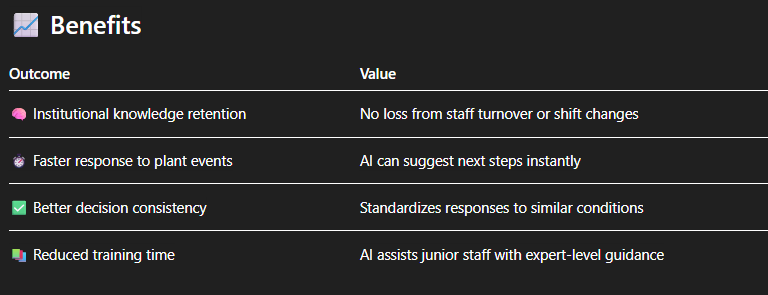

--- ## 🧠 8. **Knowledge Capture & Decision Support** Retain expert knowledge and make it accessible across shifts and plants.

### Techniques: * AI-based recommendation systems

* Natural language processing (NLP) for processing historical reports and logs

### Applications:

* AI-assisted control room advisors

* Suggesting actions based on historical performance under similar conditions

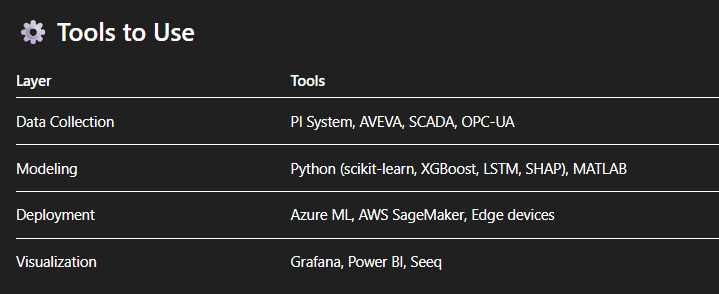

--- ## Tools & Platforms * **PI System + ML**:

For time-series process data * **Microsoft Azure ML**, **AWS SageMaker**, or **Google Vertex AI**

* **GE Digital**,

**AspenTech**,

**Seeq**, or

**Metso Metrics**

AI for Process optimization: Where do I get started?

-- ## 🧠 AI in Process Optimization – Key Steps

### 1. **Data Collection and Preprocessing** Start with gathering high-quality historical and real-time data from your plant, such as:

* Ore feed characteristics (grade, PSD, mineralogy)

* Process variables (media density, cyclone pressure, air flow, pH, temperature)

* Equipment metrics (pump pressure, torque, flow rates)

* Output results (recovery, concentrate grade, tailings composition)

✅ **Tip**:

Use a PI System, SCADA, or DCS for time-series data. Clean and standardize your data (handle missing values, outliers, etc.).

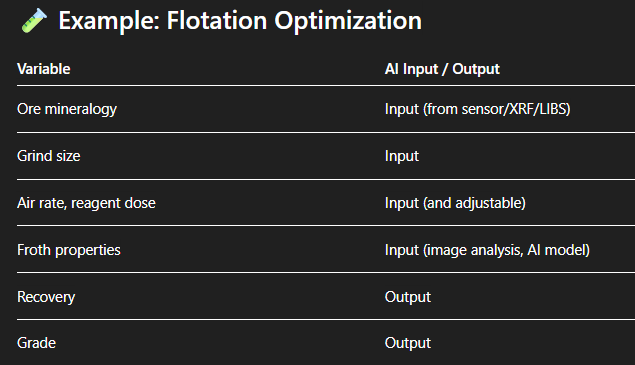

--- ### 2. **Model Development** Use **Machine Learning** to model the relationship between input parameters and process outputs.

🧪 **Use Case**: Predict flotation recovery or DMS yield based on ore type, density, cyclone pressure, feed rate.

--- ### 3. **Process Optimization Engine** Layer optimization algorithms on top of ML models.

#### Options:

* **Genetic Algorithms** or **Bayesian Optimization**: for multivariable optimization

* **Reinforcement Learning**: for continuous, real-time adjustments 🎯 Goal: Maximize recovery or grade while minimizing energy/reagent costs and maintaining throughput.

--- ### 4. **Real-Time Decision Support / Closed-Loop Control**

* Integrate the AI model into a **Digital Twin** or **APC (Advanced Process Control)** system.

* AI recommends or automatically applies parameter adjustments based on incoming sensor data.

📉 Example: Adjusting flotation air rates, reagent dosing, or cyclone underflow based on predicted optimal setpoints.

--- ### 5. **Continuous Learning** Use feedback loops to retrain models as process conditions or ore types change.

🔄 **Online Learning**: Keep updating the model with fresh data to adapt to seasonality or geological variability.

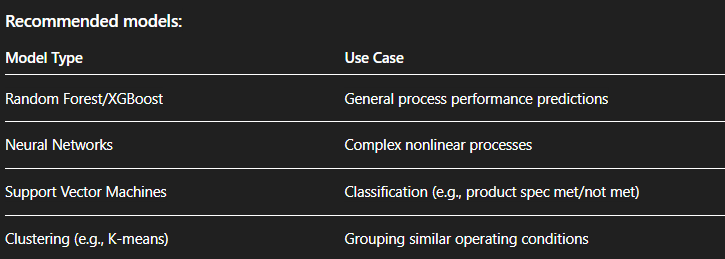

--- ## 🧪 Example: Flotation Optimization

AI learns how these inputs affect the outputs and suggests the best settings.

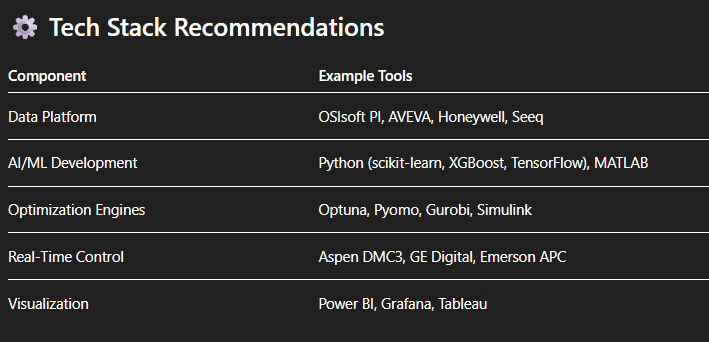

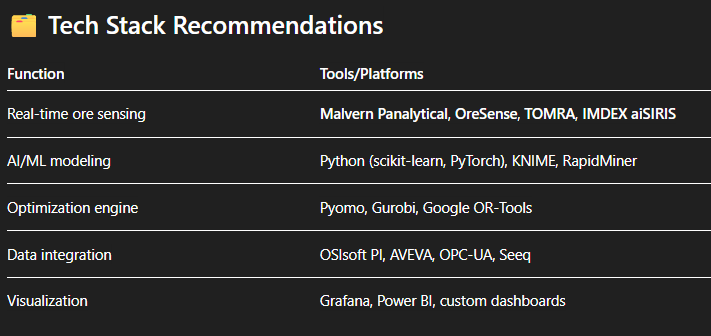

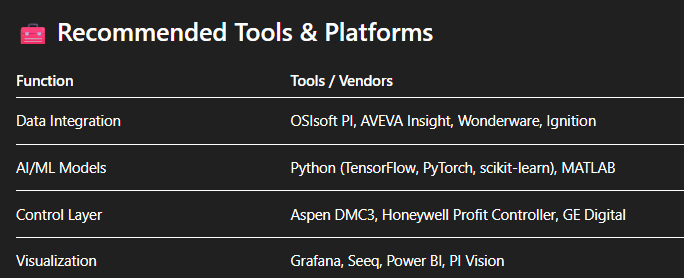

--- ## ⚙️ Tech Stack Recommendations

--- ## ✅ Benefits from AI-Driven Process Optimization

* **Higher recovery & grade**

* **Lower reagent and energy consumption**

* **Fewer process upsets**

* **Increased throughput**

* **Adaptive control for ore variability**

What is AI driven predictive maintenance?

Here’s a full breakdown of how to implement AI-driven **Predictive Maintenance (PdM)** in your operation:

--- ## 🛠️ What Is AI-Driven Predictive Maintenance? It uses **machine learning models** trained on **historical sensor and maintenance data** to **predict failures** before they happen — so you can schedule interventions **just-in-time**.

--- ## 🔁 Workflow Overview

### 1. **Data Collection** Use real-time and historical data from:

* Vibration sensors (for bearings, pumps, motors)

* Temperature sensors

* Acoustic emission sensors

* Pressure and flow readings

* Motor current/load

* Maintenance logs and failure reports

* Operational logs (runtime hours, throughput, downtime)

✅ Example: Vibration patterns from cyclone feed pumps or noise from crusher bearings.

--- ### 2. **Data Processing** Steps include:

* Filtering sensor noise

* Feature engineering: extract relevant statistics (mean, RMS, kurtosis, frequency spectra)

* Labeling data: healthy vs. failure/fault conditions Tools: Python (Pandas, SciPy), MATLAB, Seeq

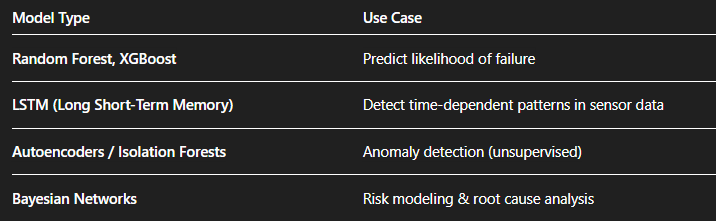

--- ### 3. **Model Development** You can use:

✅ Example:

Train a model to predict when a **hydrocyclone pump** will fail based on vibration + temperature + flow history.

--- ### 4. **Failure Prediction** Models output:

* **Probability of failure** within a future time window

* **Remaining Useful Life (RUL)**

* **Anomaly scores** for abnormal behavior

✅ Example:

* “Pump #3 has a 78% chance of seal failure within 72 hours”

* “Cyclone is operating outside of normal baseline – investigate motor load trend”

--- ### 5. **Alerts & Integration**

* Display alerts on **operator dashboards** (Grafana, Power BI)

* Trigger **work orders** in CMMS (SAP, IBM Maximo)

* Link to **SCADA systems** for automatic interventions (e.g., diverting flow to standby equipment)

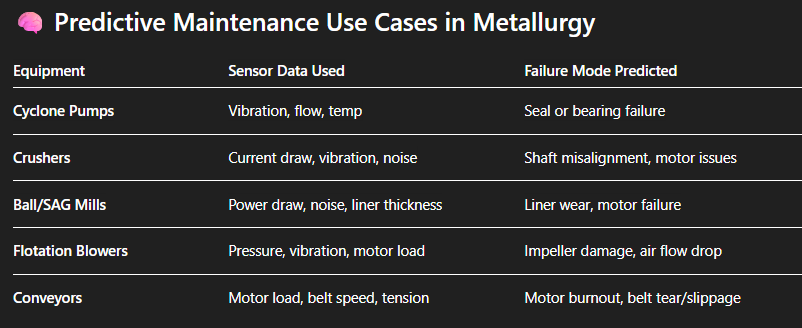

--- ## 🧠 Predictive Maintenance Use Cases in Metallurgy

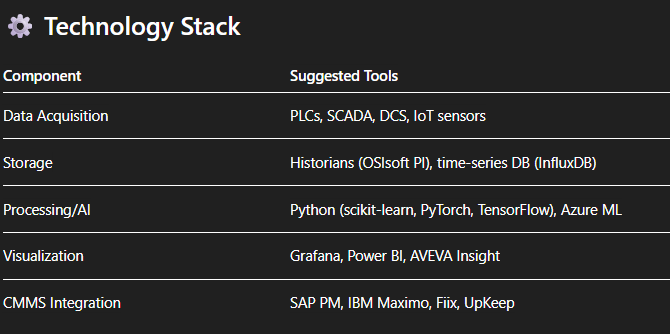

--- ## ⚙️ Technology Stack

--- ## 🔍 KPIs to Track * % reduction in **unplanned downtime**

* Increase in **equipment uptime**

* Reduction in **emergency repair costs**

* Improved **mean time between failures (MTBF)**

What is the objective of AI with regards to ore characterization and feed blending?

Here's how AI can transform this area:

--- ## 🎯 Objectives of AI in Ore Characterization & Feed Blending

* Achieve **consistent feed quality** (grade, mineralogy, particle size) * Adapt processing parameters to ore variability in real time

* Blend ores to meet **target properties** (e.g., density, hardness, grade)

* Improve **process predictability** and **reduce upsets**

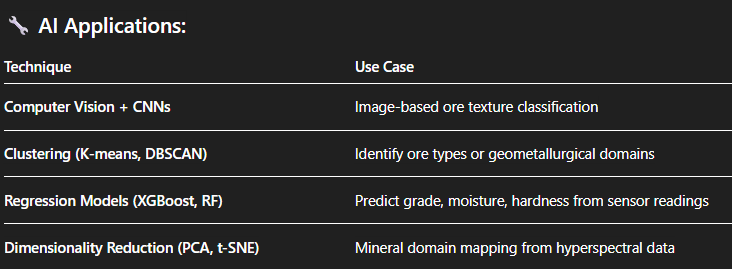

--- ## 🧪 1. **AI for Ore Characterization** AI can extract ore properties using real-time sensor data and machine learning models.

### 🔍 Inputs: * **XRF/XRD data** (chemical and mineralogical composition)

* **Hyperspectral imaging** or **LIBS** (laser-induced breakdown spectroscopy)

* **Particle size analyzers** (PSA, image-based systems)

* **Ore hardness proxies** (Bond index estimates, drop tests)

### 🔧 AI Applications:

✅ Example: Automatically classify ore types (oxide/sulfide/fresh/transitional) on a conveyor belt.

--- ## ⚗️ 2. **Real-Time Feed Blending with AI** Once ore is characterized, AI can **predictively control the blending** of material from stockpiles or direct mine sources.

### 🔀 Key Components: * Stockpile management system (with live grade, size, and hardness info)

* Belt scales, PGNAA analyzers, or lab data feeds * Real-time optimizer (e.g., Python, MATLAB, or vendor software)

### 📈 AI-Driven Optimization:

* Use ML models to **predict plant performance** (recovery, yield, wear) based on feed properties

* Use **Linear Programming** or **Genetic Algorithms** to optimize the blend ratio to:

* Match target grade

* Avoid processing upsets (e.g., too much fines or hard ore)

* Maintain consistent DMS density windows or flotation response

✅ Example: Dynamically blend three stockpiles (A, B, C) to hit a 2.8 SG DMS target while avoiding excess pyrite.

--- ## 🧠 3. **Integrated Ore-to-Plant AI Modeling** Create **digital twins** or hybrid AI models that simulate downstream impact of ore variability.

### Use Case:

* Input: real-time ore composition, PSD, moisture, hardness

* Model: predict **grindability**, **media density response**, **flotation kinetics**

* Output: recommend blending strategy and process settings

--- ## 🗂️ Tech Stack Recommendations

--- ## 📉 Measurable Benefits

* **Reduction in recovery variability** due to more stable feed

* Lower reagent and energy consumption

* Less downtime due to clogging, density shifts, or grind circuit instability

* Better product quality (e.g., fewer off-spec shipments)

--- ## ✅ You Can Start With:

1. **A blend optimizer prototype** in Python (for 2–4 stockpiles)

2. **AI model template** to classify ore type from XRF/hyperspectral data 3. **Flowchart** of an AI-integrated ore tracking and blending system Would you like help creating an **AI-based ore blending optimizer** or a **real-time characterization system** based on your available data/sensors?

What are the core attributes of an AI-driven Real Time monitoring and control system

Here’s how to implement it step by step:

--- ## ⚙️ Core Architecture of AI-Driven Real-Time Monitoring & Control

### 🧩 1. **Data Acquisition Layer** Continuously capture time-series data from:

* **Process sensors** (flow rate, pressure, density, temperature)

* **Quality analyzers** (PGNAA, XRF, XRD, froth cameras, PSD analyzers)

* **Control systems** (PLC/SCADA, DCS)

✅ Example: Real-time cyclone feed pressure, underflow density, DMS SG, flotation air rate.

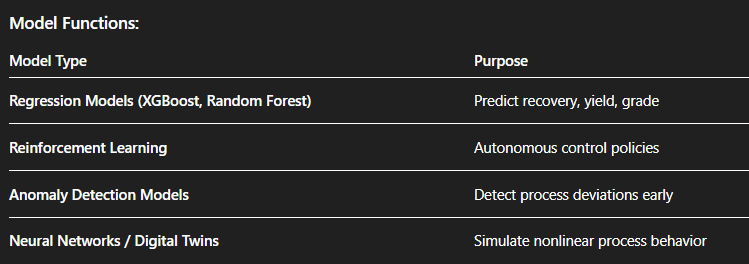

--- ### 🧠 2. **AI/ML Layer** Train models to **predict future outcomes** and recommend **optimal setpoints**.

#### Model Functions:

| ✅ Example:

Predict when media density in DMS will drift out of range based on feed changes.

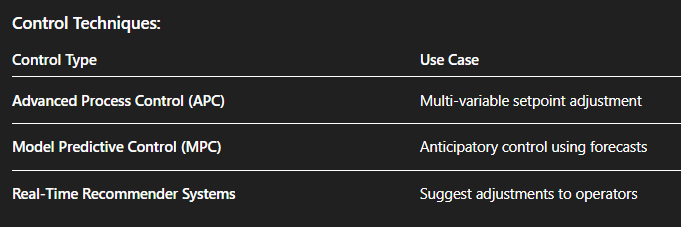

--- ### 🛠️ 3. **Control & Optimization Layer** Use AI model outputs to **adjust process parameters in real time**, either autonomously or via operator assistance.

#### Control Techniques:

| ✅ Example:

Adjust cyclone feed rate, underflow valve, and media density automatically to maintain sharp DMS cut point.

--- ### 📊 4. **Visualization & Alerts** Display actionable insights in control rooms or dashboards.

* Trends, KPIs, and model predictions (recovery, grade, downtime risk)

* AI-driven alerts (e.g., “Approaching flotation instability”)

* What-if impact of control decisions Tools: Grafana, PI Vision, Power BI, Seeq

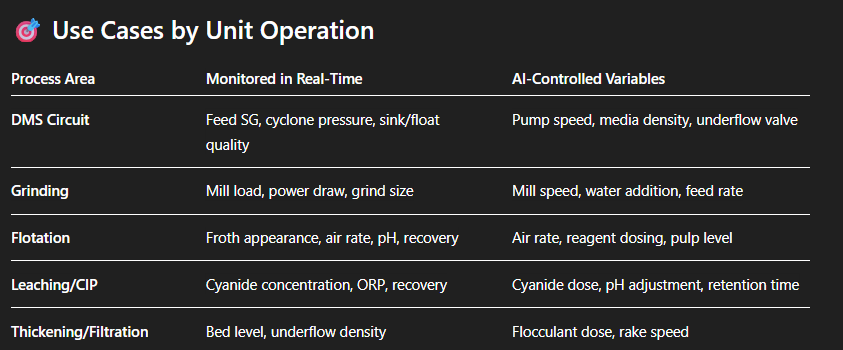

--- ## 🎯 Use Cases by Unit Operation

--- ## 🧠 Real-Time AI Example:

Flotation Control ### Inputs:

* Froth camera data (bubble size, color, texture)

* pH, air rate, pulp density, reagent dose ### AI Actions:

* Detect froth instability or grade drop

* Adjust air rate and reagent dosing live

* Predict and prevent overflow or losses

--- ## 📈 Benefits

* 📉 **Reduced variability** in recovery, grade, and throughput

* 🔄 **Faster response** to ore or equipment changes

* 📉 **Lower operating costs** (reagent, energy, wear)

* ⏱️ **Fewer manual interventions** and human error

* 📈 **Sustained optimal performance**, even under variable conditions

--- ## 🧰 Recommended Tools & Platforms

--- ## ✅ Want to Start Small?

I can help you prototype:

1. A **real-time AI monitoring dashboard** (e.g., for DMS or flotation)

2. A **Python-based control model** that predicts outcomes and suggests setpoints

3. An **alerting system** for anomalies in key process KPIs Would you like to focus on a specific process unit (e.g., grinding, DMS, flotation)? Or should I show you a flow diagram or code example?

How to use AI for Recovery and Quality predictions?

--- ## 🎯 Objectives

* Predict **metal recovery** and **product grade** in real-time or ahead of time

* Diagnose root causes of **performance drops**

* Enable **“what-if” analysis** for process changes

* Support **dynamic control** and **feedforward optimization**

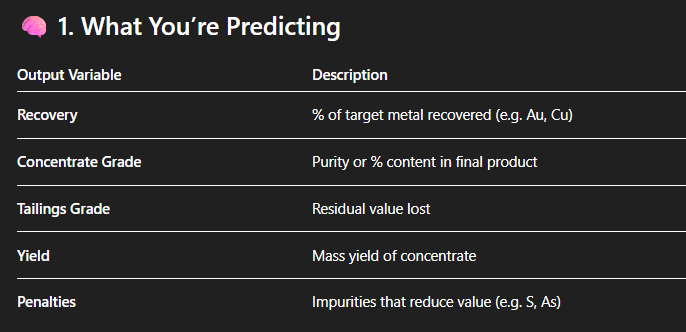

--- ## 🧠 1. What You’re Predicting

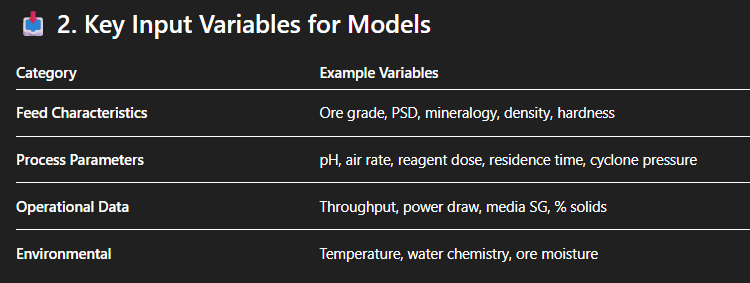

| --- ## 📥 2. Key Input Variables for Models

✅ For **DMS**: media SG, cyclone pressure, particle size

✅ For **Flotation**: pH, air rate, froth features, reagent dose

--- ## 🤖 3. AI/ML Models You Can Use

✅ Best Practice: Train multiple models and use ensemble averaging to improve accuracy.

--- ## 🧪 4. Example Use Case: Flotation Recovery Prediction

### 📥 Inputs: * Feed grade (Cu, Fe)

* Grind size (P80)

* Air flow, pH, reagent dosing

* Froth texture (from camera/CNN)

* Residence time

### 🎯 Outputs:

* Cu recovery (%)

* Cu concentrate grade (%)

* Expected tailings grade

### 🧠 Model:

* Train Random Forest or XGBoost on historical data

* Feature engineering: combine variables like air/pulp ratio, ΔpH, ore type

--- ## 🧰 5. Implementation Steps

1. **Data Preparation**

* Use cleaned time-series data (e.g., 1-min or 5-min intervals)

* Sync output tags (e.g., assay results) with input sensor data via timestamp alignment

2. **Model Training & Testing**

* Split into train/test sets by time to preserve sequence

* Use cross-validation to avoid overfitting

3. **Validation & Explainability**

* Use SHAP values or feature importance to understand drivers

* Compare predicted vs actual recovery/grade over time

4. **Deployment**

* Push model into production (on-premise or cloud)

* Connect to DCS or SCADA to provide real-time predictions and alerts

--- ## 📊 6. Visualization & Action

* Plot predicted vs actual recovery or grade in Grafana, Seeq, or Power BI

* Set up alerts for prediction drift (e.g., “Recovery expected to drop by 3% in 30 min”)

* Allow operators to simulate “what-if” scenarios by adjusting variables

--- ## ⚙️ Tools to Use

--- ## ✅ Results You Can Expect *

📈 3–10% increase in **recovery**

* 📉 5–20% reduction in **off-spec product**

* 🔄 Faster reaction time to process variation

* 🔍 Better **root cause diagnosis** of recovery dips

--- Would you like a **code template** to build a recovery prediction model (e.g., XGBoost)? Or help designing a **real-time dashboard** that shows predicted vs actual recovery in a live process?

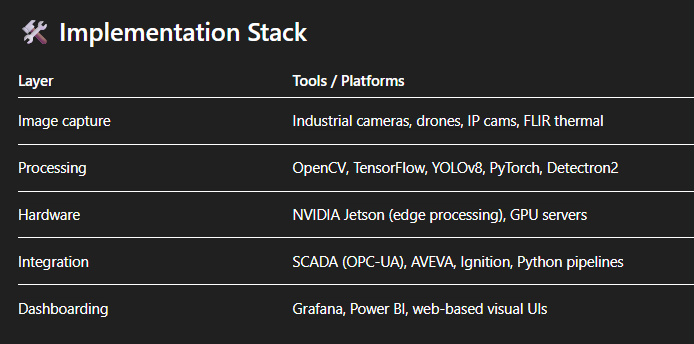

Use of AI for Image and Video Analysis

Here’s how you can leverage AI for **recovery improvement**, **equipment reliability**, and **quality control**:

--- ## 📷 1. Froth Flotation Monitoring (Real-Time Video)

### ✅ Goal: Improve flotation **recovery**, **grade**, and **stability** **AI System**:

* Uses video feeds from flotation cells

* Processes images with **convolutional neural networks (CNNs)** and optical flow

* Classifies froth conditions (e.g., “too stable”, “boiling”, “draining”) **Extracted Froth Features**:

* **Bubble size and distribution**

* **Color and brightness**

* **Texture (smooth, turbulent)**

* **Velocity / flow patterns** **Actions Enabled**:

* Auto-adjust air rate, frother dose, pulp level

* Alert operator when froth behavior deviates from target profile

* Predict recovery changes 10–30 min in advance 🛠 Example Tools: Metso VisioFroth, DeepFroth AI, custom CNN models with OpenCV + TensorFlow

--- ## 📸 2. Conveyor Belt Ore Characterization (Image Analysis)

### ✅ Goal: Maintain consistent feed to crushing, DMS, or grinding circuits **AI System**:

* Cameras mounted above conveyors

* Computer vision models estimate:

* Particle size distribution (PSD)

* Lumps vs fines ratio

* Ore color and texture (to infer ore type)

* Moisture sheen (via reflectivity) **Outcomes**:

* Control crusher gap or feeder speed to manage throughput

* Optimize blending and avoid oversize or too-fine feed

* Alert for "ore type switch" (oxide vs sulfide vs transition) 🛠 Example Tools: SmartSizer, WipWare, BeltVision, custom OpenCV + PyTorch/CNN models

--- ## 🧱 3. Leach Pad & Heap Health (Drone + AI)

### ✅ Goal: Detect **blockages**, **channeling**, or **dry spots** early **AI System**:

* Drone images or thermal cameras detect anomalies in:

* Irrigation uniformity

* Leachate pooling

* Heat zones indicating under-irrigated areas **Actions**:

* Adjust irrigation layout or flow

* Identify subsurface failures before recovery drops 🛠 Tools: DroneDeploy + CNN segmentation models + thermal camera feeds

--- ## 🧼 4. Screen, Filter & Trommel Monitoring

### ✅ Goal: Prevent downtime, improve classification Use high-speed video + computer vision to:

* Detect blinding or pegging in screens * Monitor spray pattern uniformity * Confirm oversize/fines movement 🛠 Tools: OpenCV with edge detection, motion tracking, YOLO models for particle/object detection

--- ## 🔧 5. Equipment Condition Monitoring via Video **Use Cases**:

* Visual inspection of conveyor alignment or belt damage

* Visual detection of slurry leaks, spillages, valve failures

* Monitoring motor movement or abnormal vibration visually Can use **YOLOv8**, **OpenCV motion tracking**, or **thermal imaging** for early-stage fault detection.

--- ## 📽️ 6. Digital Twin Enhancements via Video Feeds

* Use visual inputs to **validate and calibrate process models** (e.g., froth appearance vs predicted kinetics)

* Feed real-time images into **hybrid AI-physics models** for improved prediction of recovery or product quality

--- ## 🛠 Implementation Stack

--- ## 📈 Measurable Benefits

* **+5–15% improvement in recovery** (froth optimization)

* **Reduction in downtime** via early visual anomaly detection

* **Tighter control over PSD** and ore blending consistency

* **Fewer human inspections**, safer and more consistent monitoring

--- ## ✅ Next Steps for You Would you like:

* A **starter Python script** to process flotation froth video?

* A **design sketch** for an AI camera system for conveyors or tanks?

* Help choosing **hardware + model architecture** for your use case? Let me know your plant priorities, and I’ll tailor a solution (e.g., DMS camera, flotation froth, conveyor monitoring).

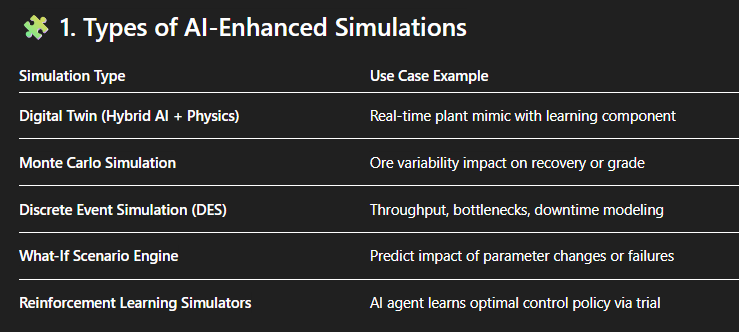

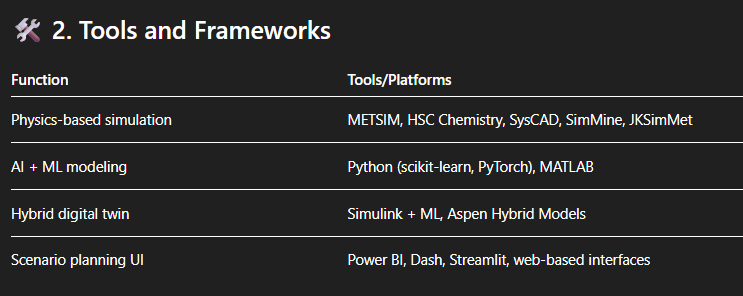

Use of AI in Simulation and Scenario Planning

--- ## 🎯 Why Use Simulation & Scenario Planning?

* 🧠 **Predict performance** under changing feed, process, or equipment conditions

* ⚖️ **Balance trade-offs** between recovery, grade, energy use, and reagent cost

* 🔄 **Train operators** and validate control strategies before implementation

* 📊 **Support decisions** with quantitative, data-driven insights

--- ## 🧩 1. Types of AI-Enhanced Simulations

--- ## 🛠 2. Tools and Frameworks

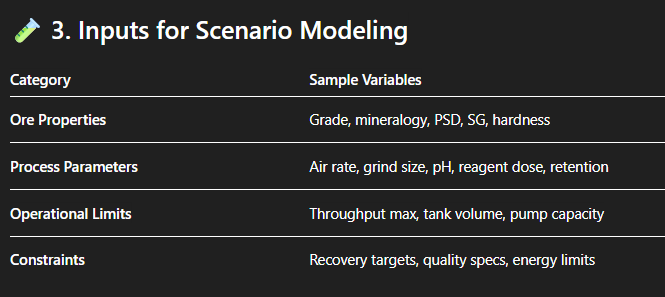

--- ## 🧪 3. Inputs for Scenario Modeling

--- ## 📈 4. Examples of Metallurgical Scenarios to Simulate

### 📊 A. **DMS Simulation**

* Vary feed SG and PSD to evaluate impact on sink/float recovery

* Change cyclone geometry or media type and simulate density windows * Use Monte Carlo to simulate impact of ore variability over 1 month

### ⚗️ B. **Flotation Circuit Simulation**

* Model frother dose vs. grade-recovery curve under 3 ore types

* Evaluate what happens if pH drifts by ±0.5 for 2 hours

* Test new collector blend before committing at plant scale

### 🪨 C. **Grinding + Classification**

* Simulate the impact of screen wear or hydrocyclone bypass

* Model throughput vs grind size vs recovery interactions

--- ## 🤖 5. AI-Driven Scenario Generator Create an AI tool that:

1. Learns from historical data and simulations

2. Suggests **“optimal paths”** to reach a recovery or grade goal

3. Warns you about **likely failure points** under specific ore types or process loads

✅ Could be built with:

* Decision trees or XGBoost for interpretable predictions

* Bayesian optimization for trade-off exploration

* Interactive Streamlit dashboard for scenario input/output

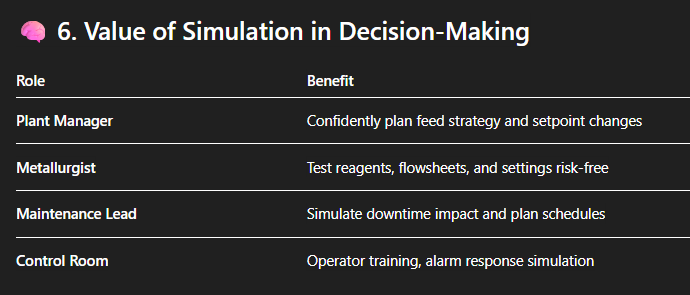

--- ## 🧠 6. Value of Simulation in Decision-Making

--- ## ✅ Quick Wins to Get Started

1. **Build a recovery prediction simulator**

— input feed + settings, get predicted output

2. **Develop a “what-if” planning tool**

— simulate pH drift, media SG loss, or feed blending

3. **Wrap existing physics model with AI**

— improve accuracy under real plant noise

--- ## 📌 Want to Try One? I can help you:

* Design a **scenario planner dashboard**

* Create a **Python-based DMS simulation with variable ore inputs**

* Develop an AI layer to enhance your HSC or METSIM model Let me know your target process area (e.g., flotation, DMS, leaching), and I’ll suggest a tailored simulation approach.

How to use AI for Knowledge capture and decision support

--- ## 🧠 What Is It? It’s an AI system that:

* **Captures expert decisions, logic, and reasoning**

* **Links historical data, documents, and outcomes**

* **Provides recommendations** based on similar past situations

* Acts as an intelligent **assistant to metallurgists, operators, and engineers**

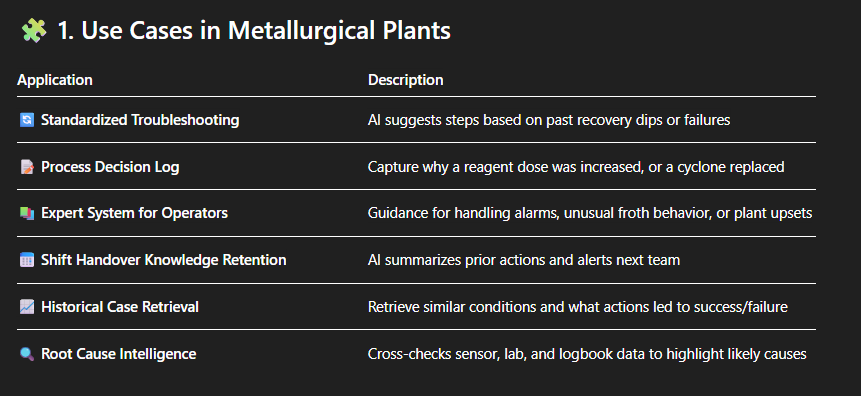

--- ## 🧩 1. Use Cases in Metallurgical Plants

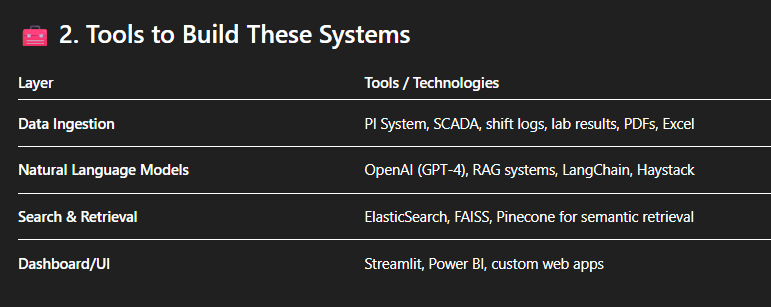

| --- ## 🧰 2. Tools to Build These Systems

--- ## 📌 3. Sample Applications

### 📁 A. **Shift Log Analyzer (AI-Augmented)**

* Digitizes handwritten/operator logs

* Uses NLP to extract key actions (e.g., “Air increased due to rising tails grade”)

* Connects logs to process data and plant outcomes

### 📚 B. **SOP Chat Assistant**

* Reads and indexes all plant SOPs, troubleshooting guides, OEM manuals

* Operators ask: “What should I do if cyclone pressure is unstable?”

* AI responds with concise, context-specific answers

### 📊 C. **Decision Tree Builder**

* Auto-generates logic trees from past decisions

* Shows “if-then” paths used by successful operators under various ore types

--- ## 🧠 4. Combine Data + Domain Knowledge Create **hybrid models** that integrate:

* **Sensor & lab data**: (e.g., rising tailings SG, media dilution)

* **Historical logs**: Operator comments and corrective actions

* **Outcome data**: How recovery or grade changed post-decision

🔍 This creates a system that not only **remembers what was done**, but **learns what worked**.

--- ## 🔄 5. Feedback Loops

* Experts validate AI recommendations (Human-in-the-loop)

* System learns from new outcomes (e.g., “This intervention improved recovery by 2%”)

* Decision suggestions improve over time

--- ## 📈 Benefits

--- ## ✅ Getting Started Here’s what you can build quickly:

1. **AI search assistant for SOPs, lab reports & logs**

2. **Interactive decision recommender** trained on past interventions

3. **Real-time suggestion system** for recovery or quality anomalies Would you like a prototype of a **decision support chatbot** for your plant? I can show you how to build one using your existing documents, logs, and process data.

What are the available tools and Platforms for AI development and application

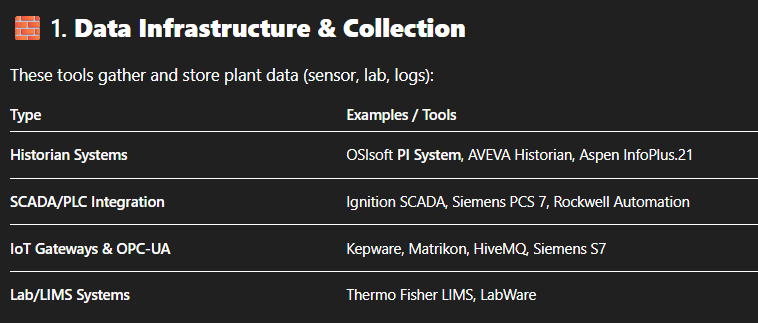

--- ## 🧱 1. **Data Infrastructure & Collection**

✅ These feed live and historical process data into AI pipelines.

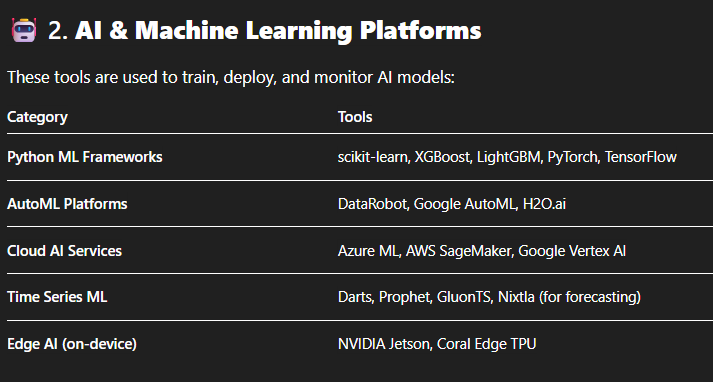

--- ## 🤖 2. **AI & Machine Learning Platforms**

These tools are used to train, deploy, and monitor AI models:

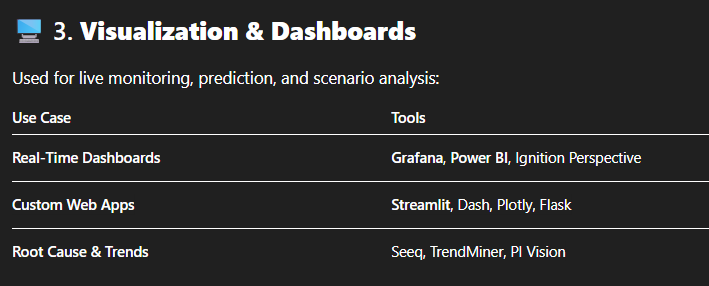

--- ## 🖥 3. **Visualization & Dashboards**

Used for live monitoring, prediction, and scenario analysis:

| ✅ AI predictions can be embedded alongside real-time plant trends.

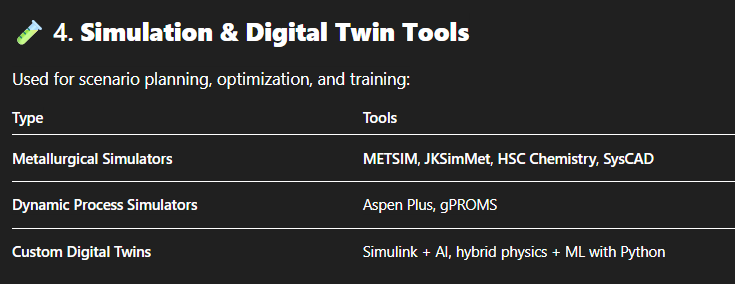

--- ## 🧪 4. **Simulation & Digital Twin Tools**

Used for scenario planning, optimization, and training:

✅ Combine simulations with AI to evaluate “what-if” cases and test interventions safely.

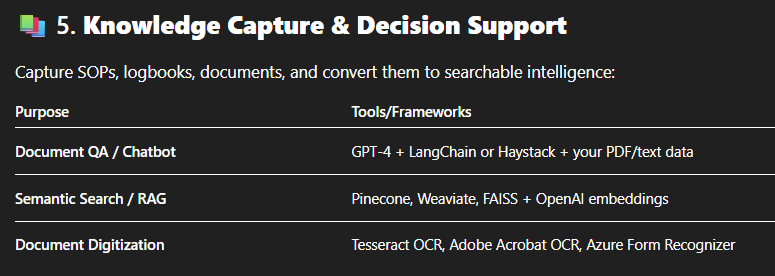

--- ## 📚 5. **Knowledge Capture & Decision Support** Capture SOPs, logbooks, documents, and convert them to searchable intelligence:

✅ Enables operators to “ask” an AI for guidance, troubleshooting, or SOP recall.

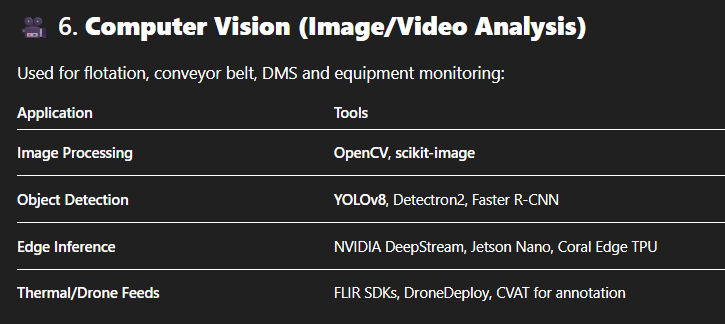

--- ## 🎥 6. **Computer Vision (Image/Video Analysis)** Used for flotation, conveyor belt, DMS and equipment monitoring:

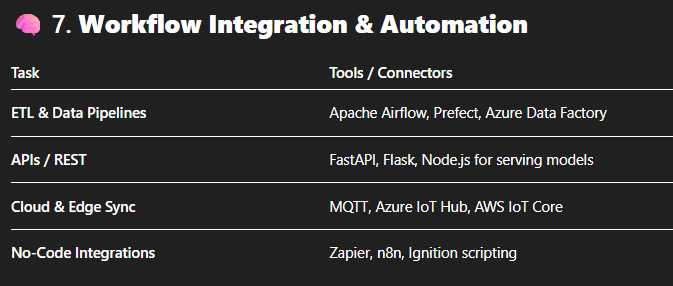

--- ## 🧠 7. **Workflow Integration & Automation**

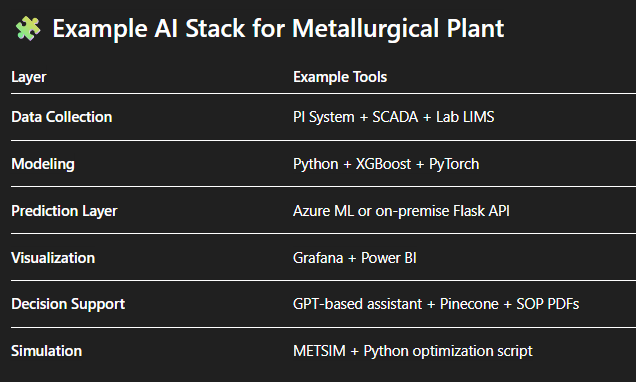

--- ## 🧩 Example AI Stack for Metallurgical Plant

--- ## ✅ Next Step Would you like:

* A suggested stack for a **DMS or flotation plant**?

* Help designing a **real-time AI dashboard**?

* Code template for deploying an **AI model on plant data**?

Let me know your process focus or site architecture — I’ll tailor a stack recommendation or prototype to match.