What are the major hazards?

## **1. Mechanical Hazards** * **Moving machinery**: Crushers, conveyors, mills, and pumps pose risks of entanglement, crushing, shearing, and cutting. * **Rotating equipment**: Shafts and pulleys can cause serious injury if not properly guarded. * **Maintenance operations**: Lockout/tagout failures during maintenance can lead to accidental startup and severe injuries. * **Material handling**: Risk of musculoskeletal injuries or being struck by moving equipment. ---

## **2. Electrical Hazards** * **High-voltage equipment**: Electrical panels, motors, and switchgear can pose shock and arc flash hazards. * **Improper grounding**: Can lead to electrocution or fire. * **Wet conditions**: Increase the risk of electrical hazards, especially around pumps and water-based processes. ---

## **3. Chemical Hazards** * **Reagents and chemicals**: Cyanide, acids (sulfuric, hydrochloric), and flocculants used in leaching, flotation, and pH control are toxic and corrosive. * **Dust inhalation**: Silica, heavy metals, and reagent dusts can cause long-term respiratory issues. * **Spills and leaks**: Can lead to toxic exposure, burns, and environmental contamination.

--- ## **4. Physical Hazards** * **Noise**: Crushers, mills, and fans often exceed safe noise levels, posing hearing damage risks. * **Vibration**: Extended exposure to vibration from equipment may affect operator health. * **Heat**: Processing equipment and environments may cause heat stress or burns. * **Radiation**: Some ores (e.g., uranium) present ionizing radiation hazards.

--- ## **5. Process Hazards** * **Overpressure and explosions**: Reactors and autoclaves under pressure may fail catastrophically. * **Fire**: Especially in areas handling flammable chemicals, lubricants, or dust. * **Slurry and tailings leaks**: Tailings dams or slurry pipelines can fail, leading to environmental and structural disasters. * **Blockages or overflows**: Can cause sudden equipment failures or spillage.

--- ## **6. Ergonomic Hazards** * **Manual handling**: Risk of back injuries and strains from lifting or awkward postures. * **Repetitive tasks**: Can lead to cumulative trauma disorders. * **Poor workstation design**: Leads to increased fatigue and injury risk.

--- ## **7. Environmental Hazards** * **Air and water pollution**: Release of dust, fumes, or contaminated water. * **Waste disposal**: Improper handling of tailings and process water can affect nearby ecosystems. * **Acid mine drainage**: Can occur from oxidation of sulfide minerals exposed during processing.

--- ## **8. Biological Hazards** * **Water stagnation**: Can breed harmful bacteria (e.g., *Legionella*) in cooling systems or ponds. * **Pests and wildlife**: Can pose risks in and around the plant area.

--- ## **9. Human Factors** * **Fatigue or inattention**: Long shifts and high-stress environments increase accident likelihood. * **Inadequate training**: Improper handling of complex machinery or chemicals. * **Lack of PPE compliance**: Can increase injury severity.

--- ### **Mitigation Strategies**

* Conduct thorough hazard identification and risk assessments (HIRA). * Implement engineering controls (guarding, ventilation, automation).

* Enforce safe operating procedures and lockout/tagout systems. * Provide PPE and ensure compliance.

* Regularly train workers on hazard awareness and emergency procedures. * Establish a strong safety culture and continuous monitoring.

Mitigating Process Plant Hazards

--- ## ✅ **1. Mechanical Hazard Mitigation**

* **Machine guarding**: Install physical barriers around moving parts (crushers, conveyors, pumps).

* **Lockout/tagout (LOTO)**: Strict enforcement of LOTO procedures during maintenance.

* **Routine maintenance**: Prevent unexpected breakdowns that could cause injury.

* **Emergency stop systems**: Install accessible emergency stops on all major machinery.

* **Operator training**: Ensure workers are competent in safe machine operation and hazard recognition.

--- ## ✅ **2. Electrical Hazard Mitigation**

* **Inspections and maintenance**: Regular testing of electrical systems, cables, and insulation.

* **Ground fault protection**: Use earth-leakage circuit breakers (ELCBs).

* **Waterproofing**: Keep electrical panels away from moisture; use IP-rated enclosures.

* **Training and permits**: Only qualified electricians perform electrical work.

* **Arc flash PPE and barriers**: Provide appropriate PPE and enforce arc flash boundaries.

--- ## ✅ **3. Chemical Hazard Mitigation**

* **Chemical handling protocols**: SOPs for storage, transfer, and use of reagents (e.g., cyanide, acids).

* **Spill containment**: Bunding, drip trays, and neutralization systems in place.

* **Safety data sheets (SDS)**: Easily accessible and understood by workers.

* **Ventilation systems**: To control fumes, vapors, and airborne dusts.

* **PPE**: Gloves, chemical-resistant suits, face shields, respirators.

--- ## ✅ **4. Physical Hazard Mitigation**

* **Noise control**: Use enclosures, silencers, and provide hearing protection.

* **Thermal shielding**: Insulate hot surfaces and provide heat-resistant PPE.

* **Dust suppression**: Water sprays, enclosures, and dust collectors at key points.

* **Radiation monitoring**: For uranium or thorium ores, use dosimeters and shielding.

--- ## ✅ **5. Process Hazard Mitigation**

* **Pressure relief systems**: Install pressure relief valves (PRVs) on autoclaves, tanks, and pipelines.

* **Instrumentation and alarms**: Monitor temperature, pressure, and flow with automatic shutdowns.

* **Process control systems (PLC/SCADA)**: Automated control and real-time feedback.

* **Emergency response planning**: Drills and equipment for chemical spills, fires, and equipment failures.

* **Routine inspections**: Tailings pipelines, tanks, and vessels must be regularly checked for wear and leaks.

--- ## ✅ **6. Ergonomic Hazard Mitigation**

* **Mechanical aids**: Hoists, trolleys, and lifts to reduce manual lifting.

* **Ergonomic design**: Adjustable workstations and control interfaces.

* **Job rotation**: Minimize repetitive strain injuries.

* **Training**: Manual handling techniques and safe body posture education. -

-- ## ✅ **7. Environmental Hazard Mitigation**

* **Tailings management**: Properly engineered dams with seepage and overflow control.

* **Water treatment systems**: To remove heavy metals, pH adjust, and reduce contamination.

* **Dust control**: Vegetative cover, chemical suppressants, or enclosures on tailings and stockpiles.

* **Waste segregation and disposal**: According to environmental regulations.

* **Air and water quality monitoring**: Routine sampling and reporting.

--- ## ✅ **8. Biological Hazard Mitigation**

* **Water treatment**: Chlorination or UV treatment to prevent bacteria buildup in process water.

* **Housekeeping**: Eliminate stagnant water and clean high-risk areas regularly.

* **Pest control**: Regular inspections and use of repellents or traps.

* **Health screening**: Regular medical checks and immunizations (e.g., for malaria or leptospirosis in some regions).

--- ## ✅ **9. Human Factor Risk Mitigation**

* **Induction training**: Comprehensive safety onboarding for all new staff and contractors.

* **PPE compliance enforcement**: Regular checks and disciplinary procedures.

* **Fatigue management**: Reasonable shift scheduling, rest breaks, and hydration stations.

* **Behavioral safety programs**: Encourage proactive safety reporting and peer accountability.

* **Signage and communication**: Clear, multilingual, and accessible safety information.

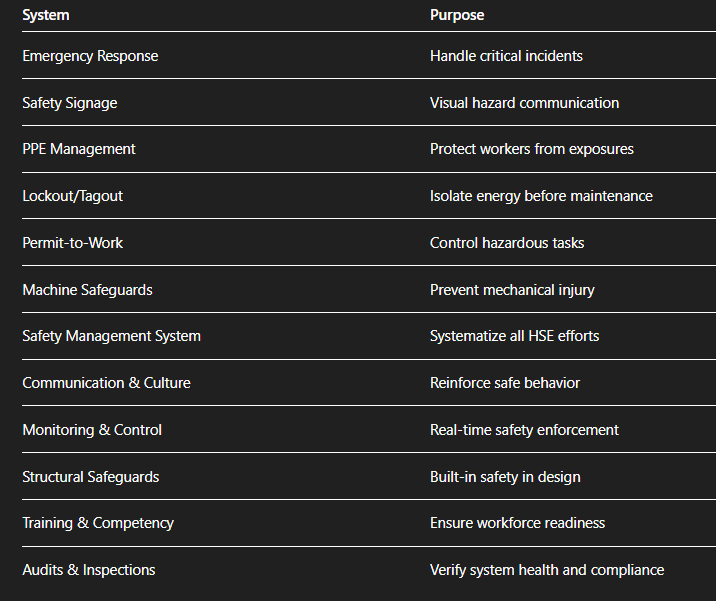

--- ## 🔄 **General Plant-wide Safety Systems**

* **Hazard identification and risk assessment (HIRA)**: Performed regularly.

* **Safety audits and inspections**: Scheduled and surprise audits to ensure compliance.

* **Incident investigation**: Thorough root cause analysis and corrective actions.

* **Emergency drills**: Simulate fire, chemical spills, and evacuation scenarios.

* **Continuous improvement**: Use feedback from incidents and near-misses to enhance systems.

Mechanical Hazards

--- ## ⚙️ **Mechanical Hazard Mitigation Strategies** Mechanical hazards typically arise from moving machinery, material handling systems, and maintenance activities.

Here's how to mitigate them effectively:

--- ### 🔒 **1. Guarding of Moving Parts**

* **Fixed guards**: Cover rotating shafts, belts, pulleys, and gears permanently unless maintenance is required.

* **Interlocked guards**: Stop the machine automatically if the guard is removed or opened.

* **Barrier guards**: Protect operators from contact with high-speed machinery (e.g., crushers, mills, screens).

* **Self-adjusting guards**: Used for equipment with varying input sizes (e.g., some types of conveyors).

--- ### 🛑 **2. Lockout/Tagout (LOTO) Procedures**

* **Formal LOTO system**: Ensure machinery is de-energized and cannot be started during maintenance.

* **LOTO training**: All workers must be trained and certified in LOTO practices.

* **Authorized personnel only**: Only trained individuals should perform LOTO.

* **Verification of isolation**: Test for zero energy before starting work.

--- ### 🧰 **3. Preventive Maintenance and Inspection**

* **Scheduled maintenance**: Reduces unexpected failures and mechanical accidents.

* **Checklists and logs**: Daily inspections of critical components (bearings, belts, guards).

* **Wear part monitoring**: Replace liners, crusher jaws, and screens before failure.

* **Lubrication systems**: Automatic or scheduled lubrication prevents overheating and mechanical seizures.

--- ### 🆘 **4. Emergency Stop Systems**

* **Accessible E-stops**: Install emergency stop buttons and pull cords along conveyors, crushers, and mills.

* **Clearly labeled**: Mark emergency systems in red with standardized symbols.

* **Test regularly**: Ensure E-stops work and are visible in case of accidents.

--- ### ⚙️ **5. Safe Equipment Design and Selection**

* **Low-maintenance designs**: Favor equipment with fewer moving parts and enclosed systems.

* **Failsafe features**: Equipment should shut down safely in case of malfunction.

* **Reverse rotation locks**: Prevent unintended startup during maintenance.

--- ### 👷 **6. Operator and Maintenance Personnel Training**

* **Machinery-specific training**: Workers must understand the hazards and controls of each machine they operate.

* **Refresher training**: Held periodically, especially after an incident or near-miss.

* **Awareness of pinch points, nip points, and rotating parts**.

--- ### 🏗️ **7. Material Handling System Safety**

* **Conveyor safety**:

* Install pull-cords and emergency stop systems.

* Ensure proper belt tracking to prevent misalignment.

* Guard nip points at rollers and transfer stations.

* **Hoisting and lifting**:

* Use certified lifting equipment.

* Train workers in load rating and sling/chain inspections.

* Implement exclusion zones during lifting.

--- ### 📐 **8. Design for Ergonomics and Accessibility**

* **Maintenance-friendly layouts**: Design platforms, ladders, and handrails for safe access to equipment.

* **Tool access**: Use swing-out components or quick-release systems to reduce manual strain during maintenance.

--- ### 👁️ **9. Signage and Visual Controls**

* **Warning signs**: Indicate hazard zones (e.g., "Keep Hands Clear", "Rotating Equipment").

* **Color coding**: Use industry-standard color codes for guards, controls, and hazardous zones.

--- ### 📊 **10. Monitoring and Automation**

* **Sensors and limit switches**: Detect blockages or overloads before they become critical.

* **Automated shutdowns**: Triggered by abnormal vibration, temperature, or load.

--- ### 🔄 **11. Incident Reporting and Feedback Loops**

* Encourage near-miss and incident reporting related to mechanical equipment. * Investigate and update procedures or equipment based on root cause analysis.

--- ### 🧯 **12. Integration with Other Systems**

* Combine mechanical safety with fire suppression (e.g., over lubricated bearings may ignite).

* Mechanical systems should tie into overall plant emergency shutdown procedures.

Electrical Hazards

--- ## ⚡ **Electrical Hazard Mitigation Strategies** Electrical hazards can result in **electric shocks, arc flashes, fires, and equipment damage**. These hazards are especially severe in processing plants due to water presence, heavy motors, and control systems.

--- ### 🧰 **1. Design and Installation Controls** * **Certified electrical design**: Ensure all systems are installed per IEC, NEC, or local standards. * **Ingress protection (IP rating)**: * Use **IP65/IP66 enclosures** in wet or dusty environments.

* Protect electrical panels from slurry splashes and dust ingress. * **Cable routing**: Use cable trays and avoid exposure to mechanical or chemical damage.

* **Explosion-proof equipment**: In areas with flammable dust or gases.

--- ### 🛑 **2. Isolation and Lockout/Tagout (LOTO)**

* **Clearly labeled isolation points**: Lockable switches for each major unit (e.g., pump, crusher, thickener motor).

* **LOTO procedures**: Standardized, documented, and enforced before all maintenance.

* **Zero-energy verification**: Use meters to confirm de-energization before starting work.

* **Lock boxes and permit systems**: For complex isolations involving multiple workers.

--- ### 🔌 **3. Grounding and Bonding**

* **Proper earthing systems**: All equipment must be grounded to prevent voltage buildup.

* **Equipotential bonding**: To prevent step and touch voltage differences. * **Regular testing**: Earth resistance testing to ensure system integrity.

--- ### 🧑🏫 **4. Training and Competency**

* **Electrical safety training**: * Mandatory for all electricians and maintenance staff.

* Covers shock, arc flash, and safe handling of energized equipment.

* **Authorized personnel only**: Only qualified individuals work on electrical systems.

* **First aid/CPR**: Staff trained in response to electrical accidents.

--- ### 🔥 **5. Arc Flash Mitigation**

* **Arc flash risk assessments**: Conduct for switchgear, MCCs, and transformers. * **Arc-rated PPE**:

* Face shields, gloves, balaclavas, suits, and boots.

* PPE must match the calculated incident energy level.

* **Arc flash labeling**: Clearly display hazard category and boundaries on all panels.

* **Remote racking systems**: Where possible, to operate breakers from a safe distance.

--- ### ⚠️ **6. Signage, Labeling, and Access Control**

* **Clear signage**: "Danger – High Voltage", "Authorized Personnel Only", etc.

* **Panel labeling**: Each circuit breaker, relay, and feeder labeled and documented.

* **Restricted access**: Electrical rooms and substations locked and access-controlled.

--- ### 📟 **7. Equipment and System Protection**

* **Circuit protection devices**: * Use MCCBs, fuses, RCDs/ELCBs, and surge protectors.

* Ensure proper sizing and coordination to avoid nuisance tripping or missed protection.

* **Thermal imaging**: Periodic scans to detect hotspots and loose connections.

* **Monitoring systems**: SCADA or PLC alarms for voltage drops, overloads, and abnormal consumption.

--- ### 🌊 **8. Mitigation of Wet and Corrosive Environments**

* **Waterproof enclosures**: IP-rated panels and sealed glands for cable entries.

* **Elevated panels and cabling**: Keep above ground/floor to avoid water exposure.

* **Corrosion-resistant materials**: Use stainless steel for junction boxes in slurry areas.

--- ### 🔁 **9. Preventive Maintenance and Testing**

* **Routine inspections**: Look for worn insulation, exposed wires, hot spots, and corrosion.

* **Test instruments**: Ground resistance, insulation resistance, loop impedance, etc.

* **Infrared thermography**: Detect overloaded circuits or loose connections early.

--- ### 🧯 **10. Fire Protection and Emergency Preparedness**

* **Electrical-rated fire extinguishers** (CO₂ or dry chemical).

* **Smoke and heat detectors** in MCC rooms.

* **Automatic fire suppression** systems in key control rooms and switchgear areas.

* **Emergency response plan**: Trained personnel and evacuation routes posted.

--- ### 🧾 **11. Documentation and Compliance**

* **Single-line diagrams**: Accurate and up-to-date.

* **Maintenance logs and inspection records**: For audits and traceability. * **Compliance audits**: Annual reviews against national and international standards (e.g., OSHA, IEC, NFPA 70E).

--- ### 📊 **12. Integration with Plant Safety Systems**

* **Emergency stop (E-stop) systems**: Electrically interlocked with control systems.

* **PLC/SCADA integration**: Alarms and shutdowns based on electrical faults or overloads. * **Uninterruptible Power Supply (UPS)**: For critical control and monitoring equipment.

Chemical Hazards

--- ## 🧪 **Chemical Hazard Mitigation Strategies** Chemical hazards in ore processing include **toxic exposure, corrosive burns, inhalation of fumes/dust, environmental contamination,** and **fire or explosion risks**. Effective mitigation ensures personnel and environmental safety.

--- ### 🧱 **1. Proper Chemical Storage**

* **Segregated storage**: Incompatible chemicals (e.g., acids and cyanide) must be stored separately.

* **Spill containment**: Use bunds or secondary containment that can hold 110–120% of the largest container's volume.

* **Ventilation**: Store volatile chemicals in ventilated areas to prevent fume buildup.

* **Signage and labeling**: Clearly mark all containers with hazard symbols and contents.

--- ### 🧴 **2. Safe Handling Procedures**

* **Standard operating procedures (SOPs)**: Documented and enforced for chemical mixing, dosing, and transfer.

* **Closed transfer systems**: For transferring toxic or volatile chemicals (e.g., cyanide dosing).

* **Slow addition protocols**: Add acid to water, not water to acid, to avoid violent reactions.

* **Dedicated tools and equipment**: For each chemical to avoid cross-contamination.

--- ### 🛑 **3. Personal Protective Equipment (PPE)**

* **Chemical-resistant gloves, aprons, and boots**: PVC, neoprene, or nitrile depending on the chemical.

* **Eye and face protection**: Full-face shields or goggles, especially with corrosives.

* **Respiratory protection**: Dust masks or respirators for dry powders, mists, or toxic fumes.

* **Emergency PPE stations**: Strategically placed for rapid access near chemical zones.

--- ### 🚿 **4. Emergency Response Infrastructure**

* **Eyewash stations and safety showers**: Within 10 seconds or 15 meters of all chemical use areas.

* **Spill kits**: Equipped with absorbents, neutralizers, PPE, and instructions. * **Neutralization agents**:

* Lime or soda ash for acid spills.

* Hydrogen peroxide or bleach for cyanide (used under controlled conditions only).

* **First aid training**: Staff trained to handle chemical exposures.

--- ### 📋 **5. Safety Data Sheets (SDS) and Labeling**

* **Accessible SDS**: Hard copy and digital versions near chemical areas.

* **Training on SDS interpretation**: So workers can understand chemical risks and first aid steps.

* **Globally Harmonized System (GHS)** labeling\*\*: Standardized hazard communication on all containers.

--- ### 🧪 **6. Ventilation and Containment**

* **Local exhaust ventilation (LEV)**: At chemical mixing, dosing, or transfer points.

* **Sealed systems**: For dangerous gases (e.g., hydrogen cyanide or SO₂).

* **Scrubbers or fume absorbers**: For emissions generated during leaching or acid reactions.

--- ### 🧠 **7. Training and Competency**

* **Hazard communication training**: Teach workers about the risks and mitigation of chemicals in use.

* **Chemical handling certification**: Mandatory for personnel managing high-risk substances (e.g., cyanide).

* **Simulation drills**: For spill response and exposure events.

--- ### ⚠️ **8. Monitoring and Detection Systems**

* **Fixed and portable gas detectors**: * For HCN, SO₂, H₂S, and chlorine in processing areas.

* **pH monitoring systems**: To prevent acid/base overdose in process tanks.

* **Leak detection**: On reagent pipelines and tanks with auto-shutdown features. -

-- ### 🛠️ **9. Engineering Controls**

* **Automated dosing systems**: Reduce manual contact with chemicals.

* **Backflow prevention devices**: In dosing lines to avoid contamination of supply tanks.

* **Drip trays and isolation valves**: At tanks, pumps, and dosing skids. * **Enclosed conveyor transfer points**: When handling dry reagent powders (e.g., lime, xanthates).

--- ### 🌍 **10. Environmental Protection**

* **Effluent treatment plants (ETPs)**: Treat chemical-laden water before discharge.

* **Cyanide detoxification systems**: (e.g., INCO process) before tailings discharge.

* **Stormwater management**: Divert clean water away from chemical areas.

* **Environmental monitoring**: Routine water and soil sampling for contamination indicators.

--- ### 🔄 **11. Maintenance and Inspections**

* **Tank and pipe integrity checks**: Inspect for corrosion, leaks, and thinning.

* **Valve and pump checks**: Ensure proper function to avoid accidental releases.

* **Calibration of dosing pumps**: Maintain accuracy in reagent application.

--- ### 📞 **12. Communication and Emergency Coordination**

* **Chemical emergency contacts**: Clearly posted and known to all staff.

* **Material inventory logs**: Maintain updated inventory with SDS cross-references.

* **Coordination with local emergency services**: Share chemical hazard plans in case of off-site impact.

Physical Hazards

--- ## 🧱 **Physical Hazard Mitigation Strategies** Physical hazards are non-chemical, non-biological dangers that result from environmental conditions, equipment operation, or the nature of the process. They can cause **hearing loss, fatigue, burns, frostbite, slips, or chronic injury**.

--- ### 🔊 **1. Noise Control** Ore processing involves crushers, mills, screens, conveyors, and pumps — all of which generate high noise levels.

#### Mitigation Strategies:

* **Engineering controls**:

* Use sound-insulated enclosures around crushers, compressors, and mills.

* Install vibration isolation mounts and noise-dampening linings on chutes.

* **Administrative controls**: * Rotate personnel to limit exposure time.

* Restrict access to high-noise zones.

* **PPE**: * Provide hearing protection (earplugs/muffs) rated to the noise level (dB).

* **Monitoring**: * Conduct regular noise mapping using dosimeters and sound level meters.

* Identify and mark hearing protection zones.

--- ### 🔧 **2. Vibration Exposure** Vibration arises from operating mobile equipment, crushers, and hand tools (e.g., jackhammers, grinders).

#### Mitigation Strategies:

* **Anti-vibration tool design**: Use tools with built-in damping or shock absorption.

* **Isolated operator cabins**: In vehicles or control rooms.

* **Work rotation and rest breaks**: To reduce long-term exposure to hand-arm vibration or whole-body vibration.

* **Monitoring**: Measure vibration levels and compare to exposure action limits (ISO 5349 & ISO 2631).

--- ### 🌡️ **3. Heat Stress and Burns** High ambient temperatures, hot process fluids, steam, and metal surfaces can pose a risk. #### Mitigation Strategies:

* **Insulation**: Cover hot process pipes, tanks, and surfaces with thermal insulation or barriers.

* **Ventilation and cooling**: Use fans, shade, and HVAC in control rooms and workstations.

* **Hydration protocols**: Provide cool drinking water and enforce hydration breaks.

* **Heat stress training**: Recognize signs of heat exhaustion and heatstroke. * **Protective clothing**: Flame- or heat-resistant gear where hot materials are handled.

--- ### ❄️ **4. Cold Stress** In colder environments or during shutdowns in cold climates, exposure can lead to hypothermia or frostbite.

#### Mitigation Strategies:

* **Heated shelters**: For breaks and standby staff.

* **Thermal PPE**: Insulated gloves, boots, and layered clothing. * **Monitor exposure time**: Especially when wind chill is a factor.

--- ### 🧼 **5. Slips, Trips, and Falls** One of the most common physical hazards in processing plants due to wet floors, uneven surfaces, and equipment layouts.

#### Mitigation Strategies:

* **Housekeeping**: * Clean spills immediately.

* Clear walkways of hoses, cables, and debris.

* **Flooring**:

* Use non-slip coatings or mats in wet zones.

* Ensure good drainage in slurry or reagent handling areas.

* **Design**:

* Install handrails on stairs and platforms.

* **Lighting**: Provide adequate illumination, especially in corridors and stairways.

* **Signage**: Clearly mark elevation changes, slippery areas, and restricted zones.

--- ### 🧲 **6. Radiation (If Applicable)** May occur from density gauges (e.g., gamma or X-ray-based), particularly in slurry pipelines.

#### Mitigation Strategies:

* **Shielding**: Use lead shields or housings to prevent exposure.

* **Access restriction**: Limit entry to areas with active radiation sources.

* **Monitoring**:

* Regularly calibrate and inspect radiation instruments.

* Personal dosimeters for workers near sources.

* **Training**: Staff trained in safe handling of radiation devices and emergency response.

--- ### 🔦 **7. Lighting Hazards** Poor lighting contributes to errors, accidents, and eye strain.

#### Mitigation Strategies: * **High-lumen LED lighting**: In all critical areas (workshops, control rooms, process zones).

* **Backup power**: Ensure lighting is maintained during power outages.

* **Periodic audits**: Assess lux levels and replace burnt-out lights promptly.

--- ### 🧍 **8. Ergonomics and Manual Handling** Improper lifting, repetitive motion, and poor workstation design can cause musculoskeletal injuries.

#### Mitigation Strategies:

* **Mechanical aids**: Hoists, conveyors, and trolleys to minimize manual lifting.

* **Training**: Manual handling techniques and awareness. * **Adjustable workstations**: For laboratory or control room tasks.

--- ### 🧯 **9. Fire and Explosion Hazards** From flammable materials, hot work, or dust accumulation.

#### Mitigation Strategies:

* **Hot work permits**: Strict control over welding, grinding, etc.

* **Dust control**: Suppression systems in dry grinding, baghouses, and ducting.

* **Fire suppression**: Fixed systems, fire extinguishers, and firewater lines. * **Housekeeping**: Remove combustible material buildup. -

Process Hazards

--- ## ⚙️ **Process Hazard Mitigation Strategies** Process hazards involve risks associated with the design, operation, control, and integrity of equipment and systems used to process materials. Failures can lead to **fires, explosions, chemical releases, mechanical failures, and uncontrolled reactions**.

--- ### 🧭 **1. Process Hazard Analysis (PHA)**

* **HAZOP (Hazard and Operability Study)**: Systematically review all nodes (e.g., tanks, pumps, cyclones) for deviations and their consequences.

* **What-if analysis**: Identify potential failures like valve misalignment, pump failure, etc.

* **Failure Modes and Effects Analysis (FMEA)**: Prioritize critical failure points and assign corrective actions.

* **Layer of Protection Analysis (LOPA)**: Determine if safeguards are adequate for high-risk scenarios.

--- ### 🏗️ **2. Inherently Safer Design (ISD)**

* **Substitute**: Use less hazardous chemicals or processes where possible (e.g., dry reagents vs liquids).

* **Minimize**: Reduce quantities of dangerous reagents stored or handled at any time.

* **Moderate**: Use chemicals at lower concentrations or pressures. * **Simplify**: Design systems with fewer steps, connections, or complex interlocks.

--- ### 🛠️ **3. Engineering Controls**

* **Process interlocks**: PLC/SCADA-controlled logic to prevent unsafe conditions (e.g., prevent mill start without feedwater).

* **Automatic shutdowns**: Triggered by high pressure, high temperature, flow deviation, or tank overflow.

* **Relief systems**: Pressure relief valves, rupture disks on vessels and pipelines.

* **Double-block and bleed** systems: For isolating hazardous lines during maintenance.

--- ### 🧪 **4. Instrumentation and Control Systems**

* **Redundant sensors**: For critical parameters (flow, level, temperature).

* **Alarms and alerts**: Audible and visual signals for out-of-spec conditions.

* **Data logging and trending**: To detect process drift or early warning signs.

* **Remote monitoring**: Centralized control room oversight.

--- ### 📋 **5. Operating Procedures and Work Instructions**

* **Standard operating procedures (SOPs)**: * Start-up, shutdown, normal operation, and emergency actions.

* **Permit to work (PTW)**: * For high-risk tasks like confined space entry, hot work, and line breaking.

* **Deviation handling**: Procedures for managing abnormal conditions.

--- ### 🧑🏫 **6. Training and Competency**

* **Process-specific training**: For operators, maintenance, and control room personnel.

* **Emergency drills**: For loss of containment, fire, explosion, or toxic gas release.

* **Refresher courses**: Periodically reinforce critical process safety concepts.

--- ### 🔍 **7. Inspection, Testing, and Preventive Maintenance (ITPM)**

* **Critical equipment registry**: Pumps, valves, tanks, pressure systems, etc.

* **Routine inspections**: Check for wear, corrosion, vibration, and leaks. * **Calibration**: Of pressure/level transmitters, flowmeters, pH probes, etc.

* **Shutdown planning**: Scheduled turnarounds for deep maintenance and testing.

--- ### 🔄 **8. Change Management**

* **Management of Change (MOC)**: * Formal process for evaluating and approving changes in equipment, process parameters, or materials.

* **Risk assessments**: Mandatory before implementing any change.

* **Documentation updates**: Drawings, SOPs, training material.

--- ### 📦 **9. Containment and Spill Control**

* **Tank bunds and sumps**: For capturing overflows or leaks.

* **Secondary containment**: For reagent and product pipelines.

* **Overflow alarms**: High-level alarms on tanks and thickeners.

* **Leak detection**: Sensors and flow imbalance detection in reagent lines.

--- ### 🚪 **10. Emergency Response Planning**

* **Process-specific ERP**: Tailored to scenarios like acid tank rupture, thickener overflow, or reagent line burst.

* **On-site emergency team**: Equipped and trained for process-related incidents.

* **Evacuation protocols and muster points**: Clearly marked and communicated.

* **Off-site consequence modeling**: For scenarios with environmental or community impact.

--- ### 📘 **11. Documentation and Compliance**

* **Process flow diagrams (PFDs)** and **piping and instrumentation diagrams (P\&IDs)**: Up-to-date and accessible.

* **Compliance with standards**: * OSHA PSM, ISO 45001, ISO 14001, local mining and environmental regulations.

* **Incident investigation reports**: Root cause analysis (RCA) for process failures.

--- ### 📈 **12. Performance Monitoring and Continuous Improvement**

* **Key process indicators (KPIs)**: * Near misses, deviations, trips, and releases.

* **Incident tracking systems**: To log and analyze trends.

* **Continuous improvement loops**: Use feedback to refine controls and procedures.

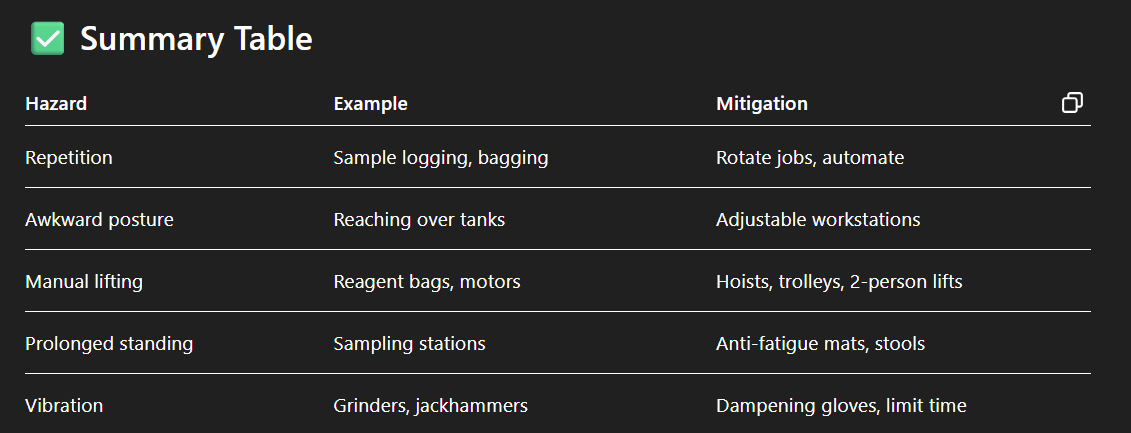

Ergonomic Hazards

--- ## 🧍♂️ **Ergonomic Hazard Mitigation Strategies** Ergonomic hazards arise from poor job design and workplace layout. Common issues include:

* Repetitive tasks (e.g., sample prep, packing, sorting),

* Awkward postures (e.g., reaching over tanks or conveyors),

* Manual lifting or pushing of heavy items (e.g., reagent bags, hoses),

* Vibration (from hand tools or mobile equipment),

* Prolonged standing or sitting.

--- ### 🛠️ **1. Engineering Controls** Modify the workplace to physically reduce risk.

* **Adjustable workstations**: Allow standing or sitting work depending on the task.

* **Ergonomic tools**: Use handles with grips, long levers, and anti-vibration designs.

* **Mechanical aids**: Use trolleys, hoists, conveyors, or vacuum lifters for:

* Sample trays

* Chemical bags

* Equipment parts

* **Work height optimization**:

* Set work surfaces at elbow height for most tasks.

* Store heavy items between knee and shoulder level.

* **Redesign layouts**:

* Minimize twisting, overhead reaching, or long carries.

* Reduce step climbing between levels.

--- ### 🧑🏫 **2. Administrative Controls** Manage how work is assigned and performed.

* **Job rotation**: Alternate between tasks to avoid repetitive strain.

* **Work-rest cycles**: Schedule short breaks to reduce fatigue.

* **Pace and workload planning**: Avoid unrealistic targets that push workers to unsafe postures or speeds.

* **Two-person lifting protocols**: For objects over 20–25 kg.

* **Limit exposure**: Restrict duration of work with vibrating tools or in awkward positions.

--- ### 🧠 **3. Training and Awareness** Teach workers how to recognize and avoid ergonomic risk factors.

* **Manual handling training**: * Safe lifting techniques: bend knees, keep loads close, avoid twisting.

* **Tool use training**: Proper grip and posture when using hand tools.

* **Ergonomic awareness sessions**: Identify early signs of strain and how to report them.

* **Stretching programs**: To improve flexibility and reduce injury risk.

--- ### 🪑 **4. Ergonomic Office and Control Room Design** For operators, technicians, and engineers in control rooms or labs.

* **Ergonomic seating**: Adjustable chairs with lumbar support and armrests.

* **Monitor positioning**: At eye level and an arm’s length away.

* **Keyboard and mouse placement**: At elbow level to prevent wrist strain. * **Footrests**: Where needed to reduce lower back pressure.

--- ### 🔄 **5. Task and Tool Redesign**

* **Repackage materials**: * Use smaller, lighter reagent bags (e.g., 10 kg instead of 25 kg).

* **Install automated sample splitters** or bag fillers to reduce repetitive scooping/lifting.

* **Modular maintenance components**: Design tanks, pumps, and gearboxes for easy removal and reinstallation.

--- ### 📊 **6. Ergonomic Risk Assessment** Regularly review plant activities for ergonomic hazards.

* Use assessment tools like:

* **RULA** (Rapid Upper Limb Assessment)

* **REBA** (Rapid Entire Body Assessment)

* **NIOSH Lifting Equation**

* Conduct walk-throughs to observe posture, force, and repetition.

* Involve employees in hazard identification and solution design.

--- ### ⚙️ **7. Maintenance and Housekeeping**

* **Fix uneven walking surfaces** or slippery areas that force awkward body movements.

* **Organize tools and parts**: Reduce reaching or bending by using shadow boards and racking.

* **Clear walkways**: Prevent overexertion from climbing or stepping over obstacles.

--- ### 👂 **8. Reporting and Feedback Systems**

* Encourage early reporting of discomfort or strain.

* Investigate ergonomic near misses and incidents.

* Include ergonomic reviews in incident investigations.

--- ## ✅ Summary Table

Environmental Hazards

--- ## 🌍 **Environmental Hazard Mitigation Strategies** Environmental hazards in ore processing include

**dust, noise, wastewater, tailings, spills, emissions, and chemical leaks**. These can cause:

* Water and soil contamination

* Air quality degradation

* Wildlife and habitat disruption

* Legal and reputational consequences

--- ### 💧 **1. Water Pollution Mitigation** Ore processing often uses large volumes of water, which can become contaminated with:

* Reagents (cyanide, flotation chemicals)

* Fine particulates

* Metals and process residues

#### Mitigation Strategies:

* **Water treatment plants**: Treat process water before discharge or recycling.

* **Zero-discharge systems**: Design for complete water reuse within the plant.

* **Sedimentation ponds**: Settle out solids before release or reuse.

* **Spill containment**:

* Bunded reagent storage tanks

* Sumps under pipelines and pumps

* **Stormwater management**: Isolate clean runoff from process areas.

--- ### 🌫️ **2. Air Emission and Dust Control** Crushing, screening, conveying, and ore transfer points generate airborne dust and emissions.

#### Mitigation Strategies:

* **Dust suppression systems**:

* Water sprays, fog cannons, or surfactants at transfer points and stockpiles.

* **Enclosures and covers**: On crushers, conveyors, bins, and loading points.

* **Baghouse filters and scrubbers**: On process exhausts and ventilation systems.

* **Vehicle speed limits**: On haul roads to reduce dust.

* **Vegetative buffers**: Plant windbreaks or grass to trap dust.

--- ### 🧪 **3. Chemical and Reagent Management** Reagents used in flotation, leaching, and thickening (e.g., cyanide, xanthates, flocculants) pose high environmental risk.

#### Mitigation Strategies:

* **Secondary containment**: For tanks, IBCs, and drums.

* **Spill response kits**: At all storage and dosing points.

* **Closed-loop dosing systems**: Reduce exposure and spills.

* **Storage protocols**: * Labeling, segregation by hazard class, MSDS availability.

* **Emergency shutoff valves**: On reagent lines and storage tanks.

* **Regular inspections**: For signs of leaks, corrosion, or overflows.

--- ### 🧱 **4. Tailings Management** Tailings from flotation or leaching processes can be acidic, metal-laden, or chemically active.

#### Mitigation Strategies:

* **Engineered tailings storage facilities (TSFs)**: Designed with liners, drains, and seepage monitoring.

* **Paste/thickened tailings**: Reduce water use and seepage potential.

* **Dry stack tailings**: Where appropriate, to minimize environmental footprint.

* **Daily inspections**: For stability, seepage, and integrity of dams and embankments.

* **Seepage recovery systems**: Reclaim and reuse water.

* **Closure plans**: Progressive rehabilitation and vegetation to prevent erosion or acid mine drainage (AMD).

--- ### 🔊 **5. Noise and Vibration Control** Environmental noise affects surrounding communities and ecosystems.

#### Mitigation Strategies:

* **Noise barriers**: Berms or walls near crushers or screening stations.

* **Acoustic enclosures**: For high-decibel machinery.

* **Limit blasting times**: In quarries associated with plant supply.

* **Monitoring**: Routine noise level assessments at the boundary.

--- ### 🐾 **6. Biodiversity and Habitat Protection** Expansion and operations may disrupt flora, fauna, and ecosystem functions.

#### Mitigation Strategies:

* **Environmental Impact Assessment (EIA)**: Before project start.

* **Buffer zones**: Around rivers, wetlands, and protected areas.

* **Habitat restoration**: Rehabilitate disturbed areas progressively.

* **Fauna relocation**: Remove and protect sensitive species before clearing.

* **Minimize footprint**: Optimize land use to reduce habitat disruption.

--- ### ⚠️ **7. Waste Management** Hazardous and non-hazardous wastes arise from labs, workshops, and general operations.

#### Mitigation Strategies:

* **Waste segregation**: Clearly label and separate hazardous, recyclable, and general waste.

* **Licensed disposal**: Use certified third parties for hazardous waste.

* **Oil traps**: In workshops and wash bays to prevent contamination.

* **Used reagent containers**: Triple rinse and return or dispose per chemical regulations.

--- ### 🧯 **8. Spill and Incident Response** Spills can lead to serious environmental contamination.

#### Mitigation Strategies:

* **Spill response plan**: Documented and practiced with trained personnel.

* **Spill kits**: Located in high-risk areas (labs, reagent stores, truck loading areas).

* **Emergency shutoff systems**: For tanks and pipelines.

* **Automatic containment valves**: For sump or bund overflow events.

* **Incident reporting systems**: Capture root causes and corrective actions.

--- ### 📊 **9. Monitoring and Compliance** Ensures ongoing control and identifies problems early.

#### Mitigation Strategies:

* **Environmental monitoring**:

* Water sampling (upstream/downstream)

* Air quality and dust level tracking

* Noise measurements at boundary

* **Compliance audits**: Against permits and environmental management plans (EMPs).

* **Reporting**: Timely submission of environmental reports to regulators.

--- ### 📘 **10. Community and Regulatory Engagement** Mitigating reputational and social risk.

#### Mitigation Strategies:

* **Community awareness programs**: Share updates and address concerns.

* **Grievance mechanisms**: For local populations to report impacts.

* **Environmental transparency**: Publish monitoring results and incident reports.

* **Compliance with standards**: ISO 14001, IFC guidelines, and national legislation.

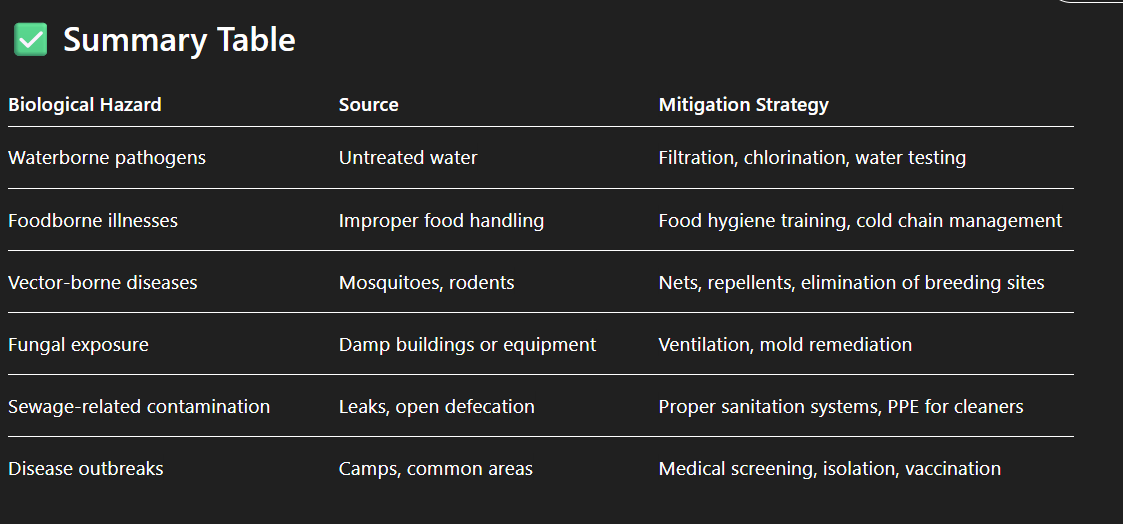

Biological Hazards

--- ## 🦠 **Biological Hazard Mitigation in Ore Processing Plants** Biological hazards refer to risks from **bacteria, viruses, fungi, parasites, and biological toxins** that can affect human health. In the mining and processing context, these often stem from:

* Contaminated water sources

* Poor hygiene in remote camps or facilities

* Vector-borne diseases (e.g., malaria, dengue)

* Rodents or wildlife contact

* Waste handling (e.g., sewage, food waste)

* Mold or fungus in damp areas

--- ### 🧼 **1. Sanitation and Hygiene** Ensuring personal and communal hygiene reduces the spread of biological agents.

**Mitigation Measures:**

* Provide **clean, running water** and handwashing stations near work and eating areas.

* Ensure **toilets and showers** are regularly cleaned and disinfected.

* Promote **personal hygiene awareness** (e.g., posters, toolbox talks).

* Supply **PPE** like gloves and masks when cleaning toilets or handling waste.

--- ### 🚰 **2. Safe Drinking Water and Food Handling** Contaminated water or improperly handled food can transmit bacteria, viruses, and parasites.

**Mitigation Measures:**

* Use **treated or bottled water** for drinking.

* Install and maintain **water purification systems** (UV, chlorine, filtration).

* Conduct **regular microbiological testing** of water supplies.

* Enforce **food safety protocols**:

* Cook food thoroughly

* Separate raw and cooked items

* Refrigerate perishables

* Clean kitchen surfaces frequently

--- ### 🦟 **3. Vector Control (Insects & Rodents)** Mosquitoes, rodents, and other pests can transmit serious diseases.

**Mitigation Measures:**

* **Drain stagnant water** to prevent mosquito breeding.

* **Apply insecticides** in high-risk areas.

* Install **window screens and mosquito nets** in camps and accommodation.

* **Rodent control programs**: Baiting, traps, sealed waste bins, rodent-proof buildings.

* Provide **vaccination programs** where applicable (e.g., yellow fever, rabies).

--- ### 🧪 **4. Waste and Sewage Management** Biological hazards thrive in unmanaged waste or sewage.

**Mitigation Measures:**

* Use **closed sewage systems or treatment plants**.

* Regularly inspect **septic tanks or pit latrines** for overflow or leaks.

* Separate **biohazardous waste** (e.g., lab swabs) and dispose through licensed channels.

* Implement **waste segregation and composting** only under controlled and hygienic systems.

--- ### 🏥 **5. Medical and Occupational Health Surveillance** Monitoring workers' health helps detect biological risks early.

**Mitigation Measures:**

* Conduct **pre-employment and routine medical screenings**.

* Implement **fever and symptom screening** during outbreaks (e.g., COVID-19, malaria season).

* Maintain **onsite medical facilities** or emergency response arrangements.

* Offer **vaccinations**: Hepatitis, tetanus, typhoid, depending on location.

--- ### 🦠 **6. Mold, Fungi, and Damp Area Control** Wet or humid processing environments (e.g., pump stations, reagent sheds) can harbor fungi and bacteria.

**Mitigation Measures:**

* Install **ventilation and dehumidification systems** in enclosed spaces.

* Conduct **regular mold inspections**, especially in changing rooms or camps.

* Replace or clean **damp or moldy materials** (e.g., insulation, wood, filters).

* Provide **respiratory PPE** when cleaning or entering mold-contaminated spaces.

--- ### 📋 **7. Training and Awareness** Educated workers can avoid many biological risks.

**Mitigation Measures:**

* Train workers on **personal hygiene**,

**food handling**,

**vector avoidance**, and **waste risks**.

* Run **induction briefings** on site-specific biological risks (e.g., malaria-endemic zones).

* Post **biological hazard signage** in food prep areas, clinics, and camp zones.

--- ### 📊 **8. Risk Assessments and Incident Management** A structured approach to identifying and managing biological risks.

**Mitigation Measures:**

* Include biological risks in the **site hazard register**.

* Perform **regular biological hazard audits** in kitchens, water tanks, and clinics.

* Maintain **incident logs** and perform **root cause analysis** for any outbreaks or exposures.

* Report and respond quickly to signs of **contagious illness clusters**.

--- ### 🧯 **9. Emergency Preparedness and Response** Planning for potential biological incidents or outbreaks.

**Mitigation Measures:**

* Develop and rehearse **infectious disease response plans** (e.g., isolation, treatment, contact tracing).

* Stock **emergency supplies**: PPE, disinfectants, first aid, test kits.

* Maintain partnerships with **local health services** or mobile medical teams.

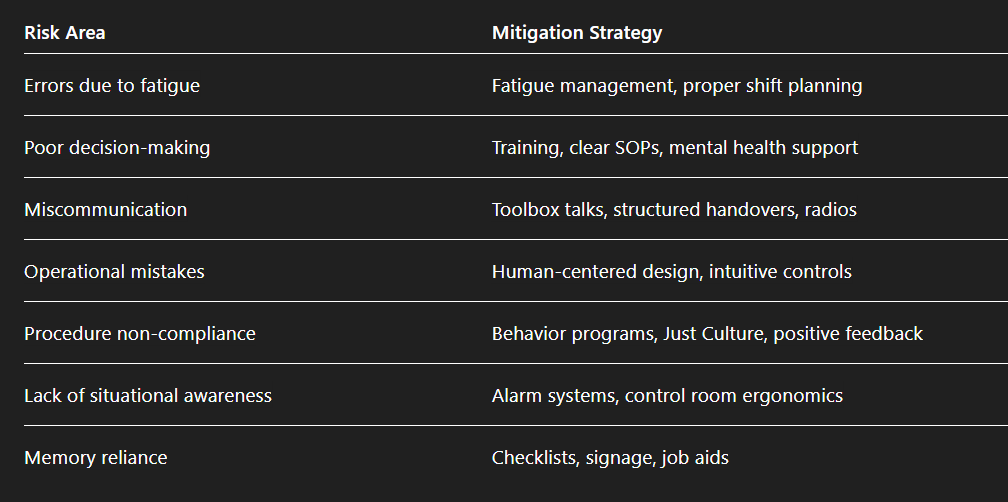

Human Factor Risk Mitigation

--- ## 🧠 **Human Factor Risk Mitigation in Ore Processing Plants** **Human factors** refer to the interactions between people, their tools, equipment, procedures, and the work environment. Failures in these interactions can result in:

* Operational errors (e.g., incorrect valve operation, misdosing chemicals) * Safety incidents (e.g., lockout/tagout violations)

* Equipment damage (e.g., improper startup) * Process upsets (e.g., delayed alarms, poor communication)

--- ## 🎯 Key Mitigation Strategies

### 🛠️ **1. Design for Human Use (Human-Centered Engineering)

** Design systems and environments to be intuitive and user-friendly.

* **Clear labeling and signage** on equipment, panels, and pipelines.

* **Standardized control layouts** to avoid confusion during emergencies.

* **Error-proofing (poka-yoke)** in control systems to prevent critical mistakes.

* **Good lighting, visibility, and access** to reduce missteps in inspections or operations.

* **Alarm management systems** that prioritize critical alerts and reduce overload.

--- ### 🧑🏫 **2. Competence, Training & Skill Development** Errors often stem from inadequate understanding or overreliance on memory.

* **Task-specific training** for all operators, including simulations for abnormal events.

* **Refresher courses** for high-risk tasks (e.g., confined space entry, reagent handling).

* **Verification of competency (VoC)** assessments. * **Cross-training** to prepare staff for task rotation and handover.

--- ### 📋 **3. Clear Procedures and Documentation** Ambiguity in procedures leads to inconsistent and unsafe practices.

* Develop **standard operating procedures (SOPs)** with input from frontline workers.

* Use **visual aids** (diagrams, flowcharts, videos) for clarity.

* Conduct **pre-task briefings or job hazard analyses (JHA)**.

* Keep **procedures accessible at point-of-use** (laminated cards, tablets, boards).

--- ### 🗣️ **4. Communication and Team Coordination** Miscommunication is a common root cause of accidents.

* Implement **shift handover protocols** (written + verbal).

* Use **two-way radio communication protocols** (closed-loop confirmation).

* Conduct **daily toolbox meetings** to review safety concerns, changes, or work priorities.

* Establish a **speak-up culture**: Encourage reporting unsafe conditions or unclear instructions.

--- ### 🧘 **5. Fatigue and Mental Health Management** Fatigue and psychological stress impair judgment and reaction times.

* **Manage shift schedules** to prevent long hours and ensure sufficient rest.

* Monitor **night shift rotations** and cumulative overtime.

* Provide access to **mental health support** (e.g., EAPs, counseling).

* Encourage **regular breaks** and rest areas in processing areas.

--- ### 🔁 **6. Human Error Analysis and Continuous Learning** Turn mistakes into opportunities to improve systems.

* Conduct **human error root cause analysis** after incidents.

* Use **learning teams or human performance reviews** to understand context.

* Apply the **"Just Culture" model**: Balance accountability and learning.

* Integrate findings into **procedure updates and retraining programs**.

--- ### 🧯 **7. Behavioral Safety Programs** Address at-risk behaviors before they lead to incidents.

* Implement **Behavior-Based Safety (BBS)** programs with peer observations.

* Recognize **safe behaviors** and provide **positive reinforcement**.

* Involve workers in setting **behavioral expectations** and reviewing trends.

--- ### 🧍♂️ **8. Ergonomics and Physical Interaction** Ergonomic design reduces strain-related errors and distraction.

* Use **tools and layouts** that reduce awkward postures and fatigue.

* Position **panels, valves, and interfaces** at natural eye or hand level.

* Avoid clutter that creates **trip or confusion hazards** during tasks.

--- ### 🧪 **9. Automation with Human Oversight** Automate repetitive or high-risk tasks, but ensure humans remain in control.

* Design **fail-safe systems** with human override capabilities.

* Ensure **HMI (Human-Machine Interface)** displays are intuitive and informative.

* Train operators to **understand automation logic**, not just button-pushing.

Summary Table

--- ## 🔄 Bonus: Integrating Human Factors into Safety Systems

* Include human factor evaluations in **HAZOPs, JSAs, and incident investigations**.

* Develop a **Human Factors Management Plan (HFMP)**.

* Train supervisors in **non-technical skills**: leadership, communication, coaching.

General Plant wide safety system

--- ## 🏭 **General Plant-wide Safety Systems for Ore Processing Plants** These systems act as the foundation for hazard prevention, detection, control, and emergency response.

--- ### 🧯 **1. Emergency Response System (ERS)** Covers plant-wide preparedness for fire, chemical spills, structural failures, explosions, or medical emergencies.

**Components:** * **Emergency Response Plan (ERP)**: Includes procedures for evacuation, fire, chemical spill, gas leaks, etc.

* **Evacuation routes and muster points**: Clearly marked and illuminated.

* **Emergency drills**: Regularly conducted for fire, spill, and first aid scenarios.

* **First aid stations and responders**: Trained and available on each shift.

* **Coordination with local emergency services**: Fire, ambulance, environmental agencies.

--- ### 📣 **2. Safety Signage and Labeling System** Visual communication is essential to warn, direct, and instruct workers.

**Components:**

* **Color-coded hazard signs**: As per ANSI/OSHA or ISO standards.

* **PPE requirement signs**: At entry to hazardous zones.

* **Process labeling**: Pipelines, valves, tanks, and chemical containers.

* **Flashing alarms**: For gas leaks, fire, or critical equipment trips.

--- ### 🎧 **3. Personal Protective Equipment (PPE) Program** Protects workers from physical, chemical, biological, and noise hazards.

**Components:** * **PPE matrix**: Matches specific tasks to required PPE.

* **Controlled distribution and tracking**: PPE issuance and replacement logs.

* **Inspection and maintenance**: For respirators, harnesses, etc.

* **Training**: Proper use, storage, and limitations of PPE.

--- ### ⚡ **4. Lockout/Tagout (LOTO) System** Ensures energy sources are isolated during maintenance or repair.

**Components:**

* **Written LOTO procedures**: For all energy sources (electrical, hydraulic, pneumatic).

* **Authorized personnel list**: Who can perform LOTO.

* **Color-coded tags and locks**: Unique to each worker.

* **Verification protocols**: Test for zero energy before work begins.

--- ### 🧪 **5. Permit-to-Work (PTW) System** Controls high-risk work through formalized permissions.

**Types of permits:**

* Hot Work (welding, cutting)

* Confined Space Entry

* Working at Heights

* Electrical Work * Excavation

* Chemical Handling **Best practices:**

* Permit holders and issuers are trained.

* Site inspections before and after task.

* Integration with risk assessments and JSAs.

--- ### 🏗️ **6. Machinery & Equipment Safety Systems** Prevent mechanical hazards and ensure safe operations.

**Includes:**

* **Guarding systems**: For conveyors, crushers, rotating parts.

* **Emergency stop buttons (e-stops)**: Accessible throughout processing areas.

* **Start-up alarms and lights**: Audible/visual alerts before machinery activates.

* **Interlocks and limit switches**: Prevent dangerous conditions from occurring.

--- ### 🧑💼 **7. Safety Management System (SMS)** A formal structure for managing safety activities and responsibilities.

**Key elements:**

* **HSE policies and objectives**

* **Risk registers**: Updated and reviewed regularly.

* **Incident reporting and investigation tools**

* **Corrective action tracking** (e.g., from audits, near misses)

* **Audits and compliance checks** Can align with **ISO 45001** or **OHSAS 18001** standards.

--- ### 🗣️ **8. Safety Communication & Engagement** Keeps safety top-of-mind and encourages a proactive safety culture.

**Tools:** * **Toolbox talks and pre-shift safety briefings**

* **Safety bulletins and dashboards**

* **Suggestion programs and safety committees**

* **Stop-work authority training**

--- ### 📊 **9. Real-time Monitoring and Control Systems** Ensures continuous control over plant operations and safety.

**Examples:**

* **SCADA/DCS systems**: With alarms and safety interlocks.

* **CCTV and thermal imaging**: In critical or remote areas.

* **Gas detectors and environmental sensors**: For O₂, H₂S, CO, dust, etc.

* **Vibration/temperature monitoring**: For rotating equipment.

--- ### 🛡️ **10. Structural and Process Safeguards** Plant design features that mitigate widespread risks.

* **Fire suppression systems**: Sprinklers, foam systems, extinguishers.

* **Blast walls or pressure relief systems**: In high-risk chemical zones.

* **Ventilation systems**: For toxic fumes and dust control.

* **Drainage and bunding systems**: For spill containment and water control.

--- ### 📚 **11. Training and Competency Systems** Ensures all personnel understand and apply safety protocols.

**Elements:**

* Inductions for all employees and contractors.

* Task-specific and refresher training.

* Emergency response training.

* Competency assessments and certification.

--- ### 📅 **12. Safety Inspection & Audit Programs** Regular verification of compliance and condition of safety systems.

**Includes:** * Daily/weekly checklists (e.g., PPE, fire equipment, e-stops)

* Monthly workplace inspections.

* Third-party or internal audits. * Follow-up and closeout of findings.

Summary Table