Introduction

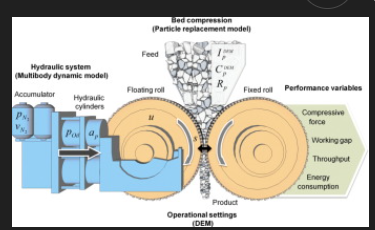

Here’s a breakdown of the key aspects and considerations related to HPGR:

### 1. **Energy Efficiency**

- HPGRs are known for their high energy efficiency compared to traditional milling methods, like SAG mills. The reduction in specific energy consumption is due to the interparticle breakage mechanism, which leads to the formation of micro-cracks in the ore, enhancing subsequent processing.

### 2. **Particle Size and Liberation**

- HPGRs produce fine particles that help liberate valuable minerals from gangue. This can result in improved recovery rates in downstream processes, such as flotation or leaching.

### 3. **Feed Preparation**

- Proper feed preparation is crucial for HPGR performance. The feed material should be of a consistent size and moisture content to ensure efficient breakage. Pre-screening and pre-crushing may be required, depending on ore characteristics.

### 4. **Wear and Maintenance**

- HPGR units experience significant wear, especially on the roller surfaces. Hard alloys, tungsten carbide studs, or segmented rolls are used to extend the life of the rolls. Regular inspections and replacements are essential for maintaining efficient operation and minimizing downtime.

### 5. **Operating Pressure**

- The pressure applied between the rolls directly affects the breakage mechanism and energy consumption. Higher pressures lead to greater particle deformation but can also increase wear on the rolls. Finding an optimal operating pressure is key for maximizing throughput while controlling maintenance costs.

### 6. **Roll Surface Design**

- Roll surface designs, such as studded, smooth, or profiled surfaces, impact the grinding efficiency and material throughput. Studded rolls typically offer higher grinding efficiencies but require careful selection based on the material's abrasiveness.

### 7. **Circulating Load and Closed-Circuit Operation**

- HPGRs often operate in a closed circuit with screening or classification equipment to manage circulating loads and optimize grinding efficiency. Closed circuits help maintain a stable particle size distribution and enhance the recovery in subsequent processes.

### 8. **Integration with Downstream Processes**

- The micro-cracks generated by HPGR enhance downstream processing, making it an ideal pre-treatment for heap leaching and other separation processes. The improved permeability in heap leaching results in higher recovery rates, particularly for low-grade ores.

### 9. **Moisture Control**

- High moisture content in the feed can lead to material buildup and blockage issues in the HPGR unit. Ensuring a controlled moisture level in the feed minimizes operational interruptions.

### 10. **Safety Considerations**

- Due to the high pressures involved, HPGR systems must have robust safety mechanisms to prevent accidental releases of pressure. Effective monitoring systems for temperature, pressure, and alignment are essential to ensure safe and stable operation.

HPGR technology is ideal for high-throughput, energy-efficient comminution and has become an integral part of mineral processing, especially for hard rock mining applications.

Energy Efficiency

Here’s a deeper look at the benefits of this micro-crack formation:

1. **Reduced Energy Demand in Secondary Grinding**:

- The weakened ore structure from micro-cracks means that less energy is required to further reduce particle sizes in downstream grinding equipment. This leads to lower overall energy consumption in the milling circuit, as mills require less power to process pre-weakened material.

2. **Improved Liberation of Valuable Minerals**:

- The micro-cracks aid in liberating valuable minerals from the surrounding gangue material, often at coarser grind sizes than conventional methods. Enhanced liberation at coarser sizes can improve recovery rates and reduce overgrinding, which is advantageous in both flotation and leaching processes.

3. **Enhanced Permeability in Heap Leaching**:

- For heap leaching, the increased permeability resulting from micro-cracks allows the leaching solution to penetrate more easily, resulting in faster and more efficient recovery of metals, particularly in lower-grade ores.

4. **Optimized for Ore Variability**:

- HPGR is also highly adaptable for handling variations in ore types, as the interparticle breakage mechanism maintains efficiency across a range of ore hardness levels. This makes it suitable for operations where ore characteristics may fluctuate over time.

In short, HPGRs not only improve energy efficiency but also set up the material for better performance in the entire mineral processing chain, adding value both in energy savings and increased recovery.

Particle Size and Liberation

Here’s how HPGR-produced fines improve downstream performance:

### 1. **Increased Mineral Liberation**

- The fine particles generated by HPGR promote effective mineral liberation by exposing more mineral surfaces, which makes it easier to separate valuable minerals from the gangue in downstream processes. This liberation happens at relatively coarse particle sizes, reducing the risk of overgrinding, which can lead to losses of valuable fines.

### 2. **Optimized Flotation Performance**

- In flotation processes, particle size and surface exposure are key factors for efficient separation. Finer particles with increased surface area, due to micro-cracks from HPGR, enhance the attachment of mineral particles to flotation reagents, boosting the efficiency of the flotation cells and leading to higher recovery rates.

### 3. **Enhanced Leaching Efficiency**

- HPGR-induced micro-cracks and fine particle distribution improve leaching efficiency by increasing solution access to the mineral surfaces. This enhanced permeability is especially beneficial for heap leaching, where the micro-cracked particles allow leach solutions to penetrate more easily and uniformly, accelerating the metal extraction process.

### 4. **Reduced Overgrinding**

- HPGR technology is also advantageous for minimizing overgrinding, a common issue in conventional milling. With overgrinding, particles become too fine, which can reduce recovery rates in flotation by making it difficult for particles to attach to air bubbles. By liberating minerals at coarser sizes, HPGR prevents excessive fines, leading to a balanced particle size distribution that optimizes recovery.

### 5. **Improved Downstream Circuit Performance**

- Since HPGR products have a narrower particle size distribution and a more uniform shape, they often require less energy in the subsequent milling stages. This consistent feed size to downstream circuits can stabilize operations, enhance throughput, and increase overall recovery efficiency.

Overall, HPGR-prepared material is primed for higher effectiveness in separation processes, ensuring that downstream flotation or leaching operations are more productive, ultimately leading to enhanced resource recovery and process efficiency.

Feed Preparation

Here’s a detailed look at key aspects of feed preparation for HPGR operations:

### 1. **Consistent Feed Size**

- **Importance of Uniform Feed Size**: HPGRs operate best when the feed material is within a specific size range. Large variations in feed size can result in uneven pressure distribution, which reduces grinding efficiency and accelerates wear on the rolls.

- **Pre-crushing Requirements**: Depending on the ore type and its natural fragmentation, pre-crushing with crushers (e.g., jaw crushers or cone crushers) might be necessary to bring the material within the optimal size range. Pre-crushing ensures that the HPGR only handles material it can process efficiently.

### 2. **Controlled Feed Moisture**

- **Impact of Moisture on Operation**: High moisture content in the feed can lead to material buildup on the rolls, clogging, and reduced throughput. If the material sticks, it can disrupt the smooth flow through the HPGR, leading to inefficiency and potential damage.

- **Moisture Level Management**: Ideally, feed material should have a low and consistent moisture level. In operations where ore has a naturally high moisture content, drying methods or dewatering processes may be required to bring the feed to acceptable levels.

### 3. **Pre-screening to Remove Undersized Material**

- **Why Pre-screening Matters**: Removing fines or undersized material (that is smaller than the intended product size) before feeding the HPGR reduces unnecessary loading on the rolls. It also minimizes overgrinding of fine particles, which can lower overall energy efficiency and unnecessarily wear down the HPGR.

- **Screening Techniques**: Depending on the ore type and the characteristics of the fines, pre-screening equipment (e.g., vibrating screens) can be installed to improve feed quality, conserve energy, and prevent operational issues in the HPGR.

### 4. **Blending for Ore Consistency**

- **Ore Variability**: Variability in ore hardness and composition can affect HPGR performance, leading to inconsistent breakage and separation efficiency. Blending feed from multiple stockpiles can help maintain a more consistent feed quality.

- **Stockpile Management**: Proper management of stockpiles allows blending to reduce variations in feed hardness and moisture, stabilizing HPGR throughput and efficiency.

### 5. **Size Distribution Control**

- **Optimizing the Particle Size Distribution**: In addition to size uniformity, controlling the feed's overall particle size distribution helps ensure efficient compression and breakage. Excessive large particles increase wear, while too many fines reduce the HPGR’s efficiency.

- **Adjusting Comminution Circuit**: Fine-tuning upstream comminution (e.g., crushers and screens) for better control of the particle size distribution can maximize HPGR efficiency and minimize energy costs.

Properly prepared feed material not only improves the efficiency of HPGRs but also contributes to smoother operation, lower wear rates, and reduced maintenance costs.

Wear and Maintenance

### 1. **Wear-Resistant Materials**

- **Tungsten Carbide Studs**: Tungsten carbide studs are widely used on HPGR rolls due to their extreme hardness and wear resistance. These studs are typically embedded on the surface of the rolls in a grid pattern, providing high resistance to abrasion and allowing for greater longevity under heavy loads and abrasive ore.

- **Hard Alloys and Composite Materials**: In addition to tungsten carbide, HPGR rolls are sometimes coated with other hard alloys and composite materials specifically designed for wear resistance. These materials help reduce surface erosion caused by the repeated high-pressure grinding of abrasive feed materials.

- **Segmented Rolls**: Many HPGRs are designed with segmented rolls, where the roll surface consists of replaceable segments. These segments can be individually replaced when worn out, reducing the need for full roll replacement and thus minimizing maintenance costs and downtime.

### 2. **Roll Surface Design and Customization**

- **Stud Design and Arrangement**: The arrangement and size of tungsten carbide studs or other surface features can be customized to match the abrasiveness and hardness of the ore being processed. Customization of the roll surface allows operators to tailor wear resistance to the specific demands of their operation.

- **Grooved or Smooth Roll Profiles**: Different roll profiles, such as grooved or smooth surfaces, can be used based on the desired product size and type of ore being processed. Grooved surfaces can enhance grip on larger particles, whereas smooth rolls are better for fine grinding applications.

### 3. **Regular Inspections and Condition Monitoring**

- **Scheduled Inspections**: HPGR rolls undergo significant wear, so regular inspections are necessary to assess wear rates and plan replacements before severe degradation occurs. Visual inspections, along with measurements of wear patterns, help operators monitor surface condition and detect signs of uneven wear.

- **Wear Sensors and Monitoring Systems**: Some modern HPGR units come equipped with wear sensors or monitoring systems that provide real-time data on roll condition. These systems can alert operators to impending maintenance needs and prevent unexpected shutdowns.

### 4. **Maintenance and Replacement**

- **Segment Replacement**: In systems with segmented rolls, only the worn segments need to be replaced, making maintenance more efficient and cost-effective. This design reduces the need for complete roll disassembly and helps minimize downtime.

- **Roll Rebuilding**: When rolls are significantly worn, they can be rebuilt by replacing the surface material or reapplying tungsten carbide studs. This process can extend the life of the rolls without the expense of full replacement.

### 5. **Operational Adjustments to Reduce Wear**

- **Pressure and Speed Optimization**: Adjusting operating parameters such as roll pressure and speed based on ore hardness and abrasiveness can reduce unnecessary wear. Running the HPGR at optimal settings for the specific feed material reduces the frequency and severity of maintenance events.

- **Proper Feed Preparation**: Ensuring consistent feed size and removing undersized particles through pre-screening can also reduce wear. Fine particles cause less wear on the rolls, so maintaining a balanced particle size distribution optimizes roll longevity.

Effective wear management with robust materials, roll customization, and preventive maintenance can greatly reduce downtime, extend the service life of HPGR rolls, and contribute to overall operational efficiency and cost savings.

Operating Pressure

### 1. **Impact on Breakage Mechanism**

- **Particle Deformation**: Higher pressures enhance particle deformation, promoting interparticle breakage and the formation of micro-cracks. This breakage mechanism is more efficient than impact grinding and achieves better mineral liberation, which is especially valuable for downstream recovery processes like flotation and leaching.

- **Micro-Crack Formation**: Higher pressures lead to greater micro-crack density within particles, weakening the ore and increasing permeability. This effect not only enhances liberation but also prepares material for more efficient processing in subsequent stages, such as heap leaching.

### 2. **Energy Consumption**

- **Efficiency Gains at Optimal Pressure**: Operating at the correct pressure optimizes the energy-to-breakage ratio, maximizing throughput per unit of energy. Lower pressures may reduce wear but can lead to insufficient breakage, requiring more energy downstream to achieve the same liberation.

- **Diminishing Returns of Excessive Pressure**: While increasing pressure generally improves breakage up to a point, excessive pressure can result in diminishing returns, where energy consumption rises disproportionately relative to improvements in particle breakage. Beyond the optimal pressure range, energy efficiency can decrease, leading to higher operating costs without significant gains in throughput or liberation.

### 3. **Effect on Wear and Maintenance**

- **Increased Wear with Higher Pressure**: Higher pressures not only compress and break particles more effectively but also place greater stress on the roll surfaces, accelerating wear. This leads to more frequent maintenance and higher replacement costs, especially if the ore is abrasive.

- **Balancing Wear and Breakage**: By finding a balance between sufficient pressure for effective breakage and manageable wear levels, operators can extend roll life and reduce downtime. Implementing wear-resistant materials (like tungsten carbide studs) and segmented roll designs can help mitigate wear at higher pressures, but even with these solutions, extreme pressure still accelerates wear.

### 4. **Optimizing Pressure for Throughput and Cost Control**

- **Testing and Calibration**: Each ore type has unique characteristics, so testing and calibration are essential to determine the optimal pressure settings for a particular operation. This involves adjusting pressure based on particle size, ore hardness, and abrasiveness until the desired balance between throughput and wear is achieved.

- **Real-Time Pressure Adjustments**: Some advanced HPGR units are equipped with control systems that monitor ore characteristics in real-time and adjust pressure dynamically. By fine-tuning pressure in response to changing feed conditions, these systems maintain an optimal balance between throughput and wear while minimizing energy costs.

### 5. **Considering Ore Variability**

- **Adaptable Pressure Settings for Ore Variability**: In mines where ore hardness and composition vary, it can be advantageous to adapt pressure settings based on real-time monitoring. This helps maintain consistent efficiency without overburdening the HPGR rolls on particularly hard or abrasive ore days, which would otherwise lead to accelerated wear and higher energy costs.

- **Blending to Stabilize Feed Hardness**:

In cases of frequent variability, blending ores with different hardness levels before feeding the HPGR can help maintain a more consistent pressure requirement, reducing the need for frequent adjustments and minimizing pressure-related wear.

In short, achieving the optimal operating pressure for HPGRs requires a careful balance between maximizing throughput, maintaining efficient energy use, and controlling wear rates. This balance depends on the specific ore characteristics and operating conditions, and dynamic monitoring and adjustments can help operators maintain efficient, cost-effective HPGR performance.

Roll Surface Design

### 1. **Studded Roll Surfaces**

- **Higher Grinding Efficiency**: Studded rolls are often chosen for their ability to enhance grinding efficiency. The studs (typically made from tungsten carbide or other hard materials) create points of increased pressure on the feed material, promoting intense interparticle breakage and the formation of micro-cracks.

- **Improved Material Grip**: The studs grip the particles more effectively than smooth surfaces, reducing slippage and enabling better throughput. This is particularly beneficial for larger, harder feed materials, as the studs can "bite" into the particles, enhancing their breakage.

- **Best for Abrasive Material with Controlled Maintenance**: Although studded surfaces are highly effective, they wear down more quickly when processing highly abrasive ores. Careful monitoring and regular maintenance are essential to replace worn studs and maintain optimal performance.

### 2. **Smooth Roll Surfaces**

- **Lower Wear for Less Abrasive Material**: Smooth roll surfaces are often used with less abrasive materials, where wear rates are lower. While smooth surfaces provide less grip than studded rolls, they have the advantage of requiring less frequent maintenance, making them cost-effective in operations with softer ore.

- **Suitable for Fine Grinding**: Smooth rolls are generally more effective for fine grinding applications, where the feed is already within a smaller size range. In such cases, excessive grip is not necessary, and smooth surfaces provide consistent pressure across the particle bed.

- **Balanced Pressure Distribution**: Smooth surfaces distribute pressure more evenly across the material bed, resulting in a more uniform particle size distribution. This can be beneficial in downstream processing stages where consistent particle size is advantageous.

### 3. **Profiled Roll Surfaces**

- **Customization for Specific Ore Characteristics**: Profiled rolls, featuring grooves or other patterns, offer a middle ground between smooth and studded rolls. The profiles can be designed to match the ore characteristics, providing customized breakage that enhances grinding efficiency without excessive wear.

- **Enhanced Throughput and Stability**: Profiles improve material stability on the roll surface, reducing the risk of material slippage and increasing throughput. The grooves or patterns help align particles for more efficient breakage, which can be especially useful for ore types with mixed particle sizes or high variability.

- **Wear Distribution and Maintenance**: Profiled rolls are designed to optimize wear distribution across the roll surface. While they can still experience significant wear, the customized pattern helps balance pressure points, often extending the time between maintenance cycles compared to studded rolls.

### 4. **Selecting the Right Roll Surface for Ore Abrasiveness**

- **Matching Surface Design with Ore Type**: For highly abrasive ore, studded rolls with tungsten carbide studs are typically the best choice due to their durability and ability to withstand heavy wear. For medium-hard or softer ores, smooth or profiled rolls can provide efficient grinding without the high maintenance demands of studded rolls.

- **Hybrid Surface Approaches**: Some operations employ hybrid roll designs that combine elements of smooth and studded or profiled surfaces to tailor the grinding characteristics to specific ore types. This flexibility can help balance efficiency with durability, reducing the need for frequent adjustments or roll replacements.

### 5. **Operational Implications**

- **Cost-Benefit Analysis**: Each roll surface type has cost implications, both in terms of maintenance frequency and overall operational efficiency. Choosing the right surface type is a trade-off between maximizing throughput and minimizing downtime and wear-related costs.

- **Testing and Adjustment**: Before full-scale implementation, it is often beneficial to conduct test runs with different surface designs to find the optimal balance for the specific ore characteristics, including abrasiveness, hardness, and particle size distribution.

In summary, selecting the appropriate HPGR roll surface design is crucial for achieving efficient grinding and balancing wear rates. Each surface type offers distinct benefits, and careful matching of roll design to ore characteristics can lead to improved throughput, lower wear, and more consistent product size, ultimately supporting higher efficiency and lower operating costs.

Circulating Load and Closed-Circuit Operation

Here’s how closed circuits enhance HPGR grinding and downstream recovery processes:

### 1. **Stable Particle Size Distribution**

- **Consistent Product Size**: In a closed circuit, screens or classifiers separate the material into the desired size fraction and recycle oversized particles back to the HPGR. This keeps the product size consistent, ensuring that the HPGR operates within its optimal parameters and delivers a uniform particle size to downstream processes.

- **Enhanced Liberation**: By maintaining a stable particle size distribution, closed circuits can enhance mineral liberation at the desired size range, increasing the efficiency of subsequent separation processes like flotation and leaching.

### 2. **Control of Circulating Load**

- **Managing Oversized Particles**: In open circuits, oversized particles can accumulate and reduce grinding efficiency. By recycling larger particles in a closed circuit, the HPGR operates more efficiently, focusing energy on particles that need further size reduction while achieving a balanced feed rate.

- **Optimizing Throughput**: Managing circulating loads helps to control the feed material presented to the HPGR, allowing for optimal throughput and preventing overloading. A well-managed circulating load minimizes energy wastage on already sufficiently sized particles, enhancing energy efficiency and throughput.

### 3. **Reduced Overgrinding and Fines Generation**

- **Targeted Grinding**: Closed-circuit operation prevents excessive production of fines by ensuring that only particles requiring further grinding are sent back to the HPGR. This helps maintain a balanced product size distribution, minimizing overgrinding, which can be detrimental in some downstream processes.

- **Improved Particle Shape**: By controlling the grinding environment and avoiding unnecessary crushing, closed circuits can produce particles with more favorable shapes, which are often more suitable for downstream processes like flotation.

### 4. **Enhanced Recovery in Downstream Processes**

- **Optimized Feed for Separation**: By delivering a consistent, controlled particle size distribution to downstream processes, closed-circuit HPGR operations enhance recovery rates in flotation, leaching, or other beneficiation methods. A well-defined size range improves reagent interaction in flotation and enhances solution permeability in leaching processes.

- **Reduced Processing Costs**: Stable particle size distribution reduces the energy and reagent costs of downstream processing, as the circuits are optimized to work with the size range that has the best recovery potential.

### 5. **Energy Efficiency and Process Stability**

- **Efficient Use of Energy**: Recycling oversized particles back to the HPGR for further reduction ensures that energy is not wasted on particles already within the desired size range. This energy efficiency leads to lower operating costs and improved environmental sustainability.

- **Stable HPGR Operation**: Closed circuits provide feedback control, keeping the HPGR load and pressure at stable levels. This minimizes fluctuations in feed rate and pressure, reducing wear on equipment and increasing the lifespan of HPGR components.

### 6. **Screening or Classification Equipment in Closed Circuits**

- **Screening Systems**: Vibrating screens or trommel screens are often used to classify the HPGR product by separating undersized particles from larger ones. Screens offer a straightforward method to manage particle size distribution and control circulating loads.

- **Classification Cyclones**: Hydrocyclones or air classifiers are sometimes employed in cases where finer size separation is needed. Cyclones can separate finer particles with precision, making them ideal for operations that require a tighter particle size range.

### 7. **Process Optimization and Monitoring**

- **Real-Time Monitoring**: Implementing sensors and control systems in a closed circuit allows for real-time adjustments to the HPGR pressure, speed, and screen or cyclone performance. This helps maintain optimal operating conditions and minimizes downtime.

- **Automated Control Systems**: Advanced control systems can adjust HPGR and screening parameters based on the circulating load and particle size distribution, enhancing efficiency and product quality.

In summary, closed-circuit HPGR operations with screening or classification equipment improve the consistency of the particle size distribution, reduce overgrinding, control circulating loads, and ensure optimal grinding efficiency. These benefits lead to higher recovery rates in downstream processes, lower energy consumption, and enhanced overall operational efficiency.

Integration with Downstream Processes

Here’s a deeper look at why HPGR pre-treatment is advantageous for heap leaching and other separation processes, especially when dealing with low-grade ores:

### 1. **Micro-Cracks and Enhanced Permeability**

- **Formation of Micro-Cracks**: HPGRs generate micro-cracks in the ore by compressing particles under high pressure, which creates fractures within individual particles rather than just on the surface. These micro-cracks improve ore permeability by forming pathways through which leaching solutions can penetrate, reaching mineral surfaces more effectively.

- **Higher Solution Flow in Heap Leaching**: Increased permeability allows the leaching solution to flow more uniformly and rapidly through the heap, reducing channeling (where the solution bypasses parts of the heap). This enhances contact between the leaching agents and the ore, resulting in improved recovery rates.

### 2. **Higher Recovery Rates for Low-Grade Ores**

- **Improved Extraction in Challenging Ore Types**: HPGR pre-treatment is especially advantageous for low-grade ores that would otherwise yield lower recoveries in traditional heap leaching setups. The micro-cracks expose more mineral surfaces, allowing the leaching solution to dissolve valuable minerals from these surfaces, increasing recovery.

- **Cost-Efficiency in Low-Grade Processing**: With low-grade ores, the economic viability of recovery can be challenging due to lower metal content. HPGR-induced micro-cracks improve recovery without adding extensive crushing or milling costs, making it a cost-effective solution for low-grade ore deposits.

### 3. **Enhanced Kinetics of Leaching**

- **Faster Leaching Rates**: The micro-cracks created by HPGR reduce the diffusion path length for the leaching solution, accelerating the leaching kinetics. This means that valuable metals are extracted more quickly, reducing overall leaching time and making the process more efficient.

- **Reduced Reagent Consumption**: Faster and more effective mineral dissolution reduces the need for prolonged reagent exposure, leading to lower reagent consumption per unit of recovered metal. This can also reduce the environmental footprint and operational costs associated with chemical use in heap leaching.

### 4. **Selective Liberation of Valuable Minerals**

- **Minimizing Waste Material Processing**: HPGR creates fractures in valuable mineral grains, which enhances selective liberation while preserving gangue material. This selectivity improves the quality of the heap leach feed, minimizing the processing of waste material and concentrating the exposure of valuable minerals to the leaching solution.

- **Higher Quality Product in Downstream Processes**: In other separation processes, such as flotation or gravity separation, the selective liberation from HPGR pre-treatment improves feed quality, leading to better separation performance and potentially higher-grade final products.

### 5. **Reduced Energy Demand for Downstream Processing**

- **Lower Milling Energy Requirements**: In cases where further grinding is needed after heap leaching, the micro-cracks created by HPGR significantly reduce the energy required in subsequent milling stages. The pre-fractured particles break more easily, lowering energy consumption and extending equipment life in mills.

- **Improved Overall Process Efficiency**: By reducing energy demands in both the leaching process (through faster extraction) and potential milling stages, HPGR contributes to an energy-efficient flow sheet, which is particularly valuable in operations focused on sustainability and cost-effectiveness.

### 6. **Reduced Fines and Improved Heap Stability**

- **Favorable Particle Size Distribution**: HPGR generally produces fewer fines compared to traditional crushers, which is beneficial for heap leaching as excessive fines can impede solution flow and create compaction issues. The relatively coarser and more permeable material from HPGR allows for better heap stability and reduces issues associated with fines blocking leach solution pathways.

- **Controlled Heap Leach Conditions**: With improved permeability and stable heap structure, operators can control leach conditions more effectively, leading to consistent and predictable metal recovery over time.

### 7. **Compatibility with Other Pre-Treatment Techniques**

- **Synergistic Effects with Other Technologies**: HPGRs can be integrated with other pre-treatment methods, like bioleaching or pre-oxidation, where micro-cracks facilitate solution access, accelerating chemical reactions on mineral surfaces. This makes HPGR a flexible and compatible solution that can enhance various leaching approaches for different ore types.

In summary, HPGR pre-treatment offers substantial advantages for heap leaching, particularly for low-grade ores, by creating micro-cracks that enhance permeability, improve leach kinetics, and increase recovery rates. Its ability to improve process efficiency while lowering energy and reagent consumption makes HPGR an ideal choice for sustainable, cost-effective mineral recovery in heap leaching and other separation processes.

Moisture Control

### 1. **Challenges of High Moisture Content in HPGR Feed**

- **Material Buildup on Roll Surfaces**: When feed material has excessive moisture, it tends to clump together, causing buildup on the roll surfaces. This buildup reduces the effective contact area, compromising the interparticle breakage mechanism and lowering grinding efficiency.

- **Increased Blockage Risk**: High-moisture materials are more prone to sticking and clogging, especially in tight spaces within the HPGR unit. This can lead to blockages in the feed chute and between the rolls, causing interruptions that require shutdowns for cleaning and maintenance.

- **Reduced Throughput and Efficiency**: Moisture can significantly reduce throughput by increasing friction and slowing the movement of material through the HPGR. This reduces the machine's capacity to handle material and may lead to inconsistent product sizing, which negatively impacts downstream processing.

### 2. **Impact on Particle Compression and Breakage**

- **Inefficient Pressure Distribution**: High-moisture material does not compress as effectively as drier material, leading to uneven pressure distribution across the particle bed. This can reduce the efficiency of particle breakage, as moisture absorbs some of the energy that would otherwise be used to induce micro-cracks in the ore.

- **Lower Liberation Potential**: Because high moisture can lead to incomplete or uneven particle breakage, it may limit mineral liberation, reducing the effectiveness of subsequent separation processes like flotation or leaching.

### 3. **Strategies for Controlling Moisture Levels**

- **Pre-Dewatering of Feed Material**: In cases where ore moisture content is naturally high, dewatering techniques such as screening, drainage, or even low-intensity drying can be applied before feeding material into the HPGR. This reduces the risk of material buildup and helps maintain efficient roll performance.

- **Consistent Moisture Monitoring**: Regular monitoring of moisture levels is essential, particularly if feed sources vary or weather conditions affect moisture content. Inline moisture sensors or sampling before feeding can help operators detect moisture variations and make necessary adjustments.

- **Feed Homogenization and Blending**: Blending higher-moisture feed material with drier material can help achieve a more consistent moisture level across the feed. Homogenization reduces the risk of wet clumps in the feed, supporting uniform material flow through the HPGR.

### 4. **Optimizing Moisture for Efficient Compression and Throughput**

- **Ideal Moisture Range**: While some moisture can be beneficial for HPGR performance by binding particles and reducing dust, too much moisture is counterproductive. Maintaining a balanced moisture level—often below 5–7%, though this depends on ore type—ensures optimal compression, breakage, and throughput.

- **Trial and Adjustment**: The ideal moisture level varies depending on ore properties, so it may require testing and adjustments. Conducting test runs with varied moisture levels can help operators determine the optimal range for a specific feed material and HPGR setup.

### 5. **Mitigating Moisture-Related Wear and Maintenance**

- **Preventing Abrasive Paste Formation**: When combined with fine particles, moisture can create an abrasive paste that accelerates wear on roll surfaces. Maintaining controlled moisture levels prevents the formation of this paste, extending the lifespan of roll surfaces and reducing maintenance frequency.

- **Reducing Downtime for Cleaning**: By controlling feed moisture, operators can reduce the need for frequent shutdowns to clean the rolls, chutes, and other areas affected by buildup. This increases operational uptime and improves the overall efficiency of the HPGR.

### 6. **Impact on Downstream Processing Efficiency**

- **Consistent Particle Size Distribution**: Controlled moisture levels contribute to more uniform particle breakage, leading to a consistent size distribution that improves downstream processing. This is particularly important in heap leaching and flotation, where particle size and permeability significantly influence recovery rates.

- **Enhanced Feed Stability**: By preventing high-moisture clumps, HPGRs produce a stable and predictable product feed, which can simplify adjustments in downstream equipment and reduce fluctuations in recovery rates.

In conclusion, managing feed moisture is crucial for maximizing HPGR performance and minimizing operational interruptions. By ensuring a controlled, consistent moisture level, operators can maintain smooth material flow, optimize energy use, and reduce wear on HPGR components, leading to increased throughput and enhanced overall efficiency.