Introduction

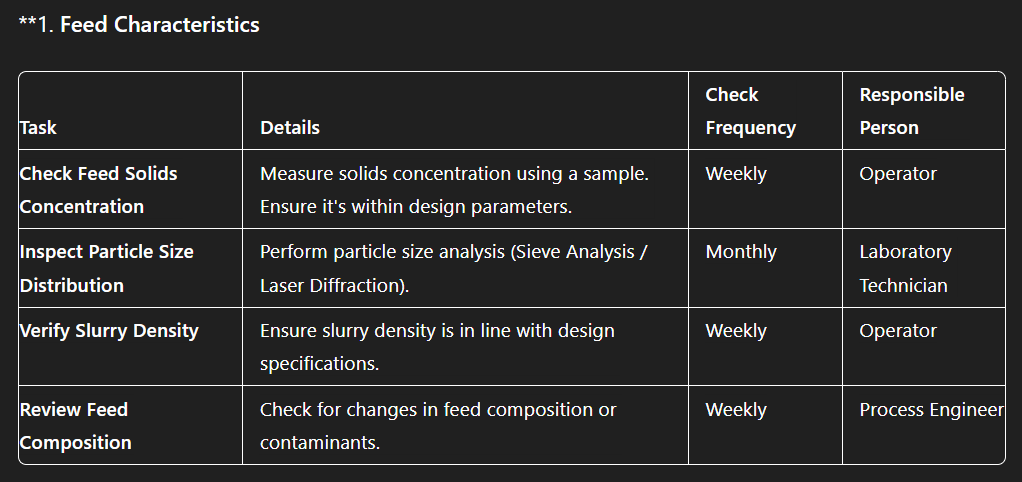

### 1. **Feed Characteristics**

- **Solids concentration**: High solids concentration can affect settling.

- **Particle size distribution**: Fine particles settle slower, leading to poor clarity.

- **Slurry density**: Check if the slurry density is within the design parameters.

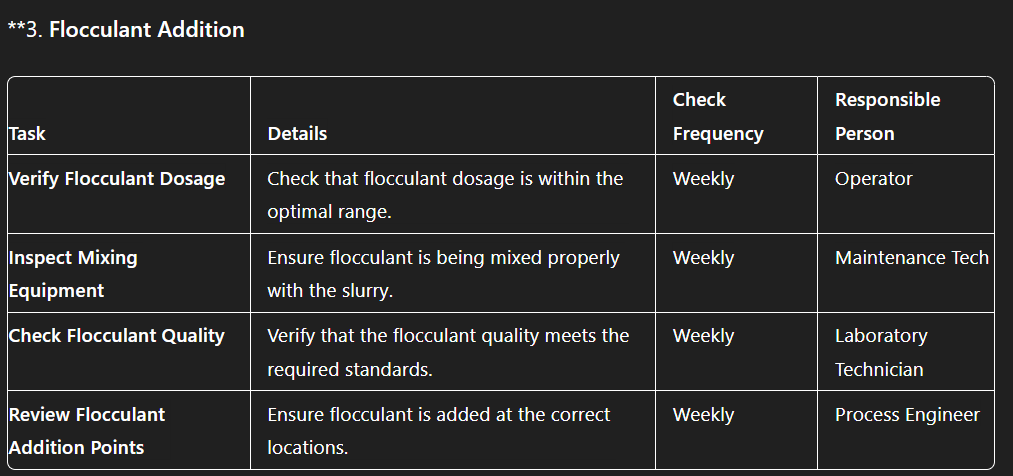

### 2. **Flocculant Addition**

- **Dosage**: Ensure the flocculant dosage is optimal. Too much or too little can both cause issues.

- **Mixing**: Proper mixing of the flocculant with the slurry is crucial for effective flocculation.

- **Quality**: Check the quality and type of flocculant being used.

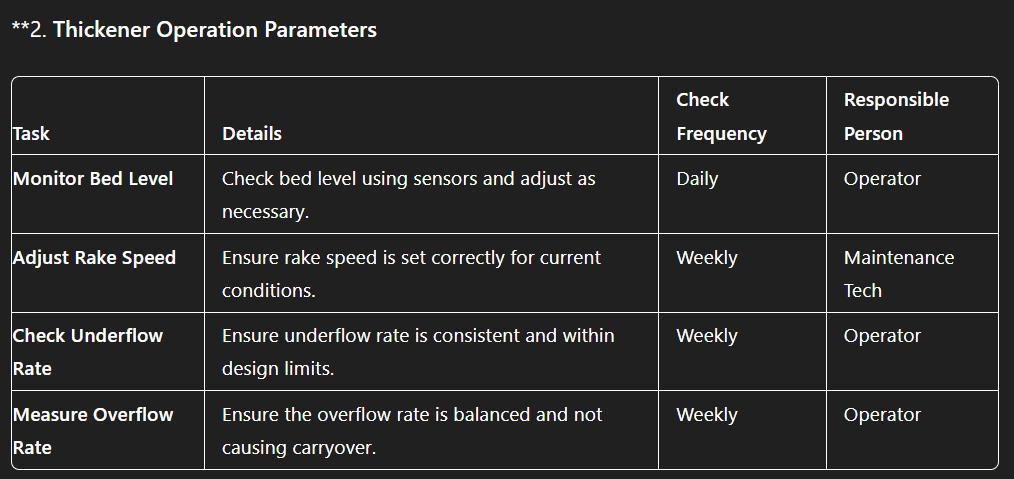

### 3. **Thickener Operation**

- **Underflow density**: Ensure the underflow density is being maintained properly.

- **Bed level**: Monitor the bed level and ensure it is within the desired range.

- **Rake speed**: Adjust the rake speed to ensure proper movement of settled solids.

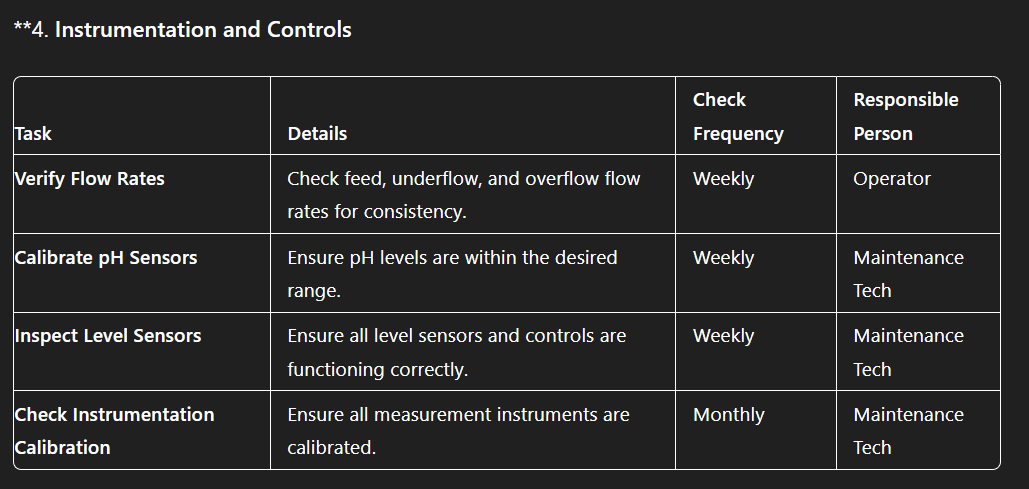

### 4. **Instrumentation and Controls**

- **Flow rates**: Check the feed, underflow, and overflow flow rates for consistency.

- **pH control**: Maintain the pH within the desired range as it can affect flocculation.

- **Level sensors**: Ensure all sensors and controls are calibrated and functioning correctly.

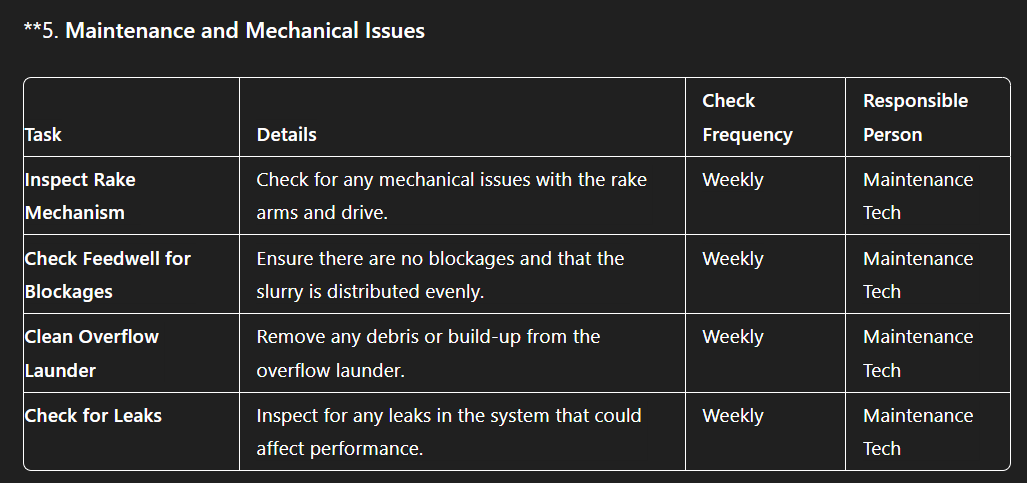

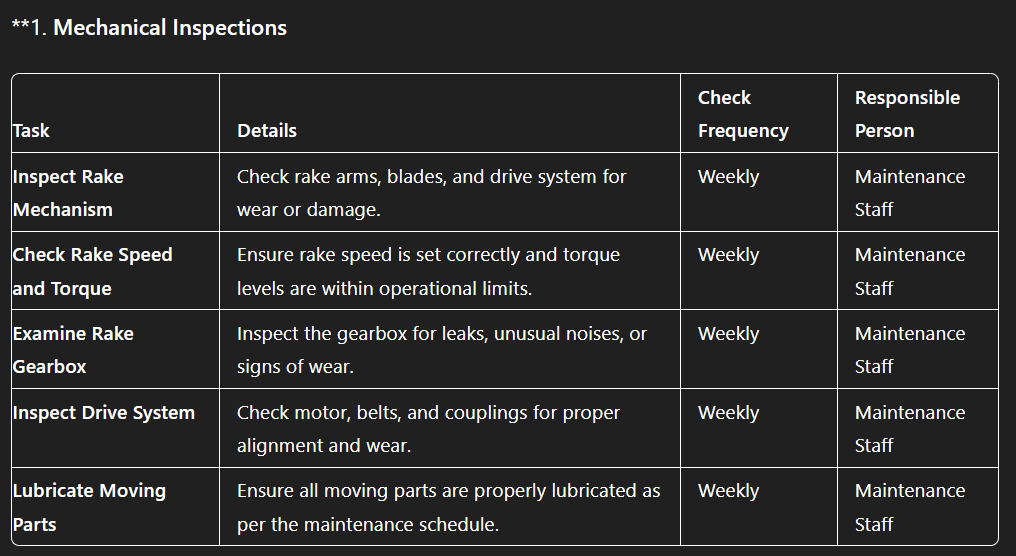

### 5. **Maintenance and Mechanical Issues**

- **Rake mechanism**: Inspect for any mechanical issues with the rake arms and drive.

- **Feed well**: Ensure the feed well is not blocked and is distributing slurry evenly.

- **Overflow launder**: Clean any debris or build-up in the overflow launder.

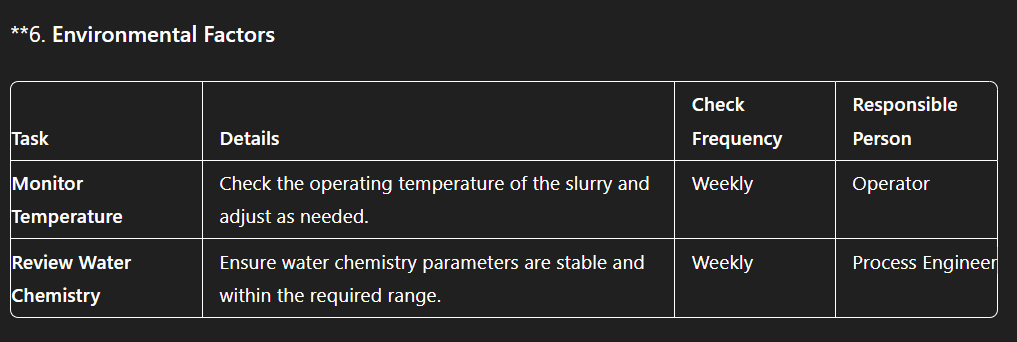

### 6. **Environmental Factors**

- **Temperature**: Flocculation can be temperature-dependent, so consider any changes in operating temperature.

- **Water chemistry**: Changes in water chemistry can affect flocculation and settling.

### Step-by-Step Troubleshooting Guide

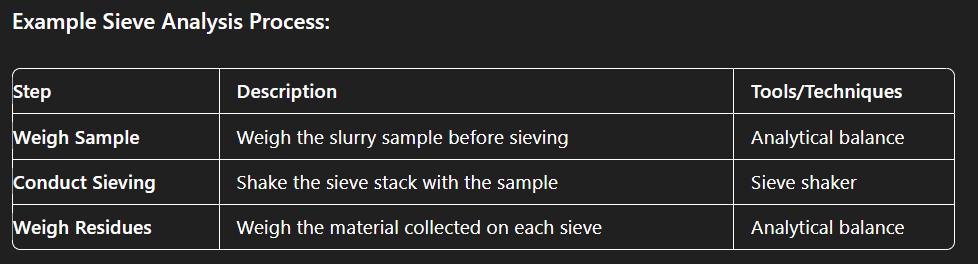

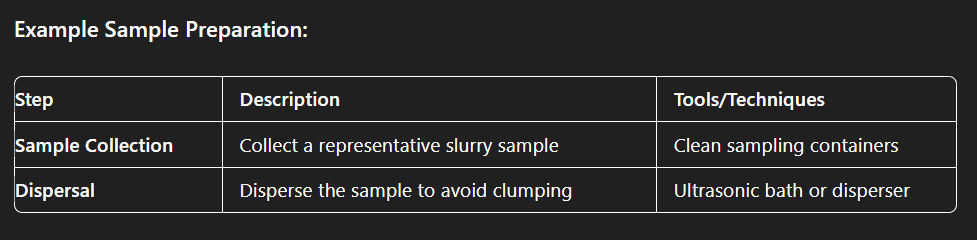

1. **Inspect the Feed**: Analyze the feed slurry for particle size distribution, density, and any changes in composition.

2. **Check Flocculant System**: Verify the flocculant type, dosage, and mixing efficiency.

3. **Monitor Thickener Parameters**: Check bed level, rake speed, and underflow density.

4. **Examine Overflow**: Inspect the overflow for signs of fine particles or changes in clarity.

5. **Review Instrumentation**: Ensure all sensors and controls are working correctly and providing accurate readings.

6. **Conduct Maintenance Checks**: Inspect mechanical components and clean any clogged or dirty parts.

7. **Adjust Operational Settings**: Fine-tune operational settings based on observations and data collected.

### Summary

Addressing thickener issues requires a systematic approach, considering both operational and mechanical factors. Regular monitoring, proper maintenance, and timely adjustments can help maintain optimal performance and ensure clear overflow.

Feed Characteristics Affecting Thickener Performance

### Feed Characteristics Affecting Thickener Performance

When troubleshooting thickener overflow clarity issues, understanding the feed characteristics is crucial.

Here are the key aspects of feed characteristics and their impact on thickener performance:

#### 1. Solids Concentration

- **Impact on Settling**: High solids concentration can lead to hindered settling, where particles interfere with each other’s settling paths, causing slower overall settling rates and potentially leading to poor overflow clarity.

- **Optimal Range**: Ensure that the solids concentration is within the design specifications of the thickener. Deviations from the optimal range can adversely affect the settling process.

- **Adjustment Strategies**: Dilute the feed slurry if the solids concentration is too high, or optimize flocculant dosing to handle higher solids load effectively.

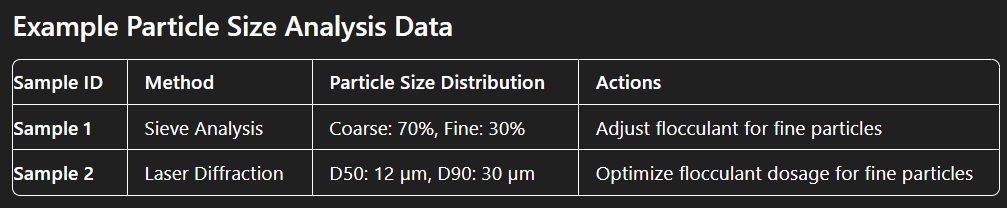

#### 2. Particle Size Distribution

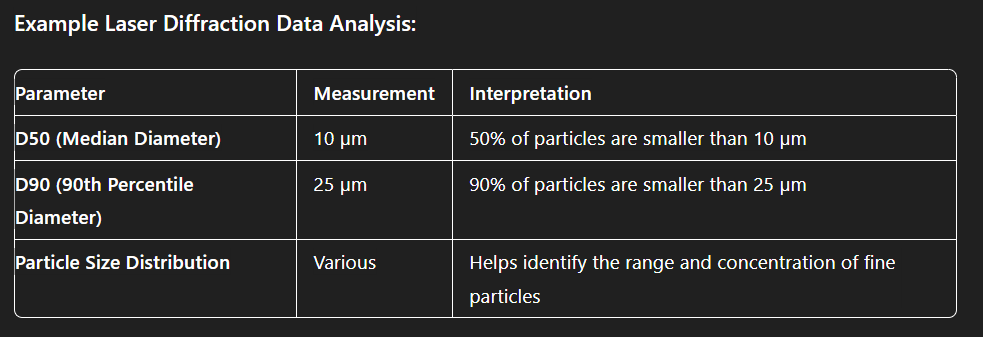

- **Fine Particles**: Fine particles (typically below 10 microns) settle much slower than coarser particles. They are more likely to be carried over with the overflow, reducing clarity.

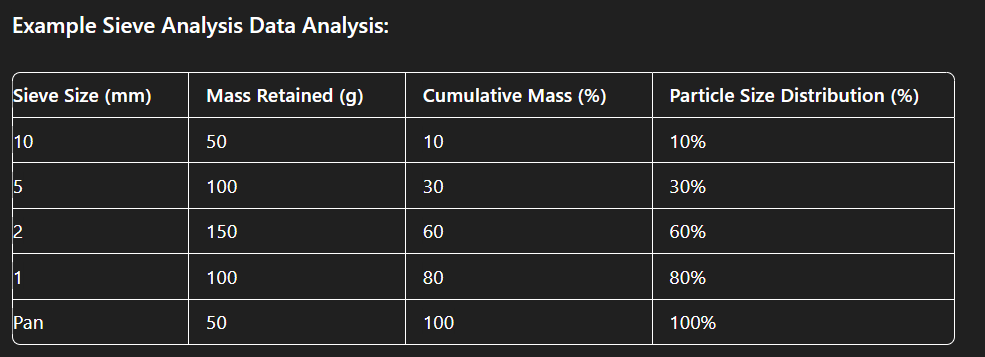

- **Distribution Analysis**: Conduct a particle size analysis to determine the distribution of particle sizes in the feed slurry. A significant proportion of fine particles might require adjustments in flocculant type or dosage.

- **Enhancing Settling**: Use coarser particles to enhance the settling process (seeding) or employ specialized flocculants designed for fine particles.

#### 3. Slurry Density

- **Design Parameters**: Ensure the slurry density is within the design parameters of the thickener. Density variations can impact the effectiveness of the settling process and the performance of the flocculant.

- **Density Control**: Monitor and adjust the slurry density to ensure it remains within the optimal range. This may involve adjustments in feed rate or dilution.

### Testing and Monitoring

1. **Solids Concentration Measurement**: Regularly measure the solids concentration of the feed slurry using techniques such as gravimetric analysis or online density meters.

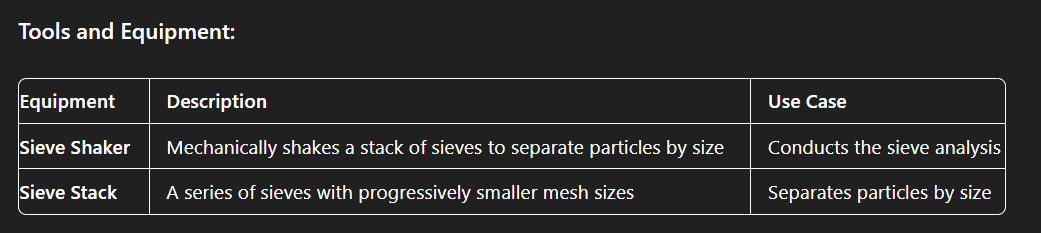

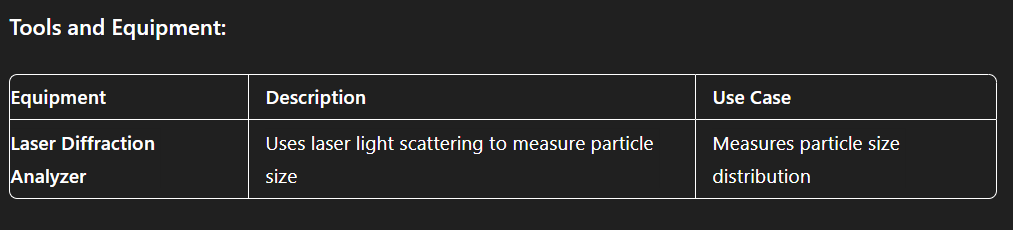

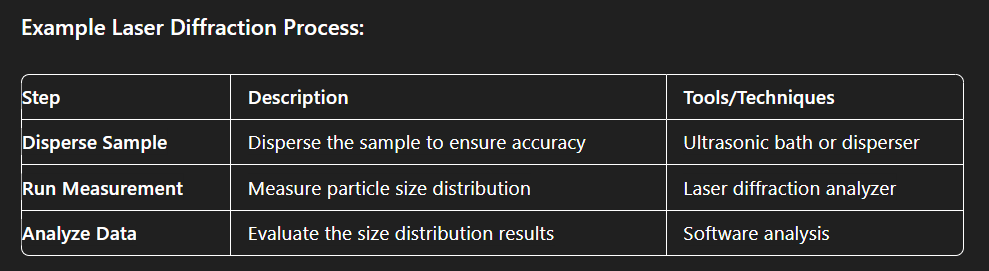

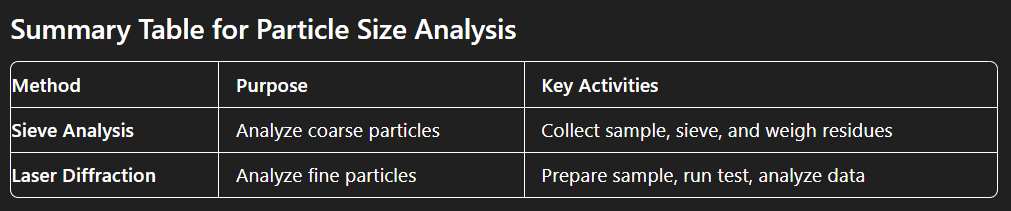

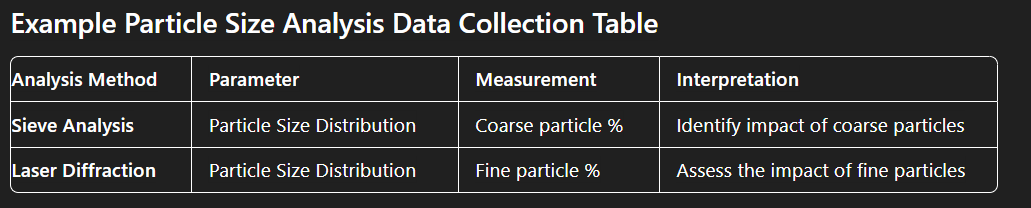

2. **Particle Size Analysis**: Use laser diffraction or sieve analysis to determine the particle size distribution of the slurry. This helps in understanding the proportion of fine particles and their impact on settling.

3. **Slurry Density Measurement**: Measure slurry density using a hydrometer, density meter, or other appropriate methods to ensure it remains within the design range.

### Operational Adjustments

1. **Feed Dilution**: Dilute the feed slurry if the solids concentration is too high. This can be done using process water or recycled water from the overflow.

2. **Flocculant Optimization**: Adjust the type and dosage of flocculant based on the particle size distribution and solids concentration. Fine-tune the mixing conditions to ensure effective floc formation.

3. **Flow Rate Control**: Maintain consistent feed flow rates to avoid sudden changes in solids concentration and density, which can disrupt the settling process.

### Practical Example

Consider a thickener designed for a feed slurry with 20% solids concentration and a specific particle size distribution. If the actual feed slurry has 30% solids concentration with a higher proportion of fine particles, you might observe poor overflow clarity. To address this:

- **Dilution**: Dilute the feed to bring the solids concentration closer to 20%.

- **Flocculant Adjustment**: Increase the dosage or change the type of flocculant to enhance flocculation of fine particles.

- **Regular Monitoring**: Continuously monitor the feed characteristics and adjust operational parameters accordingly.

### Summary

Understanding and controlling feed characteristics such as solids concentration, particle size distribution, and slurry density are crucial for maintaining thickener performance and achieving clear overflow. Regular measurement and analysis of these parameters, combined with appropriate operational adjustments, can significantly improve the efficiency of the thickening process.

Key Aspects of Thickener Operation Affecting Overflow Clarity

### Key Aspects of Thickener Operation Affecting Overflow Clarity

Effective thickener operation is crucial for maintaining overflow clarity. Here are the key operational aspects to focus on:

#### 1. Underflow Density

- **Importance**: Proper underflow density ensures that the thickener is effectively concentrating the solids and removing them from the system. Inconsistent or low underflow density can indicate issues with the thickening process.

- **Monitoring**: Regularly measure the underflow density using a densitometer or other appropriate methods to ensure it meets the target specifications.

- **Adjustments**: If the underflow density is too low, increase the underflow pump speed or adjust the flocculant dosage to enhance solids settling. If it's too high, consider reducing the pump speed or increasing dilution.

#### 2. Bed Level

- **Importance**: The bed level indicates the amount of settled solids in the thickener. Maintaining an optimal bed level is crucial for effective thickening and preventing solids from being carried over in the overflow.

- **Monitoring**: Use bed level sensors or manual measurements to monitor the bed level regularly. The optimal bed level varies depending on the thickener design and operating conditions but should generally be within a specified range.

- **Adjustments**: If the bed level is too high, it may indicate overloading or inadequate underflow removal, necessitating an increase in underflow pump speed. If the bed level is too low, it may indicate underloading or excessive underflow removal, requiring a reduction in pump speed or an increase in feed rate.

#### 3. Rake Speed

- **Importance**: The rake mechanism helps move settled solids towards the underflow outlet. Proper rake speed is essential to prevent solids from accumulating excessively and to ensure a consistent flow of thickened slurry.

-

**Monitoring**: Regularly check the rake speed settings and observe the movement of settled solids. Ensure that the rake arms are functioning properly and are not obstructed.

- **Adjustments**: Adjust the rake speed based on the observed settling rate and bed level. If the rake speed is too slow, solids may build up and cause compaction issues. If it's too fast, it may disturb the settled bed and reduce clarity.

### Practical Steps for Operational Adjustments

1. **Underflow Density Management**

- **Measurement**: Use inline density meters or manual sampling to measure the underflow density.

- **Adjustment**: Increase or decrease the underflow pump speed based on density measurements. Ensure the flocculant dosage is optimized to achieve desired underflow density.

- **Continuous Monitoring**: Implement continuous monitoring systems for real-time adjustments.

2. **Bed Level Control**

- **Sensors**: Install bed level sensors for continuous monitoring. Alternatively, conduct manual measurements using dip sticks or similar tools.

- **Target Range**: Maintain the bed level within the design specifications. Adjust the underflow pump speed or feed rate to achieve the desired bed level.

- **Alarms**: Set up alarms for bed levels outside the optimal range to prompt immediate corrective actions.

3. **Rake Speed Optimization**

- **Regular Checks**: Regularly inspect the rake mechanism for proper operation and obstructions.

- **Speed Adjustment**: Fine-tune the rake speed based on settling observations and bed level. Use variable speed drives for easy adjustments.

- **Maintenance**: Ensure regular maintenance of the rake mechanism to prevent mechanical failures that could affect speed and movement.

### Example Scenario

**Scenario**: A thickener is experiencing poor overflow clarity. The underflow density is lower than expected, and the bed level is fluctuating significantly.

**Action Plan**:

1. **Underflow Density**:

- Measure the current underflow density.

- Increase the underflow pump speed incrementally and observe the impact on density.

- Adjust the flocculant dosage if necessary to improve settling.

2. **Bed Level**:

- Install a bed level sensor if not already present.

- Monitor the bed level continuously and set the target range.

- Adjust the underflow pump speed based on bed level readings to stabilize it within the target range.

3. **Rake Speed**:

- Inspect the rake mechanism for proper operation.

- Adjust the rake speed to ensure it is neither too slow (causing build-up) nor too fast (disturbing the settled bed).

- Perform regular maintenance checks to keep the rake mechanism in optimal condition.

By focusing on these operational aspects, you can significantly improve thickener performance and ensure better overflow clarity.

Regular monitoring and timely adjustments based on real-time data are key to maintaining optimal thickener operation.

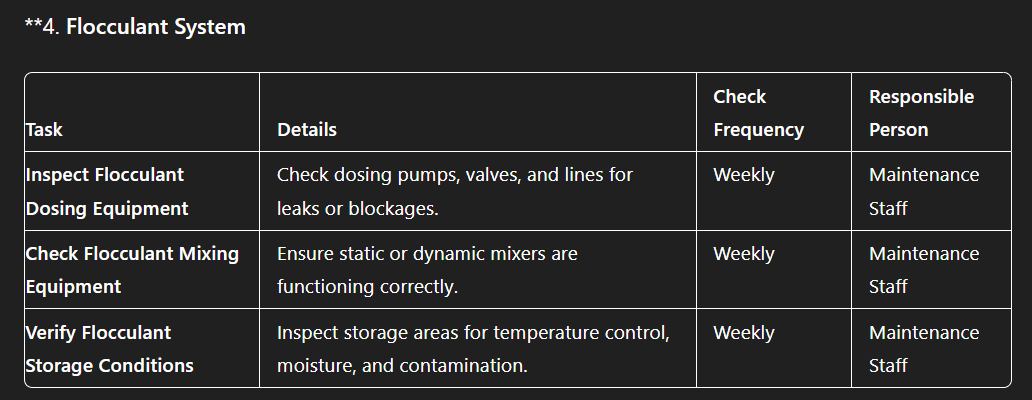

Key Aspects of Flocculant Addition Affecting Thickener Performance

### Key Aspects of Flocculant Addition Affecting Thickener Performance

Ensuring optimal flocculant addition is critical for achieving effective thickening and clear overflow.

Here are the key aspects to focus on:

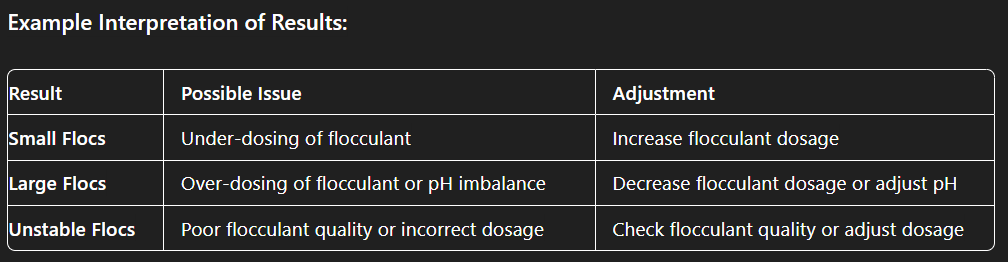

#### 1. Flocculant Dosage

- **Optimal Dosage**:

The correct dosage of flocculant is essential. Both under-dosing and over-dosing can lead to poor flocculation, resulting in inefficient settling and poor overflow clarity.

- **Under-Dosing**:

Insufficient flocculant can lead to incomplete flocculation, causing fine particles to remain suspended and be carried over with the overflow.

- **Over-Dosing**:

Excessive flocculant can cause the formation of overly large and dense flocs that can break apart, leading to re-suspension of particles.

- **Optimization Strategies**:

- **Jar Tests**: Conduct jar tests to determine the optimal flocculant dosage. This involves adding different amounts of flocculant to samples of the slurry and observing the settling behavior and clarity.

- **Dosage Control**: Implement precise dosing equipment to ensure consistent and accurate addition of flocculant.

#### 2. Mixing

- **Proper Mixing**:

Effective mixing of the flocculant with the slurry is crucial for forming strong, well-structured flocs.

- **Mixing Intensity**:

Ensure the mixing intensity is appropriate. Too gentle mixing may lead to incomplete floc formation, while too vigorous mixing can break up flocs.

- **Mixing Time**: Allow sufficient time for the flocculant to interact with the slurry. Inadequate mixing time can result in poor floc formation.

- **Mixing Techniques**:

- **In-Line Mixers**:

Use in-line mixers to ensure thorough and consistent mixing of the flocculant with the slurry.

- **Feedwell Design**:

Ensure the feedwell design promotes effective mixing of the slurry and flocculant before it enters the thickener.

#### 3. Flocculant Quality

- **Type and Quality**:

The type and quality of flocculant used can significantly impact flocculation efficiency and overall thickener performance.

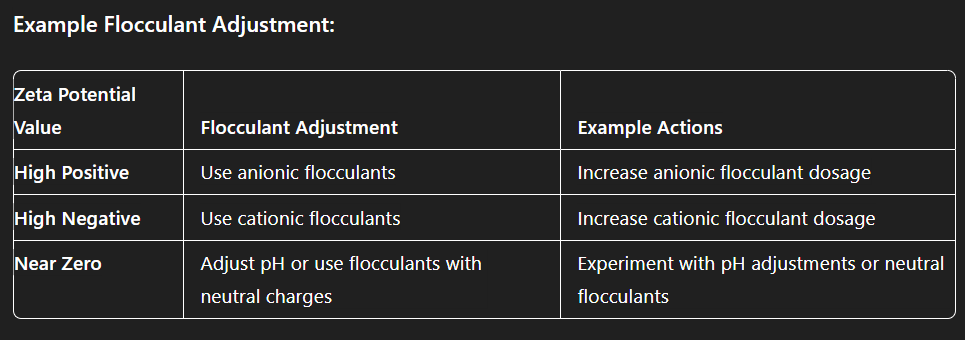

- **Flocculant Type**:

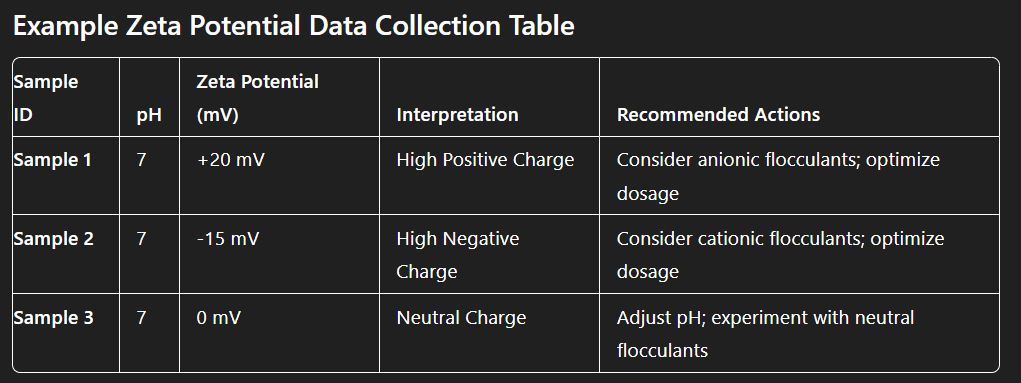

Choose the appropriate type of flocculant (cationic, anionic, or nonionic) based on the slurry characteristics and particle charge.

- **Quality Control**: Ensure the flocculant is of high quality and free from contaminants. Poor-quality flocculant can lead to inconsistent performance.

- **Quality Assurance**:

- **Supplier Verification**: Source flocculants from reputable suppliers and verify their quality through certificates of analysis.

- **Batch Testing**: Test each batch of flocculant to ensure it meets the required specifications and performs consistently.

### Practical Steps for Optimizing Flocculant Addition

1. **Determining Optimal Dosage**

- **Jar Tests**: Conduct jar tests with varying dosages to find the optimal amount of flocculant.

- **On-Site Trials**: Perform on-site trials with the selected dosage to validate laboratory findings under actual operating conditions.

- **Continuous Monitoring**: Use real-time monitoring systems to continuously adjust the dosage based on feed slurry characteristics.

2. **Ensuring Proper Mixing**

- **Mixing Equipment**: Use appropriate mixing equipment such as static mixers or dynamic mixers to achieve uniform mixing.

- **Feedwell Design**: Ensure the feedwell is designed to promote effective mixing. Consider baffles or other flow-control devices to enhance mixing efficiency.

- **Mixing Duration**: Allow sufficient time for mixing. Adjust the residence time in the mixing zone to ensure complete flocculant interaction with the slurry.

3. **Maintaining Flocculant Quality**

- **Quality Verification**: Regularly verify the quality of incoming flocculant batches through testing and supplier audits.

- **Storage Conditions**: Store flocculants in appropriate conditions to prevent degradation. Protect from extreme temperatures, moisture, and contamination.

- **Performance Testing**: Periodically test the performance of the flocculant to ensure it meets the required standards.

### Example Scenario

**Scenario**:

A thickener is experiencing poor overflow clarity, and initial observations suggest that the flocculant addition might be suboptimal.

**Action Plan**:

1. **Dosage Optimization**:

- Conduct jar tests with various dosages of the current flocculant to determine the optimal amount.

- Implement the optimal dosage in the thickener and monitor the performance.

2. **Mixing Improvement**:

- Assess the current mixing setup. If necessary, install in-line mixers to ensure thorough mixing of the flocculant and slurry.

- Evaluate the feedwell design and modify it to enhance mixing efficiency.

3. **Quality Assurance**:

- Verify the quality of the flocculant batch currently in use. If issues are found, switch to a higher-quality flocculant.

- Test different types of flocculants to find the most effective one for the specific slurry characteristics.

By focusing on these key aspects of flocculant addition—dosage, mixing, and quality—you can significantly improve thickener performance and achieve better overflow clarity. Regular monitoring and adjustments based on real-time data are crucial for maintaining optimal thickener operation.

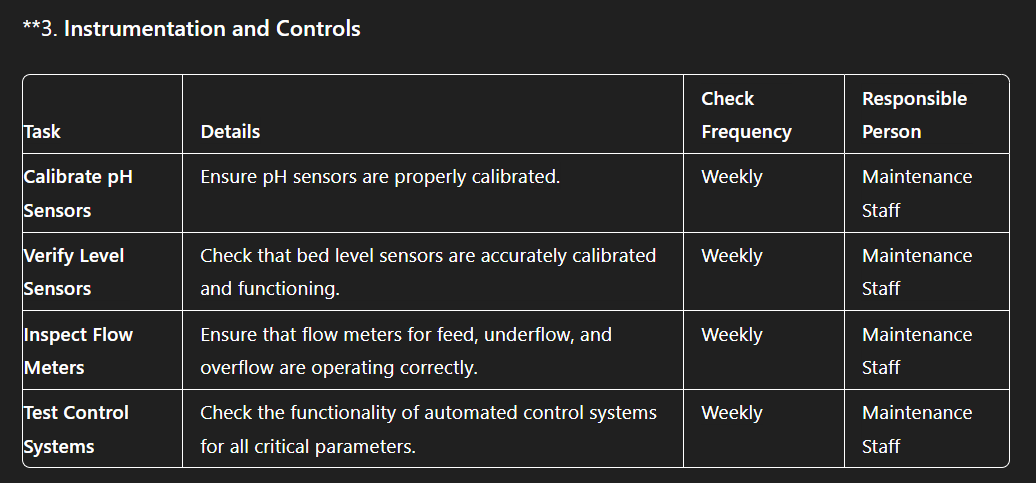

Instrumentation and Controls for Optimizing Thickener Performance

### Instrumentation and Controls for Optimizing Thickener Performance

Effective instrumentation and control systems are essential for maintaining optimal thickener operation and ensuring good overflow clarity.

Here are the key aspects to focus on:

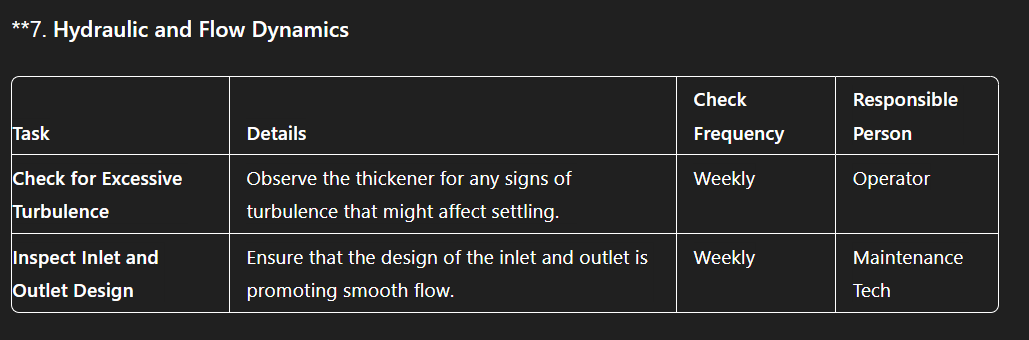

#### 1. Flow Rates

- **Importance**: Consistent flow rates for feed, underflow, and overflow are crucial for stable thickening performance.

- **Feed Flow Rate**: Fluctuations in feed flow rate can disrupt the settling process and affect the performance of the thickener.

- **Underflow Flow Rate**: Consistent underflow removal is essential to maintain the desired bed level and underflow density.

- **Overflow Flow Rate**: Monitoring the overflow rate helps in assessing the thickener's performance and identifying any carryover of fine particles.

- **Monitoring and Control**:

- **Flow Meters**: Install flow meters on feed, underflow, and overflow lines to continuously monitor flow rates.

- **Automated Controls**: Use automated control systems to adjust pump speeds and valve positions based on real-time flow rate data.

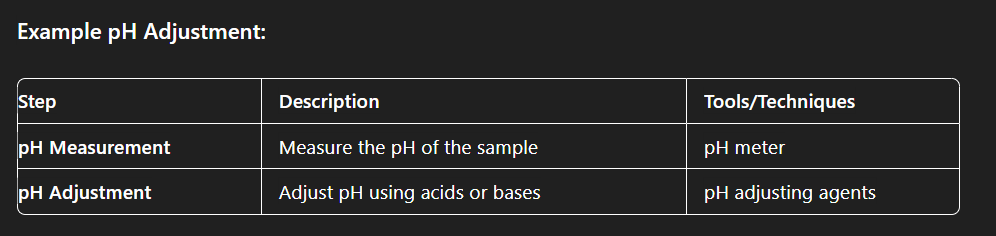

#### 2. pH Control

- **Importance**: pH can significantly affect the effectiveness of flocculants and the overall settling process.

- **Optimal pH Range**: Each type of flocculant has an optimal pH range in which it performs best. Maintaining the pH within this range ensures effective flocculation.

- **pH Fluctuations**: Sudden changes in pH can lead to poor flocculation and negatively impact overflow clarity.

- **Monitoring and Control**:

- **pH Sensors**: Install pH sensors in the feed slurry and ensure they are regularly calibrated.

- **pH Adjustment Systems**: Implement pH adjustment systems (e.g., acid or base dosing) to maintain the pH within the desired range.

#### 3. Level Sensors

- **Importance**: Accurate level sensors are essential for maintaining the optimal bed level and preventing overflows or underflows.

- **Bed Level Monitoring**: Continuous monitoring of the bed level helps in maintaining consistent thickening performance.

- **Overflow and Underflow Levels**: Monitoring the levels of overflow and underflow ensures that the thickener is operating within its design parameters.

- **Monitoring and Control**:

- **Level Sensors**: Install reliable level sensors (e.g., ultrasonic, radar) for accurate measurement of bed, overflow, and underflow levels.

- **Calibration and Maintenance**: Regularly calibrate level sensors and perform routine maintenance to ensure they are functioning correctly.

### Practical Steps for Optimizing Instrumentation and Controls

1. **Flow Rate Management**

- **Installation**: Install flow meters on all critical lines (feed, underflow, overflow).

- **Real-Time Monitoring**: Use a centralized control system to monitor flow rates in real-time.

- **Adjustments**: Implement automated controls to adjust pump speeds and valve positions based on flow rate data.

2. **pH Control**

- **Sensor Installation**: Install pH sensors in the feed slurry and ensure they are strategically placed for accurate measurements.

- **Calibration**: Regularly calibrate pH sensors to maintain accuracy.

- **pH Adjustment**: Use automated dosing systems to add acids or bases as needed to maintain the pH within the optimal range for flocculant performance.

3. **Level Sensor Optimization**

- **Sensor Placement**: Install level sensors at key points, including the thickener bed, overflow launder, and underflow outlet.

- **Regular Checks**: Perform routine checks and calibrations to ensure sensors are providing accurate data.

- **Control Systems**: Use automated level control systems to adjust underflow pump speed and feed rate based on real-time level data.

### Example Scenario

**Scenario**: A thickener is experiencing inconsistent overflow clarity and fluctuations in underflow density.

**Action Plan**:

1. **Flow Rate Management**:

- Install flow meters on the feed, underflow, and overflow lines.

- Monitor the flow rates in real-time and set up automated controls to adjust pump speeds and valve positions as needed.

2. **pH Control**:

- Install pH sensors in the feed slurry line.

- Regularly calibrate the sensors and set up automated pH adjustment systems to maintain the optimal pH range for flocculant performance.

3. **Level Sensor Optimization**:

- Install reliable level sensors to monitor the thickener bed, overflow, and underflow levels.

- Perform regular calibrations and maintenance on the sensors.

- Use automated level control systems to maintain the desired bed level and consistent underflow removal.

By focusing on these key aspects of instrumentation and controls—flow rates, pH control, and level sensors—you can significantly improve thickener performance and achieve better overflow clarity.

Regular monitoring, calibration, and automated adjustments based on real-time data are essential for maintaining optimal thickener operation.

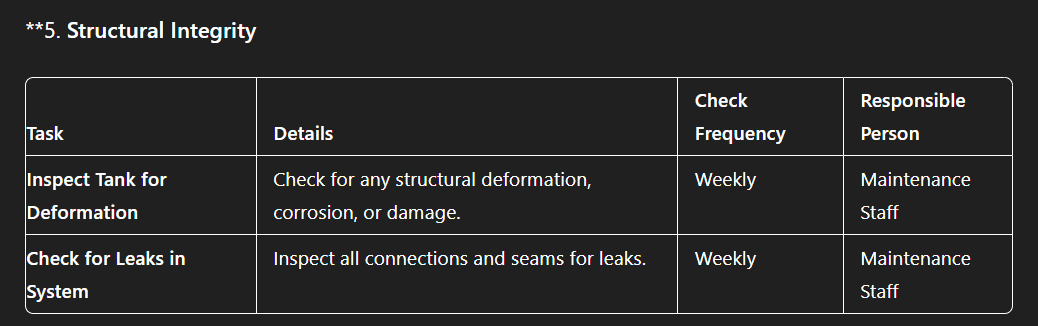

Maintenance and Mechanical Issues Affecting Thickener Performance

### Maintenance and Mechanical Issues Affecting Thickener Performance

Proper maintenance and addressing mechanical issues are critical for ensuring the optimal operation of thickeners and maintaining good overflow clarity.

Here are the key aspects to focus on:

#### 1. Rake Mechanism

- **Importance**: The rake mechanism is essential for moving settled solids towards the underflow outlet. Mechanical issues can lead to ineffective solids removal and disrupt the thickening process.

- **Common Issues**:

- **Rake Arm Damage**: Inspect for any damage or bending of the rake arms.

- **Drive Problems**: Ensure the drive mechanism is operating smoothly without excessive noise or vibration.

- **Blade Condition**: Check the condition of the rake blades for wear and tear.

- **Maintenance and Inspection**:

- **Regular Inspection**: Conduct routine inspections of the rake arms, drive mechanism, and blades.

- **Lubrication**: Regularly lubricate moving parts to prevent wear and tear.

- **Alignment**: Ensure the rake arms are properly aligned and moving freely without obstructions.

#### 2. Feed Well

- **Importance**: The feed well distributes the slurry evenly into the thickener. Blockages or poor design can lead to uneven distribution, causing localized overloading and poor settling.

- **Common Issues**:

- **Blockages**: Check for any blockages or build-up of solids in the feed well.

- **Distribution**: Ensure the feed well is designed and functioning to distribute the slurry evenly.

- **Maintenance and Inspection**:

- **Cleaning**: Regularly clean the feed well to remove any debris or build-up.

- **Design Evaluation**: Periodically evaluate the feed well design and make necessary adjustments to ensure even distribution.

- **Flow Control**: Ensure flow control devices (e.g., baffles) are in place and functioning properly.

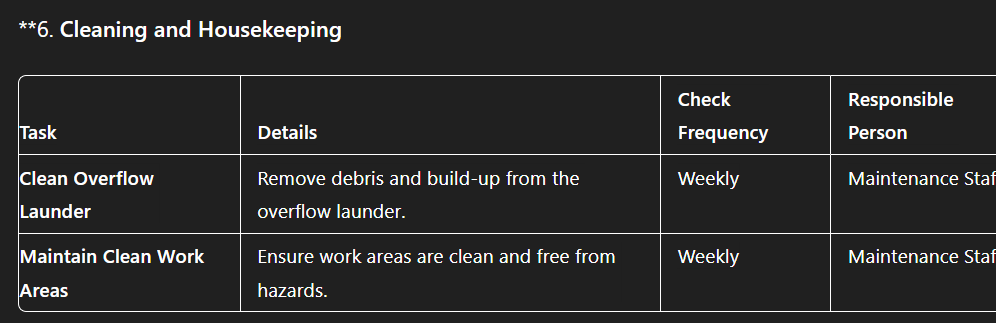

#### 3. Overflow Launder

- **Importance**: The overflow launder collects the clarified overflow from the thickener. Debris or build-up can cause uneven flow distribution and reduce clarity.

- **Common Issues**:

- **Debris Accumulation**: Inspect for any debris or build-up that could impede flow.

- **Flow Uniformity**: Ensure the overflow launder is designed to promote uniform flow distribution.

- **Maintenance and Inspection**:

- **Regular Cleaning**: Clean the overflow launder regularly to remove any debris or build-up.

- **Design Check**: Check the launder design for any features that could cause flow disturbances and adjust as needed.

- **Flow Monitoring**: Monitor the overflow for uniform flow and clarity.

### Practical Steps for Maintenance and Mechanical Inspections

1. **Rake Mechanism Maintenance**

- **Inspection Schedule**: Establish a regular inspection schedule for the rake mechanism, including visual checks and operational tests.

- **Lubrication Routine**: Implement a lubrication routine for all moving parts to ensure smooth operation.

- **Repairs and Replacements**: Promptly address any detected issues, such as damaged rake arms or worn blades, by repairing or replacing components as needed.

2. **Feed Well Maintenance**

- **Blockage Removal**: Regularly inspect and remove any blockages or build-up in the feed well.

- **Flow Distribution**: Evaluate and adjust the feed well design to ensure even slurry distribution. Consider adding or adjusting baffles if necessary.

- **Performance Checks**: Perform periodic performance checks to ensure the feed well is distributing slurry effectively.

3. **Overflow Launder Maintenance**

- **Debris Cleaning**: Implement a regular cleaning schedule for the overflow launder to prevent debris accumulation.

- **Design Evaluation**: Periodically evaluate the overflow launder design and make necessary adjustments to improve flow uniformity.

- **Flow Monitoring**: Use flow meters or visual inspections to monitor the flow distribution and clarity of the overflow.

### Example Scenario

**Scenario**: A thickener is experiencing poor overflow clarity and inconsistent underflow density. Initial observations suggest mechanical and maintenance issues may be contributing to the problem.

**Action Plan**:

1. **Rake Mechanism**:

- Conduct a thorough inspection of the rake arms, drive mechanism, and blades.

- Perform any necessary repairs, such as realigning bent rake arms or replacing worn blades.

- Implement a routine lubrication and inspection schedule.

2. **Feed Well**:

- Inspect the feed well for blockages and remove any build-up.

- Evaluate the feed well design and adjust baffles or other flow control devices to ensure even slurry distribution.

- Clean the feed well regularly to prevent future blockages.

3. **Overflow Launder**:

- Inspect and clean the overflow launder to remove any debris or build-up.

- Check the launder design for any features causing flow disturbances and make necessary adjustments.

- Monitor the overflow flow distribution and clarity regularly to ensure consistent performance.

By focusing on these key maintenance and mechanical aspects—rake mechanism, feed well, and overflow launder—you can significantly improve thickener performance and achieve better overflow clarity. Regular inspections, timely maintenance, and prompt repairs are essential for maintaining optimal thickener operation.

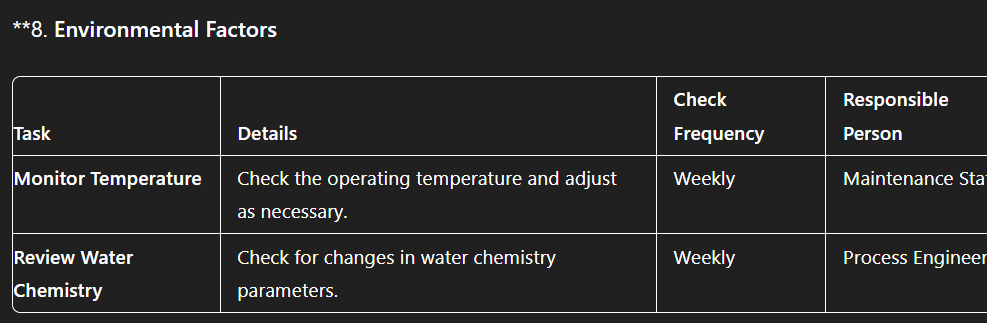

Environmental Factors Affecting Thickener Performance

### Environmental Factors Affecting Thickener Performance

Environmental factors such as temperature and water chemistry can significantly influence the thickening process and the effectiveness of flocculation. Understanding and managing these factors are crucial for maintaining optimal thickener operation and ensuring good overflow clarity.

#### 1. Temperature

- **Importance**: Temperature can affect the viscosity of the slurry and the reaction rates of flocculants, thus impacting the flocculation process and settling rates.

- **Lower Temperatures**: Can increase the viscosity of the slurry, reducing the mobility of particles and the effectiveness of flocculants, leading to slower settling rates.

- **Higher Temperatures**: Can decrease the viscosity of the slurry, improving particle mobility and potentially enhancing flocculation and settling rates.

- **Monitoring and Control**:

- **Temperature Sensors**: Install temperature sensors to monitor the temperature of the feed slurry and thickener environment.

- **Temperature Control**: Implement measures to control the temperature if significant variations are observed, such as heating elements or insulation for the thickener.

#### 2. Water Chemistry

- **Importance**: Changes in water chemistry, such as pH, hardness, and ionic composition, can affect the performance of flocculants and the settling behavior of particles.

- **pH**: The effectiveness of many flocculants is pH-dependent, so maintaining the optimal pH range is crucial for effective flocculation.

- **Hardness and Ionic Strength**: The presence of certain ions (e.g., calcium, magnesium) can impact the performance of flocculants and the stability of flocs.

- **Monitoring and Control**:

- **Chemical Analysis**: Regularly analyze the water chemistry, including pH, hardness, and ionic composition.

- **Water Treatment**: Implement water treatment measures such as pH adjustment, addition of coagulants, or use of water softeners to maintain optimal conditions for flocculation.

### Practical Steps for Managing Environmental Factors

1. **Temperature Management**

- **Monitoring**: Install temperature sensors in the feed slurry line and at various points in the thickener to continuously monitor temperature.

- **Control Measures**: Implement heating elements or insulation for the thickener and slurry lines to manage temperature variations. Consider using warm process water if feasible.

- **Adjustments**: Adjust operational parameters such as flocculant dosage based on temperature changes. Higher doses may be required at lower temperatures to achieve effective flocculation.

2. **Water Chemistry Management**

- **Regular Analysis**: Conduct regular chemical analysis of the process water to monitor pH, hardness, and ionic composition.

- **pH Control**: Use automated pH control systems to maintain the optimal pH range for the flocculants being used. Adjust the dosage of acids or bases as necessary.

- **Water Treatment**: Implement water treatment systems to address issues related to water hardness and ionic strength. This may include adding coagulants or using ion exchange systems to remove interfering ions.

### Example Scenario

**Scenario**: A thickener is experiencing poor overflow clarity, and initial observations suggest that changes in temperature and water chemistry may be contributing factors.

**Action Plan**:

1. **Temperature Management**:

- Install temperature sensors in the feed slurry line and around the thickener.

- Monitor temperature data continuously and identify any significant variations.

- Implement heating elements or insulation if the temperature is found to be too low, affecting flocculation.

- Adjust flocculant dosage based on temperature changes to ensure effective flocculation.

2. **Water Chemistry Management**:

- Conduct a thorough chemical analysis of the process water to determine pH, hardness, and ionic composition.

- Implement pH control measures to maintain the optimal pH range for the flocculants.

- If water hardness is found to be affecting flocculation, consider using water softeners or adding coagulants to address the issue.

- Monitor water chemistry regularly and adjust water treatment measures as necessary.

### Summary

By focusing on environmental factors such as temperature and water chemistry, you can significantly improve thickener performance and achieve better overflow clarity. Regular monitoring, control measures, and adjustments based on real-time data are essential for maintaining optimal thickener operation.

Determining Optimal Flocculant Dosage

### Determining Optimal Flocculant Dosage

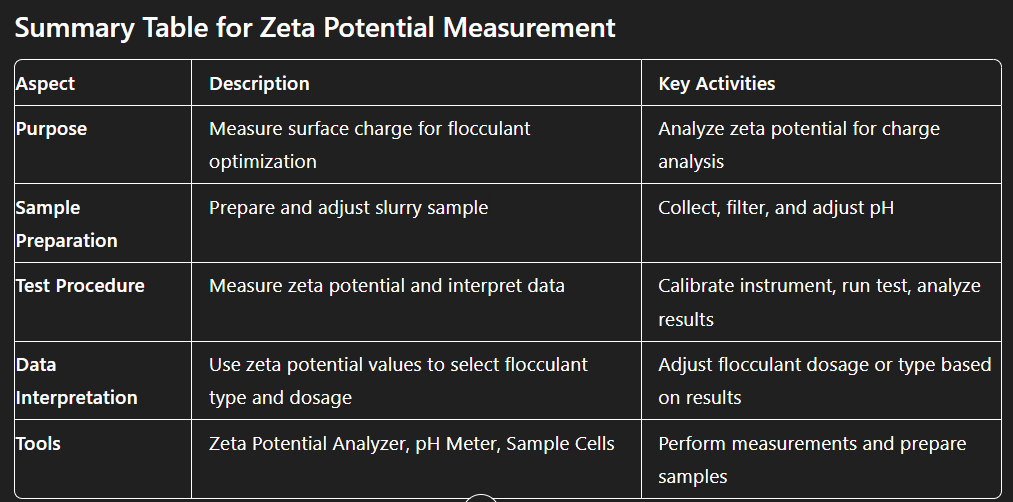

Determining the optimal dosage of flocculant is crucial for achieving effective thickening and good overflow clarity. This involves a combination of laboratory tests, on-site trials, and continuous monitoring to ensure the dosage is adjusted appropriately based on varying feed slurry characteristics.

#### 1. Jar Tests

- **Purpose**: Jar tests are small-scale experiments conducted in the laboratory to determine the optimal flocculant dosage by simulating the thickening process.

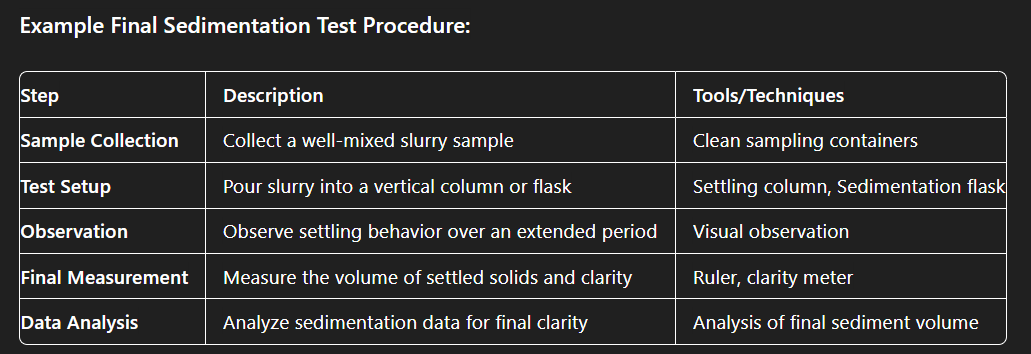

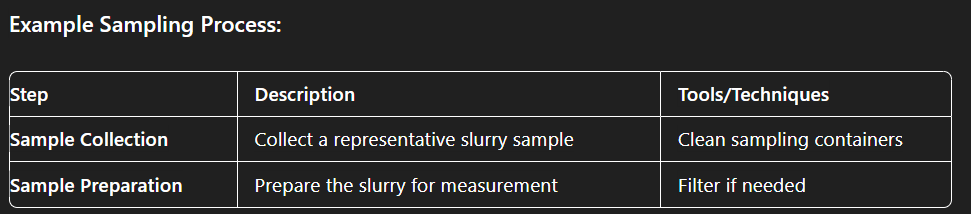

- **Procedure**:

- **Sample Collection**: Collect representative samples of the feed slurry.

- **Flocculant Addition**: Add varying dosages of flocculant to separate jars containing the slurry samples.

- **Mixing**: Mix the slurry and flocculant thoroughly and observe the flocculation and settling behavior.

- **Observation**: Monitor the settling rate, clarity of the supernatant, and the characteristics of the formed flocs.

- **Optimization**: Identify the dosage that results in the best settling rate and highest clarity of the supernatant.

- **Steps**:

- Prepare multiple jars with equal volumes of slurry.

- Add different dosages of flocculant to each jar.

- Stir each jar at a consistent rate to simulate mixing.

- Allow the slurry to settle and observe the results.

- Record the dosage that provides the best combination of settling speed and supernatant clarity.

#### 2. On-Site Trials

- **Purpose**: On-site trials validate the laboratory findings under actual operating conditions, accounting for variations in feed slurry characteristics and process dynamics.

- **Procedure**:

- **Implementation**: Apply the optimal dosage identified from jar tests to the thickener.

- **Monitoring**: Monitor the thickener performance, focusing on settling rates, underflow density, and overflow clarity.

- **Adjustment**: Adjust the dosage as needed based on real-time performance data and observations.

- **Steps**:

- Start with the optimal dosage from jar tests.

- Gradually adjust the dosage up or down based on the thickener’s performance.

- Monitor parameters such as floc size, settling rate, underflow density, and overflow clarity.

- Record observations and make necessary adjustments to find the best operating dosage.

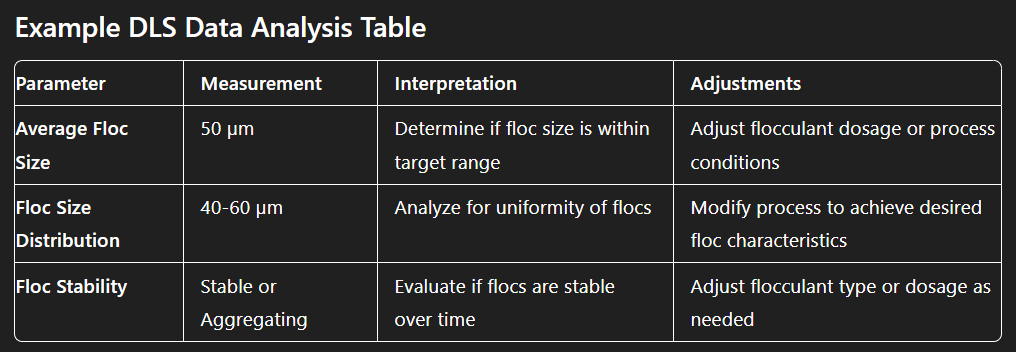

#### 3. Continuous Monitoring

- **Purpose**: Continuous monitoring ensures that the flocculant dosage is dynamically adjusted to respond to changes in feed slurry characteristics and maintain optimal thickening performance.

- **Tools**:

- **Real-Time Sensors**: Use sensors to monitor parameters such as turbidity, pH, and flow rates.

- **Automated Control Systems**: Implement automated dosing systems that adjust the flocculant addition based on real-time data.

- **Data Analysis**: Continuously analyze the data to identify trends and make proactive adjustments.

- **Steps**:

- Install real-time sensors to monitor key parameters such as feed slurry turbidity and flow rates.

- Use automated dosing systems to adjust flocculant addition based on sensor data.

- Continuously analyze performance data to detect any changes in feed slurry characteristics.

- Make proactive adjustments to the flocculant dosage to maintain optimal thickening performance.

### Example Scenario

**Scenario**:

A thickener is experiencing inconsistent overflow clarity and variations in underflow density. Laboratory jar tests suggest an optimal flocculant dosage, but it needs to be validated and adjusted on-site.

**Action Plan**:

1. **Jar Tests**:

- Collect samples of the feed slurry.

- Conduct jar tests with varying dosages of flocculant.

- Identify the dosage that results in the best settling rate and supernatant clarity.

2. **On-Site Trials**:

- Implement the optimal dosage from jar tests in the thickener.

- Monitor the thickener’s performance, focusing on settling rates, underflow density, and overflow clarity.

- Adjust the dosage based on real-time observations and performance data.

3. **Continuous Monitoring**:

- Install real-time sensors to monitor feed slurry turbidity, pH, and flow rates.

- Use automated dosing systems to adjust the flocculant addition based on real-time sensor data.

- Continuously analyze the data and make proactive adjustments to maintain optimal thickening performance.

### Summary

By following a systematic approach involving jar tests, on-site trials, and continuous monitoring, you can determine and maintain the optimal flocculant dosage for your thickener. This ensures effective flocculation, efficient settling, and good overflow clarity, ultimately improving the overall performance of the thickening process.

Ensuring Proper Mixing for Optimal Thickener Performance

### Ensuring Proper Mixing for Optimal Thickener Performance

Proper mixing of flocculant with the feed slurry is essential to ensure effective flocculation, settling, and overall thickener performance.

Here are the key aspects to focus on:

#### 1. Mixing Equipment

- **Importance**: The choice of mixing equipment significantly impacts the efficiency of flocculant dispersion and interaction with the slurry.

- **Static Mixers**: These mixers use internal baffles and flow disruptions to mix the flocculant and slurry as they pass through. They are simple, have no moving parts, and are suitable for continuous processes.

- **Dynamic Mixers**: These mixers have rotating impellers or blades that actively mix the flocculant and slurry. They are effective for high-viscosity slurries and provide better control over the mixing process.

- **Selection and Operation**:

- **Static Mixers**: Choose the appropriate size and design based on the flow rate and slurry properties. Ensure they are installed in a straight section of the pipe to maximize mixing efficiency.

- **Dynamic Mixers**: Select mixers with appropriate power and impeller design for the slurry characteristics. Regularly maintain and inspect the mixers to ensure they are functioning properly.

#### 2. Feedwell Design

- **Importance**: The feedwell is critical for distributing the slurry and flocculant evenly into the thickener. A well-designed feedwell enhances mixing efficiency and promotes uniform flocculation.

- **Baffles and Flow-Control Devices**: These features help distribute the slurry and flocculant evenly and prevent short-circuiting, which can lead to uneven mixing and poor flocculation.

- **Design Considerations**:

- **Baffles**: Install baffles to create turbulence and improve the mixing of the flocculant with the slurry.

- **Flow-Control Devices**: Use devices such as weirs or deflectors to ensure even distribution of the feed slurry and flocculant.

- **Feedwell Shape and Size**: Optimize the shape and size of the feedwell to match the flow characteristics and ensure adequate mixing time.

#### 3. Mixing Duration

- **Importance**: Adequate mixing time is essential for the flocculant to interact fully with the slurry particles, forming effective flocs that settle efficiently.

- **Residence Time**: Ensure that the residence time in the mixing zone is sufficient for complete flocculant interaction. This may require adjusting the feed rate or the size of the mixing zone.

- **Operational Adjustments**:

- **Flow Rate Control**: Adjust the feed rate to ensure sufficient residence time in the mixing zone. Slower flow rates may be necessary for higher viscosity slurries.

- **Mixing Zone Size**: Modify the size of the mixing zone or the position of the mixing equipment to achieve the desired residence time.

- **Continuous Monitoring**: Use real-time sensors to monitor the mixing process and make adjustments as needed to maintain optimal flocculation.

### Practical Steps for Ensuring Proper Mixing

1. **Mixing Equipment Selection and Maintenance**

- **Static Mixers**: Choose the right size and design for the specific application. Ensure they are properly installed and regularly inspected for any blockages or wear.

- **Dynamic Mixers**: Select mixers with the appropriate power and impeller design. Regularly maintain and inspect the mixers to ensure they are operating efficiently.

2. **Feedwell Design Optimization**

- **Install Baffles**: Use baffles in the feedwell to create turbulence and enhance mixing efficiency.

- **Use Flow-Control Devices**: Implement weirs or deflectors to ensure even distribution of the slurry and flocculant.

- **Optimize Shape and Size**: Adjust the feedwell design to match the slurry characteristics and ensure adequate mixing time.

3. **Adjusting Mixing Duration**

- **Control Feed Rate**: Adjust the feed rate to ensure sufficient residence time in the mixing zone for effective flocculation.

- **Modify Mixing Zone Size**: Adjust the size or position of the mixing zone to achieve the desired mixing duration.

- **Monitor Continuously**: Use real-time sensors to monitor the mixing process and make necessary adjustments to maintain optimal conditions.

### Example Scenario

**Scenario**: A thickener is experiencing poor overflow clarity, and initial observations suggest inadequate mixing of the flocculant with the feed slurry.

**Action Plan**:

1. **Mixing Equipment**:

- **Static Mixers**: Ensure static mixers are properly sized and installed in a straight section of the pipe. Check for blockages or wear.

- **Dynamic Mixers**: Select dynamic mixers with appropriate power and impeller design. Perform regular maintenance to ensure they are functioning correctly.

2. **Feedwell Design**:

- Install baffles in the feedwell to create turbulence and enhance mixing.

- Use weirs or deflectors to ensure even distribution of the feed slurry and flocculant.

- Optimize the shape and size of the feedwell to match the slurry characteristics.

3. **Mixing Duration**:

- Adjust the feed rate to ensure sufficient residence time in the mixing zone.

- Modify the size or position of the mixing zone to achieve the desired mixing duration.

- Use real-time sensors to monitor the mixing process and make necessary adjustments.

### Summary

By focusing on mixing equipment, feedwell design, and mixing duration, you can ensure proper mixing of flocculant with the feed slurry, leading to effective flocculation and improved thickener performance. Regular monitoring, maintenance, and adjustments based on real-time data are essential for maintaining optimal mixing conditions.

Maintaining Flocculant Quality for Optimal Thickener Performance

### Maintaining Flocculant Quality for Optimal Thickener Performance

Ensuring the quality of flocculant is crucial for achieving effective flocculation and maintaining good thickener performance.

Here are key strategies to maintain flocculant quality:

#### 1. Quality Verification

- **Importance**: Regularly verifying the quality of incoming flocculant batches ensures consistency in performance and prevents process issues caused by inferior products.

- **Procedures**:

- **Testing**: Conduct routine tests on incoming flocculant batches to verify their quality. This can include:

- **Viscosity**: Measure the viscosity to ensure it is within the specified range.

- **Charge Density**: Test the charge density to verify the flocculant’s effectiveness.

- **Molecular Weight**: Check the molecular weight distribution.

- **Supplier Audits**: Perform periodic audits of flocculant suppliers to ensure they meet quality standards and follow proper manufacturing practices.

- **Steps**:

- Establish a testing protocol for each batch of incoming flocculant.

- Set quality benchmarks based on historical performance data.

- Schedule regular audits and inspections of suppliers to ensure compliance with quality standards.

#### 2. Storage Conditions

- **Importance**: Proper storage conditions prevent the degradation of flocculants, which can affect their performance.

- **Guidelines**:

- **Temperature Control**: Store flocculants in a controlled environment to avoid extreme temperatures. Most flocculants perform best within a specific temperature range.

- **Moisture Protection**: Keep flocculants dry by storing them in sealed containers to prevent moisture absorption.

- **Contamination Prevention**: Store flocculants away from potential contaminants, including chemicals and dust, to maintain purity.

- **Steps**:

- Designate a storage area with temperature and humidity control.

- Use airtight containers for storing flocculants.

- Regularly inspect storage conditions and containers for any signs of damage or contamination.

#### 3. Performance Testing

- **Importance**: Periodically testing the performance of flocculants ensures they continue to meet the required standards and perform effectively in the thickening process.

- **Procedures**:

- **Routine Testing**: Conduct routine performance tests on stored flocculants to ensure they maintain their effectiveness.

- **Batch Comparison**: Compare performance results with previous batches to detect any significant variations.

- **Adjustment and Calibration**: Adjust flocculant dosages and mixing protocols based on performance test results to maintain optimal thickening performance.

- **Steps**:

- Implement a regular schedule for performance testing of flocculants.

- Document and analyze test results to identify trends or issues.

- Make necessary adjustments to flocculant dosing and mixing procedures based on test outcomes.

### Practical Steps for Maintaining Flocculant Quality

1. **Quality Verification Protocol**

- Establish a comprehensive testing protocol for incoming flocculant batches.

- Perform tests such as viscosity, charge density, and molecular weight distribution.

- Conduct regular supplier audits and maintain detailed records of supplier performance.

2. **Optimal Storage Conditions**

- Design and maintain a dedicated storage area with temperature and humidity control.

- Use sealed, airtight containers to store flocculants.

- Regularly inspect storage conditions and containers to prevent degradation and contamination.

3. **Routine Performance Testing**

- Develop a schedule for periodic performance testing of stored flocculants.

- Compare test results with historical data to detect any quality issues.

- Adjust flocculant dosing and mixing protocols based on performance test outcomes.

### Example Scenario

**Scenario**: A thickener operation is experiencing variations in overflow clarity, which may be due to inconsistent flocculant quality.

**Action Plan**:

1. **Quality Verification**:

- Implement a protocol for testing incoming flocculant batches for viscosity, charge density, and molecular weight distribution.

- Schedule and conduct supplier audits to ensure compliance with quality standards.

2. **Storage Conditions**:

- Designate a storage area with controlled temperature and humidity.

- Store flocculants in sealed, airtight containers to prevent moisture absorption and contamination.

- Regularly inspect the storage area and containers for any signs of degradation.

3. **Performance Testing**:

- Develop a schedule for routine performance testing of stored flocculants.

- Compare test results with historical data to identify any significant variations.

- Adjust flocculant dosing and mixing protocols based on the results of performance tests to maintain optimal thickening performance.

### Summary

Maintaining flocculant quality involves regular verification through testing and supplier audits, proper storage conditions to prevent degradation, and routine performance testing to ensure consistent effectiveness. Implementing these strategies ensures that the flocculant performs optimally, leading to better thickener performance and improved overflow clarity.

Key Thickener Operation Parameters for Optimal Performance

### Key Thickener Operation Parameters for Optimal Performance

Maintaining optimal thickener operation involves careful control and adjustment of several parameters, each of which can significantly impact settling performance and overflow clarity.

Here are the key parameters to focus on:

#### 1. Bed Level

- **Importance**: The bed level in the thickener needs to be maintained within an optimal range to ensure efficient settling and separation of solids from liquids.

- **Guidelines**:

- **Too High**: A high bed level can lead to overflow of solids, reducing clarity.

- **Too Low**: A low bed level can cause insufficient residence time for settling, leading to poor separation.

- **Steps**:

- Use bed level sensors to continuously monitor the bed level.

- Adjust the feed rate or underflow rate to maintain the correct bed level.

- Regularly calibrate bed level sensors to ensure accurate readings.

#### 2. Rake Speed

- **Importance**: The rake speed should be adjusted to match the settling rate and solids loading to ensure efficient movement and compaction of settled solids.

- **Guidelines**:

- **Too Fast**: Can disturb the settling process, leading to poor clarity.

- **Too Slow**: Can cause solids to accumulate, potentially leading to mechanical issues and reduced underflow density.

- **Steps**:

- Monitor the rake torque and adjust the rake speed based on the solids loading and settling rate.

- Use variable speed drives to fine-tune rake speed adjustments.

- Regularly inspect and maintain rake mechanisms to ensure smooth operation.

#### 3. Underflow Rate

- **Importance**: The underflow rate should be controlled to balance solids removal with maintaining a steady-state operation in the thickener.

- **Guidelines**:

- **Too High**: Can lead to insufficient residence time for settling, reducing clarity and increasing the load on downstream processes.

- **Too Low**: Can cause high bed levels and potential overflow of solids.

- **Steps**:

- Monitor the underflow density and adjust the underflow pump speed to maintain the desired rate.

- Implement control systems to automate adjustments based on real-time data.

- Conduct regular checks and calibrations of underflow density sensors.

#### 4. Overflow Rate

- **Importance**: The overflow rate needs to be monitored and controlled to prevent carryover of fine particles, which can reduce the clarity of the overflow.

- **Guidelines**:

- **Too High**: Can lead to carryover of fine particles and poor clarity.

- **Too Low**: May indicate suboptimal operation and potential process inefficiencies.

- **Steps**:

- Use flow meters to monitor the overflow rate.

- Adjust the feed rate and underflow rate to control the overflow rate.

- Regularly inspect overflow launder and weirs to ensure proper operation and prevent blockages.

### Practical Steps for Managing Thickener Operation Parameters

1. **Maintaining Bed Level**

- Install and calibrate bed level sensors for continuous monitoring.

- Adjust feed and underflow rates based on sensor data to maintain optimal bed levels.

- Conduct regular maintenance and calibration of sensors to ensure accuracy.

2. **Adjusting Rake Speed**

- Monitor rake torque and adjust speed using variable speed drives.

- Regularly inspect rake mechanisms and perform maintenance to prevent mechanical issues.

- Adjust rake speed in response to changes in solids loading and settling rate.

3. **Controlling Underflow Rate**

- Use density sensors to monitor underflow consistency.

- Adjust underflow pump speed based on real-time density data.

- Implement automated control systems to maintain steady-state operation.

4. **Monitoring Overflow Rate**

- Install flow meters to continuously monitor the overflow rate.

- Adjust feed and underflow rates to prevent excessive overflow.

- Inspect and maintain overflow launder and weirs to ensure they are free from blockages and operating correctly.

### Example Scenario

**Scenario**: A thickener is experiencing fluctuations in overflow clarity, which may be due to inconsistent operation parameters.

**Action Plan**:

1. **Bed Level**:

- Install bed level sensors if not already present.

- Continuously monitor bed level and adjust feed or underflow rates as needed.

- Calibrate sensors regularly to ensure accuracy.

2. **Rake Speed**:

- Monitor rake torque and adjust rake speed to match solids loading and settling rates.

- Use variable speed drives for precise adjustments.

- Perform regular inspections and maintenance of rake mechanisms.

3. **Underflow Rate**:

- Monitor underflow density with sensors and adjust pump speed accordingly.

- Implement automated control systems for real-time adjustments.

- Regularly check and calibrate underflow density sensors.

4. **Overflow Rate**:

- Install flow meters to monitor overflow rate.

- Adjust feed and underflow rates to control the overflow rate.

- Inspect overflow launder and weirs regularly for blockages or malfunctions.

### Summary

Maintaining optimal thickener operation involves careful control and adjustment of bed level, rake speed, underflow rate, and overflow rate. By monitoring these parameters and making necessary adjustments based on real-time data, you can ensure efficient settling, good overflow clarity, and overall thickener performance. Regular maintenance, calibration of sensors, and use of automated control systems are essential for achieving consistent results.

Bed Level Management in Thickeners

### Bed Level Management in Thickeners

Maintaining the bed level within the optimal range is crucial for ensuring efficient settling and separation of solids from liquids in thickeners.

Here’s an in-depth look at the importance, guidelines, and steps for managing bed level:

#### Importance

The bed level in the thickener needs to be within an optimal range for efficient operation:

- **High Bed Level**: Can lead to solids overflow, which reduces clarity and can cause operational issues.

- **Low Bed Level**: Results in insufficient residence time for solids to settle, leading to poor separation and lower underflow density.

#### Guidelines for Managing Bed Level

1. **Too High Bed Level**:

- Can cause solids to overflow into the launder, reducing overflow clarity.

- May lead to increased wear on mechanical components and potential blockages.

2. **Too Low Bed Level**:

- Results in insufficient residence time for settling, leading to poor separation.

- Can cause inadequate compaction of settled solids, reducing underflow density.

#### Steps for Managing Bed Level

1. **Continuous Monitoring**:

- **Bed Level Sensors**: Install bed level sensors to continuously monitor the bed level. These sensors provide real-time data on the height of the settled bed within the thickener.

- **Data Logging**: Use a data logging system to track bed level trends over time and identify patterns or irregularities.

2. **Adjustment of Feed and Underflow Rates**:

- **Feed Rate**: Adjust the feed rate to control the amount of slurry entering the thickener. This can help manage the solids loading and maintain the desired bed level.

- **Underflow Rate**: Adjust the underflow rate to control the removal of settled solids. Increasing the underflow rate lowers the bed level, while decreasing it raises the bed level.

3. **Regular Calibration of Sensors**:

- **Calibration Schedule**: Establish a regular schedule for calibrating bed level sensors to ensure they provide accurate readings. Inaccurate sensor readings can lead to improper adjustments and operational issues.

- **Calibration Procedure**: Follow the manufacturer’s guidelines for sensor calibration. This often involves comparing sensor readings with manual measurements and making necessary adjustments.

### Practical Steps for Bed Level Management

1. **Install and Monitor Bed Level Sensors**:

- Select appropriate bed level sensors based on thickener size and slurry characteristics.

- Ensure sensors are installed correctly and are protected from damage and fouling.

- Continuously monitor the bed level using the sensors and record the data for analysis.

2. **Adjust Feed and Underflow Rates**:

- Use sensor data to adjust the feed rate. Increase the feed rate if the bed level is too low and decrease it if the bed level is too high.

- Adjust the underflow rate to manage the removal of settled solids. Increase the underflow rate to lower the bed level and decrease it to raise the bed level.

3. **Calibrate Bed Level Sensors Regularly**:

- Develop a calibration schedule, such as monthly or quarterly, depending on the operational conditions and sensor stability.

- Perform manual bed level measurements and compare them with sensor readings.

- Adjust sensor settings based on the calibration results to ensure accurate bed level monitoring.

### Example Scenario

**Scenario**: A thickener is experiencing fluctuations in overflow clarity and underflow density, indicating potential issues with bed level management.

**Action Plan**:

1. **Install Bed Level Sensors**:

- If not already installed, add bed level sensors to the thickener.

- Ensure sensors are correctly positioned and protected from slurry damage.

2. **Monitor and Adjust Bed Level**:

- Continuously monitor the bed level using the sensors.

- Adjust the feed rate to control the solids loading. If the bed level is too high, reduce the feed rate. If the bed level is too low, increase the feed rate.

- Adjust the underflow rate to manage solids removal. Increase the underflow rate if the bed level is too high. Decrease the underflow rate if the bed level is too low.

3. **Regular Sensor Calibration**:

- Establish a calibration schedule and perform regular calibrations.

- Compare manual measurements of bed level with sensor readings and adjust sensor settings accordingly.

### Summary

Managing the bed level in thickeners involves continuous monitoring using bed level sensors, adjusting feed and underflow rates to maintain optimal levels, and regularly calibrating sensors to ensure accurate readings. By following these guidelines and steps, you can ensure efficient settling and separation of solids, leading to improved thickener performance and overflow clarity.

Managing Rake Speed in Thickeners

Proper adjustment of rake speed is essential for maintaining efficient thickener operation and ensuring optimal settling and compaction of solids.

Here’s a detailed guide on the importance, guidelines, and steps for managing rake speed:

#### Importance

The rake speed in a thickener must be carefully controlled to match the settling rate and solids loading. Proper rake speed ensures efficient movement and compaction of settled solids, while incorrect speed settings can lead to operational issues:

- **Too Fast**: Disturbs the settling process, causing resuspension of solids and reducing overflow clarity.

- **Too Slow**: Allows solids to accumulate excessively, potentially leading to mechanical issues and reduced underflow density.

#### Guidelines for Managing Rake Speed

1. **Too Fast Rake Speed**:

- Can cause resuspension of settled solids.

- Leads to poor overflow clarity as fines and unsettled solids are carried over.

2. **Too Slow Rake Speed**:

- Results in excessive accumulation of solids at the bottom.

- Increases the risk of rake torque overload and potential mechanical failures.

- Can cause reduced underflow density due to inadequate compaction.

#### Steps for Managing Rake Speed

1. **Monitor Rake Torque and Adjust Speed**:

- **Rake Torque Monitoring**: Continuously monitor the rake torque to assess the load on the rake mechanism. High torque indicates heavy solids loading, requiring speed adjustment.

- **Adjust Speed Based on Solids Loading and Settling Rate**: Use real-time data on solids loading and settling rate to adjust rake speed. Increase speed if the settling rate is high and solids loading is light; decrease speed if the settling rate is slow and solids loading is heavy.

2. **Use Variable Speed Drives**:

- **Fine-Tune Rake Speed Adjustments**: Implement variable speed drives (VSDs) to allow precise control over rake speed. VSDs enable smooth adjustments and help match the rake speed to changing operational conditions.

- **Automation**: Consider automating the rake speed adjustment process based on feedback from sensors monitoring the settling rate and solids loading.

3. **Regular Inspection and Maintenance**:

- **Inspect Rake Mechanisms**: Regularly inspect the rake arms, drive units, and other mechanical components for wear and damage. Look for signs of misalignment, corrosion, and mechanical stress.

- **Ensure Smooth Operation**: Lubricate moving parts and check for any obstructions or build-up that could impede rake movement. Ensure that all components are functioning smoothly to prevent mechanical failures.

### Practical Steps for Managing Rake Speed

1. **Monitor and Adjust Rake Speed**:

- Install sensors to monitor rake torque and settling rates.

- Use the data to adjust the rake speed in real-time, ensuring it matches the solids loading and settling conditions.

- Implement variable speed drives for precise control and automation of rake speed adjustments.

2. **Implement Variable Speed Drives (VSDs)**:

- Install VSDs on rake drive motors to enable smooth and precise speed adjustments.

- Use VSDs to automatically adjust rake speed based on feedback from monitoring systems.

3. **Conduct Regular Maintenance**:

- Schedule regular inspections of the rake mechanism, including arms, drive units, and other components.

- Lubricate moving parts and clear any obstructions to ensure smooth operation.

- Replace worn or damaged components to prevent mechanical failures.

###

Example Scenario

**Scenario**: A thickener is experiencing poor overflow clarity and occasional mechanical issues with the rake mechanism, indicating potential problems with rake speed management.

**Action Plan**:

1. **Monitor Rake Torque and Settling Rates**:

- Install sensors to monitor rake torque and settling rates continuously.

- Use this data to adjust the rake speed dynamically, ensuring it matches the current operational conditions.

2. **Implement Variable Speed Drives**:

- Install VSDs on the rake drive motors to allow for precise speed adjustments.

- Set up the system to automatically adjust rake speed based on real-time feedback from sensors.

3. **Regular Inspection and Maintenance**:

- Schedule regular inspections of the rake mechanism, focusing on arms, drive units, and other mechanical components.

- Lubricate moving parts, clear obstructions, and replace worn components as needed to ensure smooth operation.

### Summary

Managing rake speed in thickeners involves monitoring rake torque and settling rates, using variable speed drives for precise adjustments, and conducting regular inspections and maintenance. By following these guidelines and steps, you can ensure efficient movement and compaction of settled solids, leading to improved thickener performance and overflow clarity.

Managing Underflow Rate in Thickeners

Controlling the underflow rate is crucial for balancing solids removal with maintaining steady-state operation in a thickener. Proper management ensures efficient settling and compaction of solids, leading to optimal thickener performance.

#### Importance

The underflow rate should be controlled to ensure:

- **Efficient Solids Removal**: Proper removal of settled solids prevents excessive accumulation.

- **Steady-State Operation**: Maintaining a consistent underflow rate helps achieve a stable thickener operation, optimizing both settling and compaction processes.

#### Guidelines for Managing Underflow Rate

1. **Too High Underflow Rate**:

- **Insufficient Residence Time**: Leads to poor settling, reducing overflow clarity.

- **Increased Load on Downstream Processes**: Can cause downstream equipment to be overwhelmed by high solids content.

2. **Too Low Underflow Rate**:

- **High Bed Levels**: Causes excessive accumulation of solids, risking overflow.

- **Potential Overflow of Solids**: Can lead to mechanical issues and reduced thickener efficiency.

#### Steps for Managing Underflow Rate

1. **Monitor Underflow Density and Adjust Pump Speed**:

- **Underflow Density Monitoring**: Use sensors to continuously monitor the underflow density. This helps in assessing the concentration of solids in the underflow.

- **Adjust Pump Speed**: Adjust the speed of the underflow pump based on the density readings to maintain the desired underflow rate. Increasing pump speed reduces bed level, while decreasing it allows for more settling time.

2. **Implement Control Systems**:

- **Automated Adjustments**: Implement control systems that use real-time data from sensors to automatically adjust the underflow pump speed. This ensures consistent underflow rates and reduces the need for manual intervention.

- **Feedback Mechanisms**: Use feedback loops to continuously optimize the underflow rate based on changes in feed slurry characteristics and thickener performance.

3. **Regular Checks and Calibrations**:

- **Sensor Calibration**: Regularly calibrate underflow density sensors to ensure accurate readings. Inaccurate sensors can lead to improper adjustments and operational issues.

- **System Checks**: Conduct routine checks on the underflow system, including pumps and sensors, to ensure they are functioning correctly and efficiently.

### Practical Steps for Managing Underflow Rate

1. **Monitor and Adjust Underflow Density**:

- Install sensors to monitor the underflow density continuously.

- Adjust the underflow pump speed based on the real-time data from the sensors to maintain the desired underflow rate.

- Use data logging systems to track underflow density trends over time.

2. **Implement Automated Control Systems**:

- Install control systems that automate the adjustment of the underflow pump speed based on real-time data.

- Use feedback loops to continuously optimize the underflow rate.

3. **Conduct Regular Maintenance and Calibration**:

- Establish a schedule for regular calibration of underflow density sensors to ensure accuracy.

- Perform routine checks and maintenance on the underflow system, including pumps and sensors, to ensure smooth operation.

- Replace or repair any worn or faulty components to prevent operational disruptions.

### Example Scenario

**Scenario**: A thickener is experiencing variable bed levels and inconsistent underflow density, indicating potential issues with underflow rate management.

**Action Plan**:

1. **Monitor Underflow Density**:

- Install and calibrate underflow density sensors to monitor density continuously.

- Use the data to adjust the underflow pump speed, ensuring it matches the desired underflow rate.

2. **Implement Control Systems**:

- Install automated control systems to adjust the underflow pump speed based on real-time density data.

- Use feedback loops to optimize the underflow rate and maintain steady-state operation.

3. **Regular Maintenance and Calibration**:

- Develop a schedule for regular calibration of underflow density sensors.

- Conduct routine checks and maintenance on the underflow system.

- Address any issues promptly to prevent operational disruptions.

### Summary

Managing the underflow rate in thickeners involves monitoring underflow density, adjusting the pump speed, implementing automated control systems, and conducting regular maintenance and calibration. By following these guidelines and steps, you can ensure efficient solids removal, maintain steady-state operation, and achieve optimal thickener performance.

Managing Overflow Rate in Thickeners

Controlling the overflow rate is critical to preventing the carryover of fine particles, ensuring clear overflow and efficient thickener operation.

#### Importance

The overflow rate must be carefully monitored and controlled to:

- **Prevent Carryover of Fine Particles**: Ensuring high clarity of the overflow.

- **Optimize Thickener Performance**: Balancing the rate to avoid suboptimal operation and inefficiencies.

#### Guidelines for Managing Overflow Rate

1. **Too High Overflow Rate**:

- **Carryover of Fine Particles**: Can result in poor overflow clarity.

- **Potential Overloading**: Can overload downstream processes with fine particles.

2. **Too Low Overflow Rate**:

- **Suboptimal Operation**: May indicate that the thickener is not operating efficiently.

- **Potential Process Inefficiencies**: Low overflow rates can lead to higher retention times and reduced throughput.

#### Steps for Managing Overflow Rate

1. **Use Flow Meters to Monitor Overflow Rate**:

- **Continuous Monitoring**: Install flow meters to continuously monitor the overflow rate. This provides real-time data on the volume of liquid exiting the thickener.

- **Data Analysis**: Analyze the flow data to identify trends, fluctuations, and deviations from the optimal range.

2. **Adjust Feed and Underflow Rates**:

- **Feed Rate Adjustment**: Adjust the feed rate to control the amount of slurry entering the thickener. Increasing the feed rate can raise the overflow rate, while decreasing it can lower the overflow rate.

- **Underflow Rate Adjustment**: Adjust the underflow rate to balance the removal of settled solids and maintain a steady overflow rate. Increasing the underflow rate can reduce the overflow rate, and vice versa.

3. **Regular Inspection of Overflow Launder and Weirs**:

- **Inspect for Blockages**: Regularly inspect the overflow launder and weirs for blockages or build-up that could impede flow. Clear any obstructions to ensure smooth operation.

- **Ensure Proper Operation**: Check that the overflow launder and weirs are functioning correctly and are not damaged. Proper maintenance is essential to prevent disruptions.

### Practical Steps for Managing Overflow Rate

1. **Monitor and Analyze Overflow Rate**:

- **Install Flow Meters**: Ensure flow meters are installed at the overflow outlets to provide continuous monitoring of the overflow rate.

- **Data Logging**: Use data logging systems to track overflow rates over time, enabling analysis and identification of patterns or issues.

2. **Adjust Feed and Underflow Rates**:

- **Dynamic Adjustments**: Based on real-time overflow rate data, adjust the feed rate to control the slurry input and the underflow rate to manage solids removal.

- **Balanced Operation**: Aim for a balance where the overflow rate is within the optimal range, preventing carryover of fine particles while maintaining efficient thickener operation.

3. **Regular Maintenance and Inspection**:

- **Scheduled Inspections**: Develop a schedule for regular inspection of the overflow launder and weirs.

- **Clear Blockages**: Promptly clear any debris or build-up to ensure unimpeded overflow.

- **Maintenance**: Conduct routine maintenance to keep the overflow launder and weirs in good condition, preventing operational disruptions.

### Example Scenario

**Scenario**: A thickener is experiencing poor overflow clarity due to carryover of fine particles, suggesting issues with overflow rate management.

**Action Plan**:

1. **Monitor Overflow Rate**:

- Install flow meters if not already present.

- Continuously monitor the overflow rate and log the data for analysis.

2. **Adjust Feed and Underflow Rates**:

- Analyze the overflow rate data to determine if the rate is too high or too low.

- Adjust the feed rate to control the amount of slurry entering the thickener.

- Adjust the underflow rate to balance solids removal and maintain an optimal overflow rate.

3. **Regular Inspection and Maintenance**:

- Inspect the overflow launder and weirs for blockages or damage.

- Clear any obstructions and perform necessary maintenance to ensure proper operation.

### Summary

Managing the overflow rate in thickeners involves continuous monitoring using flow meters, adjusting feed and underflow rates, and conducting regular inspections and maintenance of the overflow launder and weirs. By following these guidelines and steps, you can prevent the carryover of fine particles, ensure high clarity of the overflow, and maintain efficient thickener operation.

Conducting Jar Tests for Optimal Flocculant Dosage

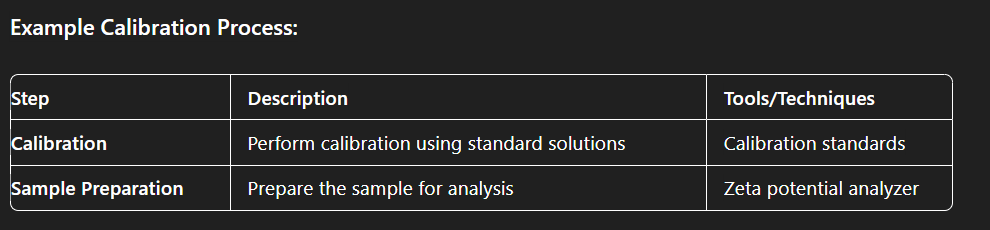

Jar tests are essential small-scale laboratory experiments that simulate the thickening process to determine the optimal flocculant dosage. These tests help in achieving the best settling rate and supernatant clarity in the thickener operation.

#### Purpose

The primary objective of jar tests is to:

- **Determine Optimal Flocculant Dosage**: Identify the flocculant dosage that results in the most efficient settling and highest clarity.

- **Simulate Thickening Process**: Replicate the conditions within the thickener to predict performance and optimize dosage before full-scale implementation.

#### Procedure

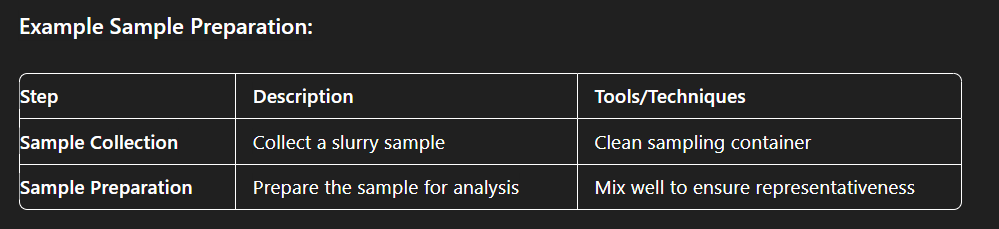

1. **Sample Collection**:

- **Collect Representative Samples**: Obtain feed slurry samples from the thickener feed. Ensure the samples are representative of the typical feed slurry to the thickener.

2. **Flocculant Addition**:

- **Prepare Varying Dosages**: Prepare multiple jars with different dosages of flocculant. This allows comparison of the effectiveness of different dosages.

3. **Mixing**:

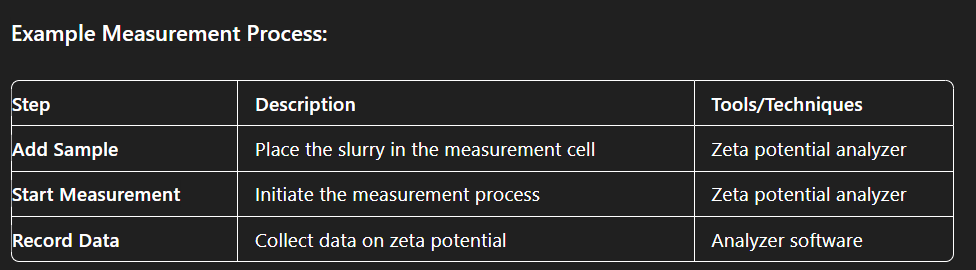

- **Thorough Mixing**: Mix the slurry and flocculant thoroughly in each jar to ensure uniform distribution of the flocculant and proper interaction with the particles.

4. **Observation**:

- **Monitor Behavior**: Observe the flocculation and settling behavior in each jar. Note the settling rate, clarity of the supernatant, and the characteristics of the formed flocs.

5. **Optimization**:

- **Identify Best Dosage**: Determine the dosage that provides the best combination of settling rate and supernatant clarity.

#### Detailed Steps

1. **Prepare Multiple Jars with Equal Volumes of Slurry**:

- **Consistent Volumes**: Use jars of the same size and fill each with an equal volume of the collected slurry sample.

- **Labeling**: Label each jar to identify the different dosages of flocculant being tested.

2. **Add Different Dosages of Flocculant to Each Jar**:

- **Varying Dosages**: Add a range of flocculant dosages to the jars. For example, if testing five jars, you might add 10, 20, 30, 40, and 50 ppm (parts per million) of flocculant to the respective jars.

3. **Stir Each Jar at a Consistent Rate**:

- **Simulate Mixing**: Stir the contents of each jar at a consistent rate to simulate the mixing conditions within the thickener. Use a mechanical stirrer if available to ensure uniform mixing.

4. **Allow the Slurry to Settle and Observe the Results**:

- **Settling Observation**: Allow the slurry to settle in each jar. Monitor and record the settling rate, the clarity of the supernatant, and the size and stability of the flocs formed.

5. **Record the Dosage that Provides the Best Combination of Settling Speed and Supernatant Clarity**:

- **Data Recording**: Note the dosage for each jar and the corresponding results. Identify which dosage results in the fastest settling and clearest supernatant.

- **Optimization**: Use the results to determine the optimal flocculant dosage for full-scale application in the thickener.

### Example Scenario

**Scenario**: A plant is experiencing suboptimal settling and poor supernatant clarity in their thickener and needs to determine the optimal flocculant dosage.

**Action Plan**:

1. **Sample Collection**:

- Collect slurry samples from the thickener feed.

2. **Prepare Jars**:

- Label and fill five jars with equal volumes of the slurry sample.

3. **Add Flocculant**:

- Add 10, 20, 30, 40, and 50 ppm of flocculant to the respective jars.

4. **Mixing and Settling**:

- Stir each jar at a consistent rate.

- Allow the slurry to settle and observe the settling behavior.

5. **Record and Optimize**:

- Record the settling rate and supernatant clarity for each dosage.

- Determine which dosage provides the best results.

### Summary