What is Mine Waste Managemnt System?

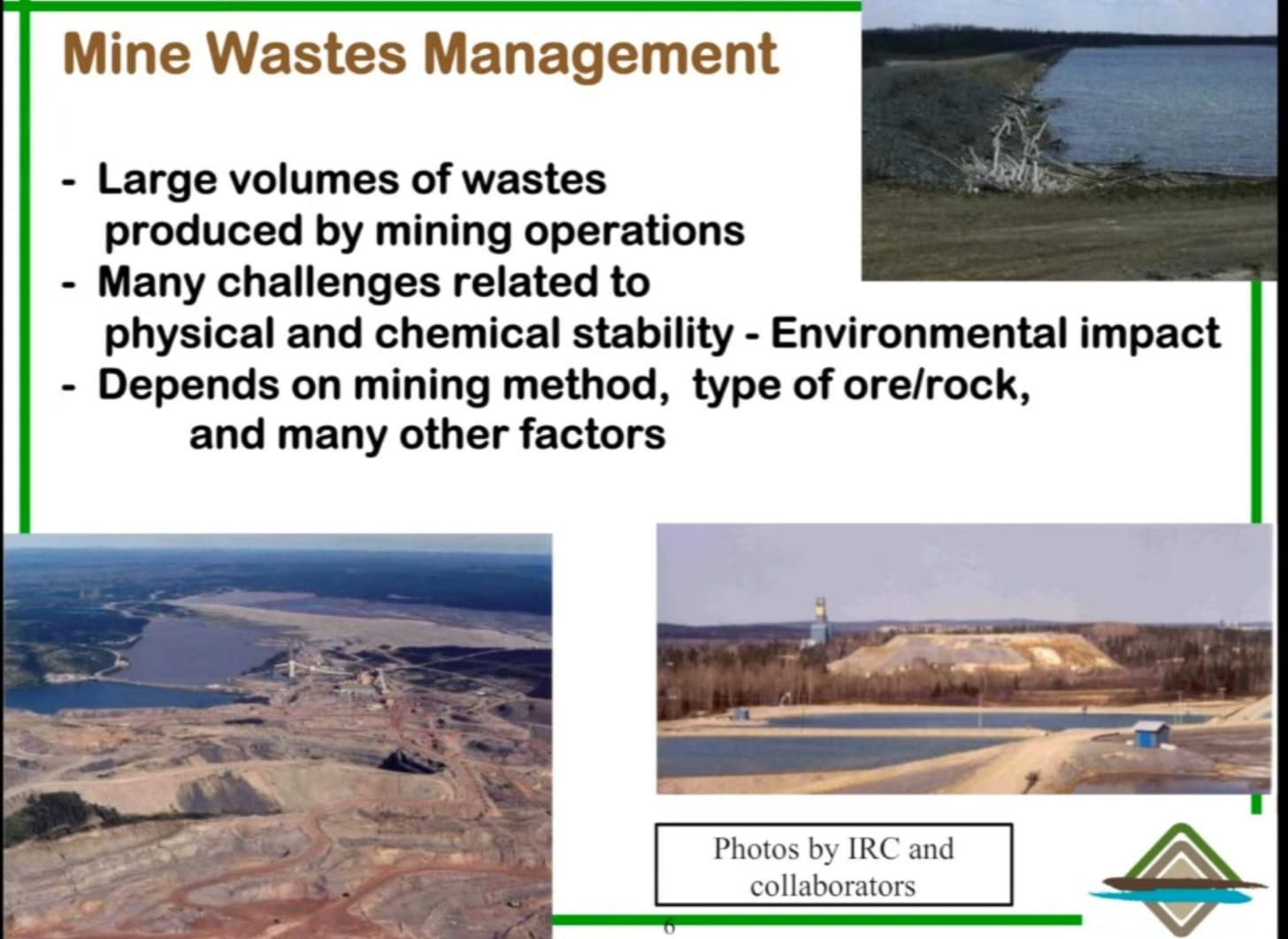

Mine waste management system refers to the methods and processes used to manage the waste generated during the extraction, processing, and refining of minerals from mines.

Mine waste includes a variety of materials such as tailings (the waste material left over after the processing of ore), overburden (the material removed to access the ore), and waste rock (the non-mineralized rock that is excavated during mining).

The main goal of mine waste management is to prevent or minimize the release of harmful substances into the environment and to ensure that the waste is disposed of safely and responsibly.

This is typically achieved through a combination of engineering controls, environmental monitoring, and regulatory oversight. Common practices in mine waste management include the use of lined storage facilities, which prevent the leaching of contaminants into surrounding soil and water, and the reclamation of mine sites after mining activities are complete.

Other strategies may include the use of waste minimization techniques to reduce the amount of waste generated, the treatment of waste to reduce its toxicity or volume, and the use of best management practices to ensure that waste is handled and disposed of safely.

What is the Objective of A Mine Waste Management System?

This includes: Preventing or minimizing the release of contaminants: Mine waste can contain various substances that may be harmful to human health and the environment.

The primary objective of mine waste management is to prevent or minimize the release of these contaminants into the environment, including air, water, and soil.

Protecting water resources: Mine waste can have a significant impact on water resources, including surface water and groundwater.

A key objective of mine waste management is to ensure that these resources are protected from contamination by properly managing and disposing of waste.

Mitigating environmental impacts: Mining activities can have significant environmental impacts, including soil erosion, habitat destruction, and loss of biodiversity.

Mine waste management aims to mitigate these impacts by minimizing the amount of waste generated, reusing or recycling waste materials where possible, and restoring disturbed areas after mining activities are complete. Ensuring compliance with regulatory requirements:

Mine waste management must comply with regulatory requirements and guidelines established by government agencies to protect human health and the environment.

The objective is to ensure that mining activities are conducted in a safe and responsible manner, and that waste is managed and disposed of in accordance with applicable laws and regulations.

Overall, the objective of mine waste management is to minimize the environmental and social impact of mining activities by managing waste in a way that protects the environment, public health, and the long-term sustainability of mining operations.

Who is responsible for Mine Waste Mangement?

In general, the mining company or operator is responsible for implementing and maintaining a mine waste management system that is safe, environmentally sound, and compliant with applicable regulations.

Within the mining company, various individuals and departments may be responsible for different aspects of the mine waste management system. This may include the mine manager, environmental manager, engineering and operations staff, and health and safety personnel.

In addition, government regulatory agencies may have oversight and enforcement authority over mine waste management systems. These agencies may require mining companies to submit plans and reports detailing their waste management practices, conduct inspections and audits of waste management facilities, and take enforcement action against non-compliant operators.

Ultimately, the responsibility for a mine waste management system rests with the mining company or operator, who must ensure that the system is designed, implemented, and maintained in a manner that protects human health and the environment.

What are the consequences of a poorly managed Mine Waste system?

Environmental degradation: Improper management of mine waste can result in soil and water pollution, degradation of ecosystems, and loss of biodiversity. This can have long-term impacts on local communities, as well as on the broader environment.

Public health impacts: Exposure to toxic substances in mine waste can have serious health impacts, including respiratory problems, neurological disorders, and cancers.

Economic impacts: The environmental and public health impacts of a poorly managed mine waste system can also have economic consequences, such as loss of income from fishing, farming, and other traditional livelihoods, as well as increased healthcare costs and loss of tourism revenue.

Legal and regulatory consequences: Poor management of mine waste can result in legal and regulatory consequences, including fines, lawsuits, and potential shutdown of mining operations.

Social consequences: Poorly managed mine waste can also have social consequences, including loss of trust and support from local communities, as well as reputational damage for mining companies.

Overall, the consequences of a poorly managed mine waste system can be significant and wide-ranging, underscoring the importance of effective management practices and responsible stewardship of natural resources.

What is the code of Practice Governing International Mine Waste Management Systems?

There are various codes of practice that govern mine waste management system, depending on the country or region where the mine is located. Some examples of these codes of practice include:

International Council on Mining and Metals (ICMM) Guidance: ICMM is a global organization that provides guidance on responsible mining practices. Its guidance on tailings management includes principles on risk management, stakeholder engagement, and emergency response planning.

Canadian Dam Association (CDA) Guidelines: The CDA is an organization that provides guidelines for the safe design, construction, operation, and maintenance of dams in Canada. Its guidelines on tailings management provide recommendations on dam design, construction, and operation, as well as emergency response planning and stakeholder engagement.

United States Environmental Protection Agency (EPA) Regulations: The EPA is a government agency that regulates environmental issues in the United States. Its regulations on mining waste include requirements for the management and disposal of mine waste, as well as standards for protecting water quality and preventing environmental contamination.

International Cyanide Management Code: The International Cyanide Management Code is a voluntary program that promotes the safe and responsible management of cyanide used in gold mining. The code provides a framework for best practices in cyanide management, including storage, transportation, and disposal.

These codes of practice provide guidance and standards for mine waste management system, and are intended to ensure that mining operations are conducted in a safe, responsible, and sustainable manner.

They typically address issues such as risk management, emergency response planning, stakeholder engagement, and environmental protection, and provide a framework for mine operators to implement best practices in waste management.

What is the code of Practice for the Southern African Region?

In the Southern African region, there are several codes of practice that govern mine waste management systems. Some of these include:

Mine Health and Safety Act (South Africa): The Mine Health and Safety Act is a South African legislation that governs the health and safety of workers in the mining industry. It includes provisions related to mine waste management, including the safe storage, handling, and disposal of waste.

SADC Protocol on Mining: The Southern African Development Community (SADC) Protocol on Mining is a regional agreement that aims to promote sustainable development in the mining sector. The protocol includes provisions related to mine waste management, including the implementation of environmental and social impact assessments, the adoption of best practices in waste management, and the promotion of stakeholder engagement.

Mining and Environment Management Code (Zimbabwe): The Mining and Environment Management Code is a code of practice that applies to all mining operations in Zimbabwe. It includes provisions related to mine waste management, including the safe disposal of waste, the rehabilitation of mining sites, and the adoption of best practices in waste management.

Guidelines for Mine Waste Dump and Stockpile Design (Botswana): The Guidelines for Mine Waste Dump and Stockpile Design is a document that provides guidance on the safe design and management of mine waste dumps and stockpiles in Botswana. It includes provisions related to the safe storage, handling, and disposal of waste, as well as the adoption of best practices in waste management.

These codes of practice aim to ensure that mining operations in the Southern African region are conducted in a safe, responsible, and sustainable manner. They provide guidance on issues such as waste management, environmental protection, and stakeholder engagement, and are intended to promote the long-term sustainability of mining operations in the region.

What is SANS?

SANS (South African National Standards) is a set of technical standards developed by the South African Bureau of Standards (SABS) to promote safety, health, and environmental protection in various industries, including the mining industry.

There are several SANS standards related to mine waste management, including:

SANS 10228: The design of tailings storage facilities: This standard provides guidelines for the safe design and management of tailings storage facilities in the mining industry. It includes provisions related to the site selection, design, construction, operation, and closure of tailings storage facilities.

SANS 10243: The handling, storage, and distribution of fuel on mines: This standard provides guidelines for the safe handling, storage, and distribution of fuel on mines, including the prevention of fuel spills and the safe disposal of fuel waste.

SANS 10286: The identification and classification of dangerous goods for transport: This standard provides guidelines for the identification and classification of dangerous goods for transport, including mine waste that may be classified as dangerous goods.

SANS 1935: The sampling of materials in the mining industry: This standard provides guidelines for the sampling of various materials in the mining industry, including mine waste.

These SANS standards provide a framework for best practices in mine waste management and are intended to promote the safe and sustainable management of waste in the mining industry in South Africa.

They cover various aspects of waste management, including design, construction, operation, and closure of waste storage facilities, as well as the safe handling and disposal of waste.

What is the SANS Framework all about?

SANS standards provide a framework for best practices in mine waste management by setting out guidelines and requirements for the safe and sustainable management of waste in the mining industry.

These standards are developed through a consensus-based process involving industry stakeholders, regulators, and technical experts, and are intended to represent the state-of-the-art in waste management practices.

By providing clear guidelines for the design, construction, operation, and closure of waste storage facilities, as well as the safe handling and disposal of waste, SANS standards help to promote the safe and sustainable management of mine waste.

They establish minimum requirements for the management of waste, including environmental protection, occupational health and safety, and social responsibility.

SANS standards also provide a means of benchmarking and measuring performance in mine waste management. Compliance with these standards can help mining companies to demonstrate their commitment to responsible waste management practices and can provide a basis for third-party certification and verification.

In addition to providing guidelines for the management of mine waste, SANS standards can also help to promote innovation and continuous improvement in waste management practices.

By establishing a common framework for waste management, SANS standards can facilitate the exchange of knowledge and best practices among mining companies and other stakeholders, and can help to drive the development of new and innovative waste management technologies and approaches.

Overall, SANS standards provide a framework for best practices in mine waste management by setting out clear guidelines and requirements for the safe and sustainable management of waste in the mining industry.

They help to promote environmental protection, occupational health and safety, and social responsibility, and can serve as a basis for benchmarking and continuous improvement in waste management practices.

What is international Best Practice when it comes to Mine Waste Management Systems?

International best practices for mine waste management systems include:

Following a risk-based approach: A risk-based approach involves identifying and assessing the risks associated with mine waste management and implementing appropriate measures to control and mitigate these risks.

Adopting a life-cycle approach: A life-cycle approach involves considering the full life cycle of mine waste facilities, from design and construction to closure and post-closure, to ensure that waste is properly managed at every stage.

Implementing effective monitoring and reporting systems: Effective monitoring and reporting systems are critical for tracking key performance indicators and ensuring compliance with regulatory requirements.

Establishing clear roles and responsibilities: Clear roles and responsibilities are essential for ensuring that all personnel involved in mine waste management are aware of their responsibilities and are properly trained to carry out their duties.

Developing and implementing emergency preparedness and response plans: Emergency preparedness and response plans are critical for ensuring that mine waste facilities are prepared to respond quickly and effectively to emergencies such as dam failures or spills.

Engaging with stakeholders: Engaging with stakeholders, including local communities and Indigenous peoples, is important for understanding their concerns and ensuring that mine waste management practices are socially and environmentally responsible.

Incorporating new technologies and innovative solutions: Incorporating new technologies and innovative solutions can help improve the efficiency and effectiveness of mine waste management systems and reduce environmental impacts.

By following these international best practices, mining companies can help ensure that their mine waste management systems are effective, efficient, and sustainable over the long term.

What internal best practice can we adopt?

Internal best practices for mine waste management systems include:

Conducting regular inspections and risk assessments: Regular inspections and risk assessments of mine waste facilities are important for identifying potential hazards and ensuring that they are properly managed.

Implementing effective monitoring and reporting systems: Mine waste management systems should include effective monitoring and reporting systems to track key performance indicators and ensure compliance with regulatory requirements.

Establishing clear roles and responsibilities: It is important to establish clear roles and responsibilities for managing mine waste, including identifying who is responsible for overseeing waste management activities, conducting inspections, and responding to emergencies.

Developing and implementing a robust training program: A comprehensive training program can help ensure that all personnel involved in mine waste management are properly trained and have the necessary skills and knowledge to carry out their responsibilities.

Implementing emergency preparedness and response plans: Effective emergency preparedness and response plans are critical for ensuring that mine waste facilities can respond quickly and effectively to emergencies, such as dam failures or spills.

Establishing a culture of safety and accountability: A culture of safety and accountability is critical for ensuring that all personnel involved in mine waste management take responsibility for their actions and prioritize safety in all activities.

By following these best practices, mining companies can help ensure that their mine waste management systems are effective, efficient, and in compliance with regulatory requirements.

Code of Practice relating to Mine Risk Management

A code of practice in the mining industry is a set of guidelines and standards that provide guidance on best practices for various aspects of mining operations, including risk management.

Risk management is an essential aspect of mining operations, as mining activities can pose significant risks to workers, communities, and the environment.

A code of practice related to risk management in the mining industry typically includes provisions related to hazard identification, risk assessment, risk control, and monitoring and review. These provisions help mining companies to identify potential hazards associated with their operations, assess the risks associated with these hazards, and implement appropriate risk control measures to mitigate these risks.

A code of practice related to risk management in the mining industry may also include requirements related to emergency response planning, incident reporting, and the establishment of health and safety management systems.

These requirements are intended to ensure that mining companies have appropriate plans and systems in place to respond to emergencies and incidents, and to promote the continuous improvement of health and safety performance.

Overall, a code of practice related to risk management in the mining industry can help to promote the safe and sustainable management of mining operations by providing clear guidance on best practices for hazard identification, risk assessment, risk control, and monitoring and review. By adopting and implementing these practices, mining companies can help to minimize the risks associated with their operations, protect workers and communities, and promote the long-term sustainability of their operations.

Guidelines in terms of Mine Waste Management SANS

SANS (South African National Standards) provides guidelines for mine waste management systems through several standards related to the design, construction, operation, and closure of tailings storage facilities (TSFs). Some of the guidelines provided by these standards include:

Site selection and characterization: The guidelines recommend that TSFs should be located in areas that minimize the risk of environmental impacts, including areas with low permeability, stable topography, and low seismicity. Site characterization should include an assessment of the geological and hydrological conditions, as well as the potential impacts of the TSF on the environment and local communities.

Design criteria: The guidelines provide specific design criteria for TSFs, including requirements for embankment design, dam safety, and spillway capacity. The design should also consider factors such as the volume and characteristics of the tailings, the potential for acid rock drainage, and the potential impacts of extreme weather events.

Construction and operation: The guidelines provide guidance on the construction and operation of TSFs, including requirements for quality assurance, construction methods, and monitoring and maintenance. The TSF should be constructed in accordance with the approved design, and monitoring should be conducted to ensure that the TSF is operating as intended.

Closure and post-closure: The guidelines provide guidance on the closure and post-closure of TSFs, including requirements for closure planning, closure criteria, and post-closure monitoring. Closure planning should begin early in the life of the TSF, and closure criteria should be based on the potential for long-term environmental impacts.

Overall, SANS provides a comprehensive framework for the safe and sustainable management of mine waste through its standards related to TSF design, construction, operation, and closure.

By following these guidelines, mining companies can help to minimize the environmental and social impacts of their operations, protect workers and local communities, and promote the long-term sustainability of their operations.

EMP disposal objectives and Policy

EMP (Environmental Management Plan) disposal objectives and policy are designed to ensure that waste disposal activities are carried out in an environmentally responsible and sustainable manner.

The objectives and policy outline the goals and principles that guide waste disposal activities, and provide a framework for decision-making and performance evaluation.

Some common objectives and policies for waste disposal include:

Minimizing environmental impact: The primary objective of EMP disposal is to minimize the environmental impact of waste disposal activities. This can be achieved by adopting waste minimization strategies, selecting appropriate disposal methods and technologies, and ensuring that waste disposal activities comply with relevant environmental regulations and standards.

Protecting public health and safety: EMP disposal activities must also protect public health and safety. This requires the implementation of appropriate risk management strategies, such as the use of protective equipment, worker training and awareness programs, and the provision of emergency response plans.

Promoting sustainability: EMP disposal should be conducted in a manner that promotes sustainability, by minimizing the use of natural resources, reducing waste generation, and encouraging the use of renewable energy sources. This can be achieved through the adoption of sustainable waste management practices, such as waste reduction, reuse, and recycling.

Stakeholder engagement: EMP disposal policies should also promote stakeholder engagement, by involving local communities, government agencies, and other stakeholders in decision-making processes. This can help to ensure that waste disposal activities are transparent, accountable, and responsive to local needs and concerns.

Overall, EMP disposal objectives and policies are designed to promote environmentally responsible and sustainable waste disposal practices, while protecting public health and safety and promoting stakeholder engagement. By adopting and implementing these policies, waste generators and waste disposal facilities can help to minimize the environmental impact of waste disposal activities, and promote the long-term sustainability of waste management practices.

Structure for Mine Waste Management Systems SANS

SANS (South African National Standards) provides a structure for the management of mine waste through its standards related to the design, construction, operation, and closure of tailings storage facilities (TSFs).

The structure for mine waste management systems can be broken down into several key components:

Policy and strategy: The first component of a mine waste management system is the development of policy and strategy documents that provide guidance on the goals and objectives of waste management activities, as well as the principles and practices that should be followed. The policy and strategy should be developed with input from relevant stakeholders, and should be regularly reviewed and updated as necessary.

Planning and design: The second component of a mine waste management system is the planning and design of waste disposal facilities. This includes site selection and characterization, design criteria, construction and operation planning, and closure and post-closure planning. The planning and design process should be conducted in accordance with relevant SANS standards, and should be based on an assessment of the environmental, social, and economic impacts of the waste disposal activities.

Implementation and monitoring: The third component of a mine waste management system is the implementation and monitoring of waste disposal activities. This includes the construction, operation, and closure of TSFs, as well as ongoing monitoring and maintenance activities. Implementation and monitoring should be conducted in accordance with relevant SANS standards, and should be based on a comprehensive risk management framework.

Reporting and communication: The fourth component of a mine waste management system is reporting and communication. This includes the preparation and submission of regular reports to regulatory agencies and other stakeholders, as well as the development of communication plans to ensure that local communities and other stakeholders are informed about waste disposal activities.

Performance evaluation and improvement: The final component of a mine waste management system is performance evaluation and improvement. This includes the regular assessment of the effectiveness of waste disposal activities, as well as the implementation of continuous improvement initiatives to ensure that waste management practices are continually improving and evolving.

Overall, the structure for a mine waste management system should be based on a comprehensive and integrated approach that incorporates policy and strategy development, planning and design, implementation and monitoring, reporting and communication, and performance evaluation and improvement. By adopting and implementing this structure, mining companies can help to minimize the environmental and social impacts of their waste disposal activities, protect workers and local communities, and promote the long-term sustainability of their operations.

SANS Training Requirements

SANS (South African National Standards) provides guidance on the training requirements for personnel involved in mine waste management activities.

The training requirements are designed to ensure that personnel have the knowledge and skills necessary to carry out their responsibilities safely and effectively.

The specific training requirements will depend on the roles and responsibilities of personnel, as well as the nature of the waste disposal activities. However, some general training requirements for mine waste management personnel may include:

Basic training: All personnel involved in mine waste management activities should receive basic training on the hazards and risks associated with waste disposal activities, as well as the relevant laws and regulations governing waste management.

Basic training should cover topics such as hazard identification, risk assessment, emergency response, and environmental compliance.

Technical training: Technical training is necessary for personnel who are responsible for the design, construction, operation, and maintenance of tailings storage facilities (TSFs). This training should cover topics such as soil mechanics, geotechnical engineering, water management, and waste management principles and practices.

Health and safety training: Personnel involved in waste disposal activities should receive training on health and safety procedures and practices, including the use of personal protective equipment, emergency response protocols, and hazard identification and control.

Regulatory compliance training: Personnel involved in waste disposal activities should also receive training on the relevant laws and regulations governing waste management, including the requirements of the National Environmental Management Act (NEMA) and other relevant environmental legislation.

Continuing education and professional development: To ensure that personnel maintain their knowledge and skills over time, continuing education and professional development opportunities should be provided. This may include attending conferences, workshops, and seminars, as well as participating in on-the-job training and mentoring programs.

Overall, the training requirements for mine waste management personnel are designed to ensure that personnel have the necessary knowledge and skills to carry out their responsibilities safely and effectively, while also complying with relevant laws and regulations. By providing comprehensive training and professional development opportunities, mining companies can promote a culture of safety and environmental responsibility, and help to ensure the long-term sustainability of their operations.

SANS Safety Procedures and Industrial Relations

Safety procedures and industrial relations are both critical components of a successful mine waste management system. Effective safety procedures help to protect workers and local communities from the hazards associated with waste disposal activities, while good industrial relations help to ensure that workers are motivated and engaged in their work, leading to higher productivity and better safety outcomes. Some of the key safety procedures that should be implemented in a mine waste management system include:

Hazard identification and risk assessment: Hazard identification and risk assessment are critical components of any safety program. These processes help to identify potential hazards associated with waste disposal activities and assess the level of risk associated with each hazard.

Personal protective equipment (PPE): PPE is essential for protecting workers from the hazards associated with waste disposal activities. PPE may include hard hats, safety glasses, respirators, and other protective gear.

Training and education: As discussed earlier, training and education are critical for ensuring that workers understand the hazards associated with waste disposal activities and how to work safely. Regular safety training and education programs should be provided to all workers involved in waste disposal activities.

Emergency response planning: Emergency response planning is essential for ensuring that workers are prepared to respond to potential accidents or incidents. Emergency response plans should be regularly reviewed and updated to ensure that they are effective.

Good industrial relations are also essential for promoting safety and productivity in a mine waste management system. Some of the key components of good industrial relations include:

Communication: Effective communication is essential for building trust and fostering positive relationships between management and workers. Regular communication channels should be established to ensure that workers are informed about safety procedures and other important issues.

Consultation and participation: Workers should be consulted and allowed to participate in the development of safety procedures and other aspects of the mine waste management system. This helps to ensure that workers have a sense of ownership and are motivated to work safely.

Grievance resolution: Effective grievance resolution procedures should be in place to ensure that workers can raise concerns and have them addressed in a timely manner.

Overall, safety procedures and good industrial relations are both essential components of a successful mine waste management system. By implementing effective safety procedures and promoting good industrial relations, mining companies can protect workers and local communities, promote productivity, and ensure the long-term sustainability of their operations.

SANS Planning

Planning is a critical component of a successful mine waste management system. Effective planning helps to ensure that waste disposal activities are carried out in a safe, efficient, and environmentally responsible manner. Some of the key elements of planning for mine waste management include:

Site selection and design: The selection and design of the waste disposal site are critical components of the planning process. Factors such as the geological and hydrological conditions, local environmental considerations, and the size and scale of the operation should be taken into account when selecting and designing a waste disposal site.

Regulatory compliance: Compliance with regulatory requirements is essential for ensuring that waste disposal activities are carried out in an environmentally responsible manner. Regulations may include requirements for water management, air emissions, waste characterization, and other aspects of waste management.

Risk assessment: Risk assessment is critical for identifying potential hazards associated with waste disposal activities and developing strategies to mitigate those risks. A comprehensive risk assessment should consider all aspects of the waste management system, including the design of the disposal site, the nature and volume of the waste, and the potential impacts on the environment and local communities.

Operational planning: Operational planning involves developing strategies and procedures for the safe and efficient operation of the waste disposal site. This may include procedures for waste handling and transport, maintenance of equipment and infrastructure, and emergency response planning.

Closure planning: Closure planning involves developing strategies for the safe and environmentally responsible closure of the waste disposal site. This may include procedures for final waste placement, site reclamation, and long-term monitoring and maintenance.

Overall, effective planning is essential for ensuring that mine waste management activities are carried out in a safe, efficient, and environmentally responsible manner. By considering all aspects of the waste management system and developing comprehensive plans and procedures, mining companies can minimize risks, protect workers and local communities, and ensure the long-term sustainability of their operations.

SANS Monitoring

Monitoring is an important component of a successful mine waste management system. Effective monitoring helps to ensure that waste disposal activities are carried out in a safe, efficient, and environmentally responsible manner. Some of the key elements of monitoring for mine waste management include:

Environmental monitoring: Environmental monitoring involves the collection and analysis of data to assess the impact of waste disposal activities on the environment. This may include monitoring of air quality, water quality, soil quality, and other environmental parameters. Environmental monitoring can help to identify potential environmental impacts and ensure that waste disposal activities are carried out in compliance with regulatory requirements.

Performance monitoring: Performance monitoring involves the collection and analysis of data to assess the performance of the waste management system. This may include monitoring of waste volumes, waste composition, and other parameters related to waste disposal activities. Performance monitoring can help to identify areas where improvements can be made to optimize the efficiency and effectiveness of the waste management system.

Operational monitoring: Operational monitoring involves the collection and analysis of data related to the operation of the waste disposal site. This may include monitoring of equipment performance, maintenance records, and other operational parameters. Operational monitoring can help to ensure that waste disposal activities are carried out safely and efficiently.

Compliance monitoring: Compliance monitoring involves the collection and analysis of data to ensure that waste disposal activities are carried out in compliance with regulatory requirements. This may include monitoring of permit conditions, waste characterization, and other regulatory parameters. Compliance monitoring can help to ensure that the waste management system is operated in a manner that is consistent with regulatory requirements.

Overall, effective monitoring is essential for ensuring that mine waste management activities are carried out in a safe, efficient, and environmentally responsible manner. By collecting and analyzing data related to environmental impacts, performance, operations, and compliance, mining companies can identify areas where improvements can be made to optimize the efficiency and effectiveness of the waste management system.

SANS Auditing and Review

Auditing and review are important components of a successful mine waste management system. Regular auditing and review help to ensure that waste disposal activities are carried out in a safe, efficient, and environmentally responsible manner. Some of the key elements of auditing and review for mine waste management include:

Internal auditing: Internal auditing involves the regular review of waste management procedures and practices by the mining company's own personnel. Internal audits help to identify areas where improvements can be made to optimize the efficiency and effectiveness of the waste management system. Internal auditing may also help to identify potential compliance issues and ensure that waste disposal activities are carried out in compliance with regulatory requirements.

External auditing: External auditing involves the review of waste management procedures and practices by independent third-party auditors. External audits help to provide an objective assessment of the effectiveness of the waste management system and identify areas where improvements can be made.

External auditing may also help to identify potential compliance issues and ensure that waste disposal activities are carried out in compliance with regulatory requirements.

Review of monitoring data: Regular review of monitoring data helps to ensure that waste disposal activities are carried out in compliance with regulatory requirements and in a manner that is protective of human health and the environment. Review of monitoring data may also help to identify potential issues with the waste management system and provide guidance for making improvements.

Overall, regular auditing and review are essential for ensuring that mine waste management activities are carried out in a safe, efficient, and environmentally responsible manner. By conducting internal and external audits, and regularly reviewing monitoring data, mining companies can identify areas where improvements can be made to optimize the efficiency and effectiveness of the waste management system and ensure compliance with regulatory requirements.

How do I know if I am Compliant?

To know if your waste management system is compliant with applicable regulations and standards, you should conduct regular monitoring, auditing, and review of the system.

Here are some steps you can take: Understand the regulatory requirements:

First, you need to be familiar with the applicable regulations and standards for mine waste management in your jurisdiction. This will help you to understand the specific requirements that your waste management system needs to meet.

Develop a waste management plan: Develop a waste management plan that outlines the procedures and practices for managing mine waste. The plan should address the entire lifecycle of the waste, from generation to disposal, and should be based on the principles of reducing, reusing, and recycling.

Implement the waste management plan: Implement the waste management plan and ensure that all personnel involved in waste management are trained on the procedures and practices outlined in the plan.

Conduct monitoring: Conduct regular monitoring of the waste management system to ensure that it is operating in compliance with regulatory requirements. This may include monitoring of waste volumes, waste composition, air and water quality, and other environmental parameters.

Conduct audits: Conduct internal and/or external audits of the waste management system to assess its effectiveness and identify areas where improvements can be made.

Review monitoring and audit data: Review the monitoring and audit data to identify any compliance issues or areas where improvements can be made to optimize the efficiency and effectiveness of the waste management system.

By taking these steps, you can ensure that your mine waste management system is compliant with applicable regulations and standards. If you identify any compliance issues or areas where improvements can be made, you can take corrective action to address them and ensure that your waste management system remains compliant.

How to develop an Audit system for Mine Waste Management?

Developing and auditing a mine waste management system involves several steps: Define the scope:

Define the scope of the waste management system, including the types of waste generated and the waste management activities that will be included in the system.

Identify regulatory requirements: Identify the regulatory requirements that apply to the management of mine waste in your jurisdiction, and ensure that the waste management system is designed to meet these requirements.

Develop a waste management plan: Develop a waste management plan that outlines the procedures and practices for managing mine waste. The plan should address the entire lifecycle of the waste, from generation to disposal, and should be based on the principles of reducing, reusing, and recycling.

Implement the waste management plan: Implement the waste management plan and ensure that all personnel involved in waste management are trained on the procedures and practices outlined in the plan.

Conduct monitoring: Conduct regular monitoring of the waste management system to ensure that it is operating in compliance with regulatory requirements. This may include monitoring of waste volumes, waste composition, air and water quality, and other environmental parameters.

Conduct internal audits: Conduct internal audits of the waste management system to assess its effectiveness and identify areas where improvements can be made.

Conduct external audits: Consider engaging an independent third-party auditor to conduct an external audit of the waste management system. This will provide an objective assessment of the system's effectiveness and identify areas where improvements can be made.

Review audit data: Review the audit data to identify any compliance issues or areas where improvements can be made to optimize the efficiency and effectiveness of the waste management system.

Implement corrective actions: If any compliance issues or areas for improvement are identified through the auditing process, implement corrective actions to address them and ensure that the waste management system remains effective and compliant.

By following these steps, you can develop and audit a mine waste management system that is effective, efficient, and compliant with regulatory requirements.

Audit Procedure

When conducting an audit of a mine waste management system, there are several procedures that should be followed:

Define the audit scope: Define the scope of the audit, including the activities and processes that will be audited, the time frame for the audit, and the personnel who will be involved in the audit.

Establish audit criteria: Establish criteria against which the waste management system will be audited. These criteria may include regulatory requirements, industry standards, company policies and procedures, and best practices.

Conduct the audit: Conduct the audit, which may include a review of documentation, observation of waste management activities, interviews with personnel involved in waste management, and sampling and analysis of waste.

Document findings: Document the findings of the audit, including any non-conformances or opportunities for improvement.

Develop corrective action plan: Develop a corrective action plan to address any non-conformances or opportunities for improvement identified during the audit.

Implement corrective actions: Implement the corrective actions identified in the corrective action plan.

Follow up: Conduct a follow-up audit to verify that corrective actions have been implemented and are effective.

Report audit results: Prepare a report of the audit results, including findings, corrective actions taken, and recommendations for improvement.

By following these procedures, an audit of a mine waste management system can help identify areas where the system is not in compliance with regulations and standards, and provide recommendations for improving the system's effectiveness and efficiency.

WHAT SHOULD BE MONITORED?

To ensure proper control of mining waste, the following should be monitored:

Waste generation: The amount and type of waste generated should be monitored to ensure that it is properly characterized and managed in accordance with regulatory requirements.

Waste storage: The storage of waste should be monitored to ensure that it is stored safely and securely, and in accordance with regulatory requirements.

Waste transportation: The transportation of waste should be monitored to ensure that it is transported safely and in compliance with regulatory requirements.

Waste disposal: The disposal of waste should be monitored to ensure that it is disposed of in an environmentally sound manner, and in compliance with regulatory requirements.

Environmental monitoring: Environmental monitoring should be conducted to ensure that the waste management practices are not causing harm to the environment. This may include monitoring of air quality, water quality, and soil quality.

Compliance monitoring: Compliance monitoring should be conducted to ensure that the waste management practices are in compliance with regulatory requirements.

Worker safety: Worker safety should be monitored to ensure that personnel involved in waste management are properly trained and equipped to perform their duties safely.

By monitoring these aspects of waste management, proper control of mining waste can be ensured, which will help to minimize the environmental and social impacts associated with mining activities.

WHAT CONTROL MEASURES SHOULD BE PUT IN PLACE?

To effectively monitor a mine waste management system, the following controls should be put in place:

Document control: All documents related to the waste management system, including procedures, plans, and records, should be controlled to ensure that they are up-to-date and accurate.

Training and competency: Personnel involved in waste management should be trained and competent in the waste management procedures and techniques.

Regular training and assessments should be conducted to ensure that personnel remain competent.

Recordkeeping: All waste management activities should be recorded and maintained in a central repository. Records should be accurate, complete, and easily retrievable.

Monitoring and measurement: Monitoring and measurement should be conducted to ensure that waste management activities are effective and in compliance with regulatory requirements.

Non-conformance management: A system should be in place to manage non-conformances identified during waste management activities, including corrective and preventive actions.

Management review: The waste management system should be reviewed periodically by senior management to ensure its continued effectiveness.

By putting these controls in place, the mine waste management system can be effectively monitored to ensure compliance with regulatory requirements, minimize environmental impacts, and protect the health and safety of personnel involved in waste management activities.

CONTROL MEASURES TO ENSURE OPERATIONAL STABILITY

To ensure stability of a mine waste site, the following controls should be put in place:

Slope stability analysis: Slope stability analysis should be conducted to determine the potential for instability in the waste piles or slopes. The analysis should consider factors such as soil type, slope angle, and water content.

Drainage: Proper drainage should be provided to prevent water buildup and reduce the risk of slope failure.

Vegetation: Vegetation should be established on the waste piles to stabilize the soil and reduce erosion.

Monitoring: Regular monitoring of the waste piles and slopes should be conducted to identify any signs of instability or movement. Monitoring may include visual inspections, geotechnical instrumentation, and remote sensing techniques.

Maintenance: Regular maintenance of the waste piles and slopes should be conducted to ensure that they remain stable over time. This may include repairing erosion, addressing drainage issues, and maintaining vegetation.

Emergency response plan: An emergency response plan should be developed and implemented in the event of a slope failure or other emergency situation.

By implementing these controls, the stability of the mine waste site can be effectively managed, reducing the risk of slope failure and associated environmental and safety risks.

WHAT IS THE ROLE OF THE REGULATOR?

The role of regulators in mine waste management is to establish and enforce regulations that govern the handling, storage, and disposal of mine waste.

These regulations are designed to protect public health and safety, as well as the environment, by ensuring that mine waste is managed in a safe and responsible manner.

Regulators may have a range of responsibilities related to mine waste management, including:

Developing and enforcing regulations: Regulators develop and enforce regulations related to mine waste management, including requirements for storage, transportation, and disposal of waste.

Permitting: Regulators may issue permits for mining operations and require compliance with waste management regulations as a condition of the permit.

Inspection and enforcement: Regulators may conduct inspections of mining operations to ensure compliance with waste management regulations. They may also take enforcement action, such as issuing fines or revoking permits, for non-compliance.

Monitoring: Regulators may monitor mining operations to ensure compliance with waste management regulations and to assess the environmental and public health impacts of waste management activities.

Emergency response: Regulators may have a role in responding to emergencies related to mine waste management, such as spills or other releases of waste.

Overall, the role of regulators is to ensure that mining operations manage their waste in a safe and responsible manner, with the goal of minimizing environmental and public health impacts.

INSPECTIONS AND RECORDS

Inspection reports: These are reports that document the results of inspections of waste management facilities, such as tailings dams, waste rock dumps, and leach pads. These reports should include information on the condition of the facility, any deficiencies or non-compliances identified, and any corrective actions taken.

Waste disposal records: These records document the types and quantities of waste generated, as well as the methods and locations of disposal. This information is important for tracking the amount and types of waste generated by mining operations, as well as for ensuring that waste is being disposed of in a safe and responsible manner.

Water quality monitoring data: These records document the results of water quality monitoring programs, which are designed to assess the impacts of mining activities on surface and groundwater quality. These records should include information on the parameters tested, the sampling locations, and the results of the monitoring.

Environmental monitoring data: These records document the results of environmental monitoring programs, which are designed to assess the impacts of mining activities on air quality, wildlife, vegetation, and other environmental factors. These records should include information on the parameters tested, the sampling locations, and the results of the monitoring.

Permitting and compliance documents: These documents include permits, plans, and reports related to mine waste management, such as environmental impact assessments, waste management plans, and compliance reports. These documents demonstrate that the mining operation is complying with regulatory requirements and that waste is being managed in a safe and responsible manner.

Overall, inspections and records are an important part of a mine waste management system and can help ensure that waste is being managed in a safe and responsible manner.

A TYPICAL OPERATIONAL PROCEDURE SHOULD INCLUDE:

The operational procedure for mine waste management can vary depending on the specific mine and the type of waste being generated. However, a typical operational procedure for mine waste management might include the following steps:

Waste characterization: Before developing a waste management plan, it is important to characterize the waste generated by the mine. This may involve analyzing the chemical and physical properties of the waste, as well as determining the volume and rate of production.

Waste minimization: Once the waste has been characterized, efforts can be made to minimize its generation. This may involve reducing the amount of waste generated by improving processes, reusing materials where possible, or recycling waste materials.

Waste storage and handling: Waste must be stored and handled appropriately to prevent contamination of soil and groundwater. This may involve using lined pits or tanks to contain the waste, or constructing tailings dams to store tailings.

Monitoring and reporting: To ensure that waste management practices are effective and compliant with regulations, monitoring and reporting must be conducted regularly. This may involve regular sampling and analysis of soil and groundwater, as well as reporting on waste volumes and disposal methods.

Closure and remediation: When mining operations are completed, it is important to properly close and remediate the waste storage and handling areas. This may involve removing contaminated soil or waste, installing barriers to prevent further contamination, or restoring the site to its original condition.

Overall, effective mine waste management requires careful planning, implementation, and monitoring to minimize environmental and social impacts and ensure compliance with regulations.

WHAT ARE THE RISKS?

There are a number of risks associated with mine waste management systems, including:

Environmental risks: Mine waste can contain toxic chemicals and heavy metals that can contaminate soil and groundwater, and harm aquatic ecosystems. Improper waste storage or disposal can result in soil and water contamination, leading to long-term environmental damage.

Health risks: Exposure to mine waste can pose health risks to workers and nearby communities. This may include respiratory problems, skin irritation, and other health impacts associated with exposure to toxic chemicals and heavy metals.

Safety risks: Tailings dams and other waste storage facilities can pose safety risks if they fail or collapse. Dam failures have the potential to cause significant damage to property, infrastructure, and human life.

Reputational risks: Poor waste management practices can damage a mining company's reputation and lead to negative publicity. This can have financial implications for the company, as investors and customers may be hesitant to do business with an operator with a poor environmental track record.

Regulatory risks: Failure to comply with waste management regulations can result in fines, legal action, and other penalties. In extreme cases, regulatory violations can result in the suspension or revocation of a mining permit, effectively shutting down the operation.

To minimize these risks, mining companies must implement robust waste management systems that prioritize environmental protection, worker and community health, and regulatory compliance. This requires careful planning, ongoing monitoring, and continuous improvement of waste management practices.

RECOMMENDED INSPECTIONS

The specific inspections required for a mine waste management system will vary depending on the type of waste being managed, the location of the mine, and the regulatory requirements in place. However, some recommended inspections for a mine waste management system may include:

Visual inspections: Regular visual inspections of waste storage facilities, such as tailings dams and waste rock dumps, can help identify signs of potential problems such as cracks, erosion, and other damage.

Instrumentation inspections: Monitoring instrumentation, such as piezometers and inclinometers, can be used to detect changes in water levels or ground movement that may indicate potential dam or slope instability.

Water quality sampling: Regular water quality sampling from nearby water bodies can help detect potential contamination from mine waste. This sampling can also help identify any changes in water quality over time.

Groundwater monitoring: Monitoring of groundwater levels and quality can help detect potential contamination from mine waste, particularly in areas where groundwater resources are used for drinking water or irrigation.

Structural inspections: Regular inspections of mine waste storage structures, such as tailings dams and waste rock dumps, can help ensure that they are structurally sound and capable of safely storing waste.

Emergency response drills: Regular emergency response drills can help ensure that mine staff are prepared to respond quickly and effectively in the event of a mine waste management emergency, such as a tailings dam failure.

These inspections should be conducted by trained personnel and documented in a formal record-keeping system. Any issues identified during inspections should be addressed promptly to minimize the risk of damage or harm.

FREQUENCY OF INSPECTIONS

Daily inspections: Some components of the mine waste management system, such as pumps, valves, and other mechanical equipment, may require daily inspections to ensure proper functioning.

Weekly inspections: Weekly inspections may be appropriate for some aspects of the mine waste management system, such as checking for signs of erosion or cracks in tailings dams and waste rock dumps.

Monthly inspections: Monthly inspections may be appropriate for some components of the mine waste management system, such as monitoring instrumentation and water quality sampling. Quarterly inspections:

Quarterly inspections may be appropriate for some components of the mine waste management system, such as groundwater monitoring and structural inspections.

Annual inspections: Annual inspections may be appropriate for some aspects of the mine waste management system, such as emergency response drills and comprehensive assessments of the entire waste management system.

It's important to note that the frequency of inspections should be determined based on the specific characteristics of the mine waste management system and any regulatory requirements that may be in place.

A Risk management program should include the following:

A risk management program for mine waste management should include the following components:

Risk assessment: Conduct a comprehensive assessment of potential risks associated with the mine waste management system, including identification of hazards, evaluation of the likelihood and potential impact of each hazard, and prioritization of risks based on severity.

Risk mitigation measures: Develop and implement measures to mitigate identified risks, such as engineering controls, administrative controls, and personal protective equipment.

Emergency response plan: Develop and implement an emergency response plan that outlines the steps to be taken in the event of an emergency or incident, such as a dam failure or spill.

Monitoring and reporting: Establish a system for monitoring and reporting on the performance of the mine waste management system, including regular inspections and evaluations of equipment and infrastructure, as well as ongoing monitoring of environmental and social impacts.

Training and education: Provide training and education to all personnel involved in the mine waste management system, including operators, supervisors, and management, to ensure that they have the knowledge and skills necessary to identify and respond to potential risks.

Stakeholder engagement: Engage with stakeholders, including local communities, regulatory agencies, and other interested parties, to ensure that their concerns and perspectives are taken into account in the development and implementation of the risk management program.

Continuous improvement: Establish a process for continuous improvement of the risk management program, including regular evaluations of performance and effectiveness, identification of areas for improvement, and implementation of corrective actions as needed.

Overall, a risk management program for mine waste management should be designed to ensure the safe and responsible management of mine waste, while also minimizing potential risks and impacts to the environment and local communities.

Primary cause of Dam Failures Recent study

The primary cause of dam failures in mining operations is often related to issues of stability and structural integrity. One common issue is related to the compaction and stabilization of waste materials.

When waste materials are not properly compacted and stabilized, they can become unstable over time, which can lead to liquefaction and subsequent failure of the dam.

For example, in 2019, a mining waste dam in Brazil failed, leading to a catastrophic collapse that killed over 270 people. The dam was built with a design that was not able to withstand the weight of the waste materials, which caused the dam to fail due to instability and liquefaction.

Another issue that can contribute to the failure of a mine waste dam is improper design or construction. This can occur when the dam is not designed with proper safety factors, or when construction is not carried out to the required standards.

Inadequate maintenance and monitoring can also contribute to the failure of a dam, as problems may go unnoticed or unaddressed until they become critical.

For example, in 2014, a mining waste dam in British Columbia, Canada, failed due to a design flaw that was not detected during construction. The dam was built with a slope that was steeper than recommended, which caused it to fail under the weight of the waste materials.

The failure resulted in the release of millions of cubic meters of waste materials into nearby waterways. In conclusion, the primary cause of dam failures in mining operations is often related to stability and structural integrity issues.

Proper compaction and stabilization of waste materials, appropriate design and construction, and adequate maintenance and monitoring are all critical factors in ensuring the safety and stability of a mine waste dam.

Mine waste management systems

Tailings and waste rock

Sludge

Covers and reclamation

Acid mine drainage

Environmental desulphurization

Properties of minerals

Measurement of hydrological and geophysical characteristics

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you, your article surprised me, there is such an excellent point of view. Thank you for sharing, I learned a lot.

Thank you for your feedback. Its really appreciated.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thank you for your kmd words, You are most welcome

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

hi!,I love your writing very so much! proportion we keep in touch extra approximately your article on AOL? I need an expert on this area to unravel my problem. May be that is you! Taking a look ahead to peer you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Your article helped me a lot, is there any more related content? Thanks!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.info/register?ref=P9L9FQKY

You produced some decent points there. I looked online for the problem and located most individuals goes in conjunction with with the site.

Your article helped me a lot, is there any more related content? Thanks!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.com/en-IN/register-person?ref=UM6SMJM3

Your article helped me a lot, is there any more related content? Thanks!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Hi, I think your website might be having browser compatibility issues. When I look at your website in Firefox, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, great blog!

YouJizz You’re wonderful! I don’t think I’ve encountered anything quite like this before. It’s refreshing to find someone with original takes on this subject. Truly, thank you for setting this up. This website is just what the internet needs – originality!

Write more, thats all I have to say. Literally, it seems as though you relied on the video to make your point. You definitely know what youre talking about, why waste your intelligence on just posting videos to your weblog when you could be giving us something informative to read?

I am not sure where you’re getting your information, but good topic. I needs to spend some time learning more or understanding more. Thanks for excellent information I was looking for this information for my mission.

After research a couple of of the weblog posts in your website now, and I actually like your means of blogging. I bookmarked it to my bookmark website checklist and will likely be checking back soon. Pls try my site as well and let me know what you think.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://accounts.binance.com/uk-UA/register?ref=W0BCQMF1

Having read this I thought it was very informative. I appreciate you taking the time and effort to put this article together. I once again find myself spending way to much time both reading and commenting. But so what, it was still worth it!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.com/kz/register?ref=RQUR4BEO

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.com/hu/register?ref=FIHEGIZ8

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Hmm is anyone else having problems with the images on this blog loading? I’m trying to find out if its a problem on my end or if it’s the blog. Any feed-back would be greatly appreciated.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Having read your blog, you obviously know what you are talking about. I’m sure visiting my page Webemail24 about Data Mining will be worth your time!

Thank you

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.