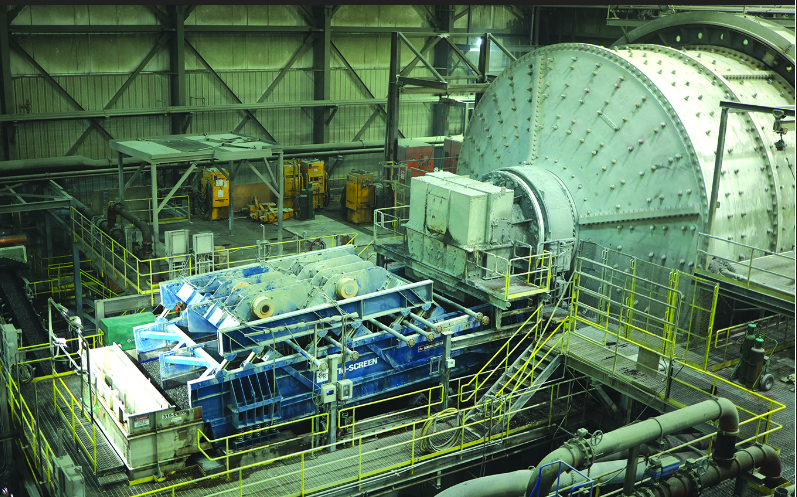

Introduction: Screening in Mineral Processing. How to maximize performance?

Here are key strategies:

### 1. **Select the Right Equipment**

- **Screen Type:**

Choose between vibrating screens, grizzly screens, trommel screens, and others based on material characteristics and processing needs.

- **Screen Surface:**

Select appropriate screen media (e.g., woven wire mesh, polyurethane, rubber) considering factors like abrasiveness, moisture content, and required separation size.

### 2. **Optimize Operating Parameters**

- **Screen Angle:** Adjust the angle to balance between capacity and efficiency. Steeper angles can increase capacity but may reduce efficiency.

- **Vibration Frequency and Amplitude:**

Optimize these settings to ensure adequate movement of material without causing blinding or pegging.

- **Feed Rate:** Control the rate to prevent overloading and ensure uniform distribution across the screen.

### 3. **Improve Screening Efficiency**

- **Uniform Feed:**

Ensure material is evenly distributed to avoid overloading sections of the screen and to improve separation.

- **Pre-screening:**

Use a pre-screen to remove fines before the main screening process, reducing the load and improving efficiency.

- **Screen Deck Configuration:**

Use multiple decks with progressively finer screens to achieve desired separation in stages.

### 4. **Regular Maintenance**

- **Inspect and Clean Screens:**

Regularly check for wear, damage, and blinding. Clean screens to prevent clogging and maintain open area.

- **Replace Worn Parts:**

Timely replacement of worn screen media, springs, and other components to maintain performance.

- **Lubrication and Alignment:**

Ensure proper lubrication of bearings and alignment of the screen to prevent mechanical failures.

### 5. **Process Control and Monitoring**

- **Real-time Monitoring:**

Use sensors and control systems to monitor parameters like vibration, screen load, and particle size distribution.

- **Data Analysis:**

Analyze performance data to identify trends and make adjustments to the process.

### 6. **Improve Material Characteristics**

- **Moisture Control:**

Manage moisture content of the feed to prevent blinding and ensure efficient screening.

- **Particle Size Distribution:**

Crush or grind material to ensure a more uniform size distribution for more effective screening.

### 7. **Training and Safety**

- **Operator Training:**

Ensure operators are well-trained in the operation and maintenance of screening equipment.

- **Safety Measures:**

Implement and follow safety protocols to protect workers and equipment.

### Summary

To maximize performance in screening within mineral processing, focus on selecting the right equipment, optimizing operational parameters, maintaining the equipment, employing effective process control and monitoring, managing material characteristics, and ensuring proper training and safety measures. Each aspect plays a crucial role in improving the overall efficiency and effectiveness of the screening process.

Select the Right Equipment for Screening in Mineral Processing

Choosing the right screening equipment is crucial for maximizing performance in mineral processing.

Here, we delve into the details of screen types and screen surfaces, ensuring optimal selection based on material characteristics and processing needs.

#### Screen Types

1. **Vibrating Screens**

- **Application:**

Suitable for a wide range of applications including coal, iron ore, gold, copper, and more.

- **Advantages:**

High capacity, effective separation, adjustable amplitude and frequency.

- **Considerations:**

Ensure proper maintenance to avoid mechanical issues, suitable for both wet and dry materials.

2. **Grizzly Screens**

- **Application:**

Primarily used for primary screening and heavy-duty scalping, such as removing fines from the feed before primary crushing.

- **Advantages:**

Robust design, handles large feed sizes, excellent for coarse materials.

- **Considerations:**

Limited precision in separation, often used in the first stage of the screening process.

3. **Trommel Screens**

- **Application:**

Effective for screening materials with varying moisture content, commonly used in gold mining, waste management, and composting.

- **Advantages:**

Good for wet and sticky materials, simple operation, and low maintenance.

- **Considerations:**

Lower capacity compared to vibrating screens, potential for clogging with certain materials.

4. **Banana Screens**

- **Application:**

Used for high-capacity screening with varying feed rates and multiple deck angles.

- **Advantages:**

High throughput, efficient separation, ideal for fine particle sizes.

- **Considerations:**

More complex design, higher initial cost, requires precise maintenance.

5. **High-Frequency Screens**

- **Application:**

Suitable for fine material separation, often used in silica sand, mineral sands, and iron ore.

- **Advantages:** Efficient for fine particle separation, high capacity, low operating cost.

- **Considerations:** Sensitive to feed rate changes, requires precise control and maintenance.

#### Screen Surfaces

1. **Woven Wire Mesh**

- **Application:** Widely used in mineral processing for various particle sizes.

- **Advantages:** High open area, good precision in separation, versatile.

- **Considerations:** Susceptible to wear and tear, not ideal for highly abrasive materials.

2. **Polyurethane**

- **Application:** Suitable for wet and dry applications, used in coal, iron ore, and other mineral processing operations.

- **Advantages:** High wear resistance, flexible, reduces blinding and pegging.

- **Considerations:** Higher initial cost compared to wire mesh, lower open area.

3. **Rubber**

- **Application:** Ideal for high-impact and abrasive applications, such as primary screening.

- **Advantages:** Excellent wear resistance, noise reduction, suitable for heavy-duty applications.

- **Considerations:** Lower open area, heavier than other screen surfaces.

4. **Perforated Plate**

- **Application:** Used in heavy-duty applications where precision is not critical, such as primary scalping.

- **Advantages:** Durable, handles large feed sizes, good impact resistance.

- **Considerations:** Limited precision in separation, lower open area.

5. **Self-Cleaning Screens**

- **Application:** Used to prevent blinding and pegging in applications with difficult-to-screen materials.

- **Advantages:** Reduces downtime, maintains high efficiency, suitable for moist and sticky materials.

- **Considerations:** More complex design, potentially higher cost.

### Key Considerations for Selection

- **Material Characteristics:** Assess the abrasiveness, moisture content, and particle size distribution of the material.

- **Capacity Requirements:** Determine the throughput needed to meet production targets.

- **Separation Efficiency:** Consider the desired precision of separation and particle size cut-off.

- **Operational Environment:** Take into account the conditions, such as whether the operation is wet or dry, and the presence of corrosive elements.

- **Maintenance and Lifespan:** Evaluate the ease of maintenance, availability of replacement parts, and the expected lifespan of the screen and surface materials.

### Conclusion

Selecting the right screening equipment involves balancing several factors, including material characteristics, processing needs, and operational considerations. By carefully choosing the appropriate screen type and surface, you can enhance the efficiency, capacity, and overall performance of your mineral processing operations.

Key Considerations for Selecting Screening Equipment

Choosing the right screening equipment for mineral processing requires a comprehensive understanding of several critical factors. Each consideration can significantly impact the efficiency, capacity, and longevity of the screening process.

Here’s a detailed look at these key considerations:

#### 1. **Material Characteristics**

- **Abrasiveness:** Materials with high abrasiveness, such as silica or iron ore, require screen surfaces that can withstand wear, like polyurethane or rubber. Less abrasive materials might be suited to woven wire mesh.

- **Moisture Content:** Wet and sticky materials can cause blinding and pegging. Trommel screens or screens with self-cleaning surfaces can help manage such materials.

- **Particle Size Distribution:** The range of particle sizes in the feed impacts the choice of screen type and deck configuration. Fine materials may need high-frequency screens, while larger particles might be better suited to grizzly screens.

#### 2. **Capacity Requirements**

- **Throughput:** Determine the volume of material that needs to be processed per hour. High-capacity needs might necessitate the use of banana screens or vibrating screens with multiple decks to handle larger loads effectively.

- **Feed Rate:** Ensure that the equipment can handle the anticipated feed rate without overloading, which can cause inefficiency and wear.

#### 3. **Separation Efficiency**

- **Precision of Separation:** The required cut-off size for particle separation will guide the choice of screen aperture and type. For precise separation, high-frequency screens or fine mesh woven wire might be necessary.

- **Desired Product Quality:** The quality and consistency of the final product are directly related to the efficiency of the screening process. Ensuring uniform feed distribution and selecting appropriate screen types are crucial.

#### 4. **Operational Environment**

- **Wet or Dry Operation:** Different screens perform better in wet versus dry conditions. For example, trommel screens are well-suited for wet materials, while vibrating screens can handle both.

- **Corrosive Elements:** If the operation environment contains corrosive substances, screens made from corrosion-resistant materials, such as stainless steel or specially coated surfaces, should be considered.

- **Temperature Extremes:** Some materials might become brittle or more pliable under extreme temperatures, affecting the choice of screen surface.

#### 5. **Maintenance and Lifespan**

- **Ease of Maintenance:** Consider screens that are easy to clean and maintain, reducing downtime. For instance, self-cleaning screens can minimize the need for frequent cleaning.

- **Availability of Replacement Parts:** Ensure that spare parts are readily available to avoid prolonged downtime. Screens with standardized components may offer easier replacement options.

- **Expected Lifespan:** The durability of the screen surface and the overall equipment should match the operational demands. High-wear applications might benefit from surfaces like rubber or polyurethane that offer extended lifespans.

### Summary

When selecting screening equipment, a thorough assessment of material characteristics, capacity requirements, separation efficiency, operational environment, and maintenance needs is essential. Each factor interplays with the others, and the optimal choice will often involve compromises to balance these considerations. Ensuring the right match between these factors and the chosen equipment will lead to improved performance, efficiency, and longevity of the screening operation in mineral processing.

Material Characteristics in Screening Equipment Selection

When selecting screening equipment for mineral processing, understanding the material characteristics is paramount.

Here’s a detailed breakdown of how abrasiveness, moisture content, and particle size distribution affect the choice of screening equipment:

#### 1. **Abrasiveness**

- **High Abrasiveness:**

- **Examples:** Silica, iron ore, and other hard minerals.

- **Recommended Screen Surfaces:**

- **Polyurethane:** Offers high wear resistance and flexibility, making it suitable for abrasive materials. It reduces maintenance frequency and extends the lifespan of the screen.

- **Rubber:** Excellent for handling high-impact and abrasive materials due to its durability and impact resistance.

- **Considerations:** Ensure that the screen surface is thick enough to withstand continuous abrasion. Regular inspections and timely replacement of worn parts are crucial to maintain efficiency.

- **Low Abrasiveness:**

- **Examples:** Limestone, gypsum, and other softer minerals.

- **Recommended Screen Surfaces:**

- **Woven Wire Mesh:** Provides a high open area for efficient screening and is suitable for materials with lower abrasiveness.

- **Perforated Plate:** Can also be used if the particle sizes are relatively large and the abrasiveness is minimal.

- **Considerations:** Woven wire mesh needs to be regularly inspected for wear and tear, as it is less durable compared to polyurethane or rubber.

#### 2. **Moisture Content**

- **High Moisture Content:**

- **Challenges:** Wet and sticky materials can cause blinding (when particles clog the screen openings) and pegging (when particles become wedged in the screen).

- **Recommended Screen Types:**

- **Trommel Screens:** Effective for handling wet and sticky materials due to their rotating drum design, which helps prevent clogging.

- **Self-Cleaning Screens:** These screens have a special design that reduces blinding and pegging, maintaining efficiency even with high-moisture materials.

- **Vibrating Screens with Spray Bars:** Incorporating water spray bars can help wash material and reduce clogging.

- **Considerations:** Ensure proper water management and drainage to prevent pooling and maximize screening efficiency.

- **Low Moisture Content:**

- **Recommended Screen Types:**

- **Vibrating Screens:** Efficient for dry materials, providing high capacity and effective separation.

- **Grizzly Screens:** Suitable for coarse, dry materials that need primary screening before further processing.

- **Considerations:** Regular cleaning to prevent dust buildup and ensure that dry materials are uniformly fed to the screen.

#### 3. **Particle Size Distribution**

- **Fine Materials:**

- **Examples:** Silica sand, fine coal, and mineral sands.

- **Recommended Screen Types:**

- **High-Frequency Screens:** Ideal for fine particle separation, providing precise cuts and high capacity for fine materials.

- **Woven Wire Mesh:** Fine mesh sizes can effectively separate fine particles.

- **Considerations:** Ensure that the screen is designed to handle fine particles without blinding. Regular monitoring and maintenance are needed to maintain efficiency.

- **Coarse Materials:**

- **Examples:** Large rocks, boulders, and primary crushed ore.

- **Recommended Screen Types:**

- **Grizzly Screens:** Effective for primary screening and removing large fines.

- **Vibrating Screens with Larger Apertures:** Suitable for handling coarse particles and providing effective separation.

- **Considerations:** The screen structure must be robust to handle the weight and impact of large particles. Regular inspection for damage is crucial to prevent breakdowns.

- **Wide Range of Particle Sizes:**

- **Recommended Screen Types:**

- **Multi-Deck Vibrating Screens:** Allow for the separation of a wide range of particle sizes in stages, using different deck configurations.

- **Banana Screens:** Designed with multiple angles to handle varying particle sizes and provide high capacity.

- **Considerations:** Ensure uniform feed distribution to maximize efficiency and prevent overloading specific sections of the screen.

### Summary

Choosing the right screening equipment based on material characteristics involves a detailed understanding of abrasiveness, moisture content, and particle size distribution. By matching the appropriate screen type and surface to these characteristics, you can enhance the efficiency, capacity, and longevity of the screening process in mineral processing. Regular maintenance and monitoring are essential to address any issues promptly and maintain optimal performance.

Capacity Requirements in Screening Equipment Selection

When selecting screening equipment for mineral processing, understanding and meeting capacity requirements is critical to ensure efficiency and productivity.

Here’s a detailed guide on how throughput and feed rate affect the choice of screening equipment:

#### 1. **Throughput**

- **Definition:** Throughput refers to the volume of material that needs to be processed per hour. It’s a key factor in determining the size and type of screening equipment.

- **High-Capacity Needs:**

- **Recommended Screen Types:**

- **Banana Screens:** Designed for high-capacity screening with a unique multi-slope design that increases throughput. Suitable for applications requiring large volumes of material to be processed.

- **Multi-Deck Vibrating Screens:** These screens use multiple decks to separate materials into various size fractions in a single pass, thus handling larger loads efficiently.

- **Trommel Screens:** Suitable for high-capacity applications, particularly with wet or sticky materials. They provide large screening areas and can handle significant material volumes.

- **Considerations:** Ensure the screen is robust enough to handle the high capacity without compromising on separation efficiency. The screen size, aperture, and design must be chosen to match the desired throughput.

- **Low to Moderate Capacity Needs:**

- **Recommended Screen Types:**

- **Single-Deck Vibrating Screens:** Effective for lower throughput applications where precise separation is required.

- **Grizzly Screens:** Suitable for primary screening with lower throughput, particularly for removing large fines before further processing.

- **Considerations:** Ensure that the screen capacity matches the processing requirements to avoid unnecessary energy consumption and wear.

#### 2. **Feed Rate**

- **Definition:** The feed rate is the rate at which material is fed into the screening equipment. It must be consistent and appropriate for the selected screen to maintain efficiency and prevent overloading.

- **High Feed Rate:**

- **Recommended Screen Types:**

- **Vibrating Screens with Adjustable Frequency and Amplitude:

** These screens can be adjusted to handle varying feed rates efficiently, ensuring consistent performance.

- **Banana Screens:** With their multi-slope design, they can handle high feed rates by distributing the load evenly across the screen.

- **Considerations:** Ensure that the feed rate does not exceed the screen’s capacity. Proper feed distribution systems, such as feeders or spreaders, can help manage high feed rates and prevent localized overloading.

- **Low to Moderate Feed Rate:**

- **Recommended Screen Types:**

- **Single-Deck Vibrating Screens:** Suitable for applications with lower feed rates, providing precise separation without overloading.

- **Grizzly Screens:** Effective for handling moderate feed rates in primary screening applications.

- **Considerations:** Even with lower feed rates, maintaining a consistent flow is crucial for efficient screening. Avoid sudden surges or drops in feed rate that could affect screen performance.

### Key Considerations for Capacity Requirements

1. **Material Volume:** Accurately estimate the volume of material to be processed per hour to select a screen with appropriate capacity.

2. **Feed Rate Management:** Implement systems to ensure a consistent feed rate, preventing surges that can overload the screen and reduce efficiency.

3. **Screen Size and Design:** Larger screens with multiple decks or unique designs like banana screens can handle higher capacities and feed rates more effectively.

4. **Operational Flexibility:** Choose screens that offer adjustable settings (e.g., frequency, amplitude) to adapt to varying feed rates and material characteristics.

5. **Maintenance and Monitoring:** Regularly monitor screen performance to ensure it is handling the feed rate and throughput efficiently. Address any signs of wear or inefficiency promptly to avoid operational disruptions.

### Summary

Understanding throughput and feed rate requirements is essential for selecting the right screening equipment. High-capacity needs may require robust and flexible screens like banana screens or multi-deck vibrating screens. Consistent and appropriate feed rates are crucial to maintaining screening efficiency and preventing equipment overload. By carefully matching screen capabilities to capacity requirements, you can optimize the performance and longevity of your screening process in mineral processing.

Key Considerations for Capacity Requirements in Screening Equipment Selection

Selection

To maximize performance in mineral processing, it's essential to consider capacity requirements carefully. This involves evaluating material volume, feed rate management, screen size and design, operational flexibility, and maintenance and monitoring practices.

Here’s an in-depth look at these key considerations:

#### 1. **Material Volume**

- **Accurate Estimation:** Determine the volume of material that needs to be processed per hour. This helps in selecting a screen with the right capacity.

- **Considerations:**

- Overestimating can lead to unnecessarily large and costly equipment.

- Underestimating can result in frequent overloading and reduced efficiency.

#### 2. **Feed Rate Management**

- **Consistent Feed Rate:** Implement systems like feeders or spreaders to ensure a consistent feed rate. Consistency helps prevent surges that can overload the screen and reduce efficiency.

- **Considerations:**

- Use vibrating feeders or conveyor belts to control the feed rate.

- Avoid sudden surges or drops in feed rate that could impact screen performance.

#### 3. **Screen Size and Design**

- **Larger Screens:** Larger screens can handle higher capacities and are often designed with multiple decks to improve separation efficiency.

- **Unique Designs:**

- **Banana Screens:** With their multi-slope design, they distribute material evenly across the screen, handling higher capacities and feed rates effectively.

- **Multi-Deck Vibrating Screens:** Allow for separation of materials into various size fractions, increasing throughput.

- **Considerations:**

- Ensure the screen design matches the material characteristics and operational needs.

- Larger screens require more space and might need more robust structural support.

#### 4. **Operational Flexibility**

- **Adjustable Settings:** Choose screens with adjustable settings, such as frequency and amplitude, to adapt to varying feed rates and material characteristics.

- **Considerations:**

- Ability to fine-tune the screen settings can optimize performance for different materials and conditions.

- Flexibility helps in handling variations in material properties and operational demands.

#### 5. **Maintenance and Monitoring**

- **Regular Monitoring:** Continuously monitor screen performance to ensure it is handling the feed rate and throughput efficiently. Look for signs of wear, inefficiency, or overloading.

- **Proactive Maintenance:**

- Schedule regular maintenance to check for wear and tear, especially in high-capacity operations.

- Replace worn parts promptly to prevent unexpected downtimes and maintain efficiency.

- **Considerations:**

- Use automated monitoring systems to track performance metrics and detect issues early.

- Regularly clean screens to prevent clogging and ensure optimal performance.

### Summary

To ensure optimal performance in screening within mineral processing, it is crucial to address the following key capacity requirements:

1. **Material Volume:** Estimate accurately to choose the right screen capacity.

2. **Feed Rate Management:** Implement systems for consistent feed rates to prevent overloading.

3. **Screen Size and Design:** Opt for larger screens or unique designs like banana screens to handle high capacities.

4. **Operational Flexibility:** Select screens with adjustable settings to adapt to changing feed rates and material characteristics.

5. **Maintenance and Monitoring:** Regularly monitor and maintain screens to ensure efficient performance and longevity.

By carefully considering these factors, you can select the most suitable screening equipment to enhance efficiency, capacity, and overall performance in mineral processing.

Key Considerations for Separation Efficiency in Screening Equipment Selection

Achieving high separation efficiency is crucial in mineral processing to ensure the quality and consistency of the final product.

Here’s a detailed look at how to enhance separation efficiency by focusing on the precision of separation and desired product quality:

#### 1. **Precision of Separation**

- **Required Cut-off Size:**

- The desired particle size for separation determines the choice of screen aperture and type.

- For precise separation, screens with smaller apertures or fine mesh woven wire are typically used.

- **Recommended Screen Types for Precision:**

- **High-Frequency Screens:** These screens operate at high frequencies, which help in achieving precise separations for fine materials.

- **Fine Mesh Woven Wire Screens:** Provide high precision due to small aperture sizes, suitable for separating fine particles.

- **Polyurethane Screens with Small Apertures:** Durable and precise, these screens are suitable for fine particle separation in abrasive environments.

- **Considerations:**

- **Screen Aperture Size:** Match the screen aperture size to the required cut-off size to ensure accurate separation.

- **Material Characteristics:** Consider the material's characteristics, such as density and shape, which can affect the separation efficiency.

#### 2. **Desired Product Quality**

- **Quality and Consistency:** The quality and consistency of the final product depend on efficient separation, ensuring that the desired particle size distribution is achieved.

- **Uniform Feed Distribution:**

- Ensure that material is evenly distributed across the screen width to prevent overloading and ensure consistent separation.

- Use feeders or spreaders to achieve uniform feed distribution.

- **Recommended Screen Types for Quality:**

- **Vibrating Screens with Multiple Decks:** These screens can handle different size fractions on each deck, improving the quality and consistency of the final product.

- **Banana Screens:** With their multi-slope design, they provide efficient separation and high capacity, enhancing product quality.

- **Considerations:**

- **Screen Type and Design:** Select the appropriate screen type and design to match the material characteristics and desired product quality.

- **Maintenance:** Regularly maintain and clean the screens to prevent clogging and ensure consistent performance.

- **Process Control:** Implement process control systems to monitor and adjust the screening process in real-time, ensuring optimal separation efficiency.

### Summary

To achieve high separation efficiency in mineral processing, focus on the following key considerations:

1. **Precision of Separation:**

- Determine the required cut-off size for particle separation and choose the appropriate screen aperture and type.

- Use high-frequency screens or fine mesh woven wire for precise separation.

2. **Desired Product Quality:**

- Ensure uniform feed distribution to prevent overloading and achieve consistent separation.

- Select screen types that match the material characteristics and desired product quality, such as multi-deck vibrating screens or banana screens.

- Implement process control and regular maintenance to maintain consistent performance and high-quality output.

By carefully considering these factors, you can optimize separation efficiency, enhancing the quality and consistency of the final product in mineral processing.

Key Considerations for the Operational Environment in Screening Equipment Selection

The operational environment plays a significant role in determining the suitability and performance of screening equipment.

Factors such as whether the operation is wet or dry, the presence of corrosive elements, and temperature extremes must be carefully considered.

Here’s a detailed look at these considerations:

#### 1. **Wet or Dry Operation**

- **Wet Operation:**

- **Challenges:** Wet materials can cause blinding (clogging of screen apertures) and require equipment that can handle moisture without compromising efficiency.

- **Recommended Screen Types:**

- **Trommel Screens:** Well-suited for wet materials due to their rotating drum design, which helps prevent clogging and improves material flow.

- **Vibrating Screens with Spray Bars:** Spray bars can help wash material, reducing blinding and improving separation efficiency.

- **Self-Cleaning Screens:** Designed to prevent clogging and maintain efficiency even with wet and sticky materials.

- **Considerations:** Ensure proper water management and drainage to prevent pooling and maximize screening efficiency.

- **Dry Operation:**

- **Challenges:** Dry materials can generate dust and may require equipment that can handle fine particles without causing air pollution or equipment wear.

- **Recommended Screen Types:**

- **Vibrating Screens:** Effective for dry materials, providing high capacity and efficient separation.

- **Grizzly Screens:** Suitable for primary screening of dry, coarse materials, removing large fines before further processing.

- **Considerations:** Implement dust control measures, such as dust covers and extraction systems, to minimize air pollution and maintain a clean working environment.

#### 2. **Corrosive Elements**

- **Presence of Corrosive Substances:**

- **Challenges:** Corrosive environments can cause rapid deterioration of screening equipment, leading to frequent maintenance and reduced lifespan.

- **Recommended Screen Materials:**

- **Stainless Steel:** Offers excellent corrosion resistance and durability, suitable for environments with high levels of corrosive substances.

- **Specially Coated Surfaces:** Coatings such as epoxy or polyurethane can provide additional protection against corrosion.

- **Considerations:** Regularly inspect and maintain screens to check for signs of corrosion. Replace or re-coat surfaces as necessary to extend equipment life.

#### 3. **Temperature Extremes**

- **High Temperatures:**

- **Challenges:** High temperatures can cause materials to become more pliable, potentially affecting separation efficiency and screen performance.

- **Recommended Screen Materials:**

- **Heat-Resistant Alloys:** Materials designed to withstand high temperatures without losing structural integrity.

- **Ceramic Screens:** Can provide excellent heat resistance for extremely high-temperature applications.

- **Considerations:** Ensure that the screening equipment is designed to handle the thermal expansion and contraction associated with high temperatures.

- **Low Temperatures:**

- **Challenges:** Low temperatures can cause materials to become brittle, leading to potential damage or reduced screening efficiency.

- **Recommended Screen Materials:**

- **Rubber Screens:** Offer flexibility and impact resistance, maintaining performance in low temperatures.

- **Flexible Polyurethane Screens:** Provide durability and resistance to brittleness in cold conditions.

- **Considerations:** Use heating elements or enclosures to maintain a stable operating temperature and prevent material from becoming too brittle.

### Summary

To optimize the performance of screening equipment in mineral processing, consider the following key factors related to the operational environment:

1. **Wet or Dry Operation:**

- For wet operations, use trommel screens, vibrating screens with spray bars, or self-cleaning screens.

- For dry operations, use vibrating screens or grizzly screens, and implement dust control measures.

2. **Corrosive Elements:**

- Use screens made from corrosion-resistant materials like stainless steel or specially coated surfaces.

- Regularly inspect and maintain screens to prevent and address corrosion.

3. **Temperature Extremes:**

- For high temperatures, use heat-resistant alloys or ceramic screens.

- For low temperatures, use rubber or flexible polyurethane screens.

- Implement measures to stabilize operating temperatures as needed.

By carefully considering these factors, you can select the most suitable screening equipment for your specific operational environment, ensuring efficiency, longevity, and optimal performance in your mineral processing operations.

Key Considerations for Maintenance and Lifespan in Screening Equipment Selection

Effective maintenance and a long lifespan are critical for the efficiency and cost-effectiveness of screening operations in mineral processing.

Here are key considerations to ensure ease of maintenance, availability of replacement parts, and optimal lifespan:

#### 1. **Ease of Maintenance**

- **Importance:** Easy-to-maintain screens reduce downtime and maintenance costs, ensuring continuous operation and efficiency.

- **Recommended Features:**

- **Self-Cleaning Screens:** These minimize the need for frequent manual cleaning by preventing material build-up and blinding.

- **Modular Designs:** Screens with modular components are easier to disassemble, inspect, and repair.

- **Quick-Release Mechanisms:** Screens with quick-release mechanisms allow for faster removal and replacement of screen panels or parts.

- **Considerations:**

- **Accessibility:** Ensure that the screen is easily accessible for regular inspection and maintenance.

- **Training:** Provide adequate training for maintenance personnel to perform efficient and safe maintenance procedures.

#### 2. **Availability of Replacement Parts**

- **Importance:** Readily available replacement parts prevent prolonged downtime and ensure continuous operation.

- **Recommended Practices:**

- **Standardized Components:** Use screens with standardized components that are commonly available and interchangeable.

- **Supplier Reliability:** Choose suppliers with a proven track record for supplying high-quality parts promptly.

- **Inventory Management:** Maintain an inventory of critical spare parts to minimize downtime in case of part failure.

- **Considerations:**

- **Lead Times:** Be aware of lead times for ordering and receiving replacement parts to plan maintenance schedules effectively.

- **Local Availability:** Whenever possible, source parts locally to reduce shipping times and costs.

#### 3. **Expected Lifespan**

- **Importance:** The lifespan of the screen surface and overall equipment impacts long-term operational costs and efficiency.

- **Recommended Materials:**

- **Rubber Surfaces:** Provide excellent wear resistance and are suitable for high-wear applications, extending the lifespan of the screen.

- **Polyurethane Screens:** Offer durability and resistance to abrasion and impact, suitable for high-wear and abrasive environments.

- **Woven Wire Mesh:** Depending on the material and application, woven wire mesh can provide a good balance between cost and durability.

- **Considerations:**

- **Operational Demands:** Match the durability of the screen materials to the specific operational demands and material characteristics.

- **Regular Inspections:** Conduct regular inspections to detect early signs of wear and address them before they lead to equipment failure.

- **Lifecycle Cost Analysis:** Perform a lifecycle cost analysis to evaluate the total cost of ownership, considering both initial investment and maintenance costs over time.

### Summary

To maximize performance and efficiency in screening operations, careful attention must be given to maintenance and lifespan considerations:

1. **Ease of Maintenance:**

- Select screens that are easy to clean and maintain, such as self-cleaning screens and those with modular designs and quick-release mechanisms.

- Ensure accessibility for maintenance and provide proper training for maintenance personnel.

2. **Availability of Replacement Parts:**

- Use screens with standardized components and reliable suppliers to ensure parts are readily available.

- Maintain an inventory of critical spare parts and be aware of lead times for ordering parts.

3. **Expected Lifespan:**

- Choose screen materials that match the operational demands, such as rubber or polyurethane for high-wear applications.

- Conduct regular inspections and perform lifecycle cost analyses to balance initial costs with long-term maintenance expenses.

By addressing these factors, you can ensure the long-term efficiency, reliability, and cost-effectiveness of your screening equipment in mineral processing operations.

Key Considerations for Optimizing Operating Parameters in Screening Equipment

Optimizing the operating parameters of screening equipment is essential to balance capacity, efficiency, and longevity. Key parameters to adjust include screen angle, vibration frequency and amplitude, and feed rate.

Here’s how to optimize these factors effectively:

#### 1. **Screen Angle**

- **Importance:** The angle of the screen deck significantly impacts both the capacity and efficiency of the screening process.

- **Optimization Tips:**

- **Steeper Angles:**

- **Pros:** Increase material flow rate, enhancing capacity.

- **Cons:** Can reduce separation efficiency as materials pass through more quickly, potentially resulting in less precise separations.

- **Shallower Angles:**

- **Pros:** Improve separation efficiency by allowing more time for materials to be sorted according to size.

- **Cons:** Can reduce overall throughput as material flow rate decreases.

- **Recommendations:**

- **Adjustable Screens:** Utilize screens with adjustable angles to find the optimal balance between capacity and efficiency based on material characteristics.

- **Testing:** Conduct trials with different angles to determine the best configuration for your specific application.

#### 2. **Vibration Frequency and Amplitude**

- **Importance:** Proper vibration settings ensure adequate material movement, reducing the risk of blinding (clogging of the screen openings) and pegging (particles getting stuck in the screen openings).

- **Optimization Tips:**

- **Frequency:**

- **Higher Frequencies:** Effective for fine particles, providing faster vibrations that help in preventing clogging.

- **Lower Frequencies:** Better for larger particles, allowing them to stratify and pass through the screen openings.

- **Amplitude:**

- **Higher Amplitude:** Moves larger particles more effectively and helps in breaking up material clumps.

- **Lower Amplitude:** Suitable for finer particles to avoid excessive agitation that might cause blinding.

- **Recommendations:**

- **Adjustable Settings:** Use screens with adjustable frequency and amplitude to fine-tune the vibration based on material properties and desired separation.

- **Regular Monitoring:** Continuously monitor and adjust settings as needed to maintain optimal performance and address changes in material feed.

#### 3. **Feed Rate**

- **Importance:** The rate at which material is fed onto the screen affects both the capacity and efficiency of the screening process.

- **Optimization Tips:**

- **Uniform Distribution:** Ensure the feed is evenly distributed across the screen width to avoid overloading specific areas and ensure consistent separation.

- **Controlled Rate:**

- **High Feed Rates:** Increase capacity but may lead to overloading and reduced efficiency if the screen cannot handle the volume.

- **Moderate Feed Rates:** Provide a balance, ensuring efficient separation without overloading the screen.

- **Recommendations:**

- **Feeders and Spreaders:** Utilize mechanical feeders and spreaders to control and distribute the material feed rate evenly.

- **Monitoring Systems:** Implement real-time monitoring systems to adjust the feed rate dynamically based on screen performance and material flow.

### Summary

To maximize the performance of screening equipment in mineral processing, it is essential to optimize key operating parameters:

1. **Screen Angle:**

- Adjust the angle to balance between capacity and efficiency. Steeper angles increase capacity but may reduce separation efficiency.

- Use adjustable screens and conduct trials to find the optimal angle for your specific application.

2. **Vibration Frequency and Amplitude:**

- Optimize vibration settings to ensure adequate material movement without causing blinding or pegging.

- Adjust frequency and amplitude based on particle size and material characteristics, and use adjustable screens to fine-tune settings.

3. **Feed Rate:**

- Control the feed rate to prevent overloading and ensure uniform distribution across the screen.

- Utilize feeders and spreaders to maintain a consistent feed rate and implement monitoring systems for dynamic adjustments.

By carefully adjusting these operating parameters, you can enhance the capacity, efficiency, and longevity of your screening equipment, ensuring optimal performance in mineral processing operations.

Optimizing Screen Angle in Screening Equipment

The angle of the screen deck is a crucial parameter that affects both the capacity and efficiency of the screening process. Adjusting the screen angle can help find the balance between throughput and separation precision. Here’s a detailed look at its importance, optimization tips, and recommendations:

#### Importance of Screen Angle

- **Capacity Impact:** The screen angle determines how quickly materials flow over the screen surface. A steeper angle generally increases the flow rate, thereby enhancing capacity.

- **Efficiency Impact:** The efficiency of particle separation is influenced by the time particles spend on the screen. Shallower angles allow for more precise separation as materials have more time to be sorted according to size.

#### Optimization Tips for Screen Angle

**Steeper Angles:**

- **Pros:**

- Increase the material flow rate.

- Enhance capacity, allowing more material to be processed in less time.

- **Cons:**

- Can reduce separation efficiency.

- Materials pass through more quickly, potentially leading to less precise separations.

**Shallower Angles:**

- **Pros:**

- Improve separation efficiency.

- Allow more time for materials to be sorted according to size, resulting in more precise separations.

- **Cons:**

- Can reduce overall throughput.

- Material flow rate decreases, potentially limiting the amount of material processed.

#### Recommendations for Screen Angle Optimization

1. **Adjustable Screens:**

- **Utilization:** Use screens with adjustable angles to customize the screen deck inclination according to material characteristics and processing requirements.

- **Flexibility:** This flexibility allows operators to tweak settings to optimize performance dynamically as operational conditions change.

2. **Testing:**

- **Conduct Trials:** Perform tests with various angles to determine the best configuration for your specific application.

- **Data Analysis:** Collect and analyze data on throughput, separation efficiency, and material characteristics to make informed adjustments.

### Summary

Optimizing the screen angle is crucial for balancing capacity and efficiency in screening operations.

**Key Points to Remember:**

- **Steeper Angles:**

- Increase capacity but may compromise separation precision.

- **Shallower Angles:**

- Enhance separation efficiency but might reduce throughput.

- **Adjustable Screens and Testing:**

- Use adjustable screens to fine-tune angles.

- Conduct trials to identify the optimal angle for your specific needs.

By carefully adjusting the screen angle, you can improve both the capacity and efficiency of your screening process, leading to better overall performance in mineral processing operations.

Optimizing Vibration Frequency and Amplitude in Screening Equipment

Properly optimizing vibration frequency and amplitude is crucial for ensuring effective material movement, reducing clogging and pegging, and improving overall screening efficiency.

Here’s a detailed overview of the importance, optimization tips, and recommendations for managing these parameters:

#### Importance of Vibration Frequency and Amplitude

- **Frequency:** The speed at which the screen vibrates affects the movement of particles across the screen surface.

- **Amplitude:** The distance the screen travels with each vibration influences how materials are agitated and separated.

#### Optimization Tips for Vibration Frequency and Amplitude

**Frequency:**

- **Higher Frequencies:**

- **Pros:** Effective for fine particles, providing rapid vibrations that help prevent clogging.

- **Cons:** May not be suitable for larger particles as it could result in poor stratification.

- **Lower Frequencies:**

- **Pros:** Better for larger particles, allowing them to stratify and pass through screen openings.

- **Cons:** Might be less effective for fine particles, potentially leading to clogging.

**Amplitude:**

- **Higher Amplitude:**

- **Pros:** Moves larger particles more effectively and helps in breaking up material clumps.

- **Cons:** Excessive amplitude can cause finer particles to be excessively agitated, leading to blinding.

- **Lower Amplitude:**

- **Pros:** Suitable for finer particles, avoiding excessive agitation and reducing the risk of blinding.

- **Cons:** May not effectively move larger particles or break up clumps.

#### Recommendations for Optimizing Vibration Settings

1. **Adjustable Settings:**

- **Utilization:** Use screens with adjustable frequency and amplitude to customize vibration settings based on material properties and desired separation.

- **Flexibility:** Allows operators to dynamically adjust settings to optimize performance for different types of materials and operational conditions.

2. **Regular Monitoring:**

- **Continuous Monitoring:** Regularly monitor screen performance to ensure that vibration settings are optimal for the current material feed.

- **Adjust as Needed:** Make necessary adjustments based on real-time data to maintain efficiency and address any issues related to clogging, pegging, or material flow.

### Summary

Optimizing vibration frequency and amplitude is key to enhancing screening efficiency and preventing operational issues such as clogging and pegging.

**Key Points to Remember:**

- **Frequency:**

- **Higher Frequencies:** Effective for fine particles, preventing clogging.

- **Lower Frequencies:**

Better for larger particles, allowing proper stratification.

- **Amplitude:**

- **Higher Amplitude:** Effective for larger particles and breaking up clumps.

- **Lower Amplitude:** Suitable for finer particles, reducing the risk of blinding.

- **Adjustable Settings and Regular Monitoring:**

- Use screens with adjustable frequency and amplitude to fine-tune vibration settings.

- Continuously monitor and adjust settings based on material characteristics and real-time performance data.

By optimizing these vibration parameters, you can achieve more effective separation, reduce downtime due to maintenance issues, and enhance the overall performance of your screening operations.

Optimizing Feed Rate in Screening Equipment

Controlling the feed rate is essential to ensure uniform material distribution, prevent overloading, and maintain efficient screening operations.

Here’s how to manage feed rate effectively:

#### Importance of Feed Rate

- **Uniform Distribution:** Ensures that the material is evenly spread across the screen, enhancing separation efficiency.

- **Prevent Overloading:** Avoids excessive material on the screen, which can lead to reduced performance and increased wear.

#### Optimization Tips for Feed Rate

**1. Control the Feed Rate:**

- **Consistent Feed:** Maintain a steady flow of material to prevent surges that can overload the screen.

- **Uniform Distribution:** Ensure that material is distributed evenly across the entire width of the screen.

**2. Utilize Feeders and Spreaders:**

- **Feeders:** Use mechanical feeders to regulate the amount of material being fed onto the screen.

- **Examples:** Vibratory feeders, belt feeders, apron feeders.

- **Spreaders:** Implement spreaders to distribute the material evenly across the screen surface.

- **Examples:** Spreader conveyors, distribution chutes.

**3. Implement Monitoring Systems:**

- **Real-Time Monitoring:** Use sensors and control systems to monitor the feed rate continuously.

- **Dynamic Adjustments:** Adjust the feed rate dynamically based on real-time data to respond to changes in material flow and characteristics.

#### Recommendations for Optimizing Feed Rate

1. **Consistent and Controlled Feeding:**

- **Utilization:** Employ mechanical feeders to control the feed rate and ensure a steady flow of material onto the screen.

- **Advantages:** Helps maintain uniform distribution, preventing overloading and improving screening efficiency.

2. **Use of Spreaders:**

- **Utilization:** Implement spreaders to achieve even distribution of material across the screen surface.

- **Advantages:** Enhances separation efficiency by ensuring that the entire screen surface is utilized effectively.

3. **Monitoring and Dynamic Adjustments:**

- **Implementation:** Install monitoring systems to track the feed rate in real-time.

- **Advantages:** Enables dynamic adjustments to the feed rate, ensuring optimal performance and preventing operational issues.

### Summary

Optimizing the feed rate is crucial for maintaining efficient screening operations. Key points to consider include:

**1. Control the Feed Rate:**

- Maintain a steady and consistent flow of material.

- Ensure uniform distribution across the screen.

**2. Utilize Feeders and Spreaders:**

- Use mechanical feeders to regulate the feed rate.

- Implement spreaders to achieve even material distribution.

**3. Implement Monitoring Systems:**

- Use real-time monitoring to track feed rate.

- Make dynamic adjustments based on real-time data to maintain optimal performance.

By effectively controlling and optimizing the feed rate, you can enhance screening efficiency, reduce wear and tear on equipment, and ensure the smooth operation of your screening processes in mineral processing.

Improving Screening Efficiency in Mineral Processing

Enhancing screening efficiency is critical to optimizing mineral processing operations. Key strategies include ensuring uniform feed distribution, implementing pre-screening processes, and configuring screen decks effectively.

Here’s a detailed approach to each of these strategies:

#### 1. Uniform Feed Distribution

**Importance:**

- **Even Loading:** Prevents overloading of specific sections of the screen, which can cause inefficiency and uneven wear.

- **Improved Separation:** Ensures consistent material flow, enhancing separation efficiency and product quality.

**Strategies:**

- **Feeders and Spreaders:** Utilize mechanical feeders and spreaders to ensure material is evenly distributed across the screen width.

- **Feed Control Systems:** Implement automated systems to monitor and adjust the feed rate dynamically, maintaining uniform distribution.

**Recommendations:**

- **Equipment:** Consider using vibratory feeders, belt feeders, or apron feeders combined with spreader conveyors or distribution chutes.

- **Monitoring:** Use sensors and control systems to continuously monitor feed distribution and make real-time adjustments.

#### 2. Pre-screening

**Importance:**

- **Load Reduction:** Removes fines and smaller particles before the main screening process, reducing the load on the primary screen.

- **Improved Efficiency:** Allows the main screen to focus on separating larger particles, enhancing overall efficiency.

**Strategies:**

- **Pre-screening Units:** Install pre-screening units to separate fines and undersized material.

- **Appropriate Mesh Size:** Use an appropriate mesh size for the pre-screen to ensure effective removal of fines without losing valuable material.

**Recommendations:**

- **Integration:** Integrate pre-screening units upstream of the main screening equipment.

- **Regular Maintenance:**

Regularly inspect and maintain pre-screening units to ensure they function correctly and efficiently.

#### 3. Screen Deck Configuration

**Importance:**

- **Gradual Separation:** Using multiple decks with progressively finer screens allows for staged separation, improving accuracy and efficiency.

- **Optimized Performance:**

Each deck handles a specific particle size range, enhancing overall screening performance.

**Strategies:**

- **Multiple Decks:** Configure screens with multiple decks, each with a progressively finer mesh.

- **Appropriate Mesh Selection:**

Select mesh sizes for each deck based on the desired particle size separation at each stage.

**Recommendations:**

- **Screen Design:** Choose screens designed for multi-deck configurations, such as banana screens or multi-slope screens.

- **Material Flow:** Ensure the material flow is managed to move progressively through each deck without overloading any single deck.

### Summary

To improve screening efficiency in mineral processing, focus on the following strategies:

1. **Uniform Feed Distribution:**

- Use feeders and spreaders to ensure even material distribution.

- Implement automated feed control systems for dynamic adjustments.

2. **Pre-screening:**

- Install pre-screening units to remove fines before the main screening process.

- Use an appropriate mesh size for effective fines removal.

3. **Screen Deck Configuration:**

- Utilize multiple decks with progressively finer screens for staged separation.

- Select appropriate mesh sizes for each deck to achieve desired particle size separation.

By implementing these strategies, you can enhance the efficiency and effectiveness of your screening operations, leading to better separation performance, reduced equipment wear, and improved overall productivity in mineral processing.

Strategies for Improving Screening Efficiency

#### 1. Feeders and Spreaders

**Importance:**

- Ensures material is evenly distributed across the screen width, preventing overloading and enhancing separation efficiency.

**Strategies:**

- **Mechanical Feeders:** Use mechanical feeders to regulate the amount of material being fed onto the screen. This ensures a consistent feed rate and prevents surges that can overload the screen.

- **Examples:** Vibratory feeders, belt feeders, apron feeders.

- **Spreaders:**

Implement spreaders to distribute the material evenly across the screen surface. This helps to utilize the entire screen area effectively and improves separation efficiency.

- **Examples:** Spreader conveyors, distribution chutes.

**Recommendations:**

- **Regular Calibration:**

Ensure feeders and spreaders are regularly calibrated and maintained to operate effectively.

- **Custom Design:** Use feeders and spreaders that are designed specifically for your material and process requirements to maximize efficiency.

#### 2. Feed Control Systems

**Importance:**

- Dynamic monitoring and adjustment of the feed rate help maintain uniform distribution and optimize screening performance.

**Strategies:**

- **Automated Feed Control Systems:**

Implement automated systems that continuously monitor the feed rate and make real-time adjustments. These systems can respond to changes in material flow and characteristics, ensuring consistent feed rates.

- **Examples:**

PLC (Programmable Logic Controller) systems, SCADA (Supervisory Control and Data Acquisition) systems.

- **Sensors and Monitoring Equipment:** Use sensors to detect feed rate, material load, and distribution across the screen. Data from these sensors can be used to adjust feeder and spreader settings automatically.

- **Examples:**

Load cells, flow meters, and ultrasonic sensors.

**Recommendations:**

- **Integration:**

Integrate feed control systems with existing plant control systems for seamless operation and better data utilization.

- **Data Analysis:**

Regularly analyze data from feed control systems to identify trends and make informed decisions for further optimization.

### Summary

Implementing effective strategies for feed distribution and control can significantly improve the efficiency of screening operations.

Here are the key points:

1. **Feeders and Spreaders:**

- **Utilize Mechanical Feeders:**

Ensure consistent material feed and prevent overloading.

- **Examples:**

Vibratory feeders, belt feeders, apron feeders.

- **Implement Spreaders:**

Achieve even material distribution across the screen.

- **Examples:**

Spreader conveyors, distribution chutes.

- **Regular Calibration and Custom Design:**

Ensure equipment is properly maintained and tailored to your specific needs.

2. **Feed Control Systems:**

- **Automated Systems:**

Use automated feed control systems to dynamically monitor and adjust feed rates.

- **Examples:**

PLC systems, SCADA systems.

- **Sensors and Monitoring:** Implement sensors to detect feed rate and material distribution, and use this data for real-time adjustments.

- **Examples:** Load cells, flow meters, ultrasonic sensors.

- **Integration and Data Analysis:**

Integrate with existing plant systems and analyze data regularly for continuous improvement.

By focusing on these strategies, you can enhance uniform feed distribution, prevent overloading, and maintain optimal screening efficiency, leading to better performance and productivity in mineral processing operations.

Regular Maintenance for Screening Equipment

Regular maintenance is essential to ensure optimal performance, extend equipment lifespan, and minimize downtime in screening operations.

Here’s a detailed guide on key maintenance practices:

#### 1. Inspect and Clean Screens

**Importance:**

- Prevents clogging and maintains the open area of the screens.

- Identifies wear and damage early to avoid operational disruptions.

**Strategies:**

- **Regular Inspections:**

- **Frequency:** Conduct routine inspections of screens for signs of wear, damage, and blinding.

- **Focus Areas:** Check screen media, support frames, and tensioning systems.

- **Cleaning:**

- **Methods:** Use appropriate cleaning methods such as manual brushing, air blasters, or water sprays to remove debris and prevent clogging.

- **Frequency:** Schedule regular cleaning intervals based on the material being processed and operational conditions.

**Recommendations:**

- **Inspection Checklist:** Develop a comprehensive checklist for screen inspections to ensure all critical areas are evaluated.

- **Training:** Train maintenance personnel on proper inspection and cleaning techniques to ensure thorough and effective maintenance.

#### 2. Replace Worn Parts

**Importance:**

- Maintains screening efficiency and performance.

- Prevents unexpected breakdowns and extends the lifespan of the equipment.

**Strategies:**

- **Timely Replacement:**

- **Screen Media:** Monitor the condition of screen media and replace them when signs of wear or damage are detected.

- **Springs and Components:**

Inspect and replace worn springs, bearings, and other critical components to maintain optimal performance.

- **Inventory Management:**

- **Spare Parts:** Maintain an inventory of commonly used spare parts to ensure quick replacements and minimize downtime.

**Recommendations:**

- **Maintenance Schedule:** Implement a regular maintenance schedule that includes the replacement of worn parts based on usage and wear patterns.

- **OEM Parts:** Use original equipment manufacturer (OEM) parts for replacements to ensure compatibility and quality.

#### 3. Lubrication and Alignment

**Importance:**

- Ensures smooth operation and reduces the risk of mechanical failures.

- Extends the life of bearings and other moving parts.

**Strategies:**

- **Proper Lubrication:**

- **Bearings:** Ensure bearings are properly lubricated according to manufacturer recommendations to prevent friction and wear.

- **Lubrication Schedule:**

Develop and adhere to a regular lubrication schedule, using the correct type and amount of lubricant.

- **Alignment:**

- **Screen Alignment:** Regularly check and adjust the alignment of the screen to prevent uneven wear and mechanical failures.

- **Vibration Monitoring:**

Use vibration monitoring tools to detect misalignment and other mechanical issues early.

**Recommendations:**

- **Lubrication System:**

Consider using automated lubrication systems to ensure consistent and accurate lubrication of bearings and other components.

- **Alignment Tools:**

Use precise alignment tools and techniques to maintain proper screen alignment and prevent operational issues.

### Summary

Regular maintenance practices are crucial for the efficient operation and longevity of screening equipment.

Key maintenance activities include:

1. **Inspect and Clean Screens:**

- Conduct routine inspections for wear, damage, and blinding.

- Clean screens regularly to prevent clogging and maintain open area.

2. **Replace Worn Parts:**

- Monitor and replace worn screen media, springs, bearings, and other components promptly.

- Maintain an inventory of spare parts for quick replacements.

3. **Lubrication and Alignment:**

- Ensure proper lubrication of bearings and other moving parts.

- Regularly check and adjust screen alignment to prevent mechanical failures.

By implementing these regular maintenance practices, you can ensure optimal performance, reduce downtime, and extend the lifespan of your screening equipment, leading to more efficient and reliable mineral processing operations.

Replacing Worn Parts in Screening Equipment

Timely replacement of worn parts is essential to maintaining screening efficiency, preventing unexpected breakdowns, and extending the lifespan of screening equipment.

Here’s a detailed approach to ensuring timely and effective replacement of worn parts:

#### Importance of Replacing Worn Parts

1. **Maintains Screening Efficiency and Performance:**

- Ensures the screen continues to operate at optimal performance levels.

- Prevents decline in separation efficiency due to worn or damaged parts.

2. **Prevents Unexpected Breakdowns:**

- Reduces the risk of unexpected equipment failures that can cause costly downtime.

- Ensures continuous operation and consistent throughput.

3. **Extends Equipment Lifespan:**

- Prolongs the useful life of the screening equipment by preventing damage to other components caused by worn parts.

- Enhances the return on investment by maximizing equipment longevity.

#### Strategies for Replacing Worn Parts

**1. Timely Replacement:**

- **Screen Media:**

- **Monitoring:** Regularly inspect the condition of screen media for signs of wear, such as tears, holes, or significant abrasion.

- **Replacement Schedule:** Establish a schedule for routine checks and replacements based on the material being processed and operational conditions.

- **Springs and Components:**

- **Inspection:** Periodically inspect springs, bearings, and other critical components for signs of wear or fatigue.

- **Replacement:** Replace worn or damaged springs and bearings to maintain optimal screen performance and prevent mechanical failures.

**2. Inventory Management:**

- **Spare Parts:**

- **Inventory Maintenance:** Keep an inventory of commonly used spare parts, including screen media, springs, bearings, and other critical components.

- **Stock Levels:** Maintain adequate stock levels to ensure quick replacements and minimize downtime in case of part failure.

#### Recommendations

**1. Timely Replacement:**

- **Screen Media:**

- **Regular Inspections:**

Conduct inspections at regular intervals to monitor the condition of the screen media.

- **Damage Detection:** Look for visible signs of wear, such as tears, holes, and excessive abrasion, and replace the media promptly when these signs are observed.

- **Springs and Components:**

- **Routine Checks:** Schedule regular checks for springs and other critical components.

- **Proactive Replacement:** Replace components showing signs of wear or fatigue before they fail, based on the manufacturer's recommended replacement intervals.

**2. Inventory Management:**

- **Spare Parts Inventory:**

- **Critical Components:** Identify and stock spare parts for critical components that are prone to wear and tear.

- **Inventory System:** Implement an inventory management system to track part usage and reorder levels, ensuring that critical parts are always available when needed.

### Summary

Replacing worn parts in screening equipment is crucial for maintaining efficiency, preventing unexpected breakdowns, and extending the equipment’s lifespan.

Key strategies include:

1. **Timely Replacement:**

- **Screen Media:** Regularly inspect and replace worn or damaged screen media.

- **Springs and Components:** Inspect and replace worn springs, bearings, and other critical components.

2. **Inventory Management:**

- **Spare Parts Inventory:** Maintain an inventory of commonly used spare parts to ensure quick replacements and minimize downtime.

- **Stock Levels:** Ensure adequate stock levels of critical components.

By implementing these strategies, you can ensure that your screening equipment operates efficiently and reliably, reducing downtime and maintenance costs while extending the lifespan of the equipment.

Process Control and Monitoring in Screening Operations

Implementing effective process control and monitoring strategies is essential for optimizing screening efficiency, ensuring consistent product quality, and minimizing downtime.

Here’s how to achieve this through real-time monitoring and data analysis:

#### 1. Real-time Monitoring

**Importance:**

- Enables immediate detection of issues and facilitates prompt corrective actions.

- Ensures continuous optimal performance of screening equipment.

**Strategies:**

- **Sensors and Control Systems:**

- **Vibration Monitoring:** Install sensors to monitor screen vibration levels. Abnormal vibrations can indicate issues such as misalignment or mechanical wear.

- **Screen Load Monitoring:** Use load sensors to track the amount of material on the screen. This helps prevent overloading and ensures uniform distribution.

- **Particle Size Distribution:**

Employ particle size analyzers to monitor the size distribution of material passing through the screen, ensuring the screening process meets specifications.

**Recommendations:**

- **Integration:** Integrate these sensors with a central control system for real-time data collection and monitoring.

- **Alerts and Notifications:**

Set up automated alerts for when parameters fall outside of desired ranges, allowing for quick intervention.

#### 2. Data Analysis

**Importance:**

- Provides insights into the performance and efficiency of the screening process.

- Helps identify patterns and trends that can be used to optimize operations.

**Strategies:**

- **Performance Data Collection:**

- **Historical Data:** Collect and store historical data on key parameters such as vibration levels, screen load, and particle size distribution.

- **Real-time Data:** Continuously collect real-time data from sensors for immediate analysis and response.

- **Data Analysis Techniques:**

- **Trend Analysis:** Analyze historical and real-time data to identify trends and patterns that may indicate declining performance or potential issues.

- **Root Cause Analysis:** Use data to identify the root causes of performance issues and implement targeted corrective actions.

- **Predictive Maintenance:** Utilize predictive analytics to anticipate maintenance needs based on data trends, reducing unplanned downtime.

**Recommendations:**

- **Software Tools:**

Use advanced data analysis and visualization tools to make sense of the collected data and gain actionable insights.

- **Continuous Improvement:**

Regularly review performance data and adjust operational parameters to continuously improve screening efficiency and product quality.

### Summary

Effective process control and monitoring strategies involve real-time monitoring of key parameters and thorough data analysis to optimize screening operations.

Key points include:

1. **Real-time Monitoring:**

- **Sensors and Control Systems:**

Implement sensors for monitoring vibration, screen load, and particle size distribution.

- **Integration and Alerts:**

Integrate sensors with control systems and set up alerts for deviations from desired parameters.

2. **Data Analysis:**

- **Performance Data Collection:**

Collect both historical and real-time data on key performance parameters.

- **Data Analysis Techniques:**

Use trend analysis, root cause analysis, and predictive maintenance to optimize operations and prevent issues.

By focusing on real-time monitoring and data analysis, you can ensure that your screening process operates efficiently and consistently, leading to better product quality, reduced downtime, and overall improved performance in mineral processing operations.

Improve Material Characteristics

### 1. Moisture Control

**Importance:**

- **Prevents Blinding:** Excessive moisture can cause fine particles to stick to the screen surface, leading to blinding and reduced throughput.

- **Enhances Efficiency:** Managing moisture ensures consistent material flow and effective separation.

**Strategies:**

- **Pre-screening or Drying:**

Use pre-screening techniques to remove excessively moist fines before they reach the main screen.

- **Moisture Measurement:**

Implement moisture sensors or meters to monitor the moisture content of the feed material.

- **Adjusting Feed Preparation:** Modify upstream processes to control moisture levels before the material reaches the screening equipment.

**Recommendations:**

- **Optimal Moisture Range:**

Determine and maintain the ideal moisture content for efficient screening based on the material type and processing requirements.

- **Regular Monitoring:**

Continuously monitor moisture levels and adjust processes as needed to maintain optimal conditions.

### 2. Particle Size Distribution

**Importance:**

- **Uniform Screening:**

A consistent particle size distribution ensures that each particle type is efficiently separated according to size.

- **Optimal Screen Performance:** Matching the screen aperture to the particle size distribution improves screening efficiency and throughput.

**Strategies:**

- **Crushing and Grinding:**

Size reduction processes such as crushing and grinding reduce larger particles to a uniform size, facilitating more effective screening.

- **Screening Analysis:** Conduct screening tests and analysis to understand the particle size distribution of the feed material.

- **Screen Selection:** Choose screens with appropriate mesh sizes that match the particle size distribution to achieve desired separation efficiency.

**Recommendations:**

- **Optimize Crushing/Grinding:**

Ensure that crushing and grinding operations are optimized to achieve the desired particle size distribution for effective screening.

- **Screen Aperture Selection:**

Select screen apertures that match the particle sizes in the feed material to maximize screening efficiency.

### Summary

Improving material characteristics such as moisture control and particle size distribution is essential for enhancing screening efficiency in mineral processing:

- **Moisture Control:**

Manage moisture levels to prevent blinding and ensure consistent material flow.

- **Particle Size Distribution:**

Crush or grind material to achieve a uniform size distribution that optimizes screening performance.

By implementing these strategies, mineral processing operations can improve overall efficiency, reduce downtime due to screen blinding or inefficient separation, and achieve better quality output. Regular monitoring and adjustments based on material characteristics will further enhance performance and operational reliability.

Screen Panel wear - management and replacement

Here’s a detailed guide on how to manage and replace screen panels:

### Managing Screen Panel Wear

#### 1. Monitoring Wear

**Importance:**

- Early detection allows for timely replacement, minimizing downtime and maintaining screening efficiency.

**Strategies:**

- **Regular Inspections:** Implement routine inspections to visually assess the condition of screen panels.

- **Wear Indicators:** Use wear indicators or markers on the screen panels to monitor wear levels.

- **Measurement Tools:** Utilize measurement tools such as calipers to quantify wear thickness and track wear progression.

**Recommendations:**

- **Frequency:** Schedule inspections based on operational hours and material characteristics (e.g., abrasive materials may require more frequent inspections).

- **Documentation:**

Maintain records of wear measurements and observations to track trends and plan replacements proactively.

#### 2. Optimizing Screen Panel Installation

**Importance:**

- Proper installation minimizes premature wear and ensures effective screening performance.

**Strategies:**

- **Correct Tensioning:** Ensure screen panels are correctly tensioned to prevent sagging or over-tensioning, which can accelerate wear.

- **Alignment:** Align screen panels properly within the screening equipment to distribute wear evenly.

- **Support Structures:** Inspect and maintain support structures to provide adequate support and reduce stress on screen panels.

**Recommendations:**

- **Installation Procedures:**

Follow manufacturer guidelines for installing and tensioning screen panels.

- **Training:** Train personnel on proper installation techniques to avoid common installation errors that can lead to premature wear.

### Replacing Screen Panels

#### 1. Timing of Replacement

**Importance:**

- Timely replacement maintains screening efficiency and prevents damage to downstream equipment.

**Strategies:**

- **Condition-Based Replacement:** Replace screen panels based on wear condition rather than fixed intervals.

- **Performance Monitoring:** Monitor screening performance indicators (e.g., throughput, particle size distribution) to identify declines that may indicate the need for replacement.

- **Scheduled Replacements:** Plan replacements during scheduled maintenance periods to minimize disruption to production.

**Recommendations:**

- **Wear Threshold:**

Establish wear thresholds based on operational requirements and material characteristics to trigger replacement.

- **Emergency Spares:** Maintain a stock of emergency spare screen panels for immediate replacement in case of unexpected failures.

#### 2. Choosing Replacement Panels

**Importance:**

- Selecting appropriate replacement panels ensures compatibility and maintains screening effectiveness.

**Strategies:**

- **Material Selection:** Choose screen panels made from materials suitable for the application (e.g., rubber, polyurethane, woven wire) based on abrasiveness and operational conditions.

- **Aperture Size and Design:** Select panels with the correct aperture size and design to achieve desired particle size distribution and separation efficiency.

- **Supplier Considerations:** Partner with reliable suppliers who offer quality products and support services.