Introduction

### Types of Conveyors in Mineral Processing

1. **Belt Conveyors**:

- **Function**:

Primarily used for transporting bulk materials over long distances.

- **Applications**:

Ideal for conveying raw materials from the mine to the processing plant, or between different stages of the processing plant.

- **Advantages**:

High efficiency, low operating cost, and the ability to handle large volumes of materials.

2. **Apron Conveyors**:

- **Function**:

Designed to handle heavy, abrasive materials.

- **Applications**:

Suitable for transporting coarse or hot materials that might damage standard conveyor belts.

- **Advantages**:

Durable and capable of handling large lumps and heavy loads.

3. **Screw Conveyors**:

- **Function**:

Used for transporting granular or small lump materials over short distances.

- **Applications**:

Commonly used in processing plants for moving materials between processes, such as from a crusher to a mill.

- **Advantages**:

Enclosed system which minimizes dust and material loss.

4. **Vibratory Conveyors**:

- **Function**:

Utilize vibration to move materials along a trough.

- **Applications**:

Often used for feeding materials into processing equipment or for separating materials by size.

- **Advantages**:

Can handle fragile materials gently and evenly distribute materials across processing equipment.

5. **Pneumatic Conveyors**:

- **Function**:

Use air pressure to transport materials through pipelines.

- **Applications**:

Typically used for fine powders or small particulate materials.

- **Advantages**:

Enclosed system that minimizes dust and contamination, suitable for handling materials over complex routes.

### Importance of Conveyors in Mineral Processing

1. **Efficiency**:

- Conveyors enable the continuous and automated transport of materials, significantly reducing manual labor and increasing the throughput of processing plants.

- They facilitate a seamless flow of materials between different stages of processing, minimizing delays and bottlenecks.

2. **Cost-effectiveness**:

- By reducing the need for trucks and other manual transport methods, conveyors help lower operational costs.

- They require less maintenance and have lower energy consumption compared to other transport methods.

3. **Safety**:

- Conveyors improve safety by reducing the need for manual material handling, thus minimizing the risk of accidents and injuries.

- Enclosed conveyor systems help control dust and prevent spillage, contributing to a cleaner and safer working environment.

4. **Flexibility and Scalability**:

- Conveyor systems can be customized to fit specific plant layouts and material characteristics.

- They can be easily expanded or modified to accommodate changes in processing requirements or increases in production capacity.

5. **Environmental Impact**:

- Conveyors help reduce the carbon footprint of mineral processing operations by minimizing the need for fuel-consuming transport vehicles.

- Enclosed systems help reduce dust emissions, contributing to better air quality and environmental compliance.

### Key Considerations in Conveyor Design

1. **Material Characteristics**:

- Understanding the properties of the material being transported (e.g., size, abrasiveness, moisture content) is crucial for selecting the appropriate conveyor type and design.

2. **Capacity and Speed**:

- The conveyor system must be designed to handle the required throughput and speed to ensure efficient processing and avoid bottlenecks.

3. **Durability and Maintenance**:

- Conveyors in mineral processing environments are subjected to harsh conditions, so materials and components must be durable and easy to maintain.

4. **Energy Efficiency**:

- Designing conveyors with energy-efficient motors and control systems can help reduce operational costs and environmental impact.

### Conclusion

Conveyors are vital for the efficiency, safety, and cost-effectiveness of mineral processing operations. By selecting the appropriate type and design of conveyor systems, processing plants can optimize their material handling processes, increase production capacity, and reduce operational costs.

Belt Conveyors

#### Function Belt conveyors are primarily used for transporting bulk materials over long distances in a continuous and efficient manner. They play a crucial role in the seamless flow of materials within a mineral processing plant.

#### Applications

1. **From Mine to Processing Plant**:

- Belt conveyors are used to transport raw materials from the extraction site (mine) to the processing plant, ensuring a steady supply of feedstock.

2. **Inter-plant Transport**:

- They are ideal for conveying materials between different stages of the processing plant, such as from crushers to mills, or from mills to separation units.

3. **Stockpile Handling**:

- Conveyors facilitate the movement of processed materials to storage areas or stockpiles for further processing or shipping.

#### Advantages

1. **High Efficiency**:

- Belt conveyors can transport large volumes of materials continuously over long distances with minimal downtime, enhancing overall plant efficiency.

2. **Low Operating Cost**:

- The operational cost of belt conveyors is relatively low compared to other forms of material transport, such as trucks or rail, due to lower energy consumption and reduced labor requirements.

3. **High Volume Handling**:

- They are capable of handling significant volumes of bulk materials, making them suitable for large-scale mineral processing operations.

4. **Flexibility and Versatility**:

- Belt conveyors can be designed to fit various plant layouts and can handle a wide range of materials, including ores, coal, and aggregates.

5. **Continuous Operation**:

- They enable continuous material flow without the need for frequent stops and starts, which is critical in maintaining steady production rates.

6. **Environmental Benefits**:

- Enclosed belt conveyors reduce dust and spillage, contributing to a cleaner and safer working environment and minimizing environmental impact.

### Key Design Considerations for Belt Conveyors

1. **Material Characteristics**:

- The design of the belt conveyor must consider the properties of the materials being transported, such as density, particle size, abrasiveness, and moisture content.

2. **Conveyor Length and Route**:

- The length of the conveyor and the route it takes must be carefully planned to optimize efficiency and minimize material handling time.

3. **Belt Selection**:

- Choosing the right belt type and material is essential for ensuring durability and performance, especially in harsh mining environments.

4. **Load Capacity**:

- The conveyor system must be designed to handle the maximum expected load to avoid overloading and potential failures.

5. **Energy Efficiency**:

- Incorporating energy-efficient motors and control systems can help reduce operational costs and environmental impact.

6. **Maintenance Accessibility**:

- The design should allow for easy access to components for maintenance and repairs to minimize downtime.

### Conclusion

Belt conveyors are a fundamental component in mineral processing, offering a reliable and cost-effective solution for transporting bulk materials over long distances. Their high efficiency, flexibility, and ability to handle large volumes make them indispensable in modern processing plants. Proper design and maintenance of belt conveyor systems are crucial to ensure their optimal performance and longevity.

Apron Conveyors

#### Function Apron conveyors are specifically designed to handle heavy, abrasive materials that are too challenging for standard conveyor belts. They consist of a series of overlapping metal plates (aprons) mounted on roller chains, which provide a robust and durable conveying surface.

#### Applications

1. **Transporting Coarse Materials**:

- Ideal for moving large, coarse materials such as rocks, ores, and gravel, which could potentially damage conventional belt conveyors.

2. **Handling Hot Materials**:

- Suitable for transporting materials at elevated temperatures that might cause standard conveyor belts to deteriorate, such as hot clinker, slag, or other materials exiting kilns and furnaces.

3. **Heavy Load Conveying**:

- Used for applications requiring the transport of extremely heavy loads, making them suitable for primary material handling in mining operations and processing plants.

#### Advantages

1. **Durability**:

- Apron conveyors are built to withstand the harshest conditions. The metal aprons provide a durable surface that resists wear and tear from abrasive materials.

2. **Heavy Load Capacity**:

- Capable of handling large lumps and heavy loads, making them ideal for applications that involve transporting bulky and weighty materials.

3. **Reduced Maintenance**:

- The robust construction of apron conveyors reduces the frequency and cost of maintenance compared to other conveyor types, especially in demanding environments.

4. **Versatility**:

- Can operate in both horizontal and inclined configurations, providing flexibility in plant layout and material flow design.

5. **Heat Resistance**:

- The metal construction allows apron conveyors to handle hot materials without the risk of damage, ensuring continuous operation even with high-temperature processes.

6. **Minimized Spillage**:

- The overlapping design of the aprons helps contain material spillage, maintaining a cleaner working environment and reducing material loss.

### Key Design Considerations for Apron Conveyors

1. **Material Properties**:

- The design must account for the size, weight, and abrasiveness of the materials being transported to ensure the conveyor can handle the specific requirements.

2. **Conveyor Length and Inclination**:

- Proper planning of the conveyor length and inclination angle is crucial for optimizing material flow and ensuring efficient operation.

3. **Chain Selection**:

- Selecting the appropriate roller chains that can support the load and provide smooth movement is essential for the longevity and reliability of the conveyor.

4. **Drive Systems**:

- The drive system must be powerful enough to move heavy loads over the required distances and inclines without excessive strain or wear.

5. **Wear Protection**:

- Incorporating wear-resistant materials or coatings on the aprons and other critical components can further extend the life of the conveyor.

6. **Ease of Maintenance**:

- Designing the conveyor with accessible components and modular sections can facilitate easier maintenance and reduce downtime.

### Conclusion

Apron conveyors are an essential tool in mineral processing for handling heavy, abrasive, and hot materials. Their durability, capacity to handle large loads, and resistance to wear and heat make them indispensable in environments where standard belt conveyors would fail. Proper design and maintenance are key to leveraging their full benefits and ensuring efficient, reliable material transport in harsh conditions.

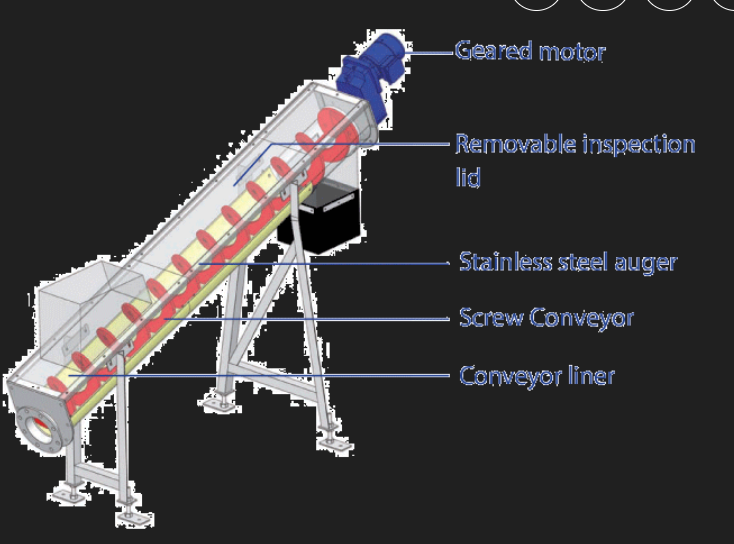

Screw Conveyors

#### Function Screw conveyors are used for transporting granular or small lump materials over short distances. They consist of a helical screw blade, known as a flight, which rotates within a tube or trough, moving materials along the conveyor path.

#### Applications

1. **Inter-process Material Transport**:

- Commonly used in processing plants for moving materials between different stages of processing, such as from a crusher to a mill, or from a screening unit to a storage bin.

2. **Controlled Feeding and Discharge**:

- Ideal for controlled feeding of materials into processing equipment, ensuring a steady and consistent flow of material.

3. **Mixing and Blending**:

- In some applications, screw conveyors can also perform mixing or blending of materials as they convey, particularly useful in chemical processing.

4. **Handling Semi-solid Materials**:

- Suitable for transporting semi-solid materials, such as sludge or wet ore concentrates, which might be difficult to handle with other types of conveyors.

#### Advantages

1. **Enclosed System**:

- The enclosed design minimizes dust and material loss, contributing to a cleaner and safer working environment.

2. **Compact and Versatile**: - Screw conveyors can be installed in confined spaces and customized to fit specific process requirements, providing versatility in plant design.

3. **Ease of Maintenance**:

- With fewer moving parts compared to other conveyor systems, screw conveyors are relatively easy to maintain and have lower maintenance costs.

4. **Flexibility**:

- Can be designed to handle a variety of materials, from fine powders to small lumps, making them adaptable to different processing needs.

5. **Energy Efficiency**:

- They consume less energy compared to other types of conveyors, especially for short-distance transport.

### Key Design Considerations for Screw Conveyors

1. **Material Characteristics**:

- The design should consider the properties of the materials being transported, such as bulk density, particle size, abrasiveness, and moisture content.

2. **Conveyor Length and Slope**:

- Screw conveyors are best suited for short distances. The length and slope should be optimized to ensure efficient material transport and prevent material backflow.

3. **Flight Design**:

- The flight design (e.g., pitch, thickness, and shape) should be tailored to the specific material and application to ensure efficient transport and minimize wear.

4. **Tubular vs. Trough Design**:

- Choosing between a tubular or trough design depends on the material and application. Tubular designs offer better containment, while trough designs can be easier to access for cleaning and maintenance.

5. **Drive Mechanism**:

- The drive system must be powerful enough to handle the required load and torque, ensuring smooth and reliable operation.

6. **Wear and Corrosion Resistance**:

- Using wear-resistant and corrosion-resistant materials for the screw and housing can extend the life of the conveyor, especially when handling abrasive or corrosive materials.

### Conclusion

Screw conveyors are a vital component in mineral processing for the efficient transport of granular and small lump materials over short distances. Their enclosed design minimizes dust and material loss, contributing to a cleaner and safer work environment.

Their versatility, ease of maintenance, and energy efficiency make them an excellent choice for various applications within processing plants. Proper design and customization are essential to maximize their benefits and ensure reliable operation.

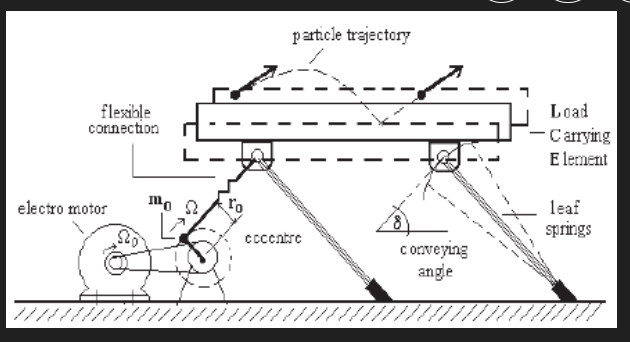

Vibratory Conveyors

#### Function Vibratory conveyors utilize vibration to move materials along a trough or bed. The vibrating motion, generated by electromagnetic, mechanical, or hydraulic systems, propels materials forward in a controlled manner.

#### Applications

1. **Feeding Processing Equipment**:

- Often used to feed materials into processing equipment such as crushers, screens, or mills. The controlled flow ensures that the equipment operates efficiently without overloading.

2. **Material Separation**:

- Suitable for separating materials by size through vibratory screening processes, where different-sized particles are sorted and directed to different downstream processes.

3. **Even Distribution**:

- Effective in evenly distributing materials across the width of processing equipment, such as evenly spreading materials across a screen deck or feeding material uniformly into a kiln or furnace.

4. **Cooling and Drying**:

- Can be used in processes where materials need to be cooled or dried as they are transported. Vibratory conveyors with perforated troughs allow air to flow through the material, facilitating these processes.

5. **Handling Fragile Materials**:

- Ideal for handling fragile or delicate materials that could be damaged by more aggressive conveying methods, such as fine powders, seeds, or processed food items.

#### Advantages

1. **Gentle Handling**:

- The vibratory motion can be finely controlled to handle fragile materials gently, minimizing the risk of damage during transport.

2. **Even Material Distribution**:

- Ensures uniform distribution of materials across processing equipment, improving efficiency and product quality.

3. **Flexibility**:

- Can be designed to handle a wide range of materials and can be easily adjusted to accommodate different process requirements.

4. **Low Maintenance**:

- With fewer moving parts than some other conveyor types, vibratory conveyors typically require less maintenance and have lower operational costs.

5. **Clean Operation**:

- Enclosed or partially enclosed designs help minimize dust generation and spillage, contributing to a cleaner work environment.

6. **Energy Efficiency**:

- Vibratory conveyors are energy-efficient, especially for short to medium-distance transport, and can be designed to use minimal power while maintaining high throughput.

### Key Design Considerations for Vibratory Conveyors

1. **Material Properties**:

- The design must account for the characteristics of the material being conveyed, such as particle size, bulk density, and moisture content, to ensure efficient transport.

2. **Amplitude and Frequency**:

- The amplitude (height) and frequency (speed) of the vibrations need to be carefully controlled to achieve the desired material flow and handling characteristics.

3. **Trough Design**:

- The trough can be open, partially enclosed, or fully enclosed, depending on the application and the need to control dust or contain the material.

4. **Drive Mechanism**:

- Choosing the appropriate drive mechanism (electromagnetic, mechanical, or hydraulic) is crucial for ensuring the conveyor operates efficiently and reliably.

5. **Wear Resistance**:

- Using wear-resistant materials for the trough and other critical components can extend the life of the conveyor, particularly when handling abrasive materials.

6. **Integration with Processing Equipment**:

- The conveyor must be designed to integrate seamlessly with other processing equipment, ensuring a smooth flow of materials and optimizing overall process efficiency.

### Conclusion

Vibratory conveyors are an essential tool in mineral processing, offering a versatile and efficient solution for transporting and handling a wide range of materials. Their ability to gently handle fragile materials, evenly distribute materials, and operate with low maintenance makes them invaluable in various applications. Proper design and customization are key to maximizing their benefits and ensuring reliable operation within processing plants.

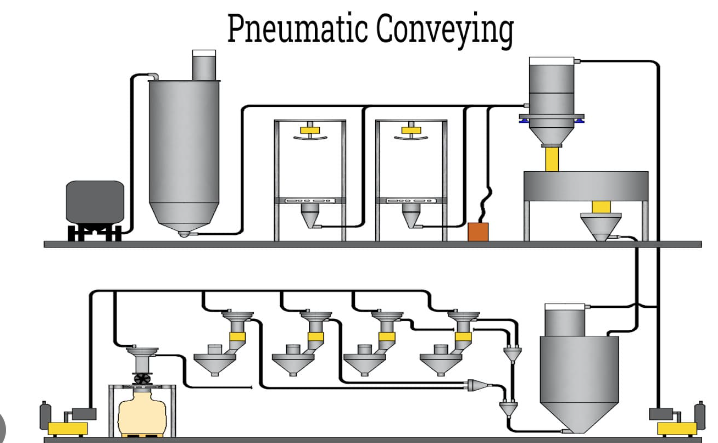

Pneumatic Conveyors

#### Function Pneumatic conveyors use air pressure or vacuum to transport materials through pipelines. They rely on the flow of air or another gas to move bulk materials, typically fine powders or small particulate materials, through enclosed tubes or ducts.

#### Applications

1. **Transporting Fine Powders**:

- Commonly used to convey fine powders such as cement, fly ash, or mineral dust from one part of a processing plant to another.

2. **Handling Small Particulate Materials**:

- Suitable for materials like grains, plastic pellets, and small granular products, often used in industries such as pharmaceuticals, food processing, and chemical manufacturing.

3. **Complex Routing**:

- Effective for moving materials over complex routes within a plant, including vertical and horizontal pathways, as well as around obstacles.

4. **Feeding Processing Equipment**:

- Used to feed materials into processing equipment like mixers, hoppers, or reactors with precise control over the material flow.

5. **Bulk Material Handling**:

- Employed in bulk material handling systems where materials need to be transferred from storage silos to various processing units.

#### Advantages

1. **Enclosed System**:

- The fully enclosed nature of pneumatic conveyors minimizes dust generation and material contamination, leading to a cleaner and safer working environment.

2. **Flexibility in Routing**:

- Capable of transporting materials over long distances and through complex routes, including vertical lifts, tight bends, and horizontal spans, providing flexibility in plant layout.

3. **Reduced Material Degradation**:

- The gentle handling of materials reduces the risk of degradation, which is particularly important for fragile or sensitive materials.

4. **Minimal Maintenance**:

- Fewer moving parts compared to mechanical conveyors result in lower maintenance requirements and reduced downtime.

5. **High Throughput**:

- Can transport large volumes of material quickly, improving the efficiency of material handling operations.

6. **Safety**: - Reduces the risk of dust explosions, particularly when handling combustible powders, by minimizing dust accumulation and using inert gases if necessary.

### Key Design Considerations for Pneumatic Conveyors

1. **Material Properties**:

- Understanding the properties of the material, such as particle size, density, abrasiveness, and moisture content, is crucial for designing an efficient pneumatic conveying system.

2. **System Design (Pressure vs. Vacuum)**:

- Deciding between a pressure system (pushing materials) and a vacuum system (pulling materials) depends on the specific application and material characteristics.

3. **Pipeline Layout**:

- The layout of the pipelines, including the length, diameter, and number of bends, affects the system's efficiency and must be optimized to minimize pressure drops and material degradation.

4. **Air Supply and Filtration**:

- Ensuring a consistent and clean air supply is critical for system performance. Adequate filtration is necessary to prevent contaminants from entering the system and affecting the material.

5. **Control Systems**:

- Advanced control systems can help monitor and regulate the flow of materials, ensuring consistent and efficient operation.

6. **Wear and Abrasion Resistance**:

- Using wear-resistant materials for pipelines and components is essential when handling abrasive materials to extend the system's lifespan.

### Conclusion

Pneumatic conveyors are a vital component in mineral processing and various other industries, providing a flexible, efficient, and clean method of transporting fine powders and small particulate materials.

Their enclosed design minimizes dust and contamination, while their ability to handle complex routing and long distances enhances plant layout flexibility. Proper design and understanding of material characteristics are key to maximizing the benefits of pneumatic conveying systems and ensuring reliable and efficient operation.

Efficiency of Conveyors in Mineral Processing

#### Continuous and Automated Transport

1. **Reduction of Manual Labor**:

- **Automated Systems**:

Conveyors automate the transport of materials, eliminating the need for manual handling and reducing labor costs and physical strain on workers.

- **Consistency**:

Automation ensures a consistent flow of materials, which is crucial for maintaining steady production rates.

2. **Increased Throughput**:

- **High Capacity**:

Conveyors are designed to handle large volumes of materials continuously, increasing the overall throughput of processing plants.

- **Speed and Efficiency**:

Materials are moved quickly and efficiently from one stage to another, enhancing productivity.

#### Seamless Flow of Materials

1. **Minimization of Delays and Bottlenecks**:

- **Continuous Operation**:

Conveyors provide a continuous flow of materials, reducing the likelihood of delays that can occur with batch processing or manual transport methods.

- **Improved Coordination**:

By synchronizing the transport of materials between different stages, conveyors help in maintaining a smooth and coordinated workflow, preventing bottlenecks.

2. **Optimized Plant Layout**:

- **Flexible Routing**:

Conveyors can be designed to navigate complex plant layouts, ensuring that materials are delivered exactly where they are needed, when they are needed.

- **Efficient Use of Space**:

The flexibility in conveyor design allows for the optimal use of available space, enabling more efficient plant layouts and better utilization of resources.

#### Additional Benefits

1. **Enhanced Safety**:

- **Reduced Handling Risks**: By minimizing the need for manual handling, conveyors reduce the risk of injuries and accidents associated with lifting and moving heavy materials.

- **Enclosed Systems**:

Many conveyors are designed with enclosures to prevent spillage and contain dust, contributing to a safer and cleaner work environment.

2. **Cost-effectiveness**:

- **Lower Operational Costs**:

Automated conveyor systems have lower operational costs compared to manual transport methods or vehicles like trucks and forklifts.

- **Energy Efficiency**:

Modern conveyor systems are designed to be energy-efficient, further reducing operational costs and environmental impact.

3. **Reliability and Durability**:

- **Long Service Life**:

Conveyors are built to withstand the harsh conditions of mineral processing environments, offering reliable performance and long service life.

- **Low Maintenance**:

With fewer moving parts and robust construction, conveyors typically require less maintenance compared to other transport methods, reducing downtime and maintenance costs.

### Conclusion

Conveyors significantly enhance the efficiency of mineral processing operations by enabling continuous and automated material transport, reducing manual labor, and increasing throughput.

Their ability to facilitate a seamless flow of materials between different stages of processing minimizes delays and bottlenecks, optimizing overall plant performance. In addition to these efficiency gains, conveyors also offer benefits in terms of safety, cost-effectiveness, and reliability, making them a crucial component in modern mineral processing plants.

Cost-effectiveness of Conveyors in Mineral Processing

### Cost-effectiveness of Conveyors in Mineral Processing

#### Reduction of Operational Costs

1. **Minimized Need for Trucks and Manual Transport**:

- **Reduced Labor Costs**:

By automating material transport, conveyors significantly lower the need for manual labor, thus reducing labor costs.

- **Lower Fuel Costs**:

Conveyors eliminate the reliance on trucks and other fuel-consuming vehicles, leading to substantial savings on fuel expenses.

- **Decreased Vehicle Maintenance**:

With fewer trucks in operation, maintenance costs for these vehicles are reduced, including savings on parts, repairs, and downtime.

2. **Lower Energy Consumption**:

- **Energy-efficient Motors**:

Modern conveyor systems are equipped with energy-efficient motors and variable frequency drives, reducing overall energy consumption.

- **Continuous Operation**:

Unlike vehicles that consume more fuel during starts and stops, conveyors operate continuously and more efficiently, leading to energy savings.

#### Reduced Maintenance Costs

1. **Fewer Moving Parts**:

- **Simpler Mechanisms**:

Conveyors have fewer moving parts compared to trucks and other transport vehicles, which means there are fewer components that can wear out or fail.

- **Less Frequent Repairs**:

The simplicity and robustness of conveyor systems result in fewer breakdowns and lower repair frequencies.

2. **Durable Construction**:

- **High-quality Materials**:

Conveyors are built with durable materials designed to withstand harsh processing environments, which reduces wear and tear.

- **Extended Lifespan**:

The longevity of conveyor systems means less frequent replacements and lower long-term capital expenditures.

3. **Lower Maintenance Requirements**:

- **Routine Maintenance**:

Conveyor systems typically require less intensive and less frequent maintenance compared to vehicles, which translates to lower maintenance costs.

- **Predictive Maintenance**:

Many modern conveyor systems are equipped with sensors and monitoring systems that enable predictive maintenance, identifying potential issues before they lead to costly failures.

#### Additional Economic Benefits

1. **Increased Productivity**:

- **Continuous Material Flow**:

Conveyors ensure a continuous and steady flow of materials, enhancing overall plant productivity and efficiency.

- **Reduced Downtime**:

Automated and reliable conveyor systems reduce downtime associated with manual transport methods and vehicle breakdowns.

2. **Enhanced Safety and Compliance**:

- **Reduced Accidents**:

By minimizing manual handling and vehicle operation, conveyors lower the risk of workplace accidents, which can result in cost savings from fewer injury-related expenses.

- **Environmental Compliance**:

Reduced fuel consumption and dust generation help plants meet environmental regulations, potentially avoiding fines and enhancing sustainability efforts.

3. **Optimized Space Utilization**:

- **Efficient Layouts**:

Conveyors can be integrated into plant layouts to optimize space utilization, reducing the need for extensive infrastructure and lowering construction costs.

- **Scalability**:

Conveyor systems can be easily expanded or reconfigured to meet changing production needs, providing cost-effective scalability.

### Conclusion

Conveyors are a cost-effective solution for material transport in mineral processing, providing significant savings in operational costs by reducing reliance on trucks and manual labor. Their lower energy consumption, reduced maintenance needs, and durable construction contribute to ongoing cost savings. Additionally, conveyors enhance productivity, safety, and space utilization, making them a financially prudent investment for mineral processing plants.

Safety Benefits of Conveyors in Mineral Processing

#### Reduction in Manual Material Handling

1. **Minimization of Accidents and Injuries**:

- **Decreased Physical Strain**:

Automating the transport of materials reduces the need for manual lifting, carrying, and moving of heavy or bulky items, which lowers the risk of musculoskeletal injuries among workers.

- **Fewer Handling Errors**:

Automated conveyors eliminate many of the errors and mishaps associated with manual material handling, such as dropping or improperly stacking materials, which can lead to accidents.

2. **Improved Ergonomics**:

- **Ergonomic Design**:

Conveyors can be designed at optimal heights and configurations to facilitate better ergonomic conditions for workers, reducing strain and injury risks associated with repetitive manual tasks.

- **Consistent Operation**:

The consistent and predictable operation of conveyors minimizes sudden movements and manual adjustments, further enhancing worker safety.

#### Enclosed Systems for Dust Control and Spill Prevention

1. **Dust Control**:

- **Reduced Airborne Particles**:

Enclosed conveyor systems contain dust within the system, preventing it from becoming airborne and improving air quality in the working environment.

- **Health Protection**:

Lower levels of airborne dust reduce the risk of respiratory issues and long-term health problems for workers, contributing to a healthier workplace.

2. **Spillage Prevention**:

- **Containment**:

Enclosed conveyors prevent materials from spilling onto the floor, which can create slip and trip hazards. This containment ensures a cleaner and safer working environment.

- **Efficient Cleanup**:

Enclosed systems make it easier to clean up any potential spills, reducing the time and labor required for maintenance and minimizing disruptions to operations.

#### Additional Safety Advantages

1. **Safe Equipment Operation**:

- **Automated Controls**:

Modern conveyor systems are equipped with advanced safety features, such as emergency stop buttons, sensors, and automated shutoff mechanisms, which enhance operational safety.

- **Predictive Maintenance**:

Integrated monitoring systems can detect potential issues early, allowing for proactive maintenance and reducing the risk of sudden failures that could pose safety hazards.

2. **Reduced Vehicle Traffic**:

- **Less Internal Traffic**:

By reducing the need for forklifts and trucks within the plant, conveyors decrease the potential for collisions and accidents associated with vehicle traffic.

- **Improved Workflow**:

The elimination of frequent vehicle movement creates a more organized and safer working environment, reducing the risk of accidents involving workers and machinery.

3. **Enhanced Fire Safety**:

- **Fire-resistant Materials**:

Conveyor systems can be constructed from fire-resistant materials and designed to prevent the accumulation of combustible dust, reducing fire hazards.

- **Isolation Zones**:

Conveyors can be equipped with isolation zones and fire suppression systems to contain and mitigate the spread of fire in the event of an incident.

4. **Compliance with Safety Regulations**:

- **Regulatory Adherence**:

Using conveyors helps facilities comply with occupational health and safety regulations by reducing manual handling and controlling dust, which can prevent costly fines and improve overall safety standards.

- **Worker Training**:

Implementing conveyor systems often includes comprehensive training programs for operators, further promoting a culture of safety and awareness.

### Conclusion

Conveyors significantly enhance safety in mineral processing plants by reducing the need for manual material handling and minimizing the risk of accidents and injuries.

Enclosed conveyor systems effectively control dust and prevent spillage, contributing to a cleaner and safer working environment. The additional safety features and regulatory compliance associated with conveyors further bolster their role in creating a secure and efficient workplace.

Flexibility and Scalability of Conveyor Systems in Mineral Processing

#### Customization to Fit Specific Plant Layouts and Material Characteristics

1. **Tailored Design**:

- **Custom Configurations**: Conveyor systems can be designed to match the unique layout of a processing plant, navigating around existing structures and equipment.

- **Material-Specific Features**:

Conveyors can be customized based on the properties of the materials being transported, such as bulk density, particle size, abrasiveness, and moisture content.

For example, belt materials, trough designs, and drive mechanisms can be selected to best handle specific materials.

2. **Versatile Routing**:

- **Horizontal and Vertical Transport**:

Conveyors can be configured to move materials horizontally, vertically, or at an incline, making it possible to transport materials between different levels of a plant.

- **Complex Pathways**:

They can be designed to follow complex pathways, including curves and bends, which allows for optimal use of space and seamless integration into existing plant infrastructure.

#### Easy Expansion and Modification

1. **Scalable Systems**:

- **Modular Components**:

Many conveyor systems use modular components that can be easily added or rearranged. This modularity makes it straightforward to extend the length of a conveyor or add additional sections as production needs grow.

- **Adaptable Framework**:

The framework of conveyor systems can be adjusted to accommodate new processing equipment or changes in plant layout without requiring significant structural modifications.

2. **Flexible Adaptation**:

- **Process Changes**:

Conveyor systems can be reconfigured to adapt to changes in processing requirements, such as new material types or changes in production processes. This adaptability ensures that the conveyor system remains efficient and effective even as processing needs evolve.

- **Increased Capacity**:

As production capacity increases, conveyor systems can be upgraded with more powerful drives, wider belts, or additional lines to handle higher volumes of material.

#### Additional Benefits

1. **Cost-Effective Upgrades**:

- **Incremental Investment**:

The ability to expand and modify conveyor systems incrementally allows plants to scale up operations without the need for large upfront capital expenditures.

- **Reduced Downtime**:

Modular and flexible designs mean that expansions and modifications can often be carried out with minimal disruption to ongoing operations, reducing downtime and associated costs.

2. **Integration with Advanced Technologies**:

- **Automation and Control**:

Conveyor systems can be integrated with advanced automation and control technologies, such as sensors and automated sorting systems, to enhance efficiency and adapt to new processing technologies.

- **Smart Conveyors**:

Implementing smart conveyor systems with real-time monitoring and control capabilities enables better handling of variable production demands and material characteristics.

3. **Future-Proofing**:

- **Long-Term Viability**:

Investing in flexible and scalable conveyor systems ensures that a processing plant can continue to meet future production goals and adapt to market changes without needing to overhaul the entire material handling infrastructure.

- **Sustainability**:

Flexible systems can be designed to incorporate sustainable practices, such as energy-efficient motors and recyclable materials, supporting long-term environmental goals.

### Conclusion

Conveyor systems offer exceptional flexibility and scalability for mineral processing operations.

Their ability to be customized to specific plant layouts and material characteristics ensures efficient and effective material handling. The ease with which they can be expanded or modified allows plants to adapt to changes in processing requirements and increases in production capacity without significant disruptions or costs.

This adaptability makes conveyors a valuable long-term investment for any processing plant looking to maintain efficiency and competitiveness in a dynamic industry.

Environmental Impact of Conveyors in Mineral Processing

#### Reduction in Carbon Footprint

1. **Minimized Use of Fuel-Consuming Vehicles**:

- **Lower Fuel Consumption**:

By replacing trucks and other fuel-consuming transport vehicles, conveyors reduce the overall fuel consumption of mineral processing operations. This reduction in fuel use directly translates to lower carbon emissions.

- **Reduced Vehicle Emissions**:

Fewer transport vehicles mean reduced emissions of carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter (PM), all of which contribute to air pollution and climate change.

2. **Energy Efficiency**:

- **Efficient Electric Motors**:

Modern conveyor systems are powered by energy-efficient electric motors, which consume less energy compared to the internal combustion engines of transport vehicles.

- **Variable Speed Drives**:

The use of variable frequency drives (VFDs) allows conveyors to operate at optimal speeds, further reducing energy consumption and enhancing overall energy efficiency.

#### Reduction in Dust Emissions

1. **Enclosed Conveyor Systems**:

- **Dust Containment**:

Enclosed conveyor systems are designed to contain dust within the system, preventing it from becoming airborne and reducing dust pollution.

- **Improved Air Quality**:

By minimizing dust emissions, enclosed conveyors contribute to better air quality within the processing plant and its surrounding environment, benefiting both workers and nearby communities.

2. **Compliance with Environmental Regulations**:

- **Regulatory Adherence**:

Reducing dust emissions helps processing plants comply with environmental regulations and standards, avoiding fines and penalties associated with non-compliance.

- **Sustainable Practices**:

Adopting enclosed conveyor systems as part of a broader strategy for dust control supports the industry's move towards more sustainable and environmentally responsible practices.

#### Additional Environmental Benefits

1. **Reduced Noise Pollution**:

- **Quieter Operation**:

Conveyor systems generally produce less noise compared to the operation of trucks and heavy vehicles, contributing to lower noise pollution in and around the processing plant.

- **Enhanced Worker Health**:

Lower noise levels improve working conditions and reduce the risk of hearing damage among plant workers.

2. **Less Land Disturbance**:

- **Compact Footprint**:

Conveyor systems, especially those that are elevated or designed to follow the contours of the land, require less ground disturbance compared to the construction and maintenance of roads and pathways for trucks.

- **Preservation of Ecosystems**:

Reduced land disturbance helps preserve local ecosystems and minimizes the impact on wildlife habitats.

3. **Waste Reduction**:

- **Efficient Material Handling**:

Conveyors facilitate more precise and efficient handling of materials, reducing spillage and waste. This efficiency not only conserves resources but also minimizes the environmental impact of waste disposal.

- **Recycling and Reusability**:

Many components of conveyor systems are recyclable or can be reused, reducing the environmental footprint associated with the disposal of equipment.

4. **Support for Renewable Energy Integration**:

- **Renewable Energy Sources**:

Conveyor systems can be integrated with renewable energy sources, such as solar or wind power, further reducing their environmental impact and supporting the transition to sustainable energy practices.

### Conclusion

Conveyor systems play a significant role in reducing the environmental impact of mineral processing operations. By minimizing the need for fuel-consuming transport vehicles, they help lower the carbon footprint and reduce emissions. Enclosed conveyor systems effectively control dust, contributing to better air quality and environmental compliance.

Additional benefits, such as reduced noise pollution, less land disturbance, and efficient material handling, further enhance their environmental advantages. Adopting conveyor systems supports the industry's move towards more sustainable and environmentally responsible practices, making them a key component in modern mineral processing operations.

Key Considerations in Conveyor Design for Mineral Processing

#### Material Characteristics

1. **Size and Shape**:

- **Particle Size**:

The size of the materials being transported affects the choice of conveyor. Larger particles may require wider belts or more robust systems like apron conveyors, while fine particles might be best suited for pneumatic or screw conveyors.

- **Shape and Uniformity**:

Irregularly shaped materials may need specialized handling systems to prevent blockages and ensure smooth transport.

2. **Abrasiveness**:

- **Wear Resistance**:

Materials with high abrasiveness require conveyors with wear-resistant components, such as reinforced belts or hardened steel parts, to withstand the constant friction and extend the system’s lifespan.

- **Lining and Coating**:

Protective linings or coatings can be applied to reduce wear and tear on conveyor surfaces.

3. **Moisture Content**:

- **Handling Wet Materials**:

Wet or sticky materials may require conveyors with special cleaning mechanisms to prevent buildup and ensure consistent flow.

- **Corrosion Resistance**:

Materials with high moisture content can lead to corrosion; therefore, using corrosion-resistant materials and coatings is essential.

4. **Bulk Density**:

- **Load Capacity**:

Understanding the bulk density of the material is crucial for determining the load capacity and structural requirements of the conveyor system.

#### Capacity and Speed

1. **Throughput Requirements**:

- **Design Capacity**:

The conveyor must be capable of handling the maximum expected throughput to avoid bottlenecks. This includes considering peak load scenarios.

- **Scalability**:

The system should be scalable to accommodate future increases in production capacity.

2. **Conveyor Speed**:

- **Optimal Speed**:

Balancing speed and capacity is essential to ensure efficient material handling without causing spillage or system strain.

- **Adjustable Speed**:

Implementing variable speed drives can help optimize the conveyor’s performance based on changing operational demands.

#### Durability and Maintenance

1. **Robust Construction**:

- **Material Selection**:

Using high-quality, durable materials in the construction of conveyors helps withstand the harsh conditions of mineral processing environments.

- **Component Strength**:

Components such as belts, chains, rollers, and bearings should be selected based on their ability to handle heavy loads and resist wear.

2. **Ease of Maintenance**:

- **Accessibility**:

Designing conveyors with easy access points for inspection and maintenance tasks can significantly reduce downtime.

- **Modular Design**:

Modular components allow for quick replacements and repairs, minimizing operational interruptions.

3. **Preventive Maintenance**:

- **Monitoring Systems**:

Incorporating sensors and monitoring systems can help detect issues early and schedule maintenance before major failures occur.

- **Maintenance Planning**: Establishing a proactive maintenance schedule based on the specific wear and tear patterns of the conveyor system.

#### Energy Efficiency

1. **Efficient Motors**:

- **High-Efficiency Motors**:

Using energy-efficient motors can significantly reduce the operational costs and environmental impact of the conveyor system.

- **Variable Frequency Drives (VFDs)**:

Implementing VFDs allows for precise control of motor speed and energy consumption, optimizing performance under varying load conditions.

2. **Power Consumption**:

- **Load Management**:

Designing the conveyor system to operate efficiently under different load conditions helps reduce unnecessary power consumption.

- **Energy Recovery Systems**:

Implementing energy recovery technologies, such as regenerative drives, can help capture and reuse energy, further enhancing efficiency.

3. **System Optimization**:

- **Design Layout**:

Optimizing the layout of the conveyor system to minimize unnecessary travel distances and elevation changes can reduce energy usage.

- **Smart Controls**:

Integrating advanced control systems that adjust the conveyor operation based on real-time data and demand can lead to significant energy savings.

### Conclusion

Designing an efficient and effective conveyor system for mineral processing involves careful consideration of material characteristics, capacity and speed requirements, durability, maintenance, and energy efficiency.

By understanding the specific properties of the materials being transported and the operational demands of the processing plant, designers can select and customize conveyor systems that enhance productivity, reduce operational costs, and minimize environmental impact. Implementing robust construction, preventive maintenance practices, and energy-efficient technologies ensures long-term reliability and sustainability of the conveyor system.

Conveyor Belt Installation in Mineral Processing

#### Pre-Installation Preparation

1. **Site Survey and Planning**:

- **Site Inspection**:

Conduct a thorough site inspection to assess the installation area and identify any potential obstacles or hazards.

- **Layout Design**:

Develop a detailed layout plan, including the conveyor path, support structures, and integration with existing systems.

- **Permits and Approvals**:

Obtain all necessary permits and approvals from regulatory bodies and ensure compliance with local safety and environmental regulations.

2. **Material and Equipment Preparation**:

- **Conveyor Components**: Ensure all conveyor components (belts, pulleys, idlers, motors, etc.) are on-site and meet the required specifications.

- **Tools and Equipment**:

Gather all necessary tools and equipment, including wrenches, clamps, measuring tapes, and safety gear.

3. **Safety Measures**:

- **Safety Plan**:

Develop a comprehensive safety plan, including risk assessments, emergency procedures, and safety protocols.

- **Training**:

Provide safety training to all personnel involved in the installation process.

#### Installation Process

1. **Foundation and Structure Installation**:

- **Support Structures**:

Erect the support structures, such as frames and brackets, ensuring they are level and securely anchored to the foundation.

- **Alignment**:

Verify the alignment of the support structures to ensure the conveyor will run straight and true.

2. **Installing the Conveyor Belt**:

- **Positioning the Belt**:

Place the conveyor belt along the path of the conveyor structure. Use a crane or other lifting devices if necessary to handle heavy or long sections of the belt.

- **Joining the Belt**:

If the belt is supplied in sections, join the sections together using mechanical fasteners or vulcanization, depending on the belt type and specifications.

- **Tensioning the Belt**:

Gradually tension the belt to the manufacturer’s recommended tension. This may involve adjusting tensioners, take-up units, or screw-type adjustments.

3. **Installing Conveyor Components**:

- **Pulleys and Idlers**: Install the pulleys (drive, tail, and bend) and idlers along the conveyor path. Ensure they are aligned correctly to prevent belt misalignment.

- **Drive System**:

Install the drive system, including the motor, gearbox, and drive pulley. Ensure all components are securely mounted and aligned.

- **Tracking Devices**:

Install any tracking devices or sensors designed to monitor and correct belt alignment during operation.

4. **Electrical and Control Systems**:

- **Wiring and Connections**:

Connect the electrical components, including the motor, control panels, and safety switches, following electrical codes and manufacturer instructions.

- **Control Systems**:

Install and configure the control systems, such as start/stop buttons, speed controllers, and emergency stop mechanisms.

#### Post-Installation Procedures

1. **Inspection and Testing**:

- **Initial Inspection**:

Conduct a thorough inspection of the entire conveyor system to ensure all components are properly installed and secured.

- **Test Run**:

Perform a test run of the conveyor system to check for proper operation, alignment, and tension. Monitor for any unusual noises, vibrations, or signs of misalignment.

2. **Adjustments and Fine-Tuning**:

- **Alignment Adjustments**: Make any necessary adjustments to the alignment of the belt, pulleys, and idlers to ensure smooth and efficient operation.

- **Tension Adjustments**:

Fine-tune the belt tension to achieve optimal performance and prevent slippage or excessive wear.

3. **Safety Checks**:

- **Safety Devices**:

Verify that all safety devices, such as emergency stops and guards, are functioning correctly and are accessible.

- **Training and Signage**:

Ensure that all personnel are trained in the operation and safety features of the conveyor system, and install appropriate warning signs and labels.

#### Maintenance and Monitoring

1. **Routine Maintenance**:

- **Regular Inspections**:

Schedule regular inspections to check for signs of wear, damage, or misalignment.

- **Lubrication**:

Keep all moving parts properly lubricated to reduce friction and wear.

- **Belt Cleaning**:

Regularly clean the belt to prevent buildup of material, which can cause misalignment and damage.

2. **Monitoring Systems**:

- **Sensors and Alarms**:

Utilize sensors and alarms to continuously monitor the conveyor system’s performance and detect any potential issues early.

- **Data Analysis**:

Analyze operational data to identify trends and predict maintenance needs, helping to prevent unexpected downtime.

### Conclusion

Proper installation of a conveyor belt in a mineral processing environment is essential for ensuring efficient and reliable operation.

By following a detailed and systematic approach, from pre-installation preparation through to post-installation procedures, and maintaining rigorous safety standards, you can achieve a successful installation that minimizes downtime and enhances productivity. Regular maintenance and monitoring further ensure the longevity and optimal performance of the conveyor system.

Belt Tracking & Conveyor Maintenance in Mineral Processing

#### Belt Tracking Belt tracking is the process of ensuring that the conveyor belt runs straight and true along the conveyor system. Proper belt tracking is essential to prevent damage, reduce wear, and maintain efficiency.

1. **Causes of Belt Misalignment**:

- **Incorrectly Installed Components**: Misalignment of pulleys, idlers, or rollers.

- **Uneven Loading**:

Uneven distribution of material on the belt can cause the belt to shift to one side.

- **Worn or Damaged Components**:

Wear and tear on conveyor components, such as idlers or rollers, can lead to misalignment.

- **Belt Tension**:

Incorrect tension can cause the belt to drift off-center.

2. **Methods for Tracking Conveyor Belts**:

- **Initial Alignment**:

Ensure all conveyor components are aligned correctly during installation.

- **Adjusting Idlers and Rollers**:

Use adjustable idlers and rollers to guide the belt back into proper alignment. Adjust these components incrementally and evenly on both sides of the belt.

- **Belt Tensioning**:

Properly tension the belt to avoid sagging or excessive tightness. Use tensioners or take-up units to adjust the tension as needed.

- **Training Idlers**:

Install training idlers that automatically guide the belt back into alignment. These idlers pivot or tilt to correct the belt's path.

- **Regular Inspection**:

Regularly inspect the belt and conveyor components for signs of misalignment, wear, or damage. Promptly address any issues found.

#### Conveyor Maintenance Regular maintenance is essential to ensure the conveyor system operates efficiently, safely, and with minimal downtime.

1. **Preventive Maintenance**:

- **Scheduled Inspections**:

Develop a maintenance schedule for routine inspections of the conveyor system. Inspect all components, including belts, pulleys, idlers, rollers, bearings, and drive systems.

- **Lubrication**:

Regularly lubricate moving parts, such as bearings and rollers, to reduce friction and wear.

- **Belt Cleaning**:

Keep the conveyor belt clean to prevent material buildup, which can lead to misalignment and damage. Use belt scrapers, brushes, or wash systems.

- **Component Replacement**:

Replace worn or damaged components promptly to prevent further damage and ensure smooth operation.

2. **Condition Monitoring**:

- **Sensors and Alarms**:

Install sensors to monitor belt tension, alignment, temperature, and other critical parameters. Use alarms to alert operators to potential issues.

- **Data Analysis**:

Analyze operational data to identify patterns and predict maintenance needs, helping to prevent unexpected failures.

3. **Common Maintenance Tasks**:

- **Belt Inspection**:

Regularly inspect the belt for signs of wear, damage, or fraying. Look for tears, cuts, or abrasions that may require repair or replacement.

- **Pulley and Idler Inspection**:

Check pulleys and idlers for alignment, wear, and proper rotation. Replace any that show signs of excessive wear or damage.

- **Drive System Maintenance**:

Inspect the drive motor, gearbox, and drive belt or chain. Ensure all components are functioning correctly and are properly lubricated.

- **Frame and Structure Check**:

Inspect the conveyor frame and support structures for any signs of damage, corrosion, or misalignment. Make necessary repairs or adjustments.

4. **Safety Protocols**:

- **Lockout/Tagout**:

Implement lockout/tagout procedures during maintenance to ensure the conveyor system is safely de-energized and cannot be accidentally started.

- **Safety Training**:

Provide training for maintenance personnel on safe work practices, proper use of tools and equipment, and emergency procedures.

### Conclusion

Effective belt tracking and regular conveyor maintenance are crucial for the efficient and safe operation of conveyor systems in mineral processing environments. Proper belt tracking prevents misalignment, reduces wear, and enhances the system's overall performance.

Implementing a comprehensive maintenance program that includes preventive maintenance, condition monitoring, and adherence to safety protocols ensures the longevity and reliability of the conveyor system. By addressing potential issues early and maintaining all components in good working condition, operators can minimize downtime, reduce operational costs, and maintain a high level of productivity.

Common Causes of Belt Misalignment

#### 1. Improper Installation

- **Misaligned Components**:

Incorrect alignment of pulleys, idlers, or rollers during installation can cause the belt to run off-center.

- **Frame Misalignment**:

If the conveyor frame is not straight or level, it can lead to belt tracking issues. #### 2. Uneven Loading

- **Asymmetric Load Distribution**: Uneven loading of material onto the conveyor belt can cause it to shift to one side. This can happen if material is fed unevenly or if the loading chute is off-center.

- **Impact Loading**:

Heavy, uneven impact of material on the belt can create temporary misalignment.

#### 3. Worn or Damaged Components

- **Worn Idlers and Rollers**:

Idlers and rollers that are worn or damaged can create uneven surfaces, causing the belt to wander.

- **Damaged Belts**:

Tears, frayed edges, or other damage to the belt itself can cause it to track improperly.

#### 4. Belt Tension Issues -

**Incorrect Tension**:

Belts that are either too loose or too tight can cause misalignment. Loose belts can sag and wander, while overly tight belts can cause excessive strain on the components.

- **Uneven Tension**:

Uneven tension across the width of the belt can cause one side to be tighter than the other, leading to tracking problems.

#### 5. Material Build-Up

- **Carryback**:

Material that sticks to the belt and is not properly removed can accumulate on pulleys and idlers, causing misalignment.

- **Spillage**:

Material that spills over the sides of the belt can accumulate on the conveyor structure and cause tracking issues.

#### 6. Misaligned Pulleys and Idlers

- **Skewed Pulleys**:

Pulleys that are not parallel or aligned properly with the conveyor can cause the belt to run to one side.

- **Out-of-Alignment Idlers**:

Idlers that are not aligned perpendicular to the belt path can create tracking problems.

#### 7.Belt and Splice Quality

- **Poor Belt Quality**:

Substandard belts that do not have uniform thickness or strength can lead to tracking issues.

- **Improper Splicing**:

Incorrectly spliced belts can have uneven surfaces or tensions, causing the belt to misalign.

#### 8. Environmental Factors

- **Temperature Changes**:

Significant changes in temperature can cause the belt material to expand or contract unevenly, leading to misalignment.

- **Contamination**:

Dirt, dust, or other contaminants on the belt or components can affect tracking.

#### 9. Structural Movement

- **Foundation Shifts**:

Movement or settling of the conveyor’s foundation can lead to misalignment of the entire structure.

- **Vibration**:

Excessive vibration from nearby equipment or the conveyor itself can cause components to move out of alignment over time.

### Addressing Belt Misalignment

#### Regular Inspections

- **Routine Checks**:

Regularly inspect the conveyor system for signs of misalignment, wear, or damage. Early detection can prevent more significant issues.

- **Component Inspection**:

Check all pulleys, idlers, rollers, and the belt for proper alignment and condition.

#### Proper Maintenance

- **Cleaning**:

Keep the conveyor belt and components clean to prevent material build-up that can cause misalignment.

- **Lubrication**:

Ensure all moving parts are properly lubricated to reduce wear and friction.

#### Corrective Actions

- **Adjustments**:

Make necessary adjustments to pulleys, idlers, and tensioners to correct any misalignment.

- **Replacement**:

Replace worn or damaged components promptly to maintain proper alignment and operation.

#### Training and Procedures

- **Operator Training**: Train operators and maintenance personnel on proper loading techniques and routine maintenance procedures.

- **Standard Operating Procedures**:

Implement and follow standard operating procedures for conveyor operation and maintenance.

### Conclusion

Understanding the common causes of belt misalignment is crucial for maintaining the efficient and reliable operation of a conveyor system in mineral processing. Regular inspections, proper maintenance, and prompt corrective actions can help prevent misalignment issues, reducing downtime and extending the life of the conveyor belt and components.

Possible Solutions for Belt Misalignment

Addressing belt misalignment in conveyor systems involves a combination of preventive measures, corrective actions, and ongoing maintenance. Here are some effective solutions to ensure proper belt alignment:

#### 1. Correct Installation

- **Ensure Proper Alignment**:

During installation, ensure that all pulleys, idlers, and the conveyor frame are perfectly aligned. Use alignment tools such as laser alignment devices to achieve precise alignment.

- **Level the Frame**:

Make sure the conveyor frame is level and straight. Any deviation can cause belt misalignment.

#### 2. Regular Maintenance and Inspection

- **Routine Checks**:

Conduct regular inspections to identify and address signs of misalignment early. This includes checking the belt, pulleys, idlers, rollers, and other components.

- **Clean Components**:

Keep all parts of the conveyor system clean. Regularly remove any material build-up on pulleys, idlers, and rollers.

- **Lubrication**:

Properly lubricate bearings and other moving parts to reduce friction and wear.

#### 3. Adjustments to Belt Tension

- **Correct Tension**:

Ensure the belt is tensioned according to the manufacturer’s specifications. Both over-tensioning and under-tensioning can cause alignment issues.

- **Even Tension**:

Make sure the tension is even across the width of the belt. Uneven tension can lead to one side being tighter than the other, causing the belt to track off.

#### 4. Proper Loading Practices

- **Even Loading**:

Load materials evenly across the width of the belt. Use loading chutes and hoppers designed to distribute material uniformly.

- **Avoid Impact Loading**:

Minimize the impact of heavy materials falling onto the belt by using impact beds or rollers.

#### 5. Use of Training Idlers

- **Install Training Idlers**:

Training idlers, also known as self-aligning idlers, can help correct minor misalignment automatically. These idlers pivot and tilt to guide the belt back into proper alignment.

- **Strategic Placement**:

Place training idlers at intervals along the conveyor, particularly in areas prone to misalignment such as near the head and tail pulleys.

#### 6. Alignment Devices and Sensors

- **Laser Alignment Tools**:

Use laser alignment tools during installation and maintenance to ensure precise alignment of all components.

- **Tracking Sensors**: Install tracking sensors that detect misalignment and provide real-time alerts, allowing for quick corrective action.

#### 7. Modify and Maintain Conveyor Structure

- **Reinforce the Frame**:

Strengthen and reinforce the conveyor frame to prevent structural movement that can lead to misalignment.

- **Foundation Stability**:

Ensure the conveyor’s foundation is stable and does not shift over time. Address any ground movement or settling issues promptly.

#### 8. Corrective Actions for Worn Components

- **Replace Worn Idlers and Rollers**:

Regularly check and replace any worn or damaged idlers and rollers. Ensure they are properly aligned during replacement.

- **Repair or Replace Damaged Belts**:

Inspect the belt for tears, fraying, or other damage. Repair or replace the belt as necessary to ensure it runs true. #### 9. Implementing Belt Tracking Systems

- **Edge Guide Rollers**:

Install edge guide rollers that keep the belt centered by providing a physical barrier on the belt edges.

- **Crowned Pulleys**:

Use crowned pulleys, which have a slightly higher center, to help guide the belt towards the center.

#### 10. Training and Standard Operating Procedures

- **Operator Training**:

Train operators and maintenance personnel on proper conveyor operation, loading techniques, and routine maintenance procedures.

- **Standard Operating Procedures (SOPs)**:

Develop and implement SOPs for all aspects of conveyor operation and maintenance. Ensure that these procedures are followed consistently.

### Conclusion

Addressing belt misalignment requires a comprehensive approach that includes proper installation, regular maintenance, and immediate corrective actions when issues arise. By implementing these solutions, you can ensure that your conveyor system operates efficiently, with minimal downtime and reduced wear on the belt and components.

Proper alignment not only enhances the performance of the conveyor system but also extends its lifespan, providing long-term benefits in mineral processing operations.

Tracking Problems and Their Impact on Operating cost

Tracking problems in conveyor systems can lead to significant and unnecessary expenses, affecting overall efficiency and increasing operational costs. Below are the main areas where tracking problems cause financial impact:

#### 1. Material Waste

- **Spillage**:

Misaligned belts can cause material to spill off the sides, leading to significant material loss.

- **Contamination**:

Spilled material can mix with other materials or contaminants, rendering it unusable.

#### 2. Maintenance Costs

- **Frequent Repairs**:

Continuous misalignment leads to excessive wear and tear on the belt and components, necessitating frequent repairs.

- **Increased Downtime**:

Unscheduled maintenance and repairs disrupt operations, leading to costly downtime.

#### 3. Clean-Up Costs

- **Labor**:

Regular clean-up of spilled materials requires additional labor, increasing labor costs.

- **Equipment**:

Specialized equipment may be needed to clean up spilled material, adding to operational expenses.

#### 4. Component Damage / Failure

- **Idlers and Rollers**:

Misalignment puts extra stress on idlers and rollers, causing premature wear and failure.

- **Bearings**:

Excessive lateral forces on bearings can lead to overheating and failure, requiring replacement.

#### 5. Structure Damage

- **Frame Wear**:

A misaligned belt can rub against the conveyor frame, causing wear and structural damage over time.

- **Support Structures**:

The additional forces exerted by a misaligned belt can lead to bending or breaking of support structures.

### Solutions to Mitigate Tracking Problems and Reduce Expenses

Implementing effective solutions to address tracking problems can help mitigate these costs and improve the overall efficiency of the conveyor system. #### Material Waste Reduction

- **Improved Loading Systems**:

Ensure even distribution of material onto the belt to prevent spillage. Use loading chutes and hoppers designed for uniform loading.

- **Belt Skirting**:

Install belt skirting along the sides to contain materials and prevent spillage.

#### Maintenance Cost Reduction

- **Regular Inspections**:

Conduct regular inspections to identify and address alignment issues before they cause significant damage.

- **Preventive Maintenance**:

Implement a preventive maintenance program that includes routine checks and timely repairs.

#### Clean-Up Cost Reduction

- **Automated Cleaning Systems**: Use belt cleaners and scrapers to automatically remove material buildup and reduce manual clean-up efforts.

- **Spillage Containment**:

Install containment systems such as catch pans or skirts to collect and manage spilled material efficiently. #### Component Damage Mitigation

- **Quality Components**:

Use high-quality, durable components that can withstand the stresses of a misaligned belt.

- **Alignment Devices**:

Install tracking and alignment devices to maintain proper belt alignment and reduce component wear.

#### Structure Damage Prevention

- **Proper Installation**:

Ensure the conveyor frame and support structures are properly aligned and installed to prevent wear and damage.

- **Regular Structural Checks**:

Conduct regular inspections of the conveyor structure to identify and repair any damage caused by misalignment.

### Proactive Measures for Long-Term Benefits #### Training and Procedures

- **Operator Training**:

Train operators on the importance of proper loading, belt tracking, and maintenance procedures.

- **Standard Operating Procedures**:

Develop and implement SOPs for conveyor operation and maintenance to ensure consistent practices.

#### Advanced Monitoring Systems

- **Sensors and Automation**:

Use sensors to monitor belt alignment in real-time and automate corrective actions.

- **Data Analytics**:

Analyze operational data to predict and prevent tracking issues, optimizing maintenance schedules.

### Conclusion

Addressing belt tracking problems is crucial for minimizing unnecessary expenses and ensuring the efficient operation of conveyor systems in mineral processing.

By implementing targeted solutions for reducing material waste, maintenance costs, clean-up costs, component damage, and structure damage, you can significantly improve the reliability and cost-effectiveness of your conveyor operations. Proactive measures, such as regular inspections, proper maintenance, and advanced monitoring, further enhance these benefits, leading to long-term operational success.

Precautions for Maintenance Personnel

To ensure the safety of maintenance personnel working on conveyor systems, it's crucial to follow strict safety protocols and guidelines. Here are key precautions to observe:

1. **Do Not Perform Maintenance While the Conveyor is Operating**

- **Safety First**:

Always prioritize safety and ensure the conveyor is completely stopped before beginning any maintenance tasks.

2. **Lockout/Tagout Procedures**

- **Lock Out the Circuit Breaker**:

Use personal padlocks to lock out the circuit breaker disconnect switch. This ensures the conveyor cannot be accidentally restarted during maintenance.

- **Tagout**:

Place a tag on the switch indicating that maintenance is being performed and the system should not be energized.

3. **Avoid Contact with Moving Parts**

- **No Touching**:

For tasks such as belt tracking or listening for bearing noise, never touch a moving belt, roller, pulley, or bearing. Always use tools or instruments designed for such inspections.

- **Observation**:

Perform visual inspections and listen for unusual noises from a safe distance.

4. **External Inspections and Adjustments**

- **Stay Outside**:

All inspections and adjustments should be performed from outside the conveyor structure. This minimizes the risk of injury from moving parts.

- **Use Proper Tools**:

Utilize appropriate tools and devices for remote inspections and adjustments. 5. **No Reaching Under or Into Running Conveyors**

- **Hands Off**: Never reach under or into the conveyor when the belt is running. Moving parts can cause serious injury.

- **Physical Barriers**:

Use physical barriers or guards to prevent accidental contact with moving parts during maintenance.

6. **Clear Personnel Before Restarting**

- **Safety Check**:

Before restarting the conveyor, ensure all personnel are clear of moving parts and have moved to a safe location.

- **Communication**:

Communicate clearly with all team members to confirm that the conveyor area is clear and it is safe to restart the system.

7. **Maintain Good Housekeeping**

- **Clean Work Area**:

Maintain a clean and organized work area around the conveyor at all times. This reduces the risk of tripping, slipping, and other accidents.

- **Remove Debris**:

Regularly remove debris and ensure walkways and access points are clear.

### Additional Safety Measures

#### Training and Awareness

- **Comprehensive Training**:

Provide thorough training for all maintenance personnel on safety protocols, lockout/tagout procedures, and the specific hazards associated with conveyor systems.

- **Regular Refresher Courses**:

Conduct regular refresher courses to keep safety knowledge up to date. #### Personal Protective Equipment (PPE)

- **Use Appropriate PPE**:

Ensure maintenance personnel wear the necessary PPE, such as gloves, safety glasses, hard hats, and steel-toed boots.

- **Inspect PPE**: Regularly inspect PPE to ensure it is in good condition and provides adequate protection.

#### Emergency Procedures

- **Emergency Stop Mechanisms**:

Familiarize all personnel with the location and operation of emergency stop mechanisms.

- **First Aid Training**:

Provide first aid training and ensure that first aid supplies are readily accessible.

### Conclusion

Adhering to these safety precautions is essential for protecting maintenance personnel from the inherent dangers associated with conveyor systems. By implementing strict lockout/tagout procedures, avoiding contact with moving parts, performing external inspections and adjustments, maintaining clear communication, and ensuring a clean work environment, you can significantly reduce the risk of accidents and injuries. Continuous training, proper use of PPE, and well-defined emergency procedures further enhance workplace safety.

Additional Precautions for Maintenance Personnel

To further ensure the safety of maintenance personnel working on conveyor systems, the following additional precautions should be observed:

1. **Clean Up Spilled Materials and Lubricants Promptly**

- **Immediate Clean-Up**:

Quickly clean up any spilled materials or lubricants to prevent slips and falls, which can cause injuries.

2. **Replace Safety Guards and Protective Devices**

- **Reinstallation**:

Always replace safety guards and protective devices before putting the conveyor back in service. This ensures that all safety mechanisms are in place to protect against moving parts.

- **Verification**:

Double-check that all guards are properly installed and secured before restarting the conveyor.

3. **Do Not Run the Conveyor with Open or Missing Chain Drive Guards**

- **Safety First**:

Never operate the conveyor with chain drive guards open or missing. These guards are essential for preventing contact with moving parts and reducing the risk of injury.

4. **Stay Alert for Hazardous Conditions**

- **Vigilance**:

Maintenance personnel should always be alert and aware of their surroundings, looking out for hazardous conditions such as loose materials, faulty equipment, or unsafe practices.

5. **Remove Sharp Edges and Protruding Objects**

- **Safety Measures**:

Remove or mitigate sharp edges and protruding objects to prevent injuries. Replace broken or worn parts promptly to maintain a safe working environment.

6. **Manage Air Hoses and Drop Cords Properly**

- **Avoid Tripping Hazards**: