Fluid Bed Roaster - Introduction

### Key Components of a Fluid Bed Roaster

1. **Feed System**:

- Introduces raw materials into the roaster at a controlled rate to maintain a stable bed height and ensure uniform processing.

2. **Distributor Plate**:

- A perforated plate or grid at the bottom of the roasting chamber that evenly distributes the fluidizing gas across the bed of particles.

3. **Fluidizing Gas**:

- Typically air or another gas that is blown through the distributor plate to fluidize the particles, creating a fluid-like state where the particles are suspended and agitated.

4. **Roasting Chamber**:

- The main body of the roaster where the fluidization and roasting processes occur.

5. **Heating System**:

- Provides the necessary heat to achieve the desired roasting temperature. This can be through burners, electric heaters, or heat exchangers.

6. **Cyclone Separator**:

- Separates entrained particles from the exhaust gas to prevent loss of material and reduce emissions.

7. **Dust Collection System**:

- Captures fine particles generated during the roasting process to prevent environmental pollution and health hazards.

8. **Exhaust System**:

- Manages the off-gases produced during roasting, which may include by-products of chemical reactions.

9. **Discharge System**:

- Removes the roasted product from the roaster in a controlled manner to maintain consistent operation.

### Summary

A fluid bed roaster is a versatile and efficient thermal processing device that utilizes fluidization to enhance heat and mass transfer. It consists of key components such as a feed system, distributor plate, heating system, cyclone separator, and dust collection system. The process involves fluidizing particles with a gas, heating them to the desired temperature, and managing the resulting products and emissions. Fluid bed roasters are widely used across various industries for roasting, drying, and chemical processing due to their operational efficiency and ability to provide uniform treatment.

How does a Fluid Bed Roaster Work?

A fluid bed roaster is a type of thermal processing equipment widely used in various industries, including mineral processing, food processing, and chemical manufacturing.

It operates on the principle of fluidization, where a bed of solid particles is transformed into a fluid-like state through the introduction of a gas, typically air. This allows for efficient heat transfer, uniform temperature distribution, and improved reaction kinetics.

#### Key Components of a Fluid Bed Roaster

1. **Feed System**: Introduces raw material (feed) into the roaster at a controlled rate.

2. **Distributor Plate**:

Distributes the fluidizing gas evenly across the bed of particles.

3. **Fluidizing Gas**:

Typically air or another gas, used to fluidize the particles and provide the necessary thermal energy for roasting.

4. **Roasting Chamber**:

The main body where fluidization and roasting occur.

5. **Heating System**:

Provides the necessary heat to achieve the desired roasting temperature, which can be burners, electric heaters, or heat exchangers.

6. **Cyclone Separator**:

Removes entrained particles from the exhaust gas.

7. **Dust Collection System**:

Captures fine particles and prevents dust emissions.

8. **Exhaust System**:

Manages the off-gases produced during roasting.

9. **Discharge System**:

Removes the roasted product from the roaster.

#### Operating Principles

1. **Feed Introduction**:

- The raw material is introduced into the roasting chamber via a feed system. The feed rate is controlled to maintain a stable bed height and ensure uniform processing.

2. **Fluidization**:

- A fluidizing gas, usually air, is blown through the distributor plate at the bottom of the roasting chamber. The gas flow rate is critical to achieving proper fluidization, where the particles are suspended and behave like a fluid.

- The uniform distribution of the gas ensures even fluidization, preventing dead zones and channeling within the bed.

3. **Heating and Roasting**:

- The heating system heats the fluidizing gas before it enters the bed or directly heats the bed through conduction and convection. This raises the temperature of the particles to the desired roasting temperature.

- The particles undergo thermal treatment, such as drying, calcination, oxidation, or reduction, depending on the specific process requirements.

- The efficient heat transfer in the fluidized state ensures uniform temperature distribution, which is crucial for consistent product quality.

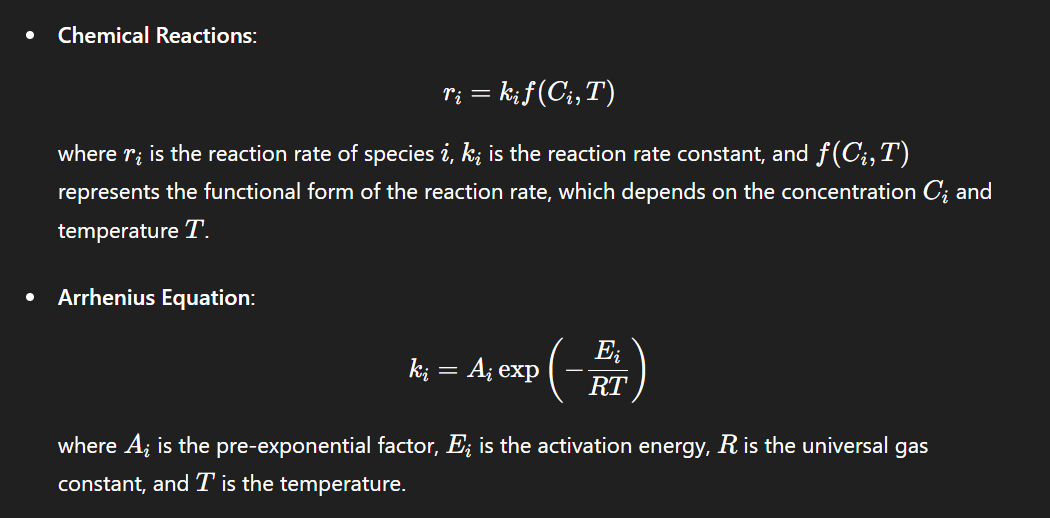

4. **Chemical Reactions**:

- During roasting, the particles may undergo various chemical reactions. For example, in mineral processing, sulfide ores are oxidized to produce oxides and release sulfur dioxide.

- The type of gas used and its composition can influence the reactions. For instance, oxygen-enriched air can accelerate oxidation reactions.

5. **Product Discharge**:

- The roasted material is discharged from the bottom or side of the roaster through a controlled discharge system. The discharge rate is regulated to maintain the desired residence time and bed height.

- Roasted particles may need cooling before further processing or handling.

6. **Exhaust and Dust Collection**:

- The exhaust gases, along with any entrained fine particles, exit the roasting chamber and pass through a cyclone separator, which removes the larger particles.

- A dust collection system captures fine particles from the exhaust stream to prevent environmental pollution and comply with safety regulations.

- Cleaned exhaust gases are then released into the atmosphere or further treated if necessary.

7. **Control and Monitoring**:

- Various sensors and control systems monitor critical parameters such as temperature, pressure, gas flow rate, and bed height.

- Advanced automation and control systems adjust the operational parameters in real-time to maintain optimal conditions, ensuring consistent product quality and efficient operation.

### Summary

A fluid bed roaster operates by fluidizing a bed of solid particles with a gas, typically air, which facilitates efficient heat transfer and uniform roasting. Key components include the feed system, distributor plate, roasting chamber, heating system, cyclone separator, dust collection system, exhaust system, and discharge system.

The process involves feed introduction, fluidization, heating and roasting, chemical reactions, product discharge, and exhaust and dust collection. Effective control and monitoring systems are essential for maintaining optimal operating conditions and ensuring high-quality product output.

Key Features and Benefits

A fluidized bed roaster is a piece of equipment where solid particles are suspended in an upward flow of gas, creating a fluid-like state.

This method is highly efficient for roasting ores because it provides uniform temperature distribution and good gas-solid contact, leading to efficient reactions.

### Key Features and Benefits:

1. **Uniform Temperature Distribution**:

The fluidized state ensures that the temperature within the bed is consistent, which is crucial for the effective and uniform roasting of ores.

2. **Efficient Gas-Solid Contact**:

The fluidization of particles allows for better interaction between the gas and solid phases, promoting more efficient chemical reactions.

3. **Improved Reaction Rates**:

Due to enhanced heat and mass transfer, the reaction rates in fluidized bed roasters are generally higher compared to other roasting methods.

4. **Scalability**:

Fluidized bed roasters can be scaled up to handle large quantities of ore, making them suitable for industrial applications.

5. **Flexibility**:

They can be used for a wide range of ores and can accommodate variations in feed composition and particle size.

### Applications in Mineral Processing:

1. **Sulfide Ores**:

Fluidized bed roasters are commonly used for roasting sulfide ores such as pyrite (FeS₂) and chalcopyrite (CuFeS₂). The roasting process converts these sulfides into oxides, which are easier to process in subsequent steps.

2. **Oxidation**:

The roasting process involves the oxidation of the sulfide ores, which releases sulfur dioxide (SO₂). This gas can be captured and converted into sulfuric acid, adding an environmental and economic benefit.

3. **Desulfurization**:

The removal of sulfur from ores not only prevents the release of harmful SO₂ gas but also enhances the quality of the final product.

4. **Gold Extraction**:

Fluidized bed roasters are also used in the pretreatment of refractory gold ores. The roasting process oxidizes the sulfide matrix, freeing the gold particles for subsequent extraction.

### Process Description:

1. **Feed Preparation**:

Ores are crushed and ground to a fine powder to ensure proper fluidization in the roaster.

2. **Fluidization**:

The powdered ore is fed into the fluidized bed roaster, where it is suspended in an upward flow of hot air or oxygen-enriched gas.

3. **Roasting**:

The ore particles undergo chemical reactions, primarily oxidation, at high temperatures (typically 500-1000°C).

4. **Gas Collection**:

The off-gases produced during roasting, mainly sulfur dioxide, are collected for further processing or environmental control.

5. **Product Discharge**:

The roasted ore is discharged from the bottom of the fluidized bed and sent to the next stage of processing, such as leaching or smelting.

### Advantages over Traditional Roasting Methods:

- **Higher Efficiency**:

The improved heat and mass transfer in fluidized bed roasters lead to higher reaction rates and better overall efficiency.

- **Lower Energy Consumption**:

Uniform temperature distribution and efficient gas-solid contact reduce the energy required for roasting.

- **Environmental Benefits**:

The capture and utilization of sulfur dioxide help mitigate environmental pollution and can provide additional economic value through the production of sulfuric acid.

Fluidized bed roasting represents a significant advancement in mineral processing technology, providing a more efficient, scalable, and environmentally friendly method for the extraction and refining of valuable metals from their ores.

The key operational aspects of a fluid bed roaster

Here are the main operational aspects to consider:

### 1. Fluidization Quality

- **Gas Flow Rate**:

The gas flow rate must be carefully controlled to achieve and maintain proper fluidization. Insufficient flow can lead to defluidization, while excessive flow can cause particle entrainment.

- **Uniform Distribution**:

The gas distribution system, including the distributor plate, should ensure uniform gas flow to prevent channeling and dead zones.

### 2. Temperature Control

- **Operating Temperature**:

The temperature should be maintained within the optimal range for the specific roasting process to ensure desired chemical reactions and avoid issues such as sintering or melting of particles.

- **Temperature Uniformity**:

Ensure uniform temperature distribution throughout the bed to prevent hotspots and uneven roasting.

- **Heating System**:

Efficient and responsive heating systems (e.g., burners, electric heaters) are essential for maintaining the desired temperature profile.

### 3. Pressure Control

- **Bed Pressure Drop**:

Monitor the pressure drop across the bed to ensure proper fluidization and detect any blockages or channeling.

- **System Pressure**:

The operating pressure should be controlled to influence reaction rates and fluidization behavior.

### 4. Feed Rate and Particle Characteristics

- **Feed Rate Control**:

Accurately control the feed rate to maintain stable operation and consistent product quality. Variations in feed rate can lead to fluctuations in bed temperature and pressure.

- **Particle Size and Distribution**:

Ensure the feed material has a suitable particle size distribution for fluidization. Uniform particle size helps maintain stable fluidization.

- **Moisture Content**:

Pre-dry the feed material if necessary to avoid agglomeration and ensure efficient fluidization.

### 5. Residence Time

- **Sufficient Residence Time**:

Ensure the particles spend enough time in the roaster to complete the desired reactions. Adjust the bed height and feed rate to control residence time.

### 6. Gas Composition

- **Type of Gas**:

The choice of fluidizing gas (air, oxygen-enriched air, etc.) should match the requirements of the roasting process.

- **Gas Purity**:

Ensure the gas used for fluidization is free from contaminants that could interfere with the roasting reactions.

### 7. Reaction Kinetics and Product Quality

- **Control of Reaction Conditions**:

Adjust operational parameters to optimize reaction rates and achieve desired product specifications.

- **Monitoring Reaction Progress**:

Use sensors and analytical techniques to monitor the extent of reactions and ensure consistent product quality.

### 8. Heat Transfer

- **Efficient Heat Transfer**:

Ensure effective heat transfer between the gas, particles, and reactor walls to maintain desired temperature profiles and process efficiency.

- **Cooling Systems**:

Implement cooling systems if necessary to control the temperature of the roasted product before further handling.

### 9. Discharge System

- **Smooth Discharge**:

Design the discharge system to facilitate the efficient removal of roasted material without causing blockages or interruptions.

- **Control of Discharge Rate**:

Control the rate at which roasted material is discharged to maintain a stable bed height and consistent operation.

### 10. Environmental and Safety Considerations

- **Emission Control**:

Implement systems to capture and treat off-gases, such as sulfur dioxide, to comply with environmental regulations.

- **Dust Control**:

Use dust collection systems to capture dust generated during fluidization and discharge to prevent health hazards and equipment damage.

- **Safety Measures**:

Include safety features to handle potential risks such as fires, explosions, and equipment failures. Ensure regular maintenance and inspection of safety systems.

### 11. Process Control and Monitoring

- **Instrumentation**:

Install adequate sensors and control systems to monitor critical parameters such as temperature, pressure, gas flow rate, and bed height.

- **Automation**:

Use advanced automation systems to enhance process control, improve efficiency, and reduce the need for manual intervention.

- **Data Logging and Analysis**:

Continuously log operational data and analyze it to identify trends, optimize performance, and troubleshoot issues.

### 12. Maintenance and Troubleshooting

- **Regular Maintenance**:

Perform regular maintenance on equipment to prevent unexpected failures and ensure reliable operation.

- **Troubleshooting Procedures**:

Establish procedures for identifying and resolving operational issues promptly to minimize downtime and maintain product quality.

### Summary

The key operational aspects of a fluid bed roaster encompass fluidization quality, temperature and pressure control, feed rate and particle characteristics, residence time, gas composition, reaction kinetics, heat transfer, discharge system, environmental and safety considerations, process control and monitoring, and maintenance and troubleshooting. By carefully managing these aspects, operators can ensure efficient, safe, and consistent performance of the fluid bed roaster in mineral processing applications.

Fluidization Quality

Ensuring proper fluidization quality is essential for the efficient and effective operation of a fluidized bed roaster.

The key factors that influence fluidization quality are the gas flow rate and the uniform distribution of the gas.

#### Gas Flow Rate

**Key Points:**

- **Achieving Fluidization**:

The gas flow rate must be sufficient to lift and suspend the particles, creating a fluidized state where the particles behave like a fluid.

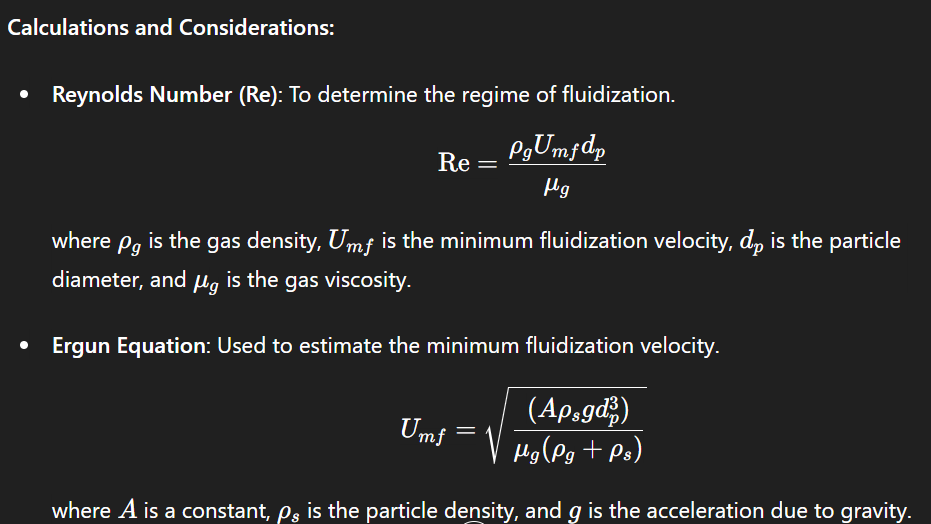

- **Minimum Fluidization Velocity (\(U_{mf}\))**:

The minimum gas velocity required to initiate fluidization. This is a critical parameter and depends on the properties of the particles (size, density) and the gas (density, viscosity).

- **Operating Velocity**:

The actual gas velocity during operation, typically higher than the minimum fluidization velocity to ensure stable fluidization.

**Implications of Incorrect Flow Rate:**

- **Insufficient Flow (Defluidization)**:

If the gas flow rate is too low, the bed will not fluidize properly, leading to poor mixing, uneven temperature distribution, and incomplete reactions.

- **Excessive Flow (Particle Entrainment)**:

If the gas flow rate is too high, particles can be carried out of the bed with the gas stream, leading to loss of material, equipment erosion, and environmental issues.

#### Uniform Distribution

**Key Points:**

- **Distributor Plate Design**:

The design of the gas distributor plate is crucial to ensure even distribution of gas across the bed.

- **Perforation Pattern**:

The size, shape, and distribution of holes in the distributor plate should be designed to provide uniform gas flow.

- **Pressure Drop**:

The pressure drop across the distributor plate should be significant enough to ensure uniform gas distribution but not so high as to waste energy.

**Types of Distributor Plates:**

- **Perforated Plate**:

Simple design with uniform holes. Suitable for systems with low-to-moderate fluidization requirements.

- **Bubble Cap Distributor**: More complex design with caps over the holes to distribute gas evenly. Suitable for higher fluidization velocities.

- **Nozzle Type Distributor**:

Uses nozzles to direct gas flow. Suitable for applications requiring precise control of gas flow distribution.

**Avoiding Channeling and Dead Zones:**

- **Channeling**:

Occurs when gas flows preferentially through certain paths, leading to poor fluidization in other areas. Can be minimized by ensuring a well-designed distributor plate and uniform particle size distribution.

- **Dead Zones**:

Areas in the bed where fluidization does not occur, leading to poor mixing and reaction inefficiency. Regular monitoring and maintenance of the distributor plate can help prevent dead zones.

**Monitoring and Adjustments:**

- **Pressure Measurement**:

Use differential pressure measurements across the bed to monitor fluidization quality.

- **Visual Inspection**:

Regularly inspect the bed and distributor plate for signs of wear, clogging, or uneven gas distribution.

- **Flow Adjustments**:

Adjust the gas flow rate and distribution as needed based on operational data to maintain optimal fluidization quality.

### Summary

Achieving and maintaining proper fluidization quality in a fluidized bed roaster is critical for efficient operation.

This involves carefully controlling the gas flow rate to ensure it is within the optimal range to achieve fluidization without causing particle entrainment. Additionally, ensuring uniform gas distribution through a well-designed distributor plate is essential to prevent channeling and dead zones, thereby maintaining consistent fluidization and optimal reaction conditions throughout the bed. Monitoring and regular adjustments based on operational data help in maintaining the desired fluidization quality.

Temperature Control in Fluid Bed Roasters

Here are the key components of temperature control:

#### 1. Operating Temperature

**Key Points:**

- **Optimal Range**:

The operating temperature should be maintained within a specific range suitable for the desired roasting reactions. This range varies depending on the material being processed and the specific reactions required.

- **Reaction Kinetics**:

Temperature influences the rate of chemical reactions, with higher temperatures generally increasing reaction rates up to a certain point.

- **Avoiding Sintering or Melting**:

The temperature should be kept below the sintering or melting point of the particles to maintain their integrity and fluidization properties.

**Considerations:**

- **Material Properties**:

Different materials have different optimal roasting temperatures based on their chemical and physical properties.

- **Reaction Type**:

Endothermic reactions may require higher temperatures, while exothermic reactions might necessitate careful temperature control to avoid excessive heat build-up.

#### 2. Temperature Uniformity

**Key Points:**

- **Uniform Distribution**:

Ensuring uniform temperature distribution throughout the bed prevents hotspots and uneven roasting, which can lead to incomplete reactions or degradation of the material.

- **Mixing and Fluidization**:

Proper fluidization promotes excellent mixing of particles and uniform heat distribution.

**Techniques for Ensuring Uniformity:**

- **Efficient Fluidization**:

Maintaining proper fluidization helps distribute heat evenly.

- **Heat Distribution Systems**:

Use internal heat exchangers or multiple heating zones to distribute heat uniformly.

- **Thermocouples and Sensors**:

Place temperature sensors at various points within the bed to monitor and control temperature distribution.

**Avoiding Hotspots:**

- **Preventing Overheating**:

Implement control systems to prevent localized overheating, which can cause sintering or degradation of particles.

- **Monitoring and Adjustment**:

Regularly monitor temperature profiles and adjust heating systems to maintain uniformity.

#### 3. Heating System

**Key Points:**

- **Types of Heating Systems**:

Various heating systems can be used, including:

- **Burners**:

Gas or oil burners provide direct heating and are commonly used in fluid bed roasters.

- **Electric Heaters**:

Provide precise temperature control and are suitable for smaller-scale operations or where clean energy is preferred.

- **Heat Exchangers**:

Internal or external heat exchangers can be used to maintain temperature profiles.

**Efficiency and Responsiveness:**

- **Quick Response**:

Heating systems should respond quickly to changes in temperature setpoints to maintain stable operation.

- **Energy Efficiency**:

Optimize the heating system for energy efficiency to reduce operating costs.

**Control Systems:**

- **PID Controllers**:

Use Proportional-Integral-Derivative (PID) controllers to maintain desired temperature setpoints accurately.

- **Advanced Automation**:

Implement advanced automation and control systems to adjust heating in real-time based on sensor inputs and process conditions.

**Integration with Cooling Systems:**

- **Cooling Requirements**:

Some processes may require cooling systems to remove excess heat and maintain optimal temperatures.

- **Heat Recovery**:

Utilize waste heat recovery systems to improve energy efficiency.

### Summary

Temperature control in fluid bed roasters involves maintaining the operating temperature within the optimal range, ensuring uniform temperature distribution, and using efficient and responsive heating systems.

Proper fluidization, monitoring, and control systems are essential to achieve the desired chemical reactions, prevent sintering or melting of particles, and maintain product quality. Advanced automation and temperature sensors play a crucial role in achieving precise and uniform temperature control.

Pressure Control in Fluid Bed Roasters

Here are the key aspects of pressure control:

#### 1. Bed Pressure Drop

**Key Points:**

- **Definition**:

Bed pressure drop is the difference in pressure between the bottom and top of the fluidized bed. It indicates the resistance to gas flow through the bed and is a critical parameter for ensuring proper fluidization.

- **Optimal Range**:

The pressure drop should be within a specific range to maintain fluidization. Too low a pressure drop may indicate insufficient fluidization, while too high a pressure drop can suggest excessive gas flow or bed clogging.

**Monitoring and Control:**

- **Pressure Sensors**:

Install pressure sensors at various points in the bed to continuously monitor the pressure drop.

- **Data Logging**:

Continuously log pressure data to detect trends and identify potential issues such as blockages or channeling.

- **Regular Calibration**:

Ensure pressure sensors are regularly calibrated for accurate measurements.

**Detection of Issues:**

- **Blockages**:

A sudden increase in pressure drop can indicate blockages in the bed or distributor plate, requiring immediate attention.

- **Channeling**:

Uneven pressure drop readings across different sections of the bed can indicate channeling, where gas bypasses certain areas, leading to poor fluidization.

**Adjustments:**

- **Gas Flow Rate**:

Adjust the gas flow rate to maintain the desired pressure drop. This may involve increasing or decreasing the gas velocity.

- **Distributor Plate Maintenance**:

Regularly inspect and clean the distributor plate to prevent clogging and ensure uniform gas distribution.

#### 2. System Pressure

**Key Points:**

- **Operating Pressure**:

The overall pressure within the fluid bed system, which influences the fluidization behavior, reaction rates, and gas solubility.

- **Impact on Reaction Rates**:

Higher system pressure can increase reaction rates for certain processes, particularly those involving gas-phase reactions.

**Control Strategies:**

-**Pressure Control Valves**: Use pressure control valves to regulate the system pressure and maintain it within the desired range.

- **Automatic Pressure Controllers**:

Implement automatic pressure controllers to adjust system pressure based on real-time data from pressure sensors.

**Influence on Fluidization:**

- **Fluidization Behavior**:

Higher system pressure can improve fluidization by increasing the density of the fluidizing gas, thus providing better support for the particles.

- **Particle Attrition**:

Increased pressure can also lead to higher particle attrition rates, which need to be monitored and managed.

**Safety Considerations:**

- **Pressure Relief Systems**:

Install pressure relief systems to prevent overpressure situations that could lead to equipment damage or safety hazards.

- **Regular Inspections**:

Conduct regular inspections and maintenance of pressure control equipment to ensure safe and reliable operation.

**Optimization:**

-

**Process Optimization**: Optimize system pressure based on the specific requirements of the roasting process. This may involve conducting experiments or simulations to determine the ideal pressure conditions.

- **Energy Efficiency**:

Balance the benefits of increased pressure with the energy costs associated with maintaining higher pressure levels.

### Summary

Pressure control in fluid bed roasters involves monitoring and adjusting the bed pressure drop and overall system pressure to ensure proper fluidization, optimize reaction rates, and maintain stable operation.

Key strategies include the use of pressure sensors, control valves, and automatic pressure controllers, along with regular maintenance and safety measures. By carefully managing these parameters, operators can achieve efficient and effective roasting processes while ensuring safety and reliability.

Feed Rate and Particle Characteristics in Fluid Bed Roasters

Effective control of the feed rate and understanding particle characteristics are crucial for maintaining stable operation, ensuring consistent product quality, and optimizing the performance of fluid bed roasters.

Here are the key aspects to consider:

#### Feed Rate Control

**Key Points:**

- **Stable Operation**:

Maintaining a consistent feed rate is essential to ensure stable bed dynamics, uniform temperature distribution, and consistent reaction conditions.

- **Impact on Temperature and Pressure**:

Variations in the feed rate can cause fluctuations in bed temperature and pressure, affecting the efficiency and effectiveness of the roasting process.

**Strategies for Control:**

- **Automated Feed Systems**:

Utilize automated feed systems with precise control mechanisms to regulate the feed rate. These systems can include gravimetric or volumetric feeders.

- **Real-Time Monitoring**:

Implement real-time monitoring of feed rate using flow meters or weight sensors to ensure accuracy.

- **Feedback Control**:

Use feedback control loops to adjust the feed rate based on real-time data from the bed, ensuring consistent operation.

**Avoiding Common Issues:**

- **Overfeeding**:

Can lead to bed overloading, increased pressure drop, and potential defluidization.

- **Underfeeding**:

Can cause bed instability, uneven temperature distribution, and incomplete reactions.

#### Particle Size and Distribution

**Key Points:**

- **Suitable Size for Fluidization**:

The particle size should be within a range that allows for proper fluidization. Typically, fine to medium-sized particles are preferred.

- **Uniform Size Distribution**:

A narrow particle size distribution helps maintain stable fluidization and prevents segregation.

**Characteristics to Consider:**

- **Mean Particle Size**:

The average size of the particles, which should be optimized for the specific roasting process.

- **Size Distribution**:

The range of particle sizes present in the feed material. A uniform distribution reduces the likelihood of channeling and dead zones in the bed.

**Methods for Ensuring Suitable Particle Size:**

- **Screening and Classification**:

Use screening and classification techniques to achieve the desired particle size distribution before feeding the material into the roaster.

- **Grinding and Milling**:

Implement grinding or milling processes to reduce the size of larger particles to within the optimal range for fluidization.

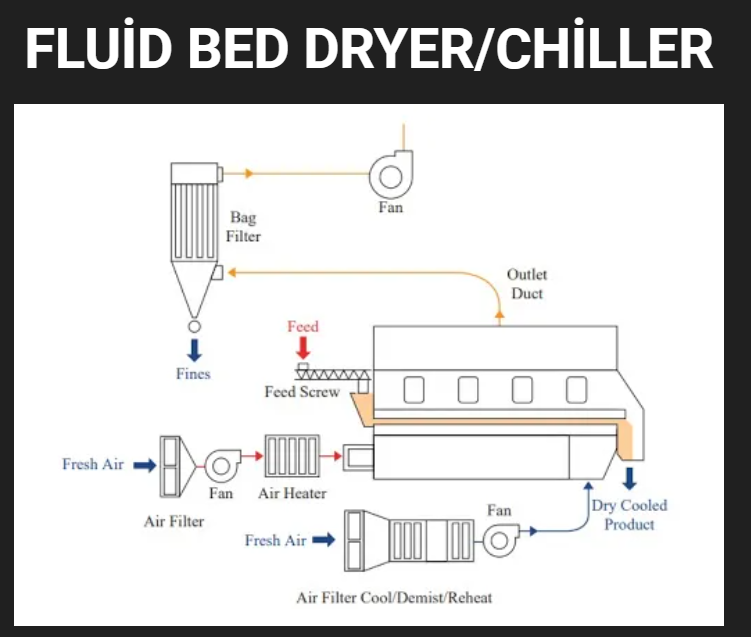

#### Moisture Content

**Key Points:**

- **Impact on Fluidization**:

High moisture content can lead to agglomeration, where particles stick together, preventing proper fluidization and causing operational issues.

- **Pre-Drying**:

Pre-drying the feed material is often necessary to reduce moisture content to an acceptable level.

**Methods for Moisture Control:**

- **Drying Systems**:

Install drying systems, such as rotary dryers or fluid bed dryers, to remove excess moisture from the feed material before it enters the roaster.

- **Monitoring Moisture Levels**:

Use moisture sensors to monitor the moisture content of the feed material in real-time, ensuring it remains within the desired range.

**Benefits of Proper Moisture Control:**

- **Improved Fluidization**:

Ensures efficient fluidization and prevents bed defluidization due to wet, sticky particles.

- **Consistent Product Quality**:

Maintains uniform roasting conditions, leading to consistent product quality.

### Summary

Effective control of the feed rate and careful management of particle characteristics, including particle size, distribution, and moisture content, are critical for the successful operation of fluid bed roasters.

Accurate feed rate control ensures stable operation and consistent product quality, while maintaining a suitable and uniform particle size distribution helps achieve efficient fluidization.

Pre-drying the feed material to manage moisture content is essential to avoid agglomeration and ensure smooth fluidization. By addressing these aspects, operators can optimize the performance of fluid bed roasters and achieve the desired outcomes in the roasting process.

Residence Time in Fluid Bed Roasters

Residence time is a critical parameter in fluid bed roasters, ensuring that particles have sufficient time to complete the desired reactions.

Proper control of residence time directly impacts the efficiency and quality of the roasting process.

#### Sufficient Residence Time

**Key Points:**

- **Definition**:

Residence time is the average time that particles spend in the fluidized bed. It must be long enough to ensure that the required chemical reactions are completed.

- **Reaction Completion**:

Adequate residence time is necessary to achieve complete roasting, avoid partially processed materials, and ensure consistent product quality.

**Factors Influencing Residence Time:**

- **Bed Height**:

Increasing the bed height can increase the residence time by providing a longer path for particles to travel.

- **Feed Rate**:

Adjusting the feed rate can help control residence time. A lower feed rate typically increases residence time, while a higher feed rate decreases it.

- **Gas Velocity**:

The velocity of the fluidizing gas can also influence residence time, as higher velocities may decrease the time particles remain in the bed.

#### Adjusting Bed Height and Feed Rate

**Bed Height:**

- **Impact on Residence Time**:

A taller bed increases the residence time by allowing particles to remain in the reactor for a longer period.

- **Optimal Bed Height**:

Determine the optimal bed height based on the desired residence time and the characteristics of the material being processed.

**Feed Rate:**

- **Impact on Residence Time**:

The feed rate inversely affects residence time; reducing the feed rate increases the residence time and vice versa.

- **Controlled Feed Rate**:

Use precise feed rate control mechanisms to adjust and maintain the desired residence time. Automated feeders with real-time adjustments can be particularly effective.

**Balancing Bed Height and Feed Rate:**

- **Integrated Approach**:

Combine adjustments to both bed height and feed rate to achieve the desired residence time while maintaining stable fluidization and optimal process conditions.

- **Pilot Testing**:

Conduct pilot tests to determine the ideal combination of bed height and feed rate for the specific material and reaction requirements.

#### Monitoring and Control

**Real-Time Monitoring:**

- **Sensors and Instruments**:

Use sensors to monitor key parameters such as bed height, feed rate, and gas velocity. Ensure data is collected in real-time to make immediate adjustments if needed.

- **Data Analysis**:

Analyze operational data to understand the relationship between residence time and process performance. Use this information to fine-tune operating parameters.

**Control Systems:**

- **Automated Controls**:

Implement automated control systems to adjust bed height and feed rate based on real-time data. These systems can use feedback loops to maintain optimal residence time.

- **Modeling and Simulation**:

Use process modeling and simulation tools to predict the effects of changes in bed height and feed rate on residence time and overall process performance.

### Summary

Ensuring sufficient residence time in fluid bed roasters is essential for the complete and consistent processing of materials.

By adjusting bed height and feed rate, operators can control residence time to meet the specific requirements of the roasting process.

Real-time monitoring and automated control systems are vital for maintaining optimal residence time, ensuring stable operation, and achieving high-quality product output.

Gas Composition in Fluid Bed Roasters

The composition of the fluidizing gas is a critical aspect of fluid bed roasting processes. The choice and purity of the gas influence the efficiency, safety, and quality of the roasting process. Here are the key considerations:

#### Type of Gas

**Key Points:**

- **Match Process Requirements**:

The type of gas used for fluidization should be chosen based on the specific requirements of the roasting process. Different gases can affect the reaction kinetics, product quality, and overall efficiency.

**Common Choices:**

- **Air**:

The most commonly used fluidizing gas due to its availability and cost-effectiveness. Suitable for many roasting processes where oxidation is required.

- **Oxygen-Enriched Air**:

Increases the oxygen concentration to enhance oxidation reactions, improving reaction rates and potentially reducing process time.

- **Inert Gases (e.g., Nitrogen, Argon)**:

Used in processes where oxidation must be minimized or avoided. Suitable for roasting materials that are sensitive to oxidation.

- **Specialty Gases**:

In some cases, specific gases like carbon dioxide or a mixture of gases might be required for particular reactions.

**Impact on Reactions:**

- **Oxidizing Atmosphere**:

Using air or oxygen-enriched air creates an oxidizing environment, which can enhance the roasting of sulfide ores or other oxidation-dependent processes.

- **Reducing Atmosphere**:

Using inert gases can create a reducing atmosphere, beneficial for processes that require reduction reactions or need to prevent oxidation.

#### Gas Purity

**Key Points:**

- **Free from Contaminants**:

The fluidizing gas should be free from contaminants that could interfere with the roasting reactions, affect product quality, or cause operational issues.

**Purity Requirements:**

- **Industrial Grade**:

For most industrial applications, using industrial-grade gases with specified purity levels is sufficient. The exact purity requirements depend on the sensitivity of the roasting process to contaminants.

- **High Purity**:

In cases where even trace contaminants can cause issues, higher purity gases might be necessary. This is common in processes involving sensitive materials or reactions.

**Sources of Contamination:**

- **Moisture**:

Water vapor can lead to unwanted reactions, agglomeration of particles, or corrosion of equipment. Use gas dryers or desiccants to remove moisture.

- **Particulate Matter**:

Particles in the gas can cause blockages in the distributor plate or interfere with fluidization. Implement gas filtration systems to remove particulates.

- **Chemical Contaminants**:

Trace chemicals in the gas can catalyze undesired reactions or poison catalysts used in the process. Ensure gas suppliers provide gases with low levels of chemical impurities.

**Monitoring and Control:**

- **Gas Quality Sensors**:

Use sensors to continuously monitor the quality and composition of the fluidizing gas.

- **Regular Testing**:

Conduct regular testing of the gas supply to ensure it meets the required purity specifications.

- **Maintenance of Gas Supply Systems**:

Regularly maintain and clean gas supply systems, including filters and dryers, to ensure consistent gas quality.

### Summary

The type and purity of the fluidizing gas are crucial parameters in fluid bed roasters. The choice of gas (air, oxygen-enriched air, inert gases, etc.) should align with the specific requirements of the roasting process to ensure optimal reaction conditions and product quality.

Ensuring the gas is free from contaminants such as moisture, particulate matter, and chemical impurities is essential to avoid interference with the roasting reactions and to maintain operational efficiency.

Continuous monitoring, regular testing, and proper maintenance of gas supply systems are necessary to ensure consistent and high-quality gas composition.

Reaction Kinetics and Product Quality in Fluid Bed Roasters

Ensuring optimal reaction kinetics and maintaining high product quality are central goals in fluid bed roasting operations.

Proper control of reaction conditions and continuous monitoring of reaction progress are essential to achieve these goals.

#### Control of Reaction Conditions

**Key Points:**

- **Optimization of Reaction Rates**:

Adjusting operational parameters such as temperature, pressure, gas composition, and residence time can optimize reaction rates, ensuring that reactions proceed at the desired rate.

- **Desired Product Specifications**:

Fine-tuning these parameters helps achieve the specific physical and chemical properties required in the final product.

**Operational Parameters:**

- **Temperature**:

- **Optimal Range**:

Each reaction has an optimal temperature range where the reaction rate is maximized without causing unwanted side reactions or degradation.

- **Control Systems**:

Implement precise temperature control systems using thermocouples and PID controllers to maintain the desired temperature profile.

- **Pressure**:

- **Influence on Reactions**:

Pressure can affect the solubility of gases in solids and liquids, altering reaction rates.

- **Adjustment**:

Use pressure control valves and sensors to maintain the optimal system pressure.

- **Gas Composition**:

- **Reactant Availability**:

Ensure that the fluidizing gas provides the necessary reactants in the correct proportions.

- **Atmosphere Control**:

Adjust the composition to create oxidizing or reducing environments as needed.

- **Residence Time**:

- **Sufficient Time**:

Adjust bed height and feed rate to provide sufficient time for reactions to complete.

- **Control Systems**:

Use real-time monitoring and control systems to adjust feed rate and maintain stable residence times.

#### Monitoring Reaction Progress

**Key Points:**

- **Continuous Monitoring**:

Employ sensors and analytical techniques to continuously monitor reaction progress, ensuring consistent product quality and allowing for real-time adjustments.

- **Data Analysis**:

Analyze data from monitoring systems to identify trends, optimize operations, and troubleshoot issues.

**Techniques and Instruments:**

- **Temperature Sensors**:

- **Placement**:

Position sensors at various points within the bed to monitor temperature distribution.

Use data to adjust heating systems and ensure uniform temperature profiles.

- **Pressure Sensors**:

- **Pressure Drop**:

Monitor pressure drop across the bed to detect changes in fluidization quality and identify potential blockages.

- **System Pressure**:

Maintain overall system pressure within desired ranges.

- **Gas Analyzers**:

- **Composition Monitoring**:

Use gas analyzers to measure the composition of the fluidizing gas and off-gases.

- **Reaction Extent**:

Determine the extent of reactions by analyzing the concentration of reactants and products.

- **Particle Size Analyzers**:

- **Quality Control**:

Regularly measure the particle size distribution of the feed and product to ensure consistency.

- **Process Adjustments**:

Adjust grinding, milling, and classification processes based on particle size data.

- **Moisture Analyzers**:

- **Moisture Content**:

Monitor the moisture content of the feed material to ensure it is within acceptable limits for fluidization.

- **Pre-Drying Systems**:

Adjust drying systems based on real-time moisture data.

- **Spectroscopic Techniques**:

- **Chemical Composition**:

Use techniques like FTIR or Raman spectroscopy to monitor the chemical composition of the bed material and products.

- **Reaction Monitoring**:

Identify intermediate and final reaction products to ensure complete reactions.

#### Ensuring Consistent Product Quality

**Quality Control Measures:**

- **Sampling**:

Regularly sample the product and feed materials for laboratory analysis.

-

**Standard Operating Procedures (SOPs)**:

Develop and adhere to SOPs for operating conditions, sampling, and analysis.

- **Quality Assurance Programs**:

Implement quality assurance programs to track and maintain product specifications.

**Real-Time Adjustments:**

- **Feedback Loops**:

Use data from sensors and analyzers to make real-time adjustments to operational parameters.

- **Automation**:

Integrate advanced automation systems to enhance process control and reduce the need for manual interventions.

### Summary

Controlling reaction conditions and continuously monitoring reaction progress are vital for optimizing reaction kinetics and ensuring consistent product quality in fluid bed roasters.

By adjusting parameters such as temperature, pressure, gas composition, and residence time, operators can optimize reaction rates and achieve desired product specifications.

Employing sensors and analytical techniques for real-time monitoring allows for immediate adjustments, maintaining stable operation and high-quality output. Implementing robust quality control and assurance measures further ensures that the final product meets the required standards.

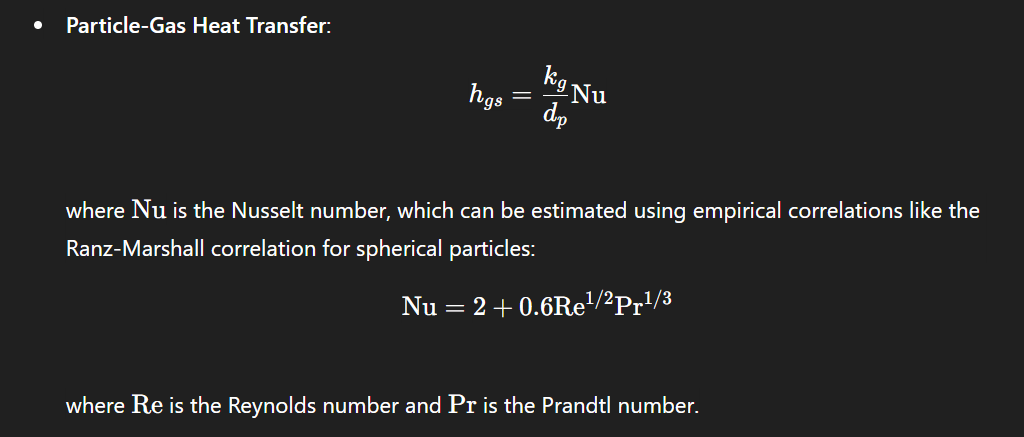

Heat Transfer in Fluid Bed Roasters

Efficient heat transfer is crucial for maintaining desired temperature profiles, ensuring process efficiency, and achieving consistent product quality in fluid bed roasters.

Proper management of heat transfer within the system and implementing cooling systems for post-processing are key aspects to consider.

#### Efficient Heat Transfer

**Key Points:**

- **Maintain Temperature Profiles**:

Effective heat transfer ensures that the entire bed maintains the required temperature for optimal reaction rates.

- **Process Efficiency**:

Good heat transfer minimizes energy consumption and enhances the overall efficiency of the roasting process.

**Mechanisms of Heat Transfer:**

- **Conduction**:

Heat transfer through direct contact between particles and between particles and reactor walls.

- **Convection**:

Heat transfer due to the movement of the fluidizing gas, which carries heat through the bed.

- **Radiation**:

Heat transfer through electromagnetic waves, significant at higher temperatures.

**Strategies for Enhancing Heat Transfer:**

- **Proper Design of Heat Exchangers**:

Incorporate well-designed heat exchangers to maximize the surface area for heat transfer.

- **Efficient Burner Systems**:

Use efficient burners or heating elements to provide uniform heat distribution throughout the bed.

- **Bed Material Properties**:

Select bed materials with high thermal conductivity to improve heat transfer rates.

- **Uniform Gas Distribution**:

Ensure uniform distribution of the fluidizing gas to prevent hot or cold spots within the bed.

- **Optimized Bed Height and Particle Size**:

Adjust bed height and particle size distribution to maximize contact between particles and fluidizing gas.

**Temperature Monitoring and Control:**

- **Thermocouples and Infrared Sensors**:

Install multiple thermocouples or infrared sensors at different points in the bed to monitor temperature distribution.

- **PID Controllers**:

Use Proportional-Integral-Derivative (PID) controllers to maintain desired temperature setpoints by adjusting heating inputs in real-time.

- **Real-Time Data Analysis**:

Continuously analyze temperature data to detect and correct deviations from the desired temperature profile.

#### Cooling Systems

**Key Points:**

- **Control Roasted Product Temperature**:

Cooling the roasted product before further handling or processing is necessary to prevent thermal damage and ensure safe handling.

- **Avoid Overheating**:

Proper cooling prevents overheating, which can degrade product quality or cause safety hazards.

**Types of Cooling Systems:**

- **Water-Cooled Heat Exchangers**:

Use water-cooled heat exchangers to rapidly remove heat from the roasted product.

- **Air-Cooled Heat Exchangers**:

Employ air-cooled heat exchangers or cooling fans for non-contact cooling of the product.

- **Fluid Bed Coolers**:

Utilize separate fluid bed coolers where cool air is fluidized through the bed of roasted material to evenly cool the particles.

- **Quenching Systems**:

Implement quenching systems using water sprays or immersion to rapidly cool the product, particularly for materials requiring rapid temperature reduction.

**Implementation and Integration:**

- **Post-Roaster Cooling Stage**:

Integrate cooling systems immediately after the roasting stage to ensure seamless process flow and efficient temperature control.

- **Temperature Monitoring**:

Use temperature sensors to monitor the cooling rate and final temperature of the product.

- **Automated Control Systems**:

Implement automated control systems to adjust cooling rates based on real-time temperature data, ensuring consistent and controlled cooling.

### Summary

Efficient heat transfer in fluid bed roasters is vital for maintaining the desired temperature profiles and ensuring process efficiency.

Key strategies include using well-designed heat exchangers, efficient heating systems, and uniform gas distribution.

Continuous monitoring and control of temperature are essential for detecting and correcting deviations.

Implementing cooling systems for the roasted product is equally important to prevent thermal damage and ensure safe handling.

Various cooling methods, such as water-cooled or air-cooled heat exchangers, fluid bed coolers, and quenching systems, can be employed based on the specific requirements of the process and material. By integrating these systems and using automated control, operators can achieve effective heat management, ensuring optimal performance and high-quality product output.

Discharge System in Fluid Bed Roasters

The discharge system is a crucial component of fluid bed roasters, ensuring smooth and controlled removal of roasted material. Effective design and operation of the discharge system help maintain stable bed height and consistent process conditions.

#### Smooth Discharge

**Key Points:**

- **Prevent Blockages**:

The design of the discharge system should prevent blockages that could disrupt the continuous operation of the roaster.

- **Minimize Interruptions**:

Ensuring a smooth discharge helps maintain consistent process conditions and product quality.

**Design Considerations:**

- **Discharge Ports**:

Strategically position multiple discharge ports to allow uniform removal of material and prevent localized buildup.

- **Valves and Gates**:

Use robust and reliable valves or gates that can handle the abrasive nature of the roasted material. Options include rotary valves, knife gate valves, or slide gates.

- **Angled Hopper**:

Design the hopper with steep angles to facilitate the gravity-assisted flow of material, reducing the risk of bridging or rat-holing.

- **Fluidizing Gas Assistance**:

Employ fluidizing gas jets near the discharge area to help keep particles in motion and prevent blockages.

**Material Flow Enhancements:**

- **Vibratory Systems**:

Integrate vibratory systems or pneumatic vibrators to keep the material moving smoothly towards the discharge ports.

- **Anti-Stick Coatings**:

Apply anti-stick coatings to the hopper and discharge chute to reduce material adhesion and buildup.

#### Control of Discharge Rate

**Key Points:**

- **Stable Bed Height**:

Controlling the discharge rate is essential for maintaining a stable bed height, which in turn ensures consistent fluidization and process conditions.

- **Consistent Operation**:

A controlled discharge rate helps avoid fluctuations in bed dynamics, contributing to steady operation and uniform product quality.

**Control Mechanisms:**

- **Automated Valves**:

Use automated control valves that can adjust the discharge rate based on real-time feedback from the bed level sensors.

- **Weight-Based Control**:

Implement weight sensors to monitor the mass of material in the bed and adjust the discharge rate accordingly to maintain a target bed height.

- **Level Sensors**:

Employ level sensors to continuously monitor the bed height and provide input to the control system for adjusting the discharge rate.

**Feedback Systems:**

- **Real-Time Monitoring**:

Use real-time data from sensors to adjust the discharge rate dynamically, ensuring stable bed height and fluidization conditions.

- **Control Algorithms**:

Implement advanced control algorithms (e.g., PID controllers) to fine-tune the discharge rate based on bed height and material flow characteristics.

**Integration with Feed Rate:**

- **Coordinated Control**:

Synchronize the discharge rate control with the feed rate to maintain overall mass balance and stable operation. Any change in feed rate should be compensated by adjusting the discharge rate to maintain the desired bed height.

### Summary

A well-designed discharge system in fluid bed roasters is essential for efficient and continuous removal of roasted material. Key design features include strategically positioned discharge ports, reliable valves or gates, angled hoppers, and potential use of vibratory systems or fluidizing gas assistance to prevent blockages and ensure smooth material flow.

Controlling the discharge rate is critical for maintaining a stable bed height and consistent process conditions. Automated control valves, weight sensors, and level sensors, along with real-time monitoring and advanced control algorithms, help achieve precise control of the discharge rate. Coordinating the discharge rate with the feed rate ensures overall mass balance and stable operation, leading to consistent product quality and process efficiency.

Environmental and Safety Considerations in Fluid Bed Roasters

Environmental and safety considerations are paramount in the design and operation of fluid bed roasters.

Proper systems and protocols must be implemented to control emissions, manage dust, and ensure safety to comply with regulations and protect both personnel and equipment.

#### Emission Control

**Key Points:**

- **Capture and Treat Off-Gases**:

Implement systems to capture and treat harmful off-gases produced during roasting to comply with environmental regulations.

- **Regulatory Compliance**:

Ensure that emissions meet local and international environmental standards.

**Emission Control Systems:**

- **Scrubbers**:

Use wet scrubbers or dry scrubbers to remove gaseous pollutants, such as sulfur dioxide (SO₂), from the exhaust stream.

- **Baghouses**:

Employ baghouse filters to capture particulate matter from the off-gases before they are released into the atmosphere.

- **Electrostatic Precipitators**:

Install electrostatic precipitators to remove fine particulates from the gas stream using electrical charges.

- **Catalytic Converters**:

Use catalytic converters to reduce NOx emissions by converting them into nitrogen and oxygen through catalytic reactions.

**Monitoring and Control:**

- **Continuous Emissions Monitoring Systems (CEMS)**: Install CEMS to continuously monitor the concentration of pollutants in the exhaust gases and ensure compliance with emission limits.

- **Automated Control Systems**:

Integrate automated control systems to adjust operational parameters in real-time based on emission data, optimizing the performance of emission control equipment.

#### Dust Control

**Key Points:**

- **Capture Dust**:

Use dust collection systems to capture dust generated during fluidization and discharge to prevent health hazards and equipment damage.

- **Health and Safety**:

Prevent inhalation of dust by workers and reduce the risk of explosions from dust accumulation.

**Dust Collection Systems:**

- **Cyclone Separators**:

Use cyclone separators to capture large dust particles from the gas stream.

- **Dust Collectors**:

Employ industrial dust collectors, such as cartridge or baghouse filters, to capture fine dust particles.

- **Local Exhaust Ventilation (LEV)**:

Implement LEV systems at points of dust generation to capture dust at the source.

**Control Measures:**

- **Enclosures and Seals**:

Design enclosures and seals around equipment and discharge points to minimize dust escape.

- **Air Curtains**:

Use air curtains at discharge points to contain and direct dust into collection systems.

- **Regular Cleaning**:

Schedule regular cleaning and maintenance of dust collection systems to ensure optimal performance.

#### Safety Measures

**Key Points:**

- **Handle Risks**:

Include safety features to manage potential risks such as fires, explosions, and equipment failures.

- **Regular Maintenance**:

Ensure regular maintenance and inspection of safety systems to maintain their effectiveness.

**Safety Systems and Protocols:**

- **Fire Suppression Systems**:

Install fire suppression systems, such as sprinklers or CO₂ extinguishers, to quickly address any fires that may occur.

- **Explosion Venting and Suppression**:

Use explosion venting panels and suppression systems to mitigate the effects of explosions within the roaster.

- **Inert Gas Blanketing**:

Apply inert gas blanketing to reduce oxygen levels and prevent combustion in sensitive areas.

- **Temperature and Pressure Sensors**:

Install sensors to monitor temperature and pressure, providing early warning of abnormal conditions.

- **Emergency Shutdown Systems (ESD)**:

Implement ESD systems to safely shut down the process in the event of a critical failure.

**Maintenance and Inspection:**

- **Routine Checks**:

Conduct routine checks and maintenance of all safety systems, including fire suppression, explosion protection, and gas monitoring equipment.

- **Safety Audits**:

Perform regular safety audits to identify potential hazards and ensure compliance with safety standards.

- **Training**:

Provide comprehensive training for personnel on emergency procedures, use of safety equipment, and response to potential incidents.

### Summary

Environmental and safety considerations in fluid bed roasters involve implementing robust systems to control emissions, manage dust, and ensure overall safety.

Emission control systems, such as scrubbers, baghouses, and CEMS, help capture and treat off-gases to comply with environmental regulations. Dust control measures, including cyclone separators, dust collectors, and LEV systems, prevent health hazards and equipment damage.

Safety measures are critical for handling potential risks such as fires, explosions, and equipment failures.

These include fire suppression systems, explosion venting, inert gas blanketing, and emergency shutdown systems. Regular maintenance, inspections, and safety training ensure the effectiveness of these systems and compliance with safety standards, protecting both personnel and the environment.

Process Control and Monitoring in Fluid Bed Roasters

Effective process control and monitoring are essential for the optimal operation of fluid bed roasters.

This involves installing the necessary instrumentation, leveraging advanced automation systems, and implementing comprehensive data logging and analysis protocols.

#### Instrumentation

**Key Points:**

- **Monitor Critical Parameters**:

Install sensors to monitor critical parameters such as temperature, pressure, gas flow rate, and bed height to ensure stable and efficient operation.

- **Accurate Measurement**:

Ensure that all instruments provide accurate and reliable measurements.

**Essential Sensors and Instruments:**

- **Temperature Sensors**:

- **Thermocouples and RTDs**:

Use thermocouples and resistance temperature detectors (RTDs) to monitor the temperature at various points in the bed.

- **Infrared Sensors**:

Employ infrared sensors for non-contact temperature measurement of the bed surface.

- **Pressure Sensors**:

- **Differential Pressure Sensors**:

Monitor the pressure drop across the bed to ensure proper fluidization.

- **Absolute Pressure Sensors**:

Measure the system pressure to maintain optimal reaction conditions.

- **Gas Flow Meters**:

- **Mass Flow Meters**:

Measure the flow rate of the fluidizing gas to control and optimize fluidization.

- **Volumetric Flow Meters**:

Use volumetric flow meters for continuous gas flow monitoring.

- **Bed Height Sensors**:

- **Level Sensors**:

Utilize level sensors such as ultrasonic or radar sensors to monitor the bed height and maintain consistent operation.

- **Capacitance Probes**:

Implement capacitance probes for accurate bed level detection.

#### Automation

**Key Points:**

- **Enhance Process Control**:

Use advanced automation systems to enhance process control, improve efficiency, and reduce manual intervention.

- **Real-Time Adjustments**:

Automation allows for real-time adjustments to maintain optimal operating conditions.

**Automation Systems:**

- **Programmable Logic Controllers (PLCs)**:

- **Process Control**:

Use PLCs for real-time process control, ensuring precise adjustments of operational parameters.

- **Integration**:

Integrate sensors and actuators with PLCs to automate control actions based on sensor feedback.

- **Distributed Control Systems (DCS)**:

- **Complex Control**:

Implement DCS for managing more complex processes and integrating multiple control loops.

- **Scalability**:

DCS systems offer scalability for large-scale operations.

- **Supervisory Control and Data Acquisition (SCADA)**:

- **Monitoring and Control**:

Use SCADA systems for comprehensive monitoring and control, providing a user-friendly interface for operators.

- **Alarm Management**:

SCADA systems can manage alarms and provide alerts for abnormal conditions.

- **Advanced Process Control (APC)**:

- **Predictive Control**:

Implement APC techniques such as model predictive control (MPC) to predict and adjust process parameters proactively.

- **Optimization**:

Use APC to continuously optimize process conditions for improved performance.

#### Data Logging and Analysis

**Key Points:**

- **Continuous Data Logging**:

Continuously log operational data to maintain a detailed record of process conditions.

- **Identify Trends and Optimize Performance**:

Analyze logged data to identify trends, optimize performance, and troubleshoot issues.

**Data Logging Systems:**

- **Data Acquisition Systems (DAS)**:

- **Comprehensive Logging**:

Use DAS to collect and store data from all sensors and instruments.

- **High-Resolution Data**:

Ensure high-resolution data logging for detailed analysis.

- **Historian Software**:

- **Data Storage**:

Use historian software to store large volumes of historical data.

- **Data Retrieval**:

Implement efficient data retrieval systems for analysis and reporting.

- **Analytics Software**:

- **Data Analysis**:

Use advanced analytics software to analyze process data and identify trends.

- **Visualization**:

Implement visualization tools to present data in an accessible and interpretable format.

- **Machine Learning and AI**:

- **Predictive Maintenance**:

Use machine learning algorithms to predict equipment failures and schedule maintenance proactively.

- **Process Optimization**: Apply AI techniques to optimize process parameters based on historical and real-time data.

### Summary

Effective process control and monitoring in fluid bed roasters involve the use of adequate instrumentation, advanced automation systems, and comprehensive data logging and analysis protocols.

**Instrumentation**

ensures accurate monitoring of critical parameters such as temperature, pressure, gas flow rate, and bed height.

**Automation systems**,

including PLCs, DCS, SCADA, and APC, enhance process control, improve efficiency, and reduce manual intervention by allowing real-time adjustments and optimization of process conditions.

**Data logging and analysis**

enable continuous recording and detailed analysis of operational data to identify trends, optimize performance, and troubleshoot issues, leveraging advanced analytics and AI for predictive maintenance and process optimization.

By integrating these elements, operators can maintain stable and efficient operation, ensuring high-quality product output and compliance with safety and environmental standards.

Maintenance and Troubleshooting in Fluid Bed Roasters

Regular maintenance and effective troubleshooting procedures are critical for ensuring the reliable operation and longevity of fluid bed roasters. Implementing a proactive maintenance schedule and having well-defined troubleshooting protocols help minimize downtime, maintain product quality, and ensure safe operation.

#### Regular Maintenance

**Key Points:**

- **Prevent Unexpected Failures**:

Regular maintenance helps prevent unexpected equipment failures.

- **Ensure Reliable Operation**:

Scheduled maintenance ensures the equipment operates reliably and efficiently.

**Maintenance Activities:**

- **Inspection**:

Regularly inspect all components, including the distributor plate, heating elements, sensors, and control systems, for signs of wear or damage.

- **Cleaning**:

Clean the bed, distributor plate, and gas flow paths to remove any accumulated dust, debris, or residues that could impair performance.

- **Lubrication**:

Lubricate moving parts, such as valves and actuators, to reduce friction and wear.

- **Calibration**:

Regularly calibrate sensors and instrumentation to maintain accuracy in monitoring critical parameters.

- **Replacement of Wear Parts**:

Replace wear parts, such as filters, seals, and gaskets, at specified intervals to prevent failures.

- **Inspection of Safety Systems**:

Check and maintain safety systems, including fire suppression, explosion venting, and emergency shutdown systems, to ensure they are in proper working order.

- **Verification of Control Systems**:

Periodically verify and update control system software to ensure optimal performance and integration with new technologies.

**Maintenance Schedule:**

- **Daily**:

Visual inspection of equipment, check for leaks, and verify the operation of sensors and control systems.

- **Weekly**:

Detailed inspection of critical components, cleaning of dust collection systems, and lubrication of moving parts.

- **Monthly**:

Calibration of sensors, checking and replacing filters, and inspection of the distributor plate and heating elements.

- **Quarterly**:

Comprehensive inspection and testing of safety systems, verification of control system software, and replacement of wear parts.

- **Annually**:

Full system shutdown for a thorough inspection, major maintenance activities, and any necessary upgrades or refurbishments.

#### Troubleshooting Procedures

**Key Points:**

.- **Prompt Issue Resolution**:

Establish procedures for promptly identifying and resolving operational issues.

- **Minimize Downtime**:

Effective troubleshooting minimizes downtime and maintains product quality.

**Common Issues and Troubleshooting Steps:**

1. **Poor Fluidization**

- **Cause**:

Incorrect gas flow rate, particle size distribution, or blockages in the distributor plate.

- **Solution**:

Adjust the gas flow rate, check and clean the distributor plate, and ensure the feed material has a suitable particle size distribution.

2. **Inconsistent Bed Temperature**

- **Cause**: Malfunctioning heating elements, poor heat distribution, or inaccurate temperature sensors.

- **Solution**:

Inspect and replace heating elements, ensure uniform gas distribution, and calibrate or replace temperature sensors.

3. **High Pressure Drop Across the Bed**

- **Cause**:

Excessive bed height, blockages, or high particle moisture content.

- **Solution**:

Reduce bed height, clean the distributor plate and gas flow paths, and ensure the feed material is properly dried.

4. **Excessive Dust Emission**

- **Cause**:

Ineffective dust collection system or high gas velocity.

- **Solution**:

Check and maintain the dust collection system, adjust gas velocity, and ensure proper sealing of the system.

5. **Product Quality Issues**

- **Cause**:

Incorrect residence time, temperature variations, or uneven fluidization.

- **Solution**:

Adjust feed rate and bed height to control residence time, ensure consistent temperature distribution, and maintain uniform fluidization.

**Troubleshooting Protocol:**

- **Initial Assessment**:

Quickly assess the situation by reviewing sensor data, control system alarms, and visual inspections.

- **Root Cause Analysis**:

Identify the root cause of the issue using systematic approaches such as the "5 Whys" technique or fishbone diagrams.

- **Corrective Actions**:

Implement corrective actions based on the identified root cause, ensuring all necessary adjustments and repairs are made.

- **Testing and Validation**:

After implementing corrective actions, test the system to ensure the issue has been resolved and the system operates correctly.

- **Documentation**:

Document the issue, root cause, corrective actions, and testing results for future reference and continuous improvement.

### Summary

Regular maintenance and effective troubleshooting are essential for the reliable operation of fluid bed roasters.

**Regular maintenance activities**,

including inspection, cleaning, lubrication, calibration, and replacement of wear parts, help prevent unexpected failures and ensure reliable operation. Establishing a detailed maintenance schedule ensures that these activities are carried out consistently.

**Troubleshooting procedures**

involve prompt identification and resolution of operational issues to minimize downtime and maintain product quality.

Common issues, such as poor fluidization, inconsistent bed temperature, high pressure drop, excessive dust emission, and product quality problems, require systematic troubleshooting steps and corrective actions.

Implementing a structured troubleshooting protocol, including initial assessment, root cause analysis, corrective actions, testing, and documentation, ensures efficient resolution of issues and continuous improvement of the system.

What are the factors to be consider when designing a fluid bed roaster?

Here are the key factors to consider:

### 1. **Feed Material Characteristics**

- **Particle Size and Distribution**:

The particle size of the feed material must be suitable for fluidization. Typically, a narrow particle size distribution is preferred to maintain uniform fluidization.

- **Density**:

The density of the feed material affects the fluidization velocity and bed dynamics.

- **Moisture Content**:

High moisture content can affect fluidization and may require pre-drying.

- **Chemical Composition**:

Understanding the chemical composition is crucial to predict the behavior during roasting and to select appropriate materials of construction.

### 2. **Fluidization Medium**

- **Type of Gas**:

The choice of gas (air, oxygen-enriched air, etc.) depends on the specific reactions required during roasting.

- **Gas Flow Rate**:

The gas flow rate must be sufficient to achieve fluidization without causing excessive entrainment of particles.

- **Gas Distribution**:

Uniform gas distribution is essential for consistent fluidization and efficient roasting.

### 3. **Operating Conditions**

- **Temperature**:

The operating temperature must be carefully controlled to ensure optimal reaction kinetics without causing sintering or melting of particles.

- **Pressure**:

The system pressure can influence fluidization behavior and reaction rates.

- **Residence Time**:

The residence time must be sufficient to complete the desired reactions.

### 4. **Reactor Design**

- **Bed Height and Diameter**:

The dimensions of the bed should be designed to achieve the desired throughput and ensure good gas-solid contact.

- **Distributor Plate Design**: The distributor plate should provide uniform gas flow and support the weight of the bed material.

- **Heat Transfer**:

Efficient heat transfer mechanisms are required to maintain the desired temperature profile within the bed.

### 5. **Materials of Construction**

- **Corrosion Resistance**:

Materials should resist corrosion from the feed material and reaction products.

- **Thermal Stability**:

Materials should withstand the high operating temperatures.

- **Erosion Resistance**:

The abrasive nature of the particles requires materials that can resist wear and tear.

### 6. **Environmental and Safety Considerations**

- **Emission Control**: Appropriate measures must be in place to capture and treat off-gases, such as sulfur dioxide, to meet environmental regulations.

- **Dust Control**: Dust generated during fluidization must be controlled to prevent health hazards and equipment damage.

- **Safety Measures**:

The design should include safety features to handle potential risks such as fires, explosions, and equipment failures.

### 7. **Economic Factors**

- **Capital and Operating Costs**:

The design should balance initial capital costs with ongoing operating expenses to ensure economic viability.

- **Scalability**:

The ability to scale up the design for larger capacities should be considered.

### 8. **Process Control and Monitoring**

- **Instrumentation**:

Adequate sensors and control systems are required to monitor and control temperature, pressure, gas flow, and other critical parameters.

- **Automation**:

Advanced automation can enhance process control, improve efficiency, and reduce the need for manual intervention.

### 9. **Feed Preparation and Handling**

- **Pre-treatment**:

Processes such as crushing, grinding, and drying may be necessary to prepare the feed material for fluidization.

- **Feed Rate Control**:

Accurate control of the feed rate is crucial to maintain stable operation.

### 10. **Product Handling and Cooling**

- **Discharge System**:

The design should facilitate the efficient removal of roasted material from the reactor.

- **Cooling**:

Roasted products may require cooling before further processing or handling.

### Summary

Designing a fluidized bed roaster involves a multidisciplinary approach that considers the characteristics of the feed material, fluidization medium, operating conditions, reactor design, materials of construction, environmental and safety considerations, economic factors, process control, and handling of both feed and product. Each of these factors plays a crucial role in ensuring the efficient, safe, and cost-effective operation of the roaster.

The key operational aspects of a fluid bed roaster

These aspects involve controlling and monitoring various parameters that influence the roasting process, ensuring smooth operation, and achieving desired product quality.

Here are the main operational aspects to consider:

### 1. Fluidization Quality

- **Gas Flow Rate**:

The gas flow rate must be carefully controlled to achieve and maintain proper fluidization. Insufficient flow can lead to defluidization, while excessive flow can cause particle entrainment.

- **Uniform Distribution**:

The gas distribution system, including the distributor plate, should ensure uniform gas flow to prevent channeling and dead zones.

### 2. Temperature Control

- **Operating Temperature**:

The temperature should be maintained within the optimal range for the specific roasting process to ensure desired chemical reactions and avoid issues such as sintering or melting of particles.

- **Temperature Uniformity**:

Ensure uniform temperature distribution throughout the bed to prevent hotspots and uneven roasting.

- **Heating System**:

Efficient and responsive heating systems (e.g., burners, electric heaters) are essential for maintaining the desired temperature profile.

### 3. Pressure Control

- **Bed Pressure Drop**:

Monitor the pressure drop across the bed to ensure proper fluidization and detect any blockages or channeling.

- **System Pressure**:

The operating pressure should be controlled to influence reaction rates and fluidization behavior.

### 4. Feed Rate and Particle Characteristics