Introduction

Here are the key components and steps involved:

### 1. **Data Collection and Analysis**

- **Ore Characteristics**: Understanding the mineralogical and chemical composition of the ore, including the size distribution, hardness, and moisture content.

- **Operational Data**: Collecting historical operational data, such as throughput, recovery rates, and reagent consumption.

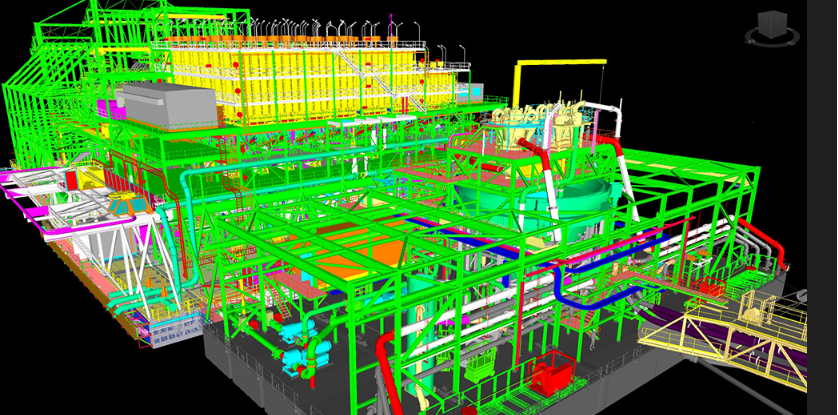

### 2. **Process Flow Diagram (PFD)**

- **Block Diagrams**: Creating high-level block diagrams to represent the sequence of processing stages, such as crushing, grinding, flotation, leaching, etc.

- **Detailed PFDs**: Developing detailed PFDs that show all equipment, piping, and process flows.

### 3. **Mathematical Modeling and Simulation**

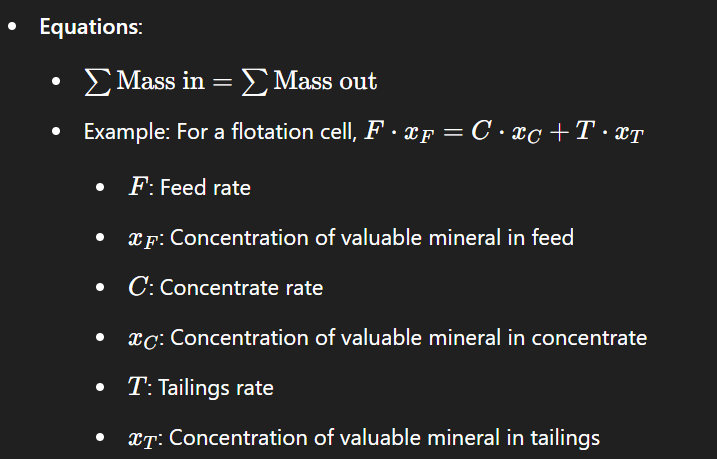

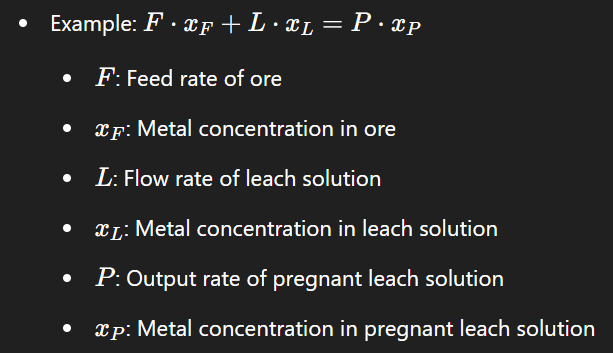

- **Mass Balances**: Establishing mass balance equations around each process unit to ensure the conservation of mass throughout the plant.

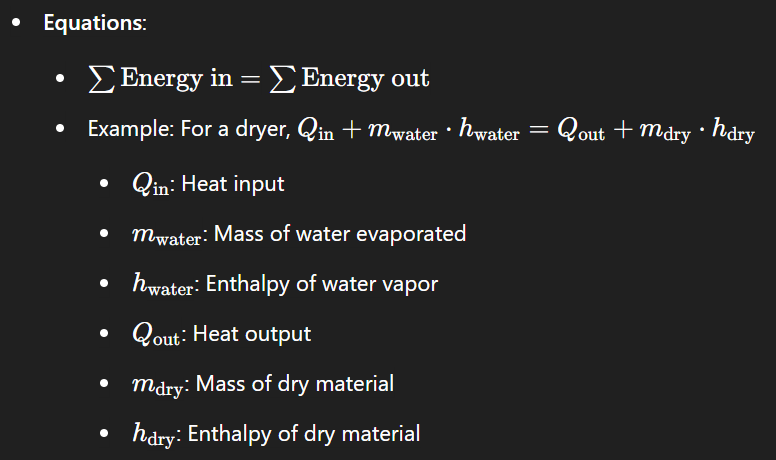

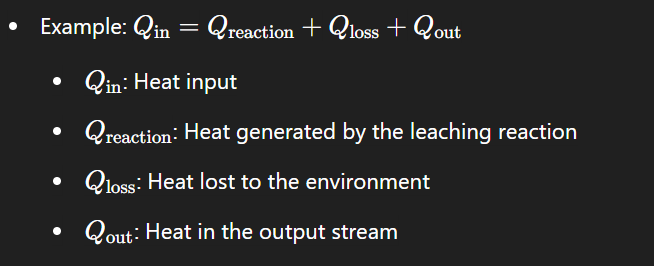

- **Energy Balances**: Similar to mass balances, but focusing on the energy consumption and distribution in the plant.

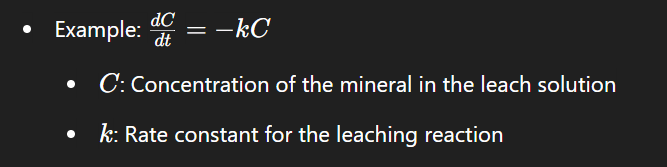

- **Kinetics and Dynamics**: Modeling the kinetics of chemical reactions and the dynamics of physical processes.

- **Simulation Software**: Using specialized software (e.g., METSIM, HSC Chemistry, Aspen Plus, JKSimMet) to simulate the entire plant.

### 4. **Equipment Modeling**

- **Crusher and Mill Models**: Representing the performance and power consumption of crushers and mills.

- **Separation Processes**: Modeling flotation cells, gravity concentrators, magnetic separators, etc.

- **Hydrometallurgical Processes**: Including leaching reactors, solvent extraction units, and electrowinning cells.

### 5. **Control Systems Design**

- **Control Loops**: Designing control loops for process variables like flow rates, pressures, temperatures, and reagent dosages.

- **Advanced Control Strategies**: Implementing model predictive control (MPC) and other advanced control strategies.

### 6. **Economic Evaluation**

- **Capital Expenditure (CapEx)**: Estimating the costs of equipment, installation, and initial setup.

- **Operational Expenditure (OpEx)**: Calculating ongoing costs, including maintenance, energy, labor, and consumables.

- **Profitability Analysis**: Conducting sensitivity analyses to understand the economic impact of different operational scenarios.

### 7. **Optimization and Validation**

- **Process Optimization**: Using the model to find optimal operating conditions that maximize recovery and minimize costs.

- **Validation**: Comparing model predictions with actual plant data to validate the model’s accuracy.

### 8. **Sensitivity and Risk Analysis**

- **Sensitivity Analysis**: Analyzing how changes in key parameters affect the plant’s performance.

- **Risk Analysis**: Identifying potential risks and uncertainties in the process and assessing their impact on plant operations.

### 9. **Reporting and Documentation**

- **Technical Reports**: Preparing detailed technical reports that document the modeling assumptions, methods, results, and recommendations.

- **Operational Guidelines**: Providing guidelines and standard operating procedures (SOPs) for plant operators based on the model findings.

### Tools and Software

- **Simulation Tools**: METSIM, HSC Chemistry, Aspen Plus, JKSimMet.

- **Process Design Software**: AutoCAD Plant 3D, AVEVA PDMS.

- **Control Systems Software**: MATLAB, Simulink, LabVIEW, DCS/PLC programming environments.

### Collaboration and Iteration

- **Interdisciplinary Collaboration**: Working closely with geologists, metallurgists, chemical engineers, and plant operators.

- **Iterative Approach**: Continuously refining the model as new data and insights become available.

By integrating these components, mineral processing plant modeling enables the efficient design, operation, and optimization of mineral processing facilities, leading to improved performance, reduced costs, and enhanced recovery rates.

What are the steps to be followed when developing a process Model?

### 1. **Define Objectives and Scope**

- **Objectives**: Determine the purpose of the model (e.g., design, optimization, control, economic evaluation).

- **Scope**: Define the boundaries of the model, including which processes and unit operations will be included.

### 2. **Data Collection**

- **Ore Characteristics**: Gather detailed information on the mineralogical, chemical, and physical properties of the ore.

- **Process Data**: Collect operational data such as feed rates, product specifications, energy consumption, reagent usage, and historical performance data.

- **Equipment Specifications**: Obtain detailed specifications for all equipment involved in the process, including capacities, efficiencies, and operational parameters.

### 3. **Process Understanding and Flow Sheet Development**

- **Process Flow Diagrams (PFDs)**: Develop high-level and detailed PFDs that outline the sequence of operations and the flow of materials through the plant.

- **Process Description**: Document a detailed description of each unit operation, including its function, inputs, outputs, and operating conditions.

### 4. **Mass and Energy Balances**

- **Mass Balance**: Establish mass balance equations around each process unit to ensure the conservation of mass. This includes accounting for all inputs, outputs, and accumulation within each unit.

- **Energy Balance**: Develop energy balance equations to track the energy consumption and distribution throughout the process.

### 5. **Mathematical Modeling of Unit Operations**

- **Crusher and Grinder Models**: Represent the performance of crushing and grinding equipment, considering factors like particle size distribution and energy consumption.

- **Separation Process Models**: Develop models for flotation cells, gravity concentrators, magnetic separators, etc., based on kinetics and separation efficiency.

- **Hydrometallurgical Models**: Model chemical processes such as leaching, solvent extraction, and electrowinning, considering reaction kinetics and equilibrium.

### 6. **Simulation and Software Implementation**

- **Simulation Software**: Choose appropriate simulation software (e.g., METSIM, HSC Chemistry, Aspen Plus, JKSimMet) and implement the process model within the software environment.

- **Model Integration**: Integrate individual unit operation models into a comprehensive process model, ensuring consistency and connectivity between units.

### 7. **Calibration and Validation**

- **Calibration**: Adjust model parameters to match observed plant data, ensuring that the model accurately represents real-world behavior.

- **Validation**: Compare model predictions with independent data sets to validate the model’s accuracy and reliability.

### 8. **Sensitivity Analysis**

- **Parameter Variation**: Systematically vary key model parameters to understand their impact on process performance.

- **Impact Assessment**: Assess the sensitivity of the process outcomes (e.g., recovery rates, throughput, costs) to changes in these parameters.

### 9. **Optimization**

- **Objective Function**: Define the objective function (e.g., maximize recovery, minimize costs) for optimization.

- **Optimization Techniques**: Use optimization algorithms (e.g., linear programming, genetic algorithms) to identify optimal operating conditions.

- **Scenario Analysis**: Evaluate different operating scenarios to determine the best strategies for achieving the desired objectives.

### 10. **Risk and Uncertainty Analysis**

- **Risk Assessment**: Identify potential risks and uncertainties in the process and model parameters.

- **Monte Carlo Simulation**: Use Monte Carlo or other probabilistic methods to assess the impact of uncertainties on process performance.

### 11. **Documentation and Reporting**

- **Model Documentation**: Prepare detailed documentation of the model, including assumptions, equations, data sources, and calibration methods.

- **Technical Reports**: Compile comprehensive reports that summarize the modeling process, results, and recommendations.

- **Operational Guidelines**: Provide guidelines and standard operating procedures (SOPs) based on model findings to assist plant operators.

### 12. **Continuous Improvement**

- **Feedback Loop**: Establish a feedback loop for continuous data collection and model refinement based on new data and insights.

- **Model Updates**: Regularly update the model to reflect changes in ore characteristics, process modifications, and operational improvements.

By following these steps, you can develop a robust and accurate process model that can be used to design, optimize, and control mineral processing plants, leading to improved efficiency, reduced costs, and enhanced recovery rates.

What are the various types of Process MOdels available?

Each type of model serves a unique purpose and is chosen based on the specific requirements of the project. Here are the main types of process models available:

### 1. **Empirical Models**

- **Description**: Based on experimental data and empirical correlations.

- **Application**: Suitable for processes where detailed mechanistic understanding is difficult to obtain but sufficient operational data is available.

- **Examples**: Regression models, response surface models.

### 2. **Mechanistic Models**

- **Description**: Based on fundamental physical and chemical principles governing the process.

- **Application**: Used when detailed knowledge of the process mechanisms is available and precise predictions are required.

- **Examples**: Population balance models for comminution, flotation kinetic models.

### 3. **Phenomenological Models**

- **Description**: Combine empirical data with fundamental principles to describe the behavior of the system.

- **Application**: Used when some mechanistic insights are available, but complete mechanistic modeling is impractical.

- **Examples**: Semi-empirical models for leaching, adsorption isotherm models.

### 4. **Data-Driven Models**

- **Description**: Rely entirely on data and statistical methods without assuming any underlying physical or chemical principles.

- **Application**: Useful for complex processes where mechanistic understanding is limited but large amounts of data are available.

- **Examples**: Machine learning models (neural networks, support vector machines), multivariate statistical models.

### 5. **First-Principles Models**

- **Description**: Derived from first principles of thermodynamics, fluid dynamics, and kinetics.

- **Application**: Used for detailed design and optimization of processes with well-understood fundamental behavior.

- **Examples**: Computational fluid dynamics (CFD) models, detailed kinetic reaction models.

### 6. **Steady-State Models**

- **Description**: Assume that process variables do not change with time, representing a snapshot of the process at equilibrium.

- **Application**: Used for design and optimization of steady-state operations, capacity planning.

- **Examples**: Steady-state mass and energy balance models.

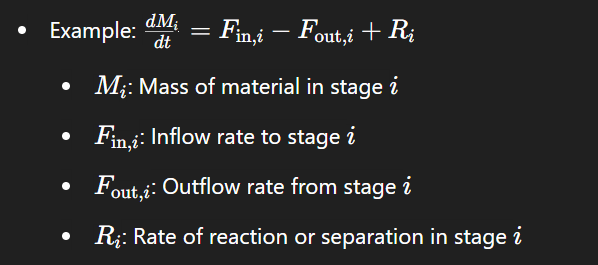

### 7. **Dynamic Models**

- **Description**: Account for changes in process variables over time, capturing transient behaviors and dynamic responses.

- **Application**: Useful for process control, transient analysis, and start-up/shutdown procedures.

- **Examples**: Dynamic simulation of flotation circuits, time-dependent leaching models.

### 8. **Black-Box Models**

- **Description**: Treat the process as a "black box," focusing on input-output relationships without detailed internal mechanisms.

- **Application**: Suitable for process control and prediction when detailed internal dynamics are not needed.

- **Examples**: Transfer function models, autoregressive moving average (ARMA) models.

### 9. **White-Box Models**

- **Description**: Provide a detailed mechanistic understanding of the process, with explicit internal states and parameters.

- **Application**: Used for comprehensive process design, optimization, and detailed analysis.

- **Examples**: Detailed reaction engineering models, full CFD models.

###

10. **Grey-Box Models**

- **Description**: Combine elements of both black-box and white-box models, incorporating some mechanistic insights along with empirical data.

- **Application**: Used when partial mechanistic understanding is available but complemented with empirical data for improved accuracy.

- **Examples**: Hybrid models for reactor design, semi-mechanistic models for separation processes.

### 11. **Stochastic Models**

- **Description**: Incorporate randomness and uncertainties in the process parameters and inputs.

- **Application**: Useful for risk analysis, reliability assessment, and understanding the impact of variability.

- **Examples**: Monte Carlo simulation models, probabilistic models for ore grade variability.

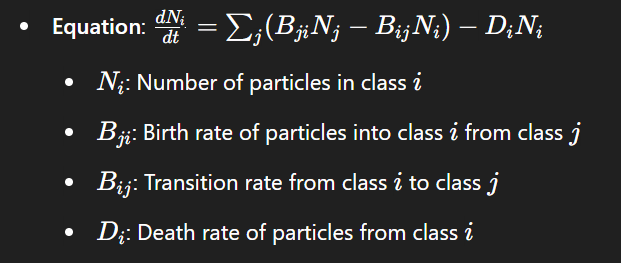

### 12. **Agent-Based Models**

- **Description**: Simulate the interactions of individual agents (e.g., particles, equipment) to understand the emergent behavior of the system.

- **Application**: Applied in complex systems where interactions at a micro level influence the macro behavior.

- **Examples**: Agent-based models for comminution and particle breakage dynamics.

### Software Tools for Process Modeling

- **METSIM**: For steady-state and dynamic process simulation.

- **HSC Chemistry**: For thermodynamic and chemical reaction modeling.

- **Aspen Plus**: For comprehensive process simulation and optimization.

- **JKSimMet**: For mineral processing plant simulation and optimization.

- **MATLAB/Simulink**: For custom modeling, simulation, and control system design.

- **COMSOL Multiphysics**: For multi-physics modeling including CFD and reaction kinetics.

By selecting and combining these types of process models, engineers can effectively design, optimize, and control mineral processing plants, ensuring efficient and cost-effective operations.

Empirical Models in Mineral Processing

Empirical models are a crucial tool in mineral processing when a detailed mechanistic understanding of a process is challenging to obtain.

These models rely heavily on experimental data and statistical correlations to predict the behavior of the process under different conditions.

Here’s a detailed look at empirical models:

#### **Description**

- **Data-Driven**: Empirical models are developed using extensive sets of experimental or operational data. These data sets are analyzed to identify patterns, correlations, and relationships between input variables (e.g., feed characteristics, operating conditions) and output variables (e.g., recovery rates, product grades).

- **Correlation-Based**: The models establish empirical correlations that can predict process outcomes based on input variables. These correlations are often derived using statistical techniques.

#### **Application**

- **When Mechanistic Models are Impractical**: Empirical models are particularly useful for complex processes where the underlying physical or chemical mechanisms are not fully understood or are too complicated to model directly.

- **Optimization and Control**: These models are used for process optimization and control because they can quickly provide predictions based on real-world data.

- **Preliminary Studies**: Useful in the early stages of process development and feasibility studies where quick insights are needed without the need for detailed mechanistic models.

#### **Examples**

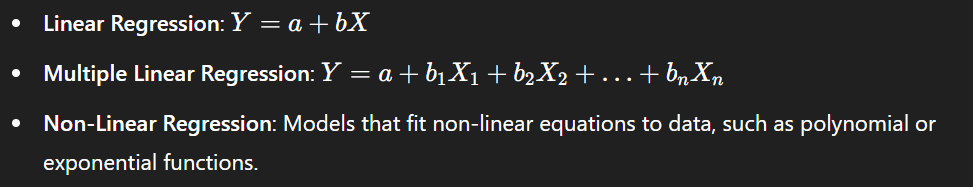

- **Regression Models**: These models use statistical techniques to fit a mathematical equation to experimental data.

Common regression methods include linear regression, multiple linear regression, and non-linear regression.

- **Linear Regression**:

- **Response Surface Models**:

These models are used to explore the relationships between several explanatory variables and one or more response variables.

They are particularly useful in optimization.

- **Quadratic Models**:

#### **Development of Empirical Models**

1. **Data Collection**: Gather a comprehensive set of experimental or operational data. This data should cover a wide range of operating conditions to ensure the model's robustness.

2. **Data Preprocessing**: Clean the data to remove any outliers or inconsistencies. Normalize or standardize the data if necessary.

3. **Model Selection**: Choose the appropriate type of empirical model based on the nature of the data and the process being studied.

4. **Parameter Estimation**: Use statistical methods to estimate the parameters of the model. Techniques like least squares regression are commonly used.

5. **Model Validation**: Validate the model using a separate set of data to ensure it accurately predicts process outcomes. Techniques like cross-validation can be employed.

6. **Refinement**: Refine the model based on validation results, adjusting parameters or adding complexity as needed.

#### **Advantages and Limitations**

**Advantages:**

- **Simplicity**: Empirical models are often simpler to develop and use than mechanistic models.

- **Quick Predictions**: They can provide rapid predictions of process performance.

- **Data Utilization**: Make effective use of available data without requiring detailed process understanding.

**Limitations:**

- **Limited Extrapolation**: These models may not perform well outside the range of conditions for which they were developed.

- **Lack of Mechanistic Insight**:

They do not provide insights into the underlying mechanisms of the process.

- **Dependence on Data Quality**:

The accuracy of empirical models is highly dependent on the quality and comprehensiveness of the data used to develop them.

#### **Example in Practice**

**Flotation Process Modeling**:

- **Objective**: To model the recovery of a specific mineral in a flotation process.

- **Data Collection**: Gather data on feed grade, reagent dosages, pH, pulp density, and other operational parameters along with the corresponding recovery rates.

- **Regression Analysis**: Perform multiple linear regression to develop a model predicting recovery based on the input variables.

- Example Model:

\( \text{Recovery} = a + b_1 \text{(Feed Grade)} + b_2 \text{(Reagent Dosage)} + b_3 \text{(pH)} + b_4 \text{(Pulp Density)} \)

- **Validation**: Use a separate set of data to validate the model’s predictions and adjust as necessary.

By following these steps and leveraging empirical models, mineral processing plants can effectively optimize and control their operations even in the absence of detailed mechanistic understanding.

Neural Networks in Mineral Processing

#### Description

Neural networks are a type of artificial intelligence (AI) and machine learning model that are designed to recognize patterns and make predictions based on data.

They consist of interconnected nodes (neurons) organized in layers, which can learn complex relationships within data. Neural networks are particularly useful in mineral processing for analyzing large datasets, optimizing processes, and predicting outcomes.

#### Applications in Mineral Processing

1. **Predictive Maintenance**

- **Description**:

Using neural networks to predict equipment failures and maintenance needs based on historical data and real-time sensor readings.

- **Benefits**:

- **Reduced Downtime**:

Early detection of potential failures allows for timely maintenance, minimizing unplanned downtime.

- **Cost Savings**:

Preventive maintenance reduces the cost associated with major repairs and extends equipment lifespan.

- **Increased Safety**:

Identifying and addressing issues before they lead to equipment failure enhances operational safety.

2. **Process Optimization**

- **Description**:

Neural networks can optimize various process parameters to improve efficiency and product quality.

- **Benefits**:

- **Improved Efficiency**:

Optimized process parameters lead to better resource utilization and energy savings.

- **Enhanced Product Quality**:

Consistent and optimal operating conditions result in higher product quality and reduced variability.

- **Adaptive Control**:

Neural networks can adapt to changing conditions and continuously optimize the process in real-time.

3. **Ore Grade Prediction**

- **Description**: Predicting the grade of ore being processed based on historical data and real-time input from sensors.

- **Benefits**:

- **Accurate Forecasting**:

Precise predictions of ore grade help in planning and adjusting processing strategies.

- **Resource Management**:

Better prediction of ore quality aids in efficient resource allocation and processing decisions.

- **Process Control**:

Real-time grade predictions allow for immediate adjustments to processing parameters, improving overall efficiency.

4. **Flotation Process Control**

- **Description**:

Using neural networks to control and optimize the flotation process, improving the separation of valuable minerals from waste.

- **Benefits**:

- **Increased Recovery Rates**:

Improved control of flotation parameters leads to higher recovery rates of valuable minerals.

- **Reduced Reagents Use**: Optimization of reagent dosages reduces costs and environmental impact.

- **Stable Operation**:

Enhanced control maintains stable and efficient flotation conditions, reducing variability in the process.

5. **Image Analysis for Mineral Sorting**

- **Description**:

Analyzing images of ore and mineral particles to classify and sort them based on visual characteristics.

- **Benefits**:

- **Higher Accuracy**:

Neural networks can identify subtle differences in particle characteristics, leading to more accurate sorting.

- **Increased Throughput**:

Automated sorting based on image analysis increases the speed and efficiency of the sorting process.

- **Reduced Waste**:

More precise sorting reduces the amount of waste material processed, improving overall yield.

#### Examples of Neural Network Models

1. **Convolutional Neural Networks (CNNs)**

- **Description**:

Specialized neural networks designed for processing and analyzing visual data, such as images.

- **Applications**:

Mineral sorting, particle size analysis, and defect detection in equipment.

2. **Recurrent Neural Networks (RNNs)**

- **Description**:

Neural networks designed for sequential data, capable of learning temporal patterns.

- **Applications**:

Predictive maintenance, process control, and time-series analysis of operational data.

3. **Feedforward Neural Networks (FNNs)**

- **Description**:

Basic neural networks where connections do not form cycles, used for straightforward pattern recognition and regression tasks.

- **Applications**:

Ore grade prediction, process parameter optimization, and classification tasks.

4. **Autoencoders**

- **Description**:

Neural networks designed for unsupervised learning, typically used for feature extraction and dimensionality reduction.

- **Applications**:

Anomaly detection in equipment performance, data compression for sensor networks, and feature extraction for complex datasets.

#### Benefits of Using Neural Networks in Mineral Processing

- **Data-Driven Insights**:

Neural networks can uncover complex patterns and relationships within large datasets that may not be apparent through traditional analysis.

- **Real-Time Processing**: Capable of processing data in real-time, providing immediate feedback and control adjustments.

- **Scalability**: Neural network models can be scaled to handle large volumes of data from multiple sources.

- **Adaptability**: Neural networks can learn and adapt to new data, continuously improving their performance over time.

### Summary

Neural networks offer significant advantages in mineral processing by enabling predictive maintenance, process optimization, ore grade prediction, flotation process control, and image analysis for mineral sorting.

By leveraging the power of neural networks, mineral processing plants can achieve improved efficiency, cost savings, enhanced product quality, and increased operational safety.

Bayesian Modeling in Mineral Processing

#### Description

Bayesian modeling is a statistical approach that incorporates prior knowledge, along with new data, to update the probability estimates for a hypothesis.

It is based on Bayes' Theorem, which provides a mathematical framework for updating beliefs as new evidence is presented.

This approach is particularly useful in mineral processing for dealing with uncertainties, making predictions, and optimizing processes based on both historical data and real-time observations.

#### Applications in Mineral Processing

1. **Ore Grade Estimation**

- **Description**:

Estimating the grade of ore based on prior geological information and new sample data.

- **Benefits**:

- **Improved Accuracy**:

Bayesian models incorporate prior geological knowledge to enhance the accuracy of ore grade predictions.

- **Uncertainty Quantification**:

Provides probabilistic estimates of ore grades, helping in risk assessment and decision-making.

- **Adaptive Learning**:

Continuously updates predictions as new sampling data becomes available.

2. **Process Control and Optimization**

- **Description**:

Using Bayesian models to optimize process parameters and control strategies by incorporating prior knowledge and real-time data.

- **Benefits**:

- **Robust Control**:

Bayesian methods account for uncertainties in process parameters, leading to more robust control strategies.

- **Dynamic Adjustment**:

Continuously updates process parameters in response to real-time data, optimizing performance.

- **Risk Management**:

Provides a probabilistic framework for understanding and managing risks associated with process variability.

3. **Predictive Maintenance**

- **Description**:

Predicting equipment failures and maintenance needs by combining historical failure data with real-time monitoring information.

- **Benefits**:

- **Early Warning**:

Bayesian models provide probabilistic forecasts of equipment failures, enabling proactive maintenance.

- **Optimized Scheduling**:

Helps in planning maintenance activities based on the likelihood of failure, reducing downtime and costs.

- **Data Integration**: Combines various data sources, including historical records and sensor data, for comprehensive predictive maintenance.

4. **Resource Estimation and Mine Planning**

- **Description**:

Estimating the quantity and quality of mineral resources by integrating geological models with sampling data.

- **Benefits**:

- **Informed Decision-Making**:

Provides probabilistic estimates of resource quantities, aiding in strategic planning and investment decisions.

- **Adaptive Resource Modeling**:

Continuously updates resource estimates as new exploration data is acquired.

- **Risk Reduction**:

Quantifies uncertainties in resource estimates, helping to mitigate risks in mine planning and development.

5. **Flotation Process Modeling**

- **Description**:

Modeling and optimizing the flotation process by incorporating prior knowledge of flotation kinetics and real-time process data.

- **Benefits**:

- **Enhanced Recovery**:

Bayesian models help optimize reagent dosages and other parameters to maximize mineral recovery.

- **Uncertainty Management**:

Accounts for uncertainties in flotation dynamics, leading to more reliable process control.

- **Continuous Improvement**:

Updates process models with new data, continuously improving flotation efficiency.

#### Examples of Bayesian Modeling Techniques

1. **Bayesian Inference**

- **Description**:

Applying Bayes' Theorem to update the probability of a hypothesis as new evidence is introduced.

- **Applications**:

Ore grade estimation, equipment failure prediction, and process optimization.

2. **Bayesian Networks**

- **Description**:

Graphical models representing the probabilistic relationships among a set of variables.

- **Applications**:

Fault diagnosis in processing plants, risk assessment, and decision support systems.

3. **Markov Chain Monte Carlo (MCMC)**

- **Description**:

A class of algorithms for sampling from a probability distribution based on constructing a Markov chain.

- **Applications**:

Complex process modeling, parameter estimation, and simulation of mineral processing operations.

4. **Hierarchical Bayesian Models**

- **Description**:

Models that incorporate multiple levels of uncertainty, allowing for complex dependencies and hierarchical structures.

- **Applications**:

Resource estimation, multi-stage process modeling, and predictive maintenance.

#### Benefits of Using Bayesian Modeling in Mineral Processing

- **Probabilistic Forecasting**:

Provides probabilistic predictions, enabling better risk assessment and management.

- **Incorporation of Prior Knowledge**:

Integrates historical data and expert knowledge with new data for improved predictions.

- **Adaptive Learning**:

Continuously updates models as new data becomes available, improving accuracy and reliability over time.

- **Comprehensive Uncertainty Quantification**:

Explicitly quantifies uncertainties in predictions and parameter estimates, aiding in decision-making under uncertainty.

- **Flexible and Robust**:

Can handle complex, non-linear relationships and dependencies among variables, making it suitable for various applications in mineral processing.

### Summary

Bayesian modeling offers significant advantages in mineral processing by providing a probabilistic framework for estimation, prediction, and optimization.

It allows for the integration of prior knowledge with new data, leading to more accurate and reliable models.

Applications in ore grade estimation, process control, predictive maintenance, resource estimation, and flotation process optimization demonstrate the versatility and power of Bayesian approaches in enhancing the efficiency and effectiveness of mineral processing operations.

Mechanistic Models in Mineral Processing

These models aim to provide a detailed and accurate representation of the processes, making them essential for precise predictions and thorough understanding.

#### **Description**

- **Fundamental Basis**: Mechanistic models rely on well-established scientific principles such as mass and energy balances, fluid dynamics, thermodynamics, and reaction kinetics.

- **Detailed Representation**: These models typically include detailed mathematical descriptions of the various phenomena occurring within the process, capturing the intricate interactions between different variables.

#### **Application**

- **Process Design and Scale-Up**: Mechanistic models are crucial for designing new processes and scaling up from laboratory or pilot plant to full-scale operations.

- **Optimization**: They are used to optimize processes by understanding the fundamental constraints and interactions, allowing for the fine-tuning of operational parameters.

- **Control Strategies**: Provide a basis for advanced control strategies that require accurate predictions of process behavior under different conditions.

- **Research and Development**: Used extensively in R&D to develop new technologies and improve existing processes through a deep understanding of the underlying mechanisms.

#### **Examples**

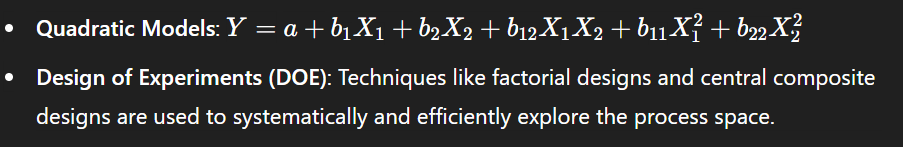

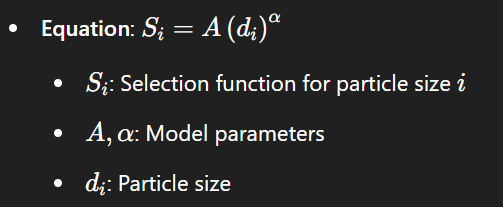

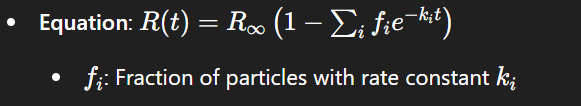

- **Population Balance Models (PBMs) for Comminution**: These models describe the size reduction process in comminution (crushing and grinding) by tracking the distribution of particle sizes.

- **Principle**: PBMs account for the rates of breakage and selection, modeling how particles of different sizes break and produce progeny of various sizes.

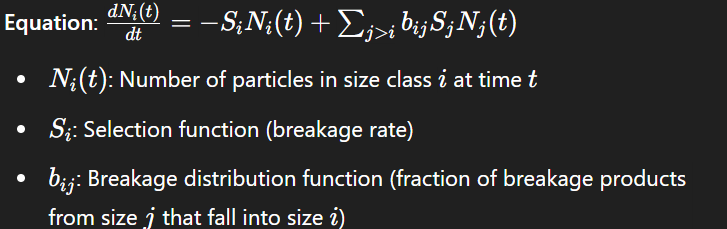

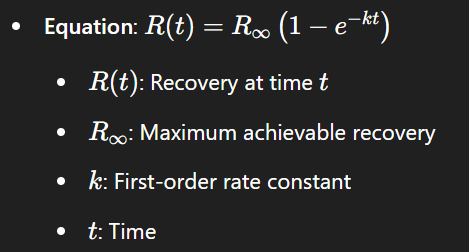

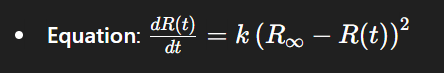

- **Flotation Kinetic Models**: These models describe the flotation process, focusing on the kinetics of bubble-particle attachment and detachment.

- **Principle**: Flotation kinetics models capture the rates of various stages in the flotation process, including collision, attachment, and detachment.

#### **Development of Mechanistic Models**

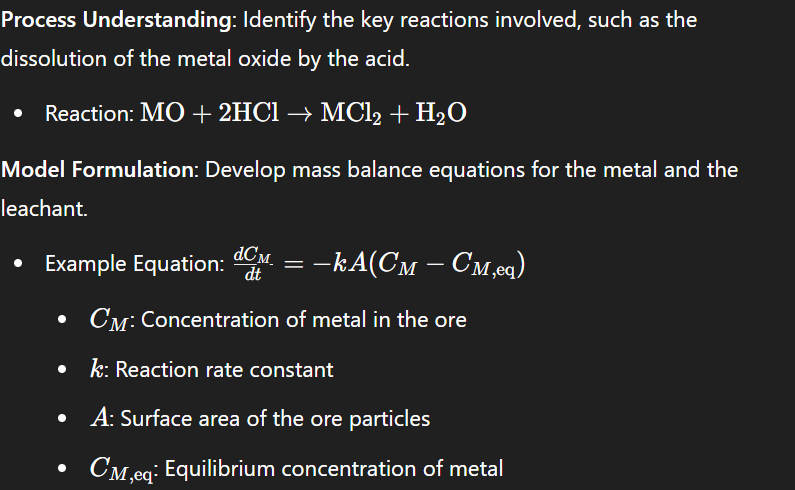

1. **Process Understanding**: Develop a thorough understanding of the process based on physical and chemical principles. This often involves literature review, theoretical analysis, and empirical observation.

2. **Model Formulation**: Formulate the model equations based on the fundamental principles. This step involves defining the relevant conservation laws (mass, energy, momentum), reaction kinetics, and transport phenomena.

3. **Parameter Identification**: Identify and estimate the parameters involved in the model, such as reaction rate constants, diffusion coefficients, and mass transfer coefficients.

4. **Model Implementation**: Implement the model using appropriate computational tools and software. This step often requires numerical methods for solving complex differential equations.

5. **Validation and Calibration**: Validate the model by comparing its predictions with experimental or operational data. Calibrate the model parameters to improve accuracy.

6. **Sensitivity Analysis**: Perform sensitivity analysis to understand the impact of different parameters on the model's predictions and identify the most critical variables.

7. **Optimization and Refinement**: Use the model for process optimization and refine it based on new data and insights.

#### **Advantages and Limitations**

**Advantages:**

- **Accuracy**: Mechanistic models can provide highly accurate predictions when based on sound principles and well-calibrated data.

- **Insightful**: They offer deep insights into the process mechanisms, which can be used to improve understanding and innovation.

- **Predictive Power**: Capable of predicting behavior under a wide range of conditions, including those not previously tested.

**Limitations:**

- **Complexity**: Developing and solving mechanistic models can be complex and computationally intensive.

- **Data Requirements**: They require detailed and accurate data for parameter estimation and validation.

- **Development Time**: Building mechanistic models often takes more time compared to empirical models.

#### **Example in Practice**

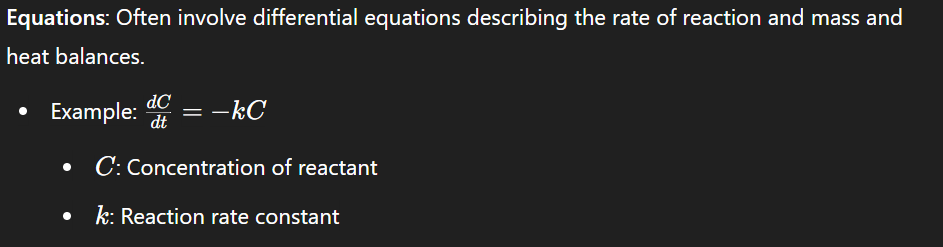

**Modeling the Leaching Process in Hydrometallurgy**:

- **Objective**: To model the leaching of a metal from its ore using a chemical leachant.

- **Parameter Estimation**:

Conduct experiments to determine\( k , A , and \ C_{M}} \).

-

**Model Implementation**:

Use numerical methods to solve the differential equations describing the leaching process.

- **Validation**: Compare model predictions with experimental leaching data and adjust parameters as necessary.

- **Optimization**: Use the model to optimize leaching conditions (e.g., temperature, acid concentration) for maximum metal recovery.

Mechanistic models are powerful tools in mineral processing, enabling precise control and optimization of complex processes through a deep understanding of the underlying mechanisms.

Phenomenological Models in Mineral Processing

These models are particularly useful when complete mechanistic modeling is impractical but some mechanistic insights are available.

#### **Description**

- **Combination Approach**: Phenomenological models blend empirical observations with fundamental theoretical principles to describe system behavior.

- **Simplified Mechanisms**: They incorporate essential mechanistic aspects without delving into all the complexities, often simplifying assumptions to make the models more manageable.

#### **Application**

- **Complex Systems**: Used in situations where the processes are too complex for purely mechanistic models, yet there's enough understanding to move beyond purely empirical correlations.

- **Operational Optimization**: Ideal for optimizing operational parameters in real-world scenarios where full mechanistic details are unknown or too complicated to model.

- **Predictive Capability**: Provide reasonable predictions within the range of collected data and known mechanisms, making them useful for process control and optimization.

#### **Examples**

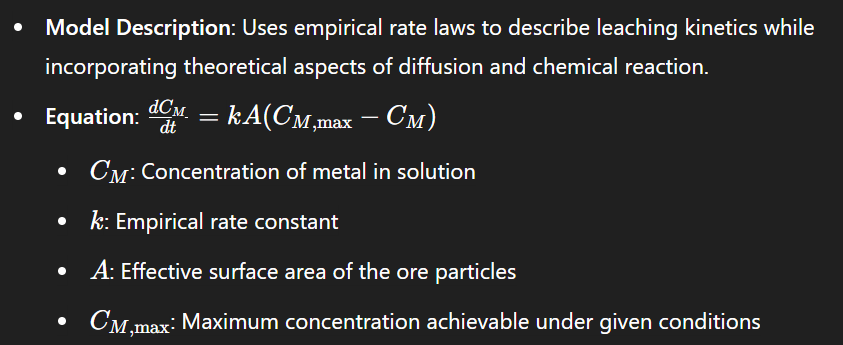

- **Semi-Empirical Models for Leaching**: Combine kinetic data from experiments with theoretical principles of mass transfer and reaction kinetics.

-

**Model Description**:

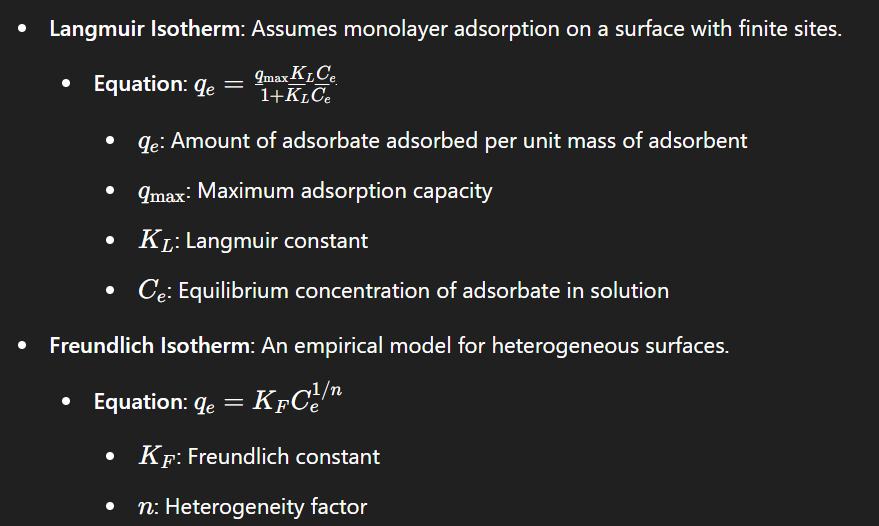

- **Adsorption Isotherm Models**: Describe the equilibrium relationship between the concentration of adsorbate on the solid surface and its concentration in the solution, incorporating empirical data with thermodynamic principles.

- **Langmuir Isotherm**:

#### **Development of Phenomenological Models**

1. **Identify Mechanistic Insights**: Gather existing knowledge on the fundamental principles and mechanisms relevant to the process.

2. **Collect Empirical Data**: Perform experiments or gather operational data to understand the process behavior under different conditions.

3. **Formulate the Model**: Develop mathematical equations that incorporate both empirical data and mechanistic insights. Simplify where necessary to make the model practical.

4. **Parameter Estimation**: Use empirical data to estimate model parameters. This often involves fitting the model to experimental data using statistical methods.

5. **Model Implementation**: Implement the model in appropriate software tools for simulation and analysis.

6. **Validation and Calibration**: Validate the model using independent data sets and calibrate it to ensure accuracy and reliability.

7. **Sensitivity Analysis**: Conduct sensitivity analysis to understand the influence of different parameters on model predictions.

8. **Optimization and Refinement**: Use the model for process optimization and continuously refine it based on new data and insights.

#### **Advantages and Limitations**

**Advantages:**

- **Balanced Approach**: Provides a balance between purely empirical and fully mechanistic models, leveraging the strengths of both approaches.

- **Practicality**: Easier to develop and use compared to complete mechanistic models, especially in complex systems.

- **Adaptability**: Can be adapted and refined as more data and insights become available.

**Limitations:**

- **Intermediate Accuracy**: While more accurate than purely empirical models, they may not be as precise as full mechanistic models.

- **Dependency on Data Quality**: The accuracy of phenomenological models heavily depends on the quality and range of empirical data.

- **Simplifying Assumptions**: Simplifications made to balance practicality can sometimes limit the model’s applicability under extreme conditions.

#### **Example in Practice**

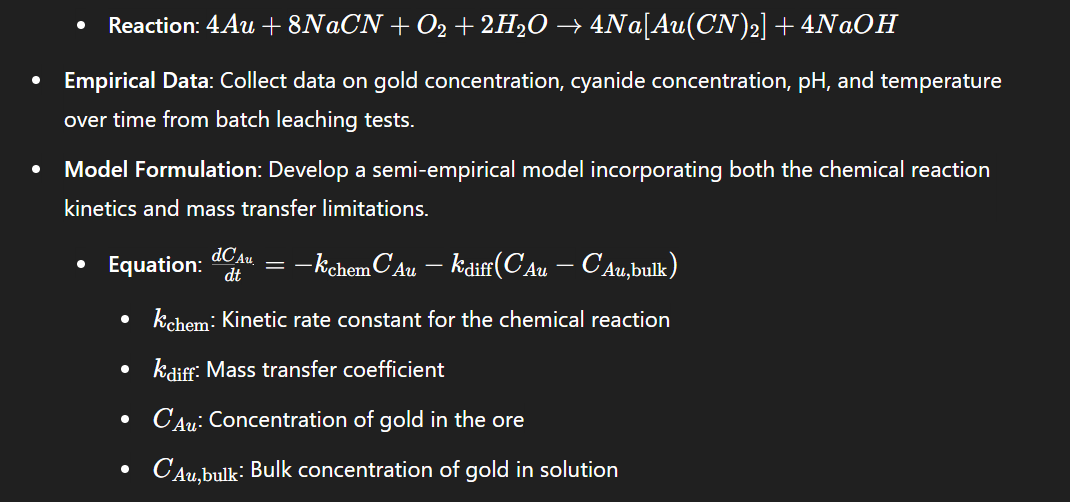

**Modeling Gold Cyanidation in Leaching**:

- **Objective**: To model the cyanidation process for extracting gold from ore, considering both the kinetics of the chemical reactions and the mass transfer limitations.

- **Mechanistic Insight**: Understand the leaching kinetics involving the dissolution of gold and the diffusion of reactants through the ore particles.

- **Parameter Estimation**: Estimate k_chem and k_diff from experimental data using regression techniques.

- **Model Validation**: Validate the model against independent leaching tests to ensure it accurately predicts gold recovery under various conditions.

- **Optimization**: Use the model to optimize leaching conditions (e.g., cyanide concentration, agitation rate) for maximum gold recovery.

Phenomenological models provide a practical and effective approach to understanding and optimizing mineral processing operations by combining the strengths of empirical data and fundamental principles.

Data-Driven Models in Mineral Processing

Data-driven models leverage large datasets and advanced statistical methods to model and predict the behavior of complex processes without assuming any underlying physical or chemical principles.

These models are particularly useful in situations where mechanistic understanding is limited or impractical to obtain.

#### **Description**

- **Data-Dependent**: These models are built entirely from data, relying on statistical and computational techniques to uncover patterns and relationships.

- **No Assumed Mechanisms**: Unlike mechanistic models, data-driven models do not incorporate explicit physical or chemical principles; instead, they use algorithms to learn from data.

#### **Application**

- **Complex Processes**: Ideal for processes with complex, nonlinear interactions that are difficult to model mechanistically.

- **Large Datasets**: Highly effective when large amounts of data are available, which can be used to train and validate the models.

- **Prediction and Control**: Used for predictive modeling, process control, anomaly detection, and optimization in real-time operations.

#### **Examples**

- **Machine Learning Models**: Utilize algorithms that learn from data to make predictions or decisions.

- **Neural Networks**: Consist of interconnected layers of nodes (neurons) that can model complex nonlinear relationships.

- **Example**: A neural network predicting ore grade based on input variables such as mineral composition, feed rate, and processing conditions.

- **Support Vector Machines (SVMs)**: Use hyperplanes to classify data points in high-dimensional space.

- **Example**: SVMs classifying different types of ores based on spectral analysis data.

- **Random Forests**: Ensemble learning method that uses multiple decision trees to improve prediction accuracy.

- **Example**: Predicting recovery rates in a flotation process based on operational parameters.

- **Multivariate Statistical Models**: Use statistical techniques to analyze multiple variables simultaneously.

- **Principal Component Analysis (PCA)**: Reduces the dimensionality of data while retaining most of the variance.

- **Example**: PCA used for exploratory data analysis in mineral processing to identify key variables affecting process performance.

- **Partial Least Squares Regression (PLSR)**: Projects predictor variables and response variables to new spaces for regression analysis.

- **Example**: PLSR predicting product quality based on feed characteristics and process parameters.

#### **Development of Data-Driven Models**

1. **Data Collection**: Gather large datasets from sensors, instruments, and historical records of the process. Ensure the data is comprehensive and representative of different operating conditions.

2. **Data Preprocessing**: Clean the data to remove noise and outliers. Normalize or standardize the data if necessary to ensure consistent scaling.

3. **Feature Selection**: Identify relevant features (input variables) that significantly impact the process output. This can be done using statistical techniques or domain expertise.

4. **Model Selection**: Choose appropriate machine learning or statistical algorithms based on the nature of the data and the problem.

5. **Model Training**: Train the selected model using a subset of the data (training set). This involves optimizing model parameters to minimize prediction error.

6. **Model Validation**: Validate the model using a separate subset of the data (validation set) to ensure it generalizes well to unseen data.

7. **Model Testing**: Test the model with an independent dataset (test set) to evaluate its performance and robustness.

8. **Implementation and Monitoring**: Implement the model in a real-time system for prediction or control. Continuously monitor its performance and retrain as necessary with new data.

#### **Advantages and Limitations**

**Advantages:**

- **Flexibility**: Can model complex, nonlinear relationships without explicit mechanistic knowledge.

- **Scalability**: Can handle large datasets and improve with more data.

- **Automation**: Suitable for automated, real-time applications in process monitoring and control.

**Limitations:**

- **Data Dependency**: Performance heavily depends on the quality and quantity of data available.

- **Lack of Insight**: Provides less mechanistic understanding of the process compared to mechanistic or phenomenological models.

- **Overfitting Risk**: Risk of overfitting to training data, which can reduce model generalizability to new data.

#### **Example in Practice**

**Predictive Maintenance in Mineral Processing Plants**:

- **Objective**: To predict equipment failures and schedule maintenance proactively, reducing downtime and improving operational efficiency.

- **Data Collection**: Collect historical data on equipment performance, operating conditions, and maintenance records.

- **Data Preprocessing**: Clean the data to remove anomalies and ensure consistency.

- **Feature Selection**: Identify key features such as vibration data, temperature readings, operational hours, and load conditions.

- **Model Selection**: Choose machine learning algorithms such as Random Forest or Gradient Boosting Machines (GBMs) for prediction.

- **Model Training**: Train the model on historical data to learn patterns indicative of impending failures.

- **Model Validation and Testing**: Validate and test the model to ensure it accurately predicts failures and minimizes false positives.

- **Implementation**: Integrate the model into the plant’s monitoring system for real-time prediction and alerts.

- **Continuous Improvement**:

Monitor model performance and retrain with new data to improve accuracy over time.

By leveraging data-driven models, mineral processing plants can enhance their predictive capabilities, optimize operations, and achieve greater efficiency and reliability.

First-Principles Models in Mineral Processing

First-principles models are derived directly from fundamental scientific principles, such as thermodynamics, fluid dynamics, and reaction kinetics.

These models aim to provide a detailed and accurate representation of processes based on well-understood physical and chemical laws.

#### **Description**

- **Fundamental Basis**:

First-principles models are constructed from the ground up using fundamental laws of nature. They are often based on equations that describe the conservation of mass, energy, and momentum, as well as chemical kinetics and thermodynamics.

- **Detailed and Accurate**:

These models are highly detailed and can provide very accurate predictions of process behavior, given that the underlying assumptions and parameters are correct.

#### **Application**

- **Detailed Design**:

Used in the detailed design phase of process development to ensure that the system operates as intended under a wide range of conditions.

- **Optimization**:

Essential for optimizing complex processes where precise control and understanding of all variables are critical.

- **Scale-Up**:

Aid in scaling up processes from laboratory or pilot scale to full-scale industrial operations by providing insights into the behavior of the system at different scales.

- **Research and Development**:

Crucial for the development of new processes and technologies, allowing researchers to explore and understand the fundamental mechanisms involved.

#### **Examples**

- **Computational Fluid Dynamics (CFD) Models**:

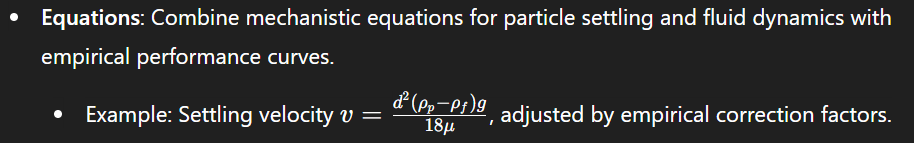

Use numerical methods to solve equations governing fluid flow, heat transfer, and mass transfer.

- **Application**: Used to simulate the flow of slurry in pipelines, the behavior of bubbles in flotation cells, or the mixing patterns in reactors.

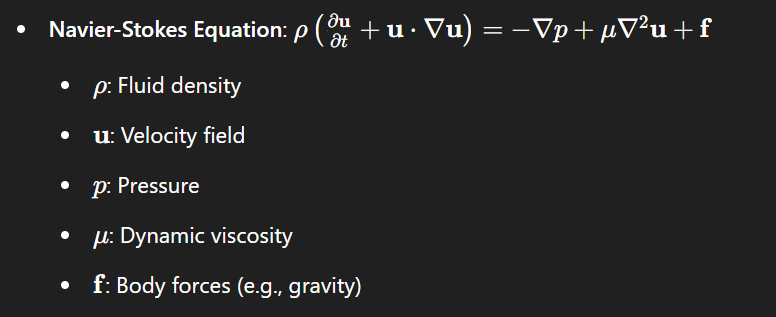

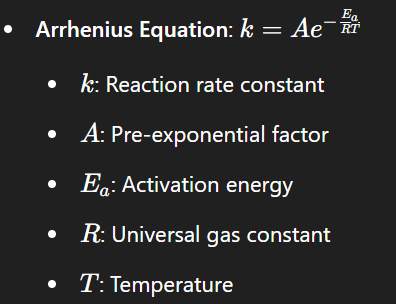

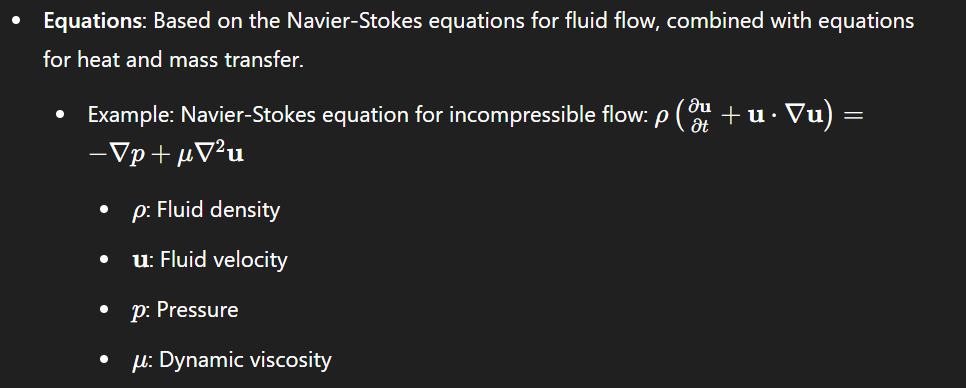

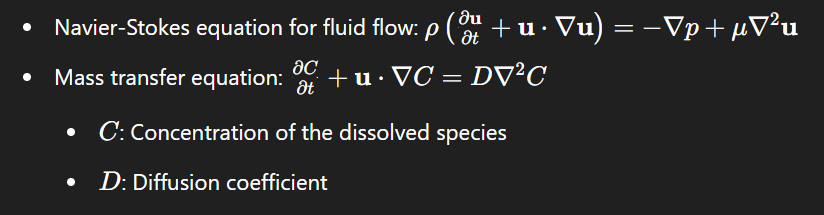

- **Equations**: Governed by the Navier-Stokes equations for fluid flow, combined with equations for heat and mass transfer.

- **Detailed Kinetic Reaction Models**: Describe the rates of chemical reactions based on fundamental kinetics and thermodynamics.

- **Application**:

Used to model processes such as leaching, roasting, and smelting, where chemical reactions play a key role.

- **Equations**:

Governed by the Arrhenius equation for reaction rates and mass balance equations.

#### **Development of First-Principles Models**

1. **Fundamental Understanding**:

Develop a deep understanding of the fundamental principles and mechanisms governing the process.

2. **Mathematical Formulation**:

Formulate the mathematical equations that describe these principles. This often involves differential equations for conservation laws and kinetic models.

3. **Parameter Estimation**:

Estimate the parameters involved in the equations, such as reaction rate constants, diffusion coefficients, and thermodynamic properties.

4. **Numerical Methods**:

Implement numerical methods to solve the complex differential equations. This may involve finite element methods, finite difference methods, or other computational techniques.

5. **Model Validation**:

Validate the model by comparing its predictions with experimental or operational data. Adjust parameters and assumptions as necessary to improve accuracy.

6. **Simulation and Analysis**:

Use the model to simulate the process under different conditions and analyze the results to gain insights and optimize performance.

7. **Continuous Improvement**:

Continuously refine the model based on new data and insights, ensuring it remains accurate and relevant.

#### **Advantages and Limitations**

**Advantages:**

- **High Accuracy**:

Can provide highly accurate and detailed predictions when the underlying principles and parameters are well understood.

- **Insightful**:

Offer deep insights into the fundamental mechanisms of the process, aiding in the development and optimization of new technologies.

- **Scalability**:

Useful for scaling up processes from laboratory to industrial scale, as they are based on fundamental principles that apply across scales.

**Limitations:**

- **Complexity**:

Developing and solving first-principles models can be highly complex and computationally intensive.

- **Data Requirements**:

Require detailed and accurate data for parameter estimation and validation.

- **Development Time**:

Building first-principles models often takes significant time and expertise.

#### **Example in Practice**

**CFD Modeling of a Flotation Cell**:

- **Objective**:

To model the hydrodynamics and bubble-particle interactions in a flotation cell to optimize the separation efficiency of valuable minerals.

- **Fundamental Principles**:

Use the Navier-Stokes equations to describe fluid flow, combined with models for bubble dynamics and particle attachment.

- **Model Formulation**:

Develop a CFD model incorporating the fluid flow equations, bubble generation and coalescence, and particle attachment kinetics.

- **Equations**:

- Navier-Stokes equations for fluid flow.

- Population balance equations for bubble size distribution.

- Kinetic equations for bubble-particle attachment and detachment.

- **Numerical Solution**:

Implement the model in CFD software (e.g., ANSYS Fluent) and solve the equations using finite volume methods.

- **Validation**: Validate the model using experimental data from laboratory-scale flotation tests.

- **Simulation**: Simulate the flotation process under various conditions (e.g., airflow rate, impeller speed) to identify optimal operating parameters.

- **Optimization**:

Use the insights gained from the simulations to optimize the design and operation of the flotation cell for maximum recovery and grade of the valuable mineral.

First-principles models provide a robust and detailed framework for understanding, designing, and optimizing mineral processing operations by leveraging the fundamental laws of nature.

Steady-State Models in Mineral Processing

Steady-state models assume that process variables remain constant over time, effectively representing a snapshot of the process at equilibrium.

These models are particularly useful for designing and optimizing processes that operate under steady conditions, as well as for capacity planning.

#### **Description**

- **Equilibrium Focus**:

Steady-state models analyze processes at equilibrium, where inputs, outputs, and internal states do not change with time.

- **Simplified Dynamics**:

By neglecting transient dynamics, these models provide a simplified view of the process, making them easier to analyze and solve.

#### **Application**

- **Process Design**:

Useful in the initial design phase to determine the necessary equipment size, configuration, and capacity to achieve desired outputs.

- **Optimization**:

Help optimize steady-state operations by identifying the best operating conditions for maximum efficiency and productivity.

- **Capacity Planning**: Assist in planning the capacity of plants and equipment to meet production targets without exceeding limitations.

#### **Examples**

- **Steady-State Mass Balance Models**:

These models focus on the conservation of mass in a system, ensuring that the mass entering a process equals the mass leaving it.

- **Application**: Used to design and optimize processes such as comminution, flotation, and leaching.

- **Equations**:

- **Steady-State Energy Balance Models**:

These models focus on the conservation of energy within a system, ensuring that the energy entering a process equals the energy leaving it.

- **Application**:

Used in processes such as roasting, smelting, and drying.

#### **Development of Steady-State Models**

1. **Define System Boundaries**:

Clearly define the boundaries of the process to identify all inputs and outputs.

2. **Data Collection**:

Gather data on feed composition, flow rates, temperatures, pressures, and other relevant process parameters.

3. **Mass and Energy Balances**:

Formulate the mass and energy balance equations based on the conservation laws.

4. **Parameter Estimation**:

Estimate the parameters needed for the balance equations, such as reaction rates, heat capacities, and enthalpies.

5. **Model Implementation**:

Implement the model using appropriate software tools (e.g., Excel, MATLAB, Aspen Plus) to solve the balance equations.

6. **Validation**:

Validate the model by comparing its predictions with actual operational data or pilot-scale results.

7. **Simulation and Optimization**:

Use the model to simulate the process under different conditions and optimize the operating parameters.

#### **Advantages and Limitations**

**Advantages:**

- **Simplicity**:

Easier to develop and solve compared to dynamic models, making them suitable for preliminary design and optimization.

- **Insightful**:

Provide clear insights into the steady-state behavior of the process, helping in understanding and optimizing operations.

- **Efficiency**:

Require less computational effort and time compared to dynamic models.

**Limitations:**

- **Neglects Dynamics**: Cannot capture transient behaviors or changes over time, limiting their applicability to steady-state conditions.

- **Assumptions**:

Often rely on simplifying assumptions that may not hold true under all operating conditions.

- **Less Flexibility**:

Less flexible in handling variations in process conditions and disturbances compared to dynamic models.

#### **Example in Practice**

**Designing a Steady-State Leaching Process**:

- **Objective**:

To design a leaching process for extracting metal from ore, ensuring the process operates efficiently at steady state.

- **Define System Boundaries**: Identify the leaching tank, feed ore, leach solution, and output solution as the system.

Develop mass balance equations for the metal and the leach solution.

Mass Balance

- **Energy Balance**:

- **Parameter Estimation**: Estimate reaction rates, heat capacities, and other parameters from laboratory experiments or literature.

- **Model Implementation**: Implement the model in a software tool to solve the balance equations.

- **Validation**: Validate the model using pilot-scale data to ensure it accurately predicts the process behavior.

- **Optimization**: Use the model to optimize feed rates, leach solution concentration, and temperature for maximum metal recovery.

Steady-state models provide a robust and simplified framework for designing and optimizing mineral processing operations, focusing on the equilibrium conditions that define the process's efficiency and capacity.

Dynamic Models in Mineral Processing

Dynamic models account for changes in process variables over time, capturing transient behaviors and dynamic responses. These models are essential for understanding and controlling processes that do not operate under steady-state conditions, such as during start-up, shutdown, or in response to disturbances.

#### **Description**

- **Time-Dependent**:

Dynamic models incorporate the time dimension, allowing them to capture how process variables evolve over time.

- **Transient Behavior**:

They can model transient behaviors and dynamic responses, providing insights into how processes respond to changes in operating conditions or external disturbances.

- **Complexity**: Typically more complex than steady-state models, requiring differential equations to describe the time evolution of process variables.

#### **Application**

- **Process Control**:

Used to design and optimize control strategies that maintain process stability and performance in the face of disturbances.

- **Transient Analysis**:

Provide insights into the behavior of processes during non-steady-state operations, such as start-up, shutdown, and load changes.

- **Safety and Reliability**:

Help identify potential issues during dynamic operations, improving safety and reliability.

#### **Examples**

- **Dynamic Simulation of Flotation Circuits**: Models the time-dependent behavior of flotation circuits, including the interaction between different stages and the effect of changes in feed composition or flow rates.

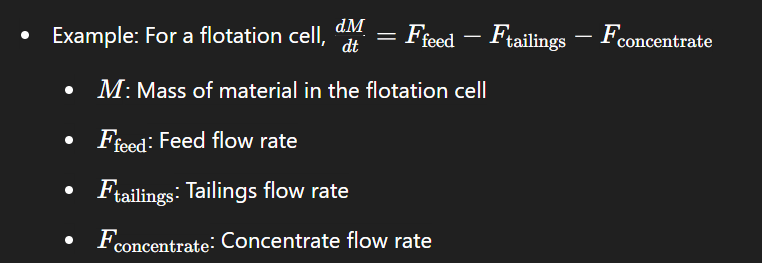

- **Equations**:

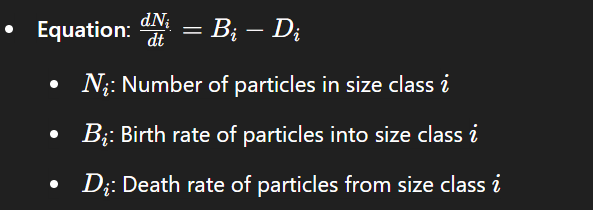

Involves mass balance equations that include time derivatives to account for accumulation and depletion of material in different stages.

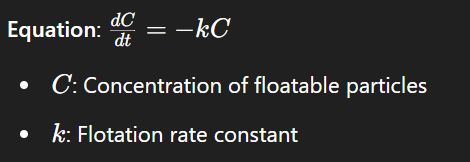

- **Time-Dependent Leaching Models**:

Capture the kinetics of leaching reactions over time, providing insights into how leaching efficiency evolves with time under different conditions.

- **Equations**: Involves kinetic rate equations that describe the rate of dissolution of valuable minerals.

#### **Development of Dynamic Models**

1. **Define System Dynamics**:

Clearly define the dynamic aspects of the process, including key variables and their time-dependent interactions.

2. **Mathematical Formulation**:

Develop differential equations that describe the time evolution of key variables based on fundamental principles such as mass, energy, and momentum conservation.

3. **Parameter Estimation**:

Estimate the parameters required for the dynamic equations, such as reaction rates, transfer coefficients, and physical properties.

4. **Numerical Methods**:

Implement numerical methods to solve the differential equations, often using software tools like MATLAB, Aspen Dynamics, or specialized process simulation software.

5. **Model Validation**:

Validate the dynamic model by comparing its predictions with experimental or operational data, adjusting parameters as necessary.

6. **Simulation and Analysis**:

Use the model to simulate the process under various dynamic conditions, analyzing the results to gain insights into process behavior and optimize performance.

7. **Implementation in Control Systems**:

Integrate the dynamic model into process control systems to enhance real-time decision-making and control strategies.

#### **Advantages and Limitations**

**Advantages:**

- **Comprehensive Understanding**:

Provide a detailed understanding of how processes behave over time, capturing transient phenomena that steady-state models cannot.

- **Control and Optimization**:

Essential for designing effective control strategies and optimizing processes under varying conditions.

- **Predictive Capability**: Can predict the effects of disturbances, enabling proactive management and mitigation of potential issues.

**Limitations:**

- **Complexity**: More complex and computationally intensive than steady-state models, requiring sophisticated mathematical and numerical techniques.

- **Data Requirements**:

Require extensive data for model development, parameter estimation, and validation.

- **Implementation Challenges**:

Integrating dynamic models into real-time control systems can be challenging due to their complexity and computational demands.

#### **Example in Practice**

**Dynamic Simulation of a Flotation Circuit**:

- **Objective**:

To model and optimize the dynamic behavior of a flotation circuit in response to changes in feed composition and operating conditions.

- **Define System Dynamics**:

Identify key variables such as feed rate, flotation cell levels, reagent dosages, and concentrate and tailings flow rates.

- **Mathematical Formulation**:

Develop mass balance equations for each flotation cell, including time derivatives to capture the accumulation and depletion of material.

- **Parameter Estimation**:

Estimate kinetic parameters for flotation reactions, residence times, and transfer coefficients from experimental data or literature.

- **Numerical Methods**:

Implement the model using numerical methods to solve the differential equations, typically using software like MATLAB or Aspen Dynamics.

- **Model Validation**:

Validate the model by comparing simulation results with operational data from the plant, refining parameters as needed.

- **Simulation and Analysis**:

Use the model to simulate the flotation circuit under different conditions, analyzing the effects of changes in feed composition, reagent dosages, and operational parameters.

- **Control Strategy Development**:

Develop and test control strategies based on the dynamic model to maintain optimal performance in the face of disturbances.

Dynamic models provide a powerful tool for understanding, controlling, and optimizing mineral processing operations by capturing the time-dependent behavior and transient responses of processes. They are essential for ensuring stability, efficiency, and reliability in dynamic and complex industrial environments.

Black-Box Models in Mineral Processing

Black-box models treat the process as a "black box," focusing on the relationship between inputs and outputs without delving into the detailed internal mechanisms.

These models are useful when the goal is to predict system behavior or control processes, especially when internal dynamics are complex or poorly understood.

#### **Description**

- **Input-Output Focus**:

Black-box models concentrate on the empirical relationships between the inputs and outputs of a system.

- **Lack of Mechanistic Insight**:

They do not provide insights into the internal workings of the process, instead relying on data-driven approaches to model behavior.

- **Simplification**:

These models simplify the modeling task by abstracting away the internal details, making them easier to develop and use when detailed mechanistic models are impractical.

#### **Application**

- **Process Control**:

Used in control systems where the primary objective is to maintain desired outputs by adjusting inputs, without needing to understand the internal dynamics.

- **Prediction**:

Useful for predicting future outputs based on current and past input-output data.

- **Rapid Prototyping**:

Allow for rapid development and deployment of models in industrial settings, facilitating quick adjustments and optimizations.

#### **Examples**

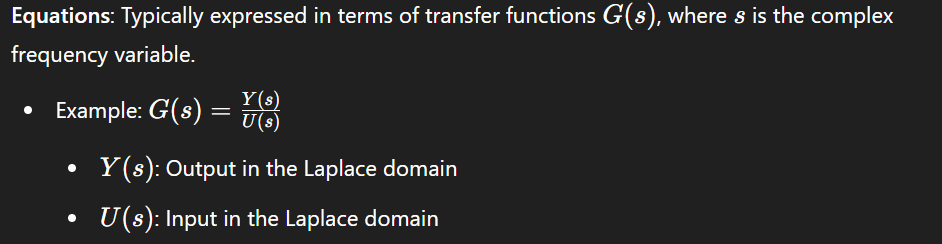

- **Transfer Function Models**:

Represent the relationship between inputs and outputs using mathematical functions, often in the Laplace or frequency domain.

- **Application**:

Widely used in control systems to design controllers that regulate process variables.

- **Equations**:

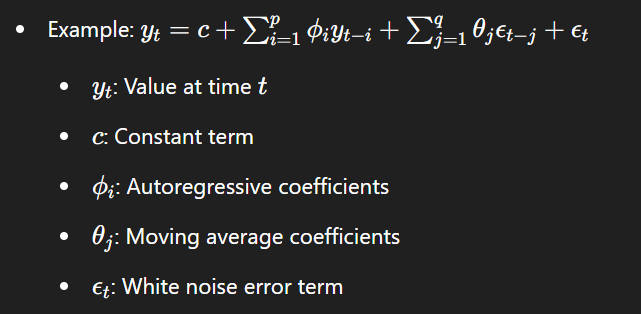

- **Autoregressive Moving Average (ARMA) Models**:

Use statistical methods to model time-series data by capturing relationships between past values and predicting future values.

- **Application**: Commonly used in process monitoring, forecasting, and control.

- **Equations**:

Combine autoregressive (AR) and moving average (MA) components.

-

#### **Development of Black-Box Models**

1. **Data Collection**:

Gather extensive input-output data from the process, ensuring it covers a wide range of operating conditions.

2. **Model Selection**:

Choose an appropriate black-box modeling approach based on the nature of the data and the modeling objectives (e.g., transfer functions, ARMA models).

3. **Parameter Estimation**:

Use statistical methods to estimate the parameters of the chosen model, often employing techniques like least squares, maximum likelihood, or Bayesian inference.

4. **Model Validation**:

Validate the model by comparing its predictions with a separate validation dataset, ensuring it generalizes well to unseen data.

5. **Implementation**:

Implement the model in a suitable software or control system for real-time prediction and control.

6. **Continuous Updating**:

Continuously update the model parameters as new data becomes available to maintain accuracy and relevance.

#### **Advantages and Limitations**

**Advantages:**

- **Simplicity**:

Easier and faster to develop compared to mechanistic or first-principles models.

- **Data-Driven**:

Can be highly accurate when trained on extensive and representative data.

- **Flexibility**:

Easily adaptable to different processes and conditions without requiring detailed knowledge of the internal mechanisms.

**Limitations:**

- **Lack of Insight**:

Do not provide understanding of the underlying process mechanisms, limiting their use for in-depth process analysis and troubleshooting.

- **Data Dependence**:

Rely heavily on the quality and quantity of data; poor or insufficient data can lead to inaccurate models.

- **Limited Extrapolation**:

May not perform well outside the range of conditions covered by the training data, limiting their predictive power in novel situations.

#### **Example in Practice**

**Developing an ARMA Model for a Flotation Process**:

- **Objective**: To develop a predictive model for the concentrate grade in a flotation process based on historical input-output data.

- **Data Collection**:

Gather time-series data on input variables (e.g., reagent dosages, airflow rates) and output variables (e.g., concentrate grade) over several months of operation.

- **Model Selection**: Choose an ARMA model to capture the time-dependent relationships between inputs and the output.

- **Parameter Estimation**: Use statistical software (e.g., R, Python) to estimate the ARMA model parameters.

- Fit the model to the data: \( y_t = c + \sum_{i=1}^p \phi_i y_{t-i} + \sum_{j=1}^q \theta_j \epsilon_{t-j} + \epsilon_t \)

- Validate the model using a separate validation dataset, checking for accuracy and generalization.

- **Implementation**: Integrate the ARMA model into the plant's control system to predict concentrate grade in real-time, allowing operators to adjust inputs to maintain desired performance.

- **Continuous Updating**: Regularly update the model parameters as new data is collected to ensure ongoing accuracy and reliability.

By focusing on input-output relationships, black-box models offer a pragmatic and efficient approach to process control and prediction in mineral processing, enabling effective operation and optimization even in the absence of detailed mechanistic understanding.

White-Box Models in Mineral Processing

These models are based on fundamental principles and are used for comprehensive process design, optimization, and detailed analysis.

#### **Description**

- **Mechanistic Understanding**:

White-box models offer a deep insight into the internal workings of the process by explicitly modeling the physical, chemical, and biological phenomena involved.

- **Detailed and Comprehensive**:

These models incorporate detailed equations and parameters representing the various aspects of the process, such as reaction kinetics, fluid dynamics, and thermodynamics.

- **High Accuracy**:

Due to their detailed nature, white-box models can provide highly accurate predictions when correctly parameterized and validated.

#### **Application**

- **Process Design**:

Used extensively in the design phase to ensure that all aspects of the process are well understood and optimized.

- **Optimization**:

Facilitate detailed optimization of process parameters to achieve the best performance.

- **Detailed Analysis**:

Allow for in-depth analysis of process behavior under various conditions, identifying potential issues and opportunities for improvement.

- **Research and Development**:

Used in R&D to develop new processes and technologies based on a thorough understanding of the underlying principles.

#### **Examples**

- **Detailed Reaction Engineering Models**:

Describe chemical reactions in detail, including reaction kinetics, mass transfer, and heat transfer.

- **Application**:

Used in processes like leaching, roasting, and smelting.

- **Computational Fluid Dynamics (CFD) Models**:

Simulate fluid flow, heat transfer, and mass transfer within the process equipment.

- **Application**:

Used in processes involving fluid dynamics, such as flotation, hydrocycloning, and slurry transport.

- **Equations**:

#### **Development of White-Box Models**

1. **Define System and Objectives**:

Clearly define the system boundaries, objectives, and key phenomena to be modeled.

2. **Mathematical Formulation**:

Develop detailed mathematical equations based on fundamental principles such as conservation of mass, energy, and momentum, and reaction kinetics.

3. **Parameter Estimation**:

Estimate the necessary parameters through experiments, literature, or existing data.

4. **Model Implementation**:

Implement the equations using appropriate numerical methods and software tools (e.g., CFD software, custom simulation codes).

5. **Validation**:

Validate the model by comparing its predictions with experimental or operational data, making adjustments as necessary to improve accuracy.

6. **Simulation and Optimization**:

Use the model to simulate the process under various conditions and optimize the design and operating parameters.

7. **Sensitivity Analysis**:

Perform sensitivity analysis to understand the impact of different parameters on the process performance.

#### **Advantages and Limitations**

**Advantages:**

- **Detailed Insights**:

Provide a deep understanding of the process, enabling precise design and optimization.

- **High Accuracy**:

Can deliver highly accurate predictions when properly validated.

- **Predictive Power**:

Useful for predicting process behavior under a wide range of conditions, including novel scenarios.

**Limitations:**

- **Complexity**:

Highly complex and time-consuming to develop and validate.

- **Data Intensive**:

Require extensive data for parameter estimation and validation.

- **Computational Demands**:

Often require significant computational resources, especially for CFD models.

#### **Example in Practice**

**Developing a CFD Model for a Flotation Cell**:

- **Objective**: To simulate the hydrodynamics and mass transfer in a flotation cell to optimize bubble-particle interactions and improve recovery rates.

- **Define System and Objectives**:

Identify the key components of the flotation cell, including the impeller, air sparger, and tank geometry.

- **Mathematical Formulation**:

Develop equations for fluid flow (Navier-Stokes), bubble dynamics, and mass transfer.

- **Parameter Estimation**:

Estimate parameters such as fluid properties, bubble sizes, and diffusion coefficients from experiments or literature.

- **Model Implementation**:

Implement the model using CFD software like ANSYS Fluent or OpenFOAM.

- **Validation**:

Validate the model by comparing simulation results with experimental data on bubble size distribution, fluid velocity profiles, and recovery rates.

- **Simulation and Optimization**:

Use the model to simulate different operating conditions (e.g., impeller speed, air flow rate) and optimize these parameters to improve recovery and concentrate grade.

- **Sensitivity Analysis**:

Conduct sensitivity analysis to determine the impact of variations in parameters like bubble size and air flow rate on flotation performance.

White-box models offer a powerful tool for the detailed design and optimization of mineral processing operations, providing deep insights and high accuracy, albeit at the cost of increased complexity and computational demands.

Grey-Box Models in Mineral Processing

Grey-box models blend the principles of black-box and white-box modeling, combining mechanistic insights with empirical data. These models leverage partial knowledge of the process mechanisms while using empirical data to fill gaps, thereby improving accuracy and applicability.

#### **Description**

- **Hybrid Approach**:

Incorporate both mechanistic equations based on fundamental principles and empirical correlations derived from data.

- **Balanced Detail**:

Provide a balance between the detailed insights of white-box models and the simplicity and adaptability of black-box models.

- **Flexibility**:

Can be adapted to processes where some mechanistic understanding exists, but complete modeling based on first principles is impractical or unnecessary.

#### **Application**

- **Process Design and Optimization**:

Used in designing and optimizing processes where partial mechanistic understanding exists, complemented by empirical data to improve model predictions.

- **Predictive Modeling**:

Useful for predicting process behavior when detailed mechanistic models are too complex or computationally intensive.

- **Control Systems**:

Implemented in control systems that require a combination of detailed understanding and empirical adjustments for real-time application.

#### **Examples**

- **Hybrid Models for Reactor Design**:

Combine reaction kinetics and mass transfer equations with empirical data on reactor performance to optimize design and operation.

- **Application**:

Used in chemical reactors where detailed kinetic data is available, but mass transfer and flow dynamics are supplemented with empirical correlations.

- **Semi-Mechanistic Models for Separation Processes**:

Integrate mechanistic descriptions of separation principles with empirical data to model complex separation units like hydrocyclones or gravity separators.

- **Application**:

Used in mineral processing units where separation efficiency depends on both fundamental principles and operational data.

- **Equations**:

#### **Development of Grey-Box Models**

1. **Identify Mechanistic and Empirical Components**:

Determine which aspects of the process can be described mechanistically and which require empirical data.

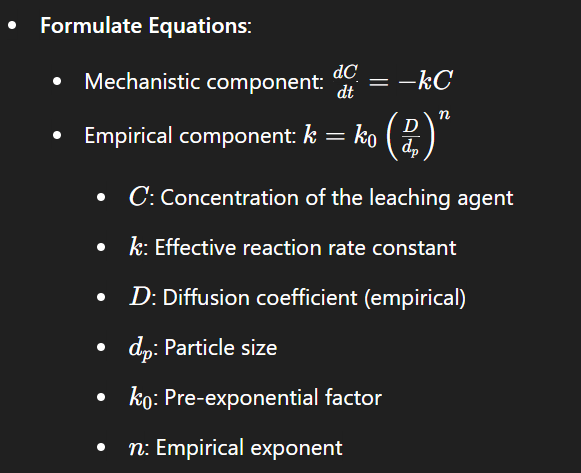

2. **Formulate Equations**:

Develop a set of equations combining mechanistic principles (e.g., reaction kinetics, mass and energy balances) with empirical correlations.

3. **Parameter Estimation**:

Estimate parameters using a combination of theoretical calculations and empirical data fitting.

4. **Model Integration**:

Integrate the mechanistic and empirical components into a cohesive model, ensuring consistency and accuracy.

5. **Validation**:

Validate the model by comparing its predictions with experimental or operational data, adjusting empirical components as needed.

6. **Implementation**:

Implement the model in simulation software or control systems for real-time application and process optimization.

7. **Continuous Improvement**:

Continuously refine the model by incorporating new data and insights to improve accuracy and robustness.

#### **Advantages and Limitations**

**Advantages:**

- **Improved Accuracy**:

Combining mechanistic and empirical approaches often yields more accurate models than purely mechanistic or empirical models alone.

- **Balanced Complexity**: